Professional Documents

Culture Documents

Work Standard COP (English)

Work Standard COP (English)

Uploaded by

asri elektronikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Standard COP (English)

Work Standard COP (English)

Uploaded by

asri elektronikCopyright:

Available Formats

Standard work IISM PT KPP #1.2 100MW Tgl :2012.10.25 Rev.

:0

KPP Guidance

Control Oil Pump Operation Page:1/4

작성자 Zakky Anshary 심의자

● Purpose Of Work : Supplying high pressure oil to EH actuators to control and to move following

valves :

1) Main steam stop valve (MSV)

2) Main steam control valve (MCV)

3) Reheat steam stop valve (RSV)

4) Intercept valve (ICV)

● Summary work

구분 내용

Name and Place Of Work 1. Control Oil Pump Operation

1. Control Oil Pump (01MAX21AP001,002)

- Type : AC Motor driven variable

displacement piston type

Important Equipment

- Capacity : 37.2 l/min.

145 barg

- Speed (synchronous ) : 1,500 rpm

1. Problem : Control Oil Pump Trip

2. Cause : - Suction Filter Dirty

Quality

- Air content of oil too much

- Noise in COP

Environment Contamination by leakage of motor bearing cooling lube oil

1. Safety Consideration

A. BRK input electrical shock caution

Important B. Work clothes curling caution due to the rotor

Check

2.Accident Case : Not Applicable

Safety

3.Near-Miss Case : Not Applicable

4.Fire Case : Not Applicable

5.Work Permit : Not Applicable

Preparation Action 1. Control Oil Quality Check

Before Work

2. Control Oil Temperature > 20° C check

3. Control Oil Level Of Control Oil tank check

4. Control Oil tank drain valve Closed Check

5. Control Oil Sampling valve closed Check

6. COP suction valves Opened Check

7. COP Discharge Valve Opened Check

8. Pressure Accumulator 77.5~82.5 barG Check

Standard work IISM PT KPP #1.2 100MW Tgl :2012.10.25 Rev. :0

KPP Guidance

Control Oil Pump Operation Page:2/4

9. Accumulator Block valve Opened Check

10. Accumulator control oil pressure release valve Closed Check

11. Blind Spectacle in line check

12. Polishing inlet Filter Openend Check

13. Control Oil return Stop Valve Opened Check

14. Instrument Valves Opened Check

APD Helmet, safety shoes, work gloves, ear plug.

Equipment

Walky talky, valve handle, detector noise & vibration,

Required

Standard work IISM PT KPP #1.2 100MW Rev. :0

KPP Guidance

Control Oil Pump operation Page:4/4

1. Control Oil Pump Operation (A: Control Room, B: Local)

작업순서 작업방법 안전/환경사항

1. COP suction valves Opened Check

1)Check Before OP (B) 2. COP Discharge Valve Opened Check BRK input

electrical shock

3. BRK Close Check caution

2) COP start (A)

1.Control Room Start,

A. Control Room Auto start

- In operation, COP trip

- Control Oil Supply Pressure ≤ 105 barG.

B. Control Room Man’ start

- Graphic in DCS

Choose COP

- Choose Sub window Man’ Click Start

C. After COP start Dis’ MOV Open check

3)Check After COP start(B) 1. Connection Vibration Check Work clothes

2. Leakage Check curling caution

due to the rotor

1.Control Room stop

4) COP stop(A) A. Control Room Man’ stop

- Graphic di DCS

Choose COP

- In Sub window, Choose Man’ stop

finish

You might also like

- PACCAR MX-13 EPA2013 Diagnostic Manual - P062A To P1223 - WK 11 2015Document440 pagesPACCAR MX-13 EPA2013 Diagnostic Manual - P062A To P1223 - WK 11 2015Ariel SanchezNo ratings yet

- Marine Diesel Engines: Maintenance, Troubleshooting, and RepairFrom EverandMarine Diesel Engines: Maintenance, Troubleshooting, and RepairRating: 4.5 out of 5 stars4.5/5 (15)

- (Chemical Injection System) - Operation and Maintenance ManualDocument19 pages(Chemical Injection System) - Operation and Maintenance Manualasri elektronikNo ratings yet

- Heatpac CBM: Component DescriptionDocument28 pagesHeatpac CBM: Component DescriptionAlexanderNo ratings yet

- Steam Power Plant Standard Operating ProceduresDocument4 pagesSteam Power Plant Standard Operating Proceduresarvidkumar8706050% (4)

- Standard Operating Procedure FOR Vacuum PumpDocument7 pagesStandard Operating Procedure FOR Vacuum Pumpsambhu100% (3)

- Standard Operating Procedure FOR Gland Steam ChargingDocument6 pagesStandard Operating Procedure FOR Gland Steam Chargingsambhu100% (1)

- HP-LP Bypass SystemDocument28 pagesHP-LP Bypass SystemMadhav Pande100% (6)

- Standard Operating Procedure Operation of Power Plant: Punyam Manufacturing INCDocument2 pagesStandard Operating Procedure Operation of Power Plant: Punyam Manufacturing INCMAYMODERN STEEL0% (1)

- Kinney KC Rotary Piston Vacuum Pump ManualDocument30 pagesKinney KC Rotary Piston Vacuum Pump Manualuh6VGEvdLtgItjlSNo ratings yet

- Afc4 - Landing GearDocument303 pagesAfc4 - Landing GearEjigayehu Lemma100% (2)

- Chemical Engineering - Size Safety-Relief Valves For Any ConditionsDocument9 pagesChemical Engineering - Size Safety-Relief Valves For Any Conditionshajar_athirah75% (4)

- Gas Pressure Regulators For Inlet Pressures Up To 100 Bar: British Standard Bs en 334:2005+A1:2009Document108 pagesGas Pressure Regulators For Inlet Pressures Up To 100 Bar: British Standard Bs en 334:2005+A1:2009vinay1999No ratings yet

- Work Standar Vapor ExtractorDocument5 pagesWork Standar Vapor Extractorasri elektronikNo ratings yet

- Work Standar MOP (English)Document4 pagesWork Standar MOP (English)asri elektronikNo ratings yet

- Work Standar Lube Oil PurifierDocument4 pagesWork Standar Lube Oil Purifierasri elektronikNo ratings yet

- E39 Ahsop 06Document11 pagesE39 Ahsop 06Sanjit SinghNo ratings yet

- Steam Power Plant Standard Operating ProceduresDocument3 pagesSteam Power Plant Standard Operating ProceduresganimechNo ratings yet

- Indiabulls Power Limited: SOP/OPNS/10 Operations DepartmentDocument2 pagesIndiabulls Power Limited: SOP/OPNS/10 Operations DepartmentAmit SoniNo ratings yet

- SOP-Cleanup CycleDocument5 pagesSOP-Cleanup CyclenodalpcrktpsNo ratings yet

- Interlocks & ProtectionsDocument7 pagesInterlocks & ProtectionsPRAVEEN KUMAR SINGH100% (1)

- On-Site Acceptance Test ProgramDocument7 pagesOn-Site Acceptance Test ProgramDaniel CorreaNo ratings yet

- Manual Book KHV-F15Document24 pagesManual Book KHV-F15Ari100% (1)

- R-ME-HC-S-020 Governor System Test RecordDocument9 pagesR-ME-HC-S-020 Governor System Test Recordrotimi olalekan fataiNo ratings yet

- Final AssignmentDocument14 pagesFinal Assignmentquik silvaNo ratings yet

- 7 CompressorDocument2 pages7 CompressorMithun Singh RajputNo ratings yet

- FAT Precedure - R 072 Nitrogen PackageDocument10 pagesFAT Precedure - R 072 Nitrogen PackageBudi UtomoNo ratings yet

- Silo D-PumpDocument2 pagesSilo D-PumpMithun Singh RajputNo ratings yet

- Alpha LubricatorDocument22 pagesAlpha LubricatorarvanitakiscNo ratings yet

- Purpose: Scope: Responsibility: Guide LineDocument3 pagesPurpose: Scope: Responsibility: Guide LineSUBHASISH MUKHERJEENo ratings yet

- TG Lube Oil FlushingDocument38 pagesTG Lube Oil Flushingjp mishraNo ratings yet

- Power Plant Operation: Power Management Institute NoidaDocument199 pagesPower Plant Operation: Power Management Institute NoidanagarajsumaNo ratings yet

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- SOP Boiler HydrotestDocument3 pagesSOP Boiler HydrotestSachin nandgaye0% (2)

- 3.SOP of Pretreatment PlantDocument4 pages3.SOP of Pretreatment PlantBARNALI MUKHERJEE100% (1)

- 2021.12.24 R-ME-HC-S-020 Governor System Commissioning ProcedureDocument12 pages2021.12.24 R-ME-HC-S-020 Governor System Commissioning Procedurerotimi olalekan fataiNo ratings yet

- Hazira Site - Control Valve Calibration SheetDocument3 pagesHazira Site - Control Valve Calibration Sheet8103 Anshu Patil100% (1)

- Scen Emergn AEDocument3 pagesScen Emergn AElilikNo ratings yet

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (2)

- Q1: Encircle The Correct Choice Out of The Four Options in Following Questions. Each Carries 2 MarksDocument3 pagesQ1: Encircle The Correct Choice Out of The Four Options in Following Questions. Each Carries 2 MarksMY NAME IS NEERAJ..:):)No ratings yet

- Technical DiaryDocument79 pagesTechnical DiaryPrakash ChoudharyNo ratings yet

- Doosan Retrofit ServiceDocument99 pagesDoosan Retrofit Servicestopless_dalian685No ratings yet

- TA1 English - Marine EngineDocument7 pagesTA1 English - Marine Enginecristian chuquicondor torresNo ratings yet

- Power Plant OperationDocument199 pagesPower Plant OperationVijay Bhargav Badam86% (7)

- Scanboilerr TextDocument7 pagesScanboilerr TextAntonio AvilesNo ratings yet

- SOP-Pumping OperationDocument14 pagesSOP-Pumping OperationVoltonix InfratechNo ratings yet

- Flow Chart EHV Transformer Installation PDFDocument1 pageFlow Chart EHV Transformer Installation PDFPandurang Yadav100% (1)

- IQ and OQ Check List For OSD Site UtilitiesDocument9 pagesIQ and OQ Check List For OSD Site UtilitiesRahul VermaNo ratings yet

- SOP - ID FanDocument2 pagesSOP - ID Fanarvidkumar87060No ratings yet

- Mill Reject SystemDocument22 pagesMill Reject Systemgangatharan100% (1)

- Flare Ignition ProcedureDocument4 pagesFlare Ignition ProcedurebeyNo ratings yet

- N2 Chain Thawing - SOP U O 48 05Document6 pagesN2 Chain Thawing - SOP U O 48 05Harmohan KaulNo ratings yet

- Indiabulls Power Limited: SOP/OPNS/09 Operations DepartmentDocument3 pagesIndiabulls Power Limited: SOP/OPNS/09 Operations DepartmentAmit Soni100% (1)

- Ajuste de Flujo MinimoDocument2 pagesAjuste de Flujo MinimoRonaldo GaleanoNo ratings yet

- 020-SOP of H2 CYLINDER Room ChargingDocument4 pages020-SOP of H2 CYLINDER Room ChargingsambhuNo ratings yet

- SVC Manual Bugxter BR150Document74 pagesSVC Manual Bugxter BR150Clément DunauxNo ratings yet

- Standard Training Materials - R1Document65 pagesStandard Training Materials - R1Marco MacaNo ratings yet

- 01 TramsmissionDocument47 pages01 TramsmissionBach Nguyen Xuan100% (1)

- SLK-KTG1-OPR-CL-TBN-004 Lube Oil System Check ListDocument2 pagesSLK-KTG1-OPR-CL-TBN-004 Lube Oil System Check ListoksaNo ratings yet

- Calibre Maximo FlujoDocument2 pagesCalibre Maximo FlujoRonaldo GaleanoNo ratings yet

- Indiabulls Power Limited: SOP/OPNS/08 Operations DepartmentDocument2 pagesIndiabulls Power Limited: SOP/OPNS/08 Operations DepartmentAmit SoniNo ratings yet

- Hyd0029 DX Control Valve KVMG 270Document39 pagesHyd0029 DX Control Valve KVMG 270Abdelrahman SharafNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Work Standar MOP (English)Document4 pagesWork Standar MOP (English)asri elektronikNo ratings yet

- Work Standar Vapor ExtractorDocument5 pagesWork Standar Vapor Extractorasri elektronikNo ratings yet

- Work Standar Lube Oil PurifierDocument4 pagesWork Standar Lube Oil Purifierasri elektronikNo ratings yet

- (Gantry Crane) - Operation and Maintenance ManualDocument179 pages(Gantry Crane) - Operation and Maintenance Manualasri elektronikNo ratings yet

- (Sea Water Pump) - Operation and Maintenance ManualDocument31 pages(Sea Water Pump) - Operation and Maintenance Manualasri elektronikNo ratings yet

- (Sampling System) Operation and Maintenance ManualDocument21 pages(Sampling System) Operation and Maintenance Manualasri elektronikNo ratings yet

- Achmad Gunawan - Harley2021Document10 pagesAchmad Gunawan - Harley2021asri elektronikNo ratings yet

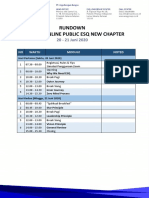

- Rundown Training Online Public Esq New Chapter: 20 - 21 Juni 2020Document1 pageRundown Training Online Public Esq New Chapter: 20 - 21 Juni 2020asri elektronikNo ratings yet

- Trane VAV Equipment SpecificationsDocument52 pagesTrane VAV Equipment Specificationsyu4212No ratings yet

- RS Clare Oil & Gas BrochureDocument12 pagesRS Clare Oil & Gas BrochureVALENTIN PATRASNo ratings yet

- BQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiDocument4 pagesBQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiArie WigunaNo ratings yet

- Piping & Instrumentation DiagramDocument20 pagesPiping & Instrumentation DiagramOladayo Siyanbola100% (2)

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- SOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFDocument9 pagesSOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFYASH ENGINEERING SOLUTIONSNo ratings yet

- Error Code Sh-240Document8 pagesError Code Sh-240Huấn Đặng100% (1)

- Otsc - Control Final-BoilerDocument85 pagesOtsc - Control Final-BoilerKumar100% (1)

- Viza Ball ValveDocument56 pagesViza Ball Valvevinoj chandranNo ratings yet

- TGB Blade 250 Service ManualDocument217 pagesTGB Blade 250 Service Manualyornletard100% (3)

- Yixin CatalogueDocument23 pagesYixin CatalogueImran Niaz KhanNo ratings yet

- DD15 Master Training Rev2MexicoDocument138 pagesDD15 Master Training Rev2MexicoNava RobertoNo ratings yet

- Tec2 IomDocument99 pagesTec2 IomNaser JahangiriNo ratings yet

- Hassi Bir Rekaiz Field Development Phase1: Process Data Sheet Front End Engineering DesignDocument6 pagesHassi Bir Rekaiz Field Development Phase1: Process Data Sheet Front End Engineering Designahmed.njahNo ratings yet

- Building UtilitiesDocument47 pagesBuilding UtilitiesJim Bryan RazNo ratings yet

- Quantum Frac Gravel Pack SystemDocument2 pagesQuantum Frac Gravel Pack SystemDavide BoreanezeNo ratings yet

- P01-E12 Rev 1 Sep 2015 Dynamic Effects On Piping SystemsDocument11 pagesP01-E12 Rev 1 Sep 2015 Dynamic Effects On Piping Systems234ahmedNo ratings yet

- Material Log StatusDocument24 pagesMaterial Log StatusJamesNo ratings yet

- Series AP Directly Operated Proportional ValvesDocument11 pagesSeries AP Directly Operated Proportional ValveshendranatjNo ratings yet

- Operation Manual: Encapsulator B-390Document56 pagesOperation Manual: Encapsulator B-390princesslove521_4165No ratings yet

- Periodical Service Report FormDocument2 pagesPeriodical Service Report FormsuriantoNo ratings yet

- VT 551Document108 pagesVT 551Mohamed HarbNo ratings yet

- Air Source Heat Pump Installation and Maintenance Manual With Pre-Plumbed Cylinders & Underfloor HeatingDocument36 pagesAir Source Heat Pump Installation and Maintenance Manual With Pre-Plumbed Cylinders & Underfloor HeatingDKCNo ratings yet

- 3-4 Power Train Disassembly and AssemblyDocument148 pages3-4 Power Train Disassembly and AssemblyKadir Koray BozyelNo ratings yet

- Service Air CompresorDocument75 pagesService Air CompresorDamitha100% (2)

- Vacuum Oven Operation ManualDocument12 pagesVacuum Oven Operation ManualanasribdNo ratings yet