Professional Documents

Culture Documents

Weld Design BS 5950-1 (Ok)

Weld Design BS 5950-1 (Ok)

Uploaded by

Zaido Al HalabiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Design BS 5950-1 (Ok)

Weld Design BS 5950-1 (Ok)

Uploaded by

Zaido Al HalabiCopyright:

Available Formats

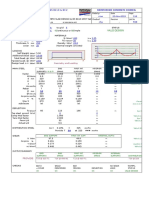

Weld Design to BS 5950-1:

Y

Factored Forces

VX = 3.04 kN shear hor.

VY = 0.2 kN shear vert. X

VZ = 0 kN axial

MX = 0.289 kN-m

MY = 0.019 kN-m

MZ = 0 kN-m

0

dw = 30 mm weld depth

bw = 38 mm weld breadth

tw = 3 mm fillet weld thickness

Lw = 2*bw = 76 mm total fillet weld length

Swy = bw2/3 = 481 mm2 weld section modulus (bending about y-axis)

2

Swz = bw*dw = 1140 mm weld section modulus (bending about x-axis)

2 2 3

Iw = bw*(3*dw +bw )/6 26245 mm weld polar moment of inertia

Weld Forces

fxw = VX*1000/Lw = 40 N/mm

fyw = VY*1000/Lw = 3 N/mm

fzw = VZ*1000/Lw = 0 N/mm

fxMy = MY*10002/Swy = 39 N/mm

fxMz = MZ*10002/Swz = 0 N/mm

2

fyMx = MX*1000 *(dw/2)/Iw 165 N/mm

2

fzMx = MX*1000 *(bw/2)/Iw 209 N/mm

Resultant Shear

Fw = sqrt [(fxw+fxMy+fxMz)2 +(fyw+fyMx)2 + (fzw+fzMx)2 ]= 280 N/mm

Weld Shear Capacity

pw = 220 mPa fillet weld design strength (Table 37 BS 5950-1)

aw = 0.707*tw = 2.1 mm fillet weld effective throat size

Pw = pw*aw = 467 N/mm weld capacity per unit length

Fw/Pw = 0.60 < 1.0 Therefore OK!

Z

us (bending about y-axis)

us (bending about x-axis)

Weld Design to BS 5950-1: Weld as Lines

Factored Forces Y

VX = 8.7 kN

VY = 11.07 kN

VZ = 0 kN X Z

MX = 0 kN-m

MY = 0 kN-m

MZ = 0 kN-m

dw = 100 mm weld depth

bw = 10 mm weld breadth

tw = 5 mm fillet weld thickness

Lw = 2*dw = 200 mm total fillet weld length

Swy = bw*dw = 1000 mm2 weld section modulus (bending about y-axis)

2 2

Swz = dw /3 = 3333 mm weld section modulus (bending about x-axis)

2 2 3

Iwx = dw*(3*bw +dw )/6 171667 mm weld polar moment of inertia

Weld Forces

fxw = VX*1000/Lw = 44 N/mm

fyw = VY*1000/Lw = 55 N/mm

fzw = VZ*1000/Lw = 0 N/mm

fxMy = MY*10002/Swy = 0 N/mm

fxMz = MZ*10002/Swz = 0 N/mm

2

fyMx = MX*1000 *(dw/2)/Iwx 0 N/mm

2

fzMx = MX*1000 *(bw/2)/Iwx 0 N/mm

Resultant Shear

Fw = sqrt [(fxw+fxMy+fxMz)2 +(fyw+fyMx)2 + (fzw+fzMx)2 ]= 70 N/mm

Weld Shear Capacity

pw = 220 mPa fillet weld design strength (Table 37 BS 5950-1)

aw = 0.707*tw = 3.5 mm fillet weld effective throat size

Pw = pw*aw = 778 N/mm weld capacity per unit length

Fw/Pw = 0.09 < 1.0 Therefore OK!

us (bending about y-axis)

us (bending about x-axis)

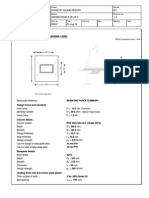

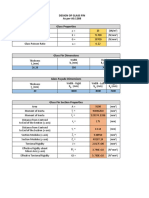

Weld Design to BS 5950-1: Square and Rectangular Hollow Section

Factored Forces

FX = 0.17 kN

Y

FY = 1.67 kN

FZ = 0 kN

MX = 0 kN-m

MY = 0 kN-m X Z

MZ = 2.019 kN-m

bw = 40 mm weld breadth

dw = 40 mm weld depth

tw = 10 mm fillet weld thickness

Lw = 2(bw+dw) = 160 mm total fillet weld length

Swy = bw*dw + (bw2/3) = 2133.333333 mm2 weld section modulus (bending about y-axis)

2

Swz = dw*bw + (dw /3) = 2133.333333 mm2 weld section modulus (bending about z-axis)

3 3

Iwx = (bw+dw) /6 85333.33333 mm weld polar moment of inertia

Weld Forces

fxw = FX*1000/Lw = 1 N/mm

fyw = FY*1000/Lw = 10 N/mm

fzw = FZ*1000/Lw = 0 N/mm

fzM = MX*10002*(dw/2)/Iwx = 0 N/mm

fyM = MX*10002*(bw/2)/Iwx = 0 N/mm

2

fxMy = MY*1000 /Swy = 0 N/mm

fxMz = MZ*10002/Swz = 946 N/mm

Resultant Shear

Fw = sqrt [(fxw+fxMy+fxMz)2 +(fyw+fyM)² + (fzw+fzM)2 ]= 948 N/mm

Weld Shear Capacity

pw = 220 mPa fillet weld design strength (Table 37 BS 5950-1)

aw = 0.707*tw = 7.1 mm fillet weld effective throat size

Pw = pw*aw = 1555 N/mm weld capacity per unit length

Fw/Pw = 0.61 < 1.0 Therefore OK!

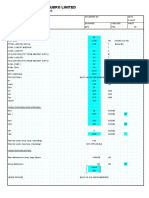

Weld Design to BS 5950-1:

Y

Factored Forces

VX = 20.02 kN axial

VY = 0.28 kN shear vert.

X Z

VZ = 0 kN shear hor.

MX = 0 kN-m

MY = 0 kN-m

MZ = 0 kN-m

dw = 250 mm weld depth

bw = 56 mm weld breadth

tw = 4 mm fillet weld thickness

Lw = 4*dw = 1000 mm total fillet weld length

Swy = 2*bw*dw = 28000 mm2 weld section modulus (bending about y-axis)

2 2

Swz = 2*dw /3 = 41666.66667 mm weld section modulus (bending about x-axis)

2 2 3

Iw = 2*dw*(3*bw +dw )/6 5992333 mm weld polar moment of inertia

Weld Forces

fxw = VX*1000/Lw = 20 N/mm

fyw = VY*1000/Lw = 0 N/mm

fzw = VZ*1000/Lw = 0 N/mm

fxMy = MY*10002/Swy = 0 N/mm

fxMz = MZ*10002/Swz = 0 N/mm

2

fyMx = MX*1000 *(dw/2)/Iw 0 N/mm

2

fzMx = MX*1000 *(bw/2)/Iw 0 N/mm

Resultant Shear

Fw = sqrt [(fxw+fxMy+fxMz)2 +(fyw+fyMx)2 + (fzw+fzMx)2 ]= 20 N/mm

Weld Shear Capacity

pw = 220 mPa fillet weld design strength (Table 37 BS 5950-1)

aw = 0.707*tw = 2.8 mm fillet weld effective throat size

Pw = pw*aw = 622 N/mm weld capacity per unit length

Fw/Pw = 0.03 < 1.0 Therefore OK!

us (bending about y-axis)

us (bending about x-axis)

Weld Design to BS 5950-1:

Factored Forces

VX = 0.76 kN shear hor.

VY = 7.83 kN shear vert. Y

VZ = 12.07 kN axial

MX = 0 kN-m X Z

MY = 1.207 kN-m

MZ = 0.783 kN-m

dw = 116 mm weld depth

bw = 200 mm weld breadth

tw = 6 mm fillet weld thickness

Lw = 4*bw = 800 mm total fillet weld length

Swy = 2*bw2/3 = 26667 mm2 weld section modulus (bending about y-axis)

2

Swz = 2*bw*dw = 46400 mm weld section modulus (bending about x-axis)

2 2 3

Iw = 2*bw*(3*dw +bw )/6 5357867 mm weld polar moment of inertia

Weld Forces

fxw = VX*1000/Lw = 1 N/mm

fyw = VY*1000/Lw = 10 N/mm

fzw = VZ*1000/Lw = 15 N/mm

fxMy = MY*10002/Swy = 45 N/mm

fxMz = MZ*10002/Swz = 17 N/mm

2

fyMx = MX*1000 *(dw/2)/Iw 0 N/mm

2

fzMx = MX*1000 *(bw/2)/Iw 0 N/mm

Resultant Shear

Fw = sqrt [(fxw+fxMy+fxMz)2 +(fyw+fyMx)2 + (fzw+fzMx)2 ]= 66 N/mm

Weld Shear Capacity

pw = 220 mPa fillet weld design strength (Table 37 BS 5950-1)

aw = 0.707*tw = 4.2 mm fillet weld effective throat size

Pw = pw*aw = 933 N/mm weld capacity per unit length

Fw/Pw = 0.07 < 1.0 Therefore OK!

us (bending about y-axis)

us (bending about x-axis)

Weld Design to ADM: Circular Hollow Section

Factored Forces

FX = 0 kN

FY = 0.56 kN Y

FZ = 0 kN

MX = 0 kN-m

MY = 0 kN-m X

MZ = 0.08 kN-m

D= 20 mm weld diameter

tw = 5 mm weld thickness

Lw = πD = 62.8318 mm total weld length

Swy = πD2/2 = 628.318 mm2 weld section modulus (bending about y-axis)

2 2

Swz = πD /2 = 628.318 mm weld section modulus (bending about z-axis)

Iwx = πD3/4 = 6283.18 mm3 weld polar moment of inertia

Weld Forces

fxw = FX*1000/Lw = 0 N/mm

fyw = FY*1000/Lw = 9 N/mm

fzw = FZ*1000/Lw = 0 N/mm

fyMx = MX*10002*(D/2)/Iwx = 0 N/mm

fzMx = MX*10002*(D/2)/Iwx = 0 N/mm

2

fxMy = MY*1000 /Swy = 0 N/mm

2

fxMz = MZ*1000 /Swz = 127 N/mm

Resultant Shear

Fw = sqrt [(fxw+fxMy+fxMz)2 +(fyw+fyM)2 + (fzw+fzM)2 ]= 128 N/mm

Weld Shear Capacity

pw = 115 mPa weld design strength (Table 7.3-1M ADM)

aw = 0.707*tw = 3.5 mm fillet weld effective throat size

Fsw = pw*aw/1.95 = 208.474 N/mm

Fw/Pw = 0.61 < 1.0 Therefore OK!

Z

us (bending about y-axis)

us (bending about z-axis)

You might also like

- Laminated Glass Effective Thickness: (ASTM E1300 - 09a - APPENDIX X11)Document2 pagesLaminated Glass Effective Thickness: (ASTM E1300 - 09a - APPENDIX X11)Zaido Al Halabi100% (1)

- Applied Linear Regression Models by John Neter, William Wasserman, Michael H. KutnerDocument561 pagesApplied Linear Regression Models by John Neter, William Wasserman, Michael H. KutnerGina McCaffrey91% (11)

- RAISE Plus WEEKLY PLAN FOR BLENDED LEARNING TleDocument3 pagesRAISE Plus WEEKLY PLAN FOR BLENDED LEARNING TleRomeo jr RamirezNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- Earth-And-Life-Science-G11-Whlp-Week-1-2 - Quarter 2 HeDocument2 pagesEarth-And-Life-Science-G11-Whlp-Week-1-2 - Quarter 2 Hecristina maquinto100% (5)

- Tann Designs & Engineers: Welding Design CheckDocument1 pageTann Designs & Engineers: Welding Design CheckSiva JaseNo ratings yet

- 2 Bolt True 4 Bolt True True OKDocument1 page2 Bolt True 4 Bolt True True OKVlad CiupituNo ratings yet

- Steel Deck DesignDocument25 pagesSteel Deck DesignJanaka KarunarathnaNo ratings yet

- Suhas 21/4/2005: Distance Longer DRN Distance Longer DRN From Face of Pedestal/Col From Face of Pedestal/ColDocument26 pagesSuhas 21/4/2005: Distance Longer DRN Distance Longer DRN From Face of Pedestal/Col From Face of Pedestal/ColSuhas MangaloreNo ratings yet

- EN WalerDocument8 pagesEN WalervsnsfbNo ratings yet

- Composite Column DesignDocument95 pagesComposite Column DesignYanfei JinNo ratings yet

- Location: Pit Slab Section Properties: Calculation For Crackwidth Check (Y Direction Bottom)Document2 pagesLocation: Pit Slab Section Properties: Calculation For Crackwidth Check (Y Direction Bottom)Pitolwala ZuzarNo ratings yet

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument11 pages"Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionMustafa RupawalaNo ratings yet

- Pe Endorsement For Design of New FCC and Guard House BuildingDocument7 pagesPe Endorsement For Design of New FCC and Guard House Buildingjasekan.dcNo ratings yet

- CV DM 001 100dpiDocument58 pagesCV DM 001 100dpighazi andonoNo ratings yet

- Solid MOdel - Beam DesignDocument31 pagesSolid MOdel - Beam Designblisscutest beagleNo ratings yet

- Project Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Document2 pagesProject Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Sơn Nguyễn-LêNo ratings yet

- Repair & Rehabilitation of Distressed Structures (Repair & Retrofitting)Document26 pagesRepair & Rehabilitation of Distressed Structures (Repair & Retrofitting)sahilkaushikNo ratings yet

- Pile Capacity NewDocument1 pagePile Capacity NewChowdhury PriodeepNo ratings yet

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDocument4 pagesColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNo ratings yet

- Pile Cap DesignDocument3 pagesPile Cap Designkazi Shahanewaz HossainNo ratings yet

- Section Propeties To Staad Parametric FormationDocument160 pagesSection Propeties To Staad Parametric FormationVignesh VenkatasubramanianNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument10 pagesLarsen & Toubro Limited: ECC Division - EDRCDesign explorer olomizanaNo ratings yet

- Lifting Frame - Strength Analysis Report R 01Document29 pagesLifting Frame - Strength Analysis Report R 01Vineeth NakanNo ratings yet

- Metro Standard StructDwgs 080613Document41 pagesMetro Standard StructDwgs 080613rpazbNo ratings yet

- Anchorage DetailDocument3 pagesAnchorage DetailShyamontika Choudhury ChakrabartiNo ratings yet

- Annexure III-Dowel Bar Design - YGDocument2 pagesAnnexure III-Dowel Bar Design - YGUma RongaliNo ratings yet

- DBR - Buffer ShopDocument15 pagesDBR - Buffer Shopvikas WaghmareNo ratings yet

- I Shaped Plate Girder AISC LRFD Design V2.0Document2 pagesI Shaped Plate Girder AISC LRFD Design V2.0Dipak BorsaikiaNo ratings yet

- Design of 9m Wide Nallah & SWD DrainDocument29 pagesDesign of 9m Wide Nallah & SWD Drainsushil deshmukhNo ratings yet

- Section Properties and CapacitiesDocument19 pagesSection Properties and CapacitiesRufus ChengNo ratings yet

- Design of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Document4 pagesDesign of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Prasad SamantNo ratings yet

- ATRUCTDocument75 pagesATRUCTRadu StratilaNo ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- Wind ASCE 7 05 MBMA B01 A01Document30 pagesWind ASCE 7 05 MBMA B01 A01subramanyaNo ratings yet

- Span/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span FactorDocument1 pageSpan/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span Factorshamen amarasekaraNo ratings yet

- Welded & Pinned Connection Design CalculationDocument14 pagesWelded & Pinned Connection Design CalculationPrakash Singh RawalNo ratings yet

- Circular ColumnDocument17 pagesCircular Columnkarthikmr85No ratings yet

- 07 Steel Lagging PDFDocument1 page07 Steel Lagging PDFThaungMyintNo ratings yet

- Design Load Basis Report Tensile Canopy - Vedvan - Noida - R0Document27 pagesDesign Load Basis Report Tensile Canopy - Vedvan - Noida - R0Neeraj KumarNo ratings yet

- Strut and WalingDocument2 pagesStrut and WalingChan Kin CheungNo ratings yet

- Planning, Analysis and Design of Open Air Cricket Stadium: Presented byDocument12 pagesPlanning, Analysis and Design of Open Air Cricket Stadium: Presented byCatherine J. RoseNo ratings yet

- CorbelDocument12 pagesCorbelSri Datta Kiran Kuchibhatla67% (3)

- Boundry Wall DesignDocument1 pageBoundry Wall DesignMian M KhurramNo ratings yet

- Pile Cap 10P-PC7Document6 pagesPile Cap 10P-PC7balaji gmscNo ratings yet

- Padghe - Cable Trench With Bells FormulaDocument50 pagesPadghe - Cable Trench With Bells FormulaAnindit MajumderNo ratings yet

- Eccentric Footing Design PDFDocument9 pagesEccentric Footing Design PDFmsiddiq1No ratings yet

- Bore Pile Design Bs 8004Document2 pagesBore Pile Design Bs 8004nabeel hameedNo ratings yet

- Deck Sheet Height Calculation For 150mm SlabDocument2 pagesDeck Sheet Height Calculation For 150mm SlabHarmandeep Singh BhattiNo ratings yet

- Design of S R Flanged Beam: Bending Only. (Limit State Method)Document3 pagesDesign of S R Flanged Beam: Bending Only. (Limit State Method)sayali surveNo ratings yet

- Design of Steel ColumnDocument7 pagesDesign of Steel ColumnKim Javier EstaNo ratings yet

- Analysis of 2 - Pile Group - Pc2 MX Design Data: Load Case 100 DL+LL Joint No MZ Grid Mark Column LoadDocument9 pagesAnalysis of 2 - Pile Group - Pc2 MX Design Data: Load Case 100 DL+LL Joint No MZ Grid Mark Column LoadMythili BysaniNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CDocument7 pagesSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CKhan EngrNo ratings yet

- SBC For Crane FoundationDocument2 pagesSBC For Crane FoundationAnonymous UebIaD8A8CNo ratings yet

- EC2-BE-deflection Rev3Document6 pagesEC2-BE-deflection Rev3Dong LINo ratings yet

- Base Plate DesignDocument4 pagesBase Plate DesignrichardchiamNo ratings yet

- Calculation of Effective LengthDocument3 pagesCalculation of Effective Lengthbuildcon100% (1)

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4amirNo ratings yet

- Col FootDocument23 pagesCol Footsujit naikwadiNo ratings yet

- Summary Safe of Structural Design of Box and WallDocument7 pagesSummary Safe of Structural Design of Box and WallRatul PalodhiNo ratings yet

- Finite Element Analysis of Structures through Unified FormulationFrom EverandFinite Element Analysis of Structures through Unified FormulationNo ratings yet

- Circular WeldDocument12 pagesCircular WeldJohn Paul UmaliNo ratings yet

- Base PlateDocument52 pagesBase PlateRameez Ahmed AbbasiNo ratings yet

- Bracket WeldDocument6 pagesBracket Weldlim kang haiNo ratings yet

- 4597-AAB-SC-09 R0v1 39Document1 page4597-AAB-SC-09 R0v1 39danieldumapitNo ratings yet

- STAAD AnalysisDocument4 pagesSTAAD AnalysisZaido Al HalabiNo ratings yet

- Project Data: Project Name Project Number Author Description Date 19/07/2023 Code ENDocument7 pagesProject Data: Project Name Project Number Author Description Date 19/07/2023 Code ENZaido Al HalabiNo ratings yet

- SJ MeplaDocument5 pagesSJ MeplaZaido Al HalabiNo ratings yet

- Screws CapacitiesDocument1 pageScrews CapacitiesZaido Al HalabiNo ratings yet

- MAA-TGAC-ANC-CALC-00015 Rev.0Document44 pagesMAA-TGAC-ANC-CALC-00015 Rev.0Zaido Al HalabiNo ratings yet

- Uae045 801 Ibd HR1 Ar Cal 0077Document17 pagesUae045 801 Ibd HR1 Ar Cal 0077Zaido Al HalabiNo ratings yet

- Compression Case - Pa2Document6 pagesCompression Case - Pa2Zaido Al HalabiNo ratings yet

- The Grove - SL Sys1Document11 pagesThe Grove - SL Sys1Zaido Al HalabiNo ratings yet

- STR'L Calc. For Concrete Edge Verification of BKT5Document16 pagesSTR'L Calc. For Concrete Edge Verification of BKT5Zaido Al HalabiNo ratings yet

- 1 Input Data: Hilti PROFIS Engineering 3.1.1Document10 pages1 Input Data: Hilti PROFIS Engineering 3.1.1Zaido Al HalabiNo ratings yet

- Excel For Glass FinDocument4 pagesExcel For Glass FinZaido Al HalabiNo ratings yet

- Qvil Tgac TB Ar XX SD 3104Document1 pageQvil Tgac TB Ar XX SD 3104Zaido Al HalabiNo ratings yet

- Top EdgeDocument15 pagesTop EdgeZaido Al HalabiNo ratings yet

- Qvil Tgac TB Ar XX SD 3104Document1 pageQvil Tgac TB Ar XX SD 3104Zaido Al HalabiNo ratings yet

- Qvil Tgac TB Ar XX SD 3100Document1 pageQvil Tgac TB Ar XX SD 3100Zaido Al HalabiNo ratings yet

- Drafts - Wall Mounted Bracket (BKT2)Document14 pagesDrafts - Wall Mounted Bracket (BKT2)Zaido Al HalabiNo ratings yet

- Qvil Tgac TB Ar XX SD 3103Document1 pageQvil Tgac TB Ar XX SD 3103Zaido Al HalabiNo ratings yet

- 1 Input Data: Hilti PROFIS Engineering 3.0.72Document10 pages1 Input Data: Hilti PROFIS Engineering 3.0.72Zaido Al HalabiNo ratings yet

- Qvil Tgac TB Ar XX SD 3101Document1 pageQvil Tgac TB Ar XX SD 3101Zaido Al HalabiNo ratings yet

- Bsen 13334Document13 pagesBsen 13334Zaido Al HalabiNo ratings yet

- Bottom Edge BracketDocument14 pagesBottom Edge BracketZaido Al HalabiNo ratings yet

- Emf Values of Organic CompoundsDocument34 pagesEmf Values of Organic CompoundsPrabir SahaNo ratings yet

- Programme - DIES Alumni Forum - Preliminary 2022 - 10.10Document6 pagesProgramme - DIES Alumni Forum - Preliminary 2022 - 10.10D SusiloNo ratings yet

- Automated Object Oriented Door BellDocument3 pagesAutomated Object Oriented Door Bellcarl eliot100% (1)

- How To Design An Innovative WorkplaceDocument2 pagesHow To Design An Innovative WorkplacemuskanNo ratings yet

- Quality ManagementDocument21 pagesQuality Managementnitin pal singhNo ratings yet

- Sepl Esr GSRDocument4 pagesSepl Esr GSRSyed Mohd MehdiNo ratings yet

- University of Illinois The Grainger College of EngineeringDocument5 pagesUniversity of Illinois The Grainger College of EngineeringVinamr SachdevaNo ratings yet

- Introduction To LinguisticsDocument14 pagesIntroduction To LinguisticsasdfadsNo ratings yet

- Brooks Biotechnology and The Politics of Truth From The Green Revolution To An Evergreen RevolutionDocument20 pagesBrooks Biotechnology and The Politics of Truth From The Green Revolution To An Evergreen RevolutionDianaVictoriaNo ratings yet

- Management 3-4-1Document9 pagesManagement 3-4-1Jewel Galvez OctavianoNo ratings yet

- Design and Operation of High-Rate Filters-Part 3Document5 pagesDesign and Operation of High-Rate Filters-Part 3305773253No ratings yet

- Leviton AppNote RetentionForceTechnologyDocument5 pagesLeviton AppNote RetentionForceTechnologySajeda M. Al-TalafhaNo ratings yet

- Maths Memo Grade 8 June 2011 1Document4 pagesMaths Memo Grade 8 June 2011 123mofokengbokangNo ratings yet

- From Haiku To Shinrin-Yoku: A Brief History of Forest BathingDocument3 pagesFrom Haiku To Shinrin-Yoku: A Brief History of Forest BathingEfra LlebaríaNo ratings yet

- Accomplishment Report English Reading 2023 2024Document7 pagesAccomplishment Report English Reading 2023 2024SHERYLDUQUENo ratings yet

- Carbonate ClassificationDocument5 pagesCarbonate ClassificationArpit UpadhyayNo ratings yet

- Embankment Construction MethodologyDocument16 pagesEmbankment Construction MethodologyTinwin HtutNo ratings yet

- College-Algebra, Take Home Test 2Document3 pagesCollege-Algebra, Take Home Test 2Michelle Morgan LongstrethNo ratings yet

- APADocument2 pagesAPANovianto Dwi putraNo ratings yet

- Assignment 4 - Techno - MauricioDocument4 pagesAssignment 4 - Techno - Mauricioairu mauricioNo ratings yet

- Lec 3 (Linked List)Document12 pagesLec 3 (Linked List)Dr LolaNo ratings yet

- 1.2 Bus Admittance Matrix: FormulationDocument11 pages1.2 Bus Admittance Matrix: FormulationMohamed Elsir100% (1)

- Translating English Sentences To Mathematical Sentences and Vice-VersaDocument8 pagesTranslating English Sentences To Mathematical Sentences and Vice-VersaDana0% (1)

- Single Cell AnalysisDocument22 pagesSingle Cell AnalysisJonathan MilhomensNo ratings yet

- CFDLV13 N12 P32 44Document13 pagesCFDLV13 N12 P32 44Rahmat Azis NabawiNo ratings yet

- Mandal-Ekofisk (!) Petroleum System in The Central Graben of The North SeaDocument18 pagesMandal-Ekofisk (!) Petroleum System in The Central Graben of The North SeaJuan Pablo Rea VásquezNo ratings yet