Professional Documents

Culture Documents

2020 AUS Fine Chem 2sideV8Mar172020

2020 AUS Fine Chem 2sideV8Mar172020

Uploaded by

milad aghazadeCopyright:

Available Formats

You might also like

- 020 Gerwin Wijsman GraceDocument20 pages020 Gerwin Wijsman GraceNduong NguyenNo ratings yet

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- Isoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDocument16 pagesIsoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDavid RodriguesNo ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- TDS ValCOOL VPTechP 2017 Us En-R1Document1 pageTDS ValCOOL VPTechP 2017 Us En-R1Jesus D. Gutierrez G.No ratings yet

- Additives PE Swapan DharaDocument79 pagesAdditives PE Swapan DharatrydeepNo ratings yet

- Technical Data Sheet High Performance Thread SealantDocument2 pagesTechnical Data Sheet High Performance Thread SealantDani DaniNo ratings yet

- Lushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingDocument2 pagesLushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingelsobkiNo ratings yet

- TDS PACACEL L75-191 CR-89 April 2018Document4 pagesTDS PACACEL L75-191 CR-89 April 2018oscar veraNo ratings yet

- Stepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)Document4 pagesStepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)s0n1907No ratings yet

- Estabilización Del Polietileno Reciclado Posconsumo: Roberto NunezDocument45 pagesEstabilización Del Polietileno Reciclado Posconsumo: Roberto NunezFrancisco PiñaNo ratings yet

- Optimal Tech Coating News Vol 20Document2 pagesOptimal Tech Coating News Vol 20Javeria Ahmed100% (1)

- Orientation For New StaffDocument33 pagesOrientation For New StaffEyqa RazaliNo ratings yet

- KBR Olefins Technologies Jeff Caton 6826Document24 pagesKBR Olefins Technologies Jeff Caton 6826swaggeroni yololo100% (1)

- Di Ethyl Phthalate (DEP) Indo GSPDocument2 pagesDi Ethyl Phthalate (DEP) Indo GSPdhiraj1212inNo ratings yet

- 00034top Latex e 2014 EN - (EN) PDFDocument3 pages00034top Latex e 2014 EN - (EN) PDFdieselakiasNo ratings yet

- Technical Data Sheet: PVC - Resin SG58JDocument2 pagesTechnical Data Sheet: PVC - Resin SG58JSunday TesshaNo ratings yet

- Q927225 00 4EN - RevCDocument3 pagesQ927225 00 4EN - RevCstelios nikoladosNo ratings yet

- Essential Expertise: For Mineral ProcessingDocument4 pagesEssential Expertise: For Mineral ProcessingPedro DuarteNo ratings yet

- B-1114print Essential Expertise Mining PDFDocument4 pagesB-1114print Essential Expertise Mining PDFlpbeauchamp09No ratings yet

- N-Heptanoic Acid: Cas-No: 111-14-8 Ec NR: 203-838-7 Reach (Europe)Document2 pagesN-Heptanoic Acid: Cas-No: 111-14-8 Ec NR: 203-838-7 Reach (Europe)juliushasan2No ratings yet

- Loctite 435™: Technical Data SheetDocument3 pagesLoctite 435™: Technical Data SheettejassidhpuraNo ratings yet

- Polytone: ABR Series/Thermoplastic Acrylic ResinsDocument7 pagesPolytone: ABR Series/Thermoplastic Acrylic ResinsAdhvik PuriNo ratings yet

- About Kline - GPCA 2019Document9 pagesAbout Kline - GPCA 2019Dilip ChandwaniNo ratings yet

- Cleaner Production: December 2004Document24 pagesCleaner Production: December 2004api-3695407No ratings yet

- VAM-GPS-2016 - 01012016-Wi CT Feedback HSZ CT V3Document29 pagesVAM-GPS-2016 - 01012016-Wi CT Feedback HSZ CT V3Nabila ApriantiNo ratings yet

- Technical Data Sheet: PVC - Resin SP660Document2 pagesTechnical Data Sheet: PVC - Resin SP660kashyappathak01No ratings yet

- Materials For A Better Life: History HighlightsDocument1 pageMaterials For A Better Life: History HighlightsprabhjotbhangalNo ratings yet

- OLERIS N-HeptanolDocument2 pagesOLERIS N-HeptanolSnoopyNguyenNo ratings yet

- FCC LabDocument12 pagesFCC LabHassanNo ratings yet

- Chevron Phillips Chemicals: Presented By: Akasha Noor Trainee Engineer Excel Technological ServicesDocument26 pagesChevron Phillips Chemicals: Presented By: Akasha Noor Trainee Engineer Excel Technological ServicesTania NoorNo ratings yet

- FICHA TÉCNICA DE RESINA POLYESTER TEREFTÁLICA P-202-TerephthalicDocument3 pagesFICHA TÉCNICA DE RESINA POLYESTER TEREFTÁLICA P-202-TerephthalicJuancho CurryNo ratings yet

- TWO H Chem LTD.: Nova-P Nova-PDocument2 pagesTWO H Chem LTD.: Nova-P Nova-PKingsley BaptistaNo ratings yet

- POLYVEST HT enDocument4 pagesPOLYVEST HT enChoon Zhe ShyiNo ratings yet

- Roboze ArgoDocument12 pagesRoboze ArgoGregorio PisaneschiNo ratings yet

- Surfactants Guide - Personal-care-ENDocument48 pagesSurfactants Guide - Personal-care-ENGui TaingNo ratings yet

- 124826carboset® CR-785Document17 pages124826carboset® CR-785ForeverNo ratings yet

- TK236 Spec SheetDocument1 pageTK236 Spec Sheetproject.paldacaNo ratings yet

- Technical Data Sheet Permatex Form-A-Gasket No. 1 SealantDocument2 pagesTechnical Data Sheet Permatex Form-A-Gasket No. 1 SealantThis is my nameNo ratings yet

- Carbon Graphite Component by Helwig CarbonDocument3 pagesCarbon Graphite Component by Helwig CarbonSaikat PurkaitNo ratings yet

- Miramer M100D TDS - Rev4.0Document1 pageMiramer M100D TDS - Rev4.0Adesh GurjarNo ratings yet

- Acetone MSDSDocument5 pagesAcetone MSDSCarl Samuel ReyesNo ratings yet

- TAIPOL® 4202 - TSRC Corporation - Dexco PolymersDocument2 pagesTAIPOL® 4202 - TSRC Corporation - Dexco PolymersSafiullah KhanNo ratings yet

- CCL Presentation June 2018Document44 pagesCCL Presentation June 2018TRUCAL NABLNo ratings yet

- Specifications: Stimulation Fluids: Sample of Testing CapabilitiesDocument1 pageSpecifications: Stimulation Fluids: Sample of Testing CapabilitiesAchraf AkidNo ratings yet

- Fire Mechanisms and Phosphate EstersDocument40 pagesFire Mechanisms and Phosphate EstersahmetNo ratings yet

- Chemical TechnologyDocument52 pagesChemical TechnologySenthil KumarNo ratings yet

- The Growing Demand For High Vis PAO Within AsiaDocument32 pagesThe Growing Demand For High Vis PAO Within AsiaDhroov SharmaNo ratings yet

- Huntsmann Isolamento F and F HFO Catalyst DevelopmentDocument25 pagesHuntsmann Isolamento F and F HFO Catalyst DevelopmentCorentin HüniNo ratings yet

- 05 Dunlop Unique FeaturesDocument31 pages05 Dunlop Unique FeaturesFikret YenenNo ratings yet

- Thermolatent Curing Agents For Low Temperature 1K Epoxy Adhesive ApplicationsDocument27 pagesThermolatent Curing Agents For Low Temperature 1K Epoxy Adhesive Applicationss0n1907No ratings yet

- Koch Membrane Systems - Pharma Presentation-2017Document49 pagesKoch Membrane Systems - Pharma Presentation-2017Mohammed A. Helal100% (1)

- Condensia Catalogue BrochureDocument24 pagesCondensia Catalogue Brochure吉启周No ratings yet

- 19.02.additives For PlasticsDocument61 pages19.02.additives For Plasticsjraman24No ratings yet

- PVC TdsDocument2 pagesPVC TdsGİZEM D.No ratings yet

- Ami Cable 2015 ArkemaDocument34 pagesAmi Cable 2015 Arkemaabilio_j_vieiraNo ratings yet

- Cold Applied TapeDocument3 pagesCold Applied TapeKolusu SivakumarNo ratings yet

- Polymer Additives PQRI Poster PDFDocument1 pagePolymer Additives PQRI Poster PDFKapilSahuNo ratings yet

- Solutions For Water & Sanitary Applications: Trelleborg Se Aling SolutionsDocument8 pagesSolutions For Water & Sanitary Applications: Trelleborg Se Aling SolutionsLuis Silva NavarroNo ratings yet

- Adhesives Technology for Electronic Applications: Materials, Processing, ReliabilityFrom EverandAdhesives Technology for Electronic Applications: Materials, Processing, ReliabilityNo ratings yet

- Etching OpperDocument8 pagesEtching OpperAnil SharmaNo ratings yet

- Carbohydrate Metabolism The RuminantDocument12 pagesCarbohydrate Metabolism The RuminantJuni ClaudiaNo ratings yet

- CDC Vaccine IngredientsDocument6 pagesCDC Vaccine IngredientsAndrea Coulter100% (1)

- Aerobic Anaerobic RespirationDocument15 pagesAerobic Anaerobic RespirationTing Ming ChanNo ratings yet

- Training Report On Bio-FetilizerDocument22 pagesTraining Report On Bio-FetilizerAnanya SatuluriNo ratings yet

- Nutrient ManagementDocument37 pagesNutrient Managementasl33% (3)

- Microbial Lecture 6Document6 pagesMicrobial Lecture 6Tri WiyonoNo ratings yet

- Vaishali Randive, Et AlDocument8 pagesVaishali Randive, Et AlOENDRIL DASNo ratings yet

- 9.GOC & IsomerismDocument37 pages9.GOC & IsomerismVinod AgrawalNo ratings yet

- M.Sc. Part 1 Sem 1 (Wef 2021-22)Document22 pagesM.Sc. Part 1 Sem 1 (Wef 2021-22)Shifa ChaudhariNo ratings yet

- Chem Yellow PresentDocument12 pagesChem Yellow PresentChris MazisNo ratings yet

- Colorants Textiles PDFDocument2 pagesColorants Textiles PDFKatNo ratings yet

- Spsc-Testing Service-Umerkot, 4TH Self - Assessment (Mcat)Document45 pagesSpsc-Testing Service-Umerkot, 4TH Self - Assessment (Mcat)Ab Hadi100% (1)

- Poster ATExDocument1 pagePoster ATExmarius_brkt6284No ratings yet

- World/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisDocument3 pagesWorld/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisChé FeNo ratings yet

- Directory Feb 2013Document81 pagesDirectory Feb 2013Indrajit GhoshNo ratings yet

- History of Organic Chemistry 2Document2 pagesHistory of Organic Chemistry 2MiaNo ratings yet

- Heat Resistant Stoving Enamel Based On PKHWDocument1 pageHeat Resistant Stoving Enamel Based On PKHWnanoNo ratings yet

- Total Lipid Reagent Set (Colorimeyric Method) : Procedures (Manual)Document2 pagesTotal Lipid Reagent Set (Colorimeyric Method) : Procedures (Manual)Savrabh BhosaleNo ratings yet

- Roadmap For Supplier Improvement Program 2020-21Document5 pagesRoadmap For Supplier Improvement Program 2020-21shobha shelarNo ratings yet

- Chemistry As Level P 1 MCQs Classified TDocument34 pagesChemistry As Level P 1 MCQs Classified THussnain100% (3)

- 1Document1 page1yetruperkaNo ratings yet

- Permanganate Colorimetric Rapid Method For Chemical Oxygen Demand in SeawaterDocument3 pagesPermanganate Colorimetric Rapid Method For Chemical Oxygen Demand in SeawaterRika Epi SusantiNo ratings yet

- The Chemistry of LifeDocument15 pagesThe Chemistry of LifeNatalie MaskensNo ratings yet

- Epoxy Coating GuideDocument8 pagesEpoxy Coating GuideAzlan Othman100% (1)

- Final CPTDocument19 pagesFinal CPTAgha SufyanNo ratings yet

- Succinate Dehydrogenase: An Ideal Target For Fungicide DiscoveryDocument20 pagesSuccinate Dehydrogenase: An Ideal Target For Fungicide DiscoveryJoão LourençoNo ratings yet

- Comparisons of Epoxy Technology For Protective Coatings and Linings in Wastewater Facilities PDFDocument6 pagesComparisons of Epoxy Technology For Protective Coatings and Linings in Wastewater Facilities PDFarthurms325100% (1)

- A Simple Large-Scale Synthesis of Nearly Monodisperse Gold and Silver Nanoparticles With Adjustable Sizes and With Exchangeable SurfactantsDocument3 pagesA Simple Large-Scale Synthesis of Nearly Monodisperse Gold and Silver Nanoparticles With Adjustable Sizes and With Exchangeable Surfactants陈君泽No ratings yet

- Ijramt2 5 4Document6 pagesIjramt2 5 4thiri phyo waiNo ratings yet

2020 AUS Fine Chem 2sideV8Mar172020

2020 AUS Fine Chem 2sideV8Mar172020

Uploaded by

milad aghazadeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2020 AUS Fine Chem 2sideV8Mar172020

2020 AUS Fine Chem 2sideV8Mar172020

Uploaded by

milad aghazadeCopyright:

Available Formats

Austin Chemical Company, Inc.

Your Technology Solutions Provider www.austinchemical.com

1565 Barclay Boulevard • Buffalo Grove, IL 60089 U.S.A.

Tel: 847-520-9600 • info@austinchemical.com

Sustainability

Process Research & Development, Green Chemistry,

Impurities, Reference Standards

Services(#1 S&P)

— 325 plus personnel 170 PhD’s

Raptor® Continuous Commercial Processing

— (5-300 Liters per Hour ≈ 1 to 60 Kg per Hour)

Fine Chemicals

Markets/Industries Served: (Grams to Commercial)

• Additives • Apparel & Footwear • Functional Fluids • Performance Coatings

• Adhesives • Automotive • High Performance TPE • Sealants

• Aerospace • Coatings • Inks • Tires

• Elastomers • Micro-Reactors/Continuous • Transportation

• Agriculture Flow Technology

• Electronics

Products and Technologies

Additives Metallocene Vinyl Phosphonic Acid MercachemSyncom Raft Agents Alkylborane VELVETOL®

(VPA) Complexes

Air sensitive packaging • Adhesion Promoter Syncom Bio Based High

n-Butyl Lithium

Highly Engineered

Acidic Surface Binders • Flame Retardant Properties Partner Company Performance Polyols

• Metal Complexation properties Novel OLED's

Polymers

H

• Dispersing Benefits Green PTA, PET & FDCA Narrow Molecular Weight HO O

Surface Modifiers Conductive Thiophenes n

Cl Zr Cl 0 Control Stereochemistry

H 2C Molecular Weight:

500 – 2700 g / mol

Polyols P OH Acrylates CAS-No.: 345260-48-2

Styrenes

INNOVASSYNTH

TECHNOLOGIES(I) LTD

0H

Silanes & Siloxanes MSA/MSC Lactates Metallic Compounds Raptor Technology Surface Modification Specialty Solvents

Hexamethyldisilazane Methanesulfonic Acid Ethyl Lactate Ruthenium High Performance Dimethylimidazolidinone

Hexamethyldisiloxane Methanesulfonyl Metathesis Flow Chemistry Adhesion Properties

Lactic Acid (DMI)

Me3SiCl, Me2SiCl2, MeSiCl3

Chloride Catalysts • Phosgenation SIK7903-10 Cyclopentyl Methyl Ether

HSiCl3, SiCl4, MeHSiCl2,

Sodium Lactate

Methanesulfonyl Diaryl Magnesium • Ozonolysis Aerospace (CPME)

Me2HSiCl Sodium Pyruvate Dimethyl Sulfoxide (DMSO)

Reagent Quality Ar2Mg • Organometallic O

Lactides O Propylene Carbonate,

Organolithium • High Pressure P

OH

HO High Purity

Organosodium • Cryogenic P OH

HO

Phosphine, Carbene

Industrial & High Performance Processing Materials Specialty Packed

Sodium Ethyl Methyl Butyl Ethyl Methyl

Processing Solvents

Lactic Acid

Lactate Lactate Lactate Lactate Pyruvate Pyruvate

DL-Alanine

Available in 20 L quantities

pH buffers

Acetone 67-64-1

Anti-microbials —————————————————————————

Methanol 67-56-1

Detergents For Electronics —————————————————————————

200 Proof Ethanol 64-17-5

—————————————————————————

Detergents Isopropyl Alcohol 67-63-0

—————————————————————————

Solvents For Paint And Inks Tetrahydrofuran 109-99-9

—————————————————————————

Ethyl Acetate 141-78-6

Solvents For Polymers —————————————————————————

Isopropyl Acetate 108-21-4

Electroless Ni-plating —————————————————————————

2-Methyltetrahydrofuran 96-47-9

Agrochemicals —————————————————————————

tert-Butyl Methyl Ether 1634-04-4

—————————————————————————

Bioremediation Agent Toluene 108-88-3

—————————————————————————

Heptane 142-82-5

Additives For CMP Slurry

• —————————————————————————

Austin Chemical Company, Inc.

www.austinchemical.com

1565 Barclay Boulevard • Buffalo Grove, IL 60089 U.S.A.

Tel: 847-520-9600 • info@austinchemical.com

VELVETOL® HO O n

H GREEN

PO3G Polypropanediol Plant-derived polyol: stands out with its

Properties of Velvetol ®

[LIQUID] Molecular Weight: 500 – 2700 g/mol

CAS-No.: 345260-48-2 consistent quality & range of applications.

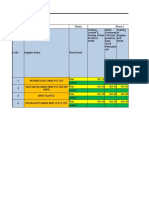

Property Units H500 H1000 H2000 H2700

Applications of Velvetol®

Content % 100 100 100 100

Elast erform.

Molecular weight

g

Da lto n 400 - 600 900 - 1100 1900 - 2100 2600 - 2800

rs

rintin

Leat etic

ome

ings

sive

Careonal

ants

Hydroxyl number mg KOH/Kg 280 - 187 125 - 102 59.1 - 53.4 40.7 - 43.9

her

h

meq KOH/

P

t

Adhe

CPR* (Alkalinity)

Coat

3D P

-2.0 - +2.0 -2.0 - +2.0 -2.0 - +2.0 -2.0 - +2.0

Synt

Pain

Pers

Seal

30 Kg

High

ppm <5 <5 <5 <5

Acid number mg KOH/g < 0.05 < 0.05 < 0.05 < 0.05

Na metal content ppm < 10 < 10 < 10 < 10 H500

Other Metal

ppm <5 <5 <5 <5

Content**

H1000

Peroxide Content ppm <5 <5 <5 <5

Water ppm < 500 < 500 < 500 < 500

Color max 50 max 50 max 50 max 50 max 120 H2000

Viscosity 40°C mPa•s 90 - 120 200 - 300 750 - 900 1450 - 1850

Density 40°C g /mL 1.02 1.018 1.016 1.016 H2700

Melting Point °C 0-5 12 - 14 16 - 18 23 - 25

* Controlled Polymerization Rate ** K, Ca, Mg, Fe, Al

Outstanding Properties and Unique INNOVASSYNTH

A

Characteristics of Velvetol® TECHNOLOGIES(I) LTD

• Low mp (9–22°C), low viscosity (100–1500 cp)

• High boiling point (>340°C) Organometallic Capabilities

• Low freezing point (down to –50°C with additives) • Custom packing tailored to user batch size

• High thermal heat capacity • Inert shipping and packing

• Pumpable liquids (9–19°C) versus • Dedicated labs

(poly tetramethylene ether)-glycol (23–28°C) • Made to order on customer requirements

• Hydrolysis resistant, high oxidative stability

• Air & Moisture sensitive operations

• More resistant against acid and heat compared to PTMEG

• Water-soluble / insoluble depending on the molecular weight • Pyrophoric material handling

• Excellent abrasion resistance

• Improved flexibility and low temperature (Tg<30°C) Metallocenes Catalysts

• Increases the content of bio-based materials in end products • Silica mounting of Metallocene precursors

(up to 80 % in elastomers, up to 30 % in plasticizers)

• Good processibility (low mp, low viscosity, slow crystallization DMBA Donor Flu Donor NPNPN

rates, low Tg )

N,N-Dimethylbenzamide

CAS# 611-74-5

9,9’-bis(methoxymethyl)fluorene

CAS# 182121-12-6 Ligands/

• Thermo-oxidatively stable Purity by GC —> 99%

Use: Ligand/Donor in metal

Purity by GC —> 99%

Use: Ligand/Donor in metal

Catalyst

• Increased durability in various end use applications including catalyst synthesis catalyst synthesis

Purity by titration —> 80%

artificial leather and coatings R3

• 100% sustainable content R N R

• Environmentally friendly and safe P P

• Low volatility and bio-degradable R1 N N R1

• Clear liquids with low or no melting points R2 R2

Applications Characteristics VPA O VPA-DME O

• Metal Treatment • Applicability as Monomer,

• Corrosion Inhibitor Polymer & Co-Polymer

• Coatings • Adhesion Promotion P P

• Oilfield Chemicals • Strong Metal Complexation Properties OH OMe

• Water Treatment • Dispersion Benefits

OH OMe

• Cement Additive • Flame-Retardant Properties

You might also like

- 020 Gerwin Wijsman GraceDocument20 pages020 Gerwin Wijsman GraceNduong NguyenNo ratings yet

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- Isoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDocument16 pagesIsoalky Process Technology,: A New Era For Alkylation With Ionic Liquid AlkylationDavid RodriguesNo ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- TDS ValCOOL VPTechP 2017 Us En-R1Document1 pageTDS ValCOOL VPTechP 2017 Us En-R1Jesus D. Gutierrez G.No ratings yet

- Additives PE Swapan DharaDocument79 pagesAdditives PE Swapan DharatrydeepNo ratings yet

- Technical Data Sheet High Performance Thread SealantDocument2 pagesTechnical Data Sheet High Performance Thread SealantDani DaniNo ratings yet

- Lushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingDocument2 pagesLushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingelsobkiNo ratings yet

- TDS PACACEL L75-191 CR-89 April 2018Document4 pagesTDS PACACEL L75-191 CR-89 April 2018oscar veraNo ratings yet

- Stepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)Document4 pagesStepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)s0n1907No ratings yet

- Estabilización Del Polietileno Reciclado Posconsumo: Roberto NunezDocument45 pagesEstabilización Del Polietileno Reciclado Posconsumo: Roberto NunezFrancisco PiñaNo ratings yet

- Optimal Tech Coating News Vol 20Document2 pagesOptimal Tech Coating News Vol 20Javeria Ahmed100% (1)

- Orientation For New StaffDocument33 pagesOrientation For New StaffEyqa RazaliNo ratings yet

- KBR Olefins Technologies Jeff Caton 6826Document24 pagesKBR Olefins Technologies Jeff Caton 6826swaggeroni yololo100% (1)

- Di Ethyl Phthalate (DEP) Indo GSPDocument2 pagesDi Ethyl Phthalate (DEP) Indo GSPdhiraj1212inNo ratings yet

- 00034top Latex e 2014 EN - (EN) PDFDocument3 pages00034top Latex e 2014 EN - (EN) PDFdieselakiasNo ratings yet

- Technical Data Sheet: PVC - Resin SG58JDocument2 pagesTechnical Data Sheet: PVC - Resin SG58JSunday TesshaNo ratings yet

- Q927225 00 4EN - RevCDocument3 pagesQ927225 00 4EN - RevCstelios nikoladosNo ratings yet

- Essential Expertise: For Mineral ProcessingDocument4 pagesEssential Expertise: For Mineral ProcessingPedro DuarteNo ratings yet

- B-1114print Essential Expertise Mining PDFDocument4 pagesB-1114print Essential Expertise Mining PDFlpbeauchamp09No ratings yet

- N-Heptanoic Acid: Cas-No: 111-14-8 Ec NR: 203-838-7 Reach (Europe)Document2 pagesN-Heptanoic Acid: Cas-No: 111-14-8 Ec NR: 203-838-7 Reach (Europe)juliushasan2No ratings yet

- Loctite 435™: Technical Data SheetDocument3 pagesLoctite 435™: Technical Data SheettejassidhpuraNo ratings yet

- Polytone: ABR Series/Thermoplastic Acrylic ResinsDocument7 pagesPolytone: ABR Series/Thermoplastic Acrylic ResinsAdhvik PuriNo ratings yet

- About Kline - GPCA 2019Document9 pagesAbout Kline - GPCA 2019Dilip ChandwaniNo ratings yet

- Cleaner Production: December 2004Document24 pagesCleaner Production: December 2004api-3695407No ratings yet

- VAM-GPS-2016 - 01012016-Wi CT Feedback HSZ CT V3Document29 pagesVAM-GPS-2016 - 01012016-Wi CT Feedback HSZ CT V3Nabila ApriantiNo ratings yet

- Technical Data Sheet: PVC - Resin SP660Document2 pagesTechnical Data Sheet: PVC - Resin SP660kashyappathak01No ratings yet

- Materials For A Better Life: History HighlightsDocument1 pageMaterials For A Better Life: History HighlightsprabhjotbhangalNo ratings yet

- OLERIS N-HeptanolDocument2 pagesOLERIS N-HeptanolSnoopyNguyenNo ratings yet

- FCC LabDocument12 pagesFCC LabHassanNo ratings yet

- Chevron Phillips Chemicals: Presented By: Akasha Noor Trainee Engineer Excel Technological ServicesDocument26 pagesChevron Phillips Chemicals: Presented By: Akasha Noor Trainee Engineer Excel Technological ServicesTania NoorNo ratings yet

- FICHA TÉCNICA DE RESINA POLYESTER TEREFTÁLICA P-202-TerephthalicDocument3 pagesFICHA TÉCNICA DE RESINA POLYESTER TEREFTÁLICA P-202-TerephthalicJuancho CurryNo ratings yet

- TWO H Chem LTD.: Nova-P Nova-PDocument2 pagesTWO H Chem LTD.: Nova-P Nova-PKingsley BaptistaNo ratings yet

- POLYVEST HT enDocument4 pagesPOLYVEST HT enChoon Zhe ShyiNo ratings yet

- Roboze ArgoDocument12 pagesRoboze ArgoGregorio PisaneschiNo ratings yet

- Surfactants Guide - Personal-care-ENDocument48 pagesSurfactants Guide - Personal-care-ENGui TaingNo ratings yet

- 124826carboset® CR-785Document17 pages124826carboset® CR-785ForeverNo ratings yet

- TK236 Spec SheetDocument1 pageTK236 Spec Sheetproject.paldacaNo ratings yet

- Technical Data Sheet Permatex Form-A-Gasket No. 1 SealantDocument2 pagesTechnical Data Sheet Permatex Form-A-Gasket No. 1 SealantThis is my nameNo ratings yet

- Carbon Graphite Component by Helwig CarbonDocument3 pagesCarbon Graphite Component by Helwig CarbonSaikat PurkaitNo ratings yet

- Miramer M100D TDS - Rev4.0Document1 pageMiramer M100D TDS - Rev4.0Adesh GurjarNo ratings yet

- Acetone MSDSDocument5 pagesAcetone MSDSCarl Samuel ReyesNo ratings yet

- TAIPOL® 4202 - TSRC Corporation - Dexco PolymersDocument2 pagesTAIPOL® 4202 - TSRC Corporation - Dexco PolymersSafiullah KhanNo ratings yet

- CCL Presentation June 2018Document44 pagesCCL Presentation June 2018TRUCAL NABLNo ratings yet

- Specifications: Stimulation Fluids: Sample of Testing CapabilitiesDocument1 pageSpecifications: Stimulation Fluids: Sample of Testing CapabilitiesAchraf AkidNo ratings yet

- Fire Mechanisms and Phosphate EstersDocument40 pagesFire Mechanisms and Phosphate EstersahmetNo ratings yet

- Chemical TechnologyDocument52 pagesChemical TechnologySenthil KumarNo ratings yet

- The Growing Demand For High Vis PAO Within AsiaDocument32 pagesThe Growing Demand For High Vis PAO Within AsiaDhroov SharmaNo ratings yet

- Huntsmann Isolamento F and F HFO Catalyst DevelopmentDocument25 pagesHuntsmann Isolamento F and F HFO Catalyst DevelopmentCorentin HüniNo ratings yet

- 05 Dunlop Unique FeaturesDocument31 pages05 Dunlop Unique FeaturesFikret YenenNo ratings yet

- Thermolatent Curing Agents For Low Temperature 1K Epoxy Adhesive ApplicationsDocument27 pagesThermolatent Curing Agents For Low Temperature 1K Epoxy Adhesive Applicationss0n1907No ratings yet

- Koch Membrane Systems - Pharma Presentation-2017Document49 pagesKoch Membrane Systems - Pharma Presentation-2017Mohammed A. Helal100% (1)

- Condensia Catalogue BrochureDocument24 pagesCondensia Catalogue Brochure吉启周No ratings yet

- 19.02.additives For PlasticsDocument61 pages19.02.additives For Plasticsjraman24No ratings yet

- PVC TdsDocument2 pagesPVC TdsGİZEM D.No ratings yet

- Ami Cable 2015 ArkemaDocument34 pagesAmi Cable 2015 Arkemaabilio_j_vieiraNo ratings yet

- Cold Applied TapeDocument3 pagesCold Applied TapeKolusu SivakumarNo ratings yet

- Polymer Additives PQRI Poster PDFDocument1 pagePolymer Additives PQRI Poster PDFKapilSahuNo ratings yet

- Solutions For Water & Sanitary Applications: Trelleborg Se Aling SolutionsDocument8 pagesSolutions For Water & Sanitary Applications: Trelleborg Se Aling SolutionsLuis Silva NavarroNo ratings yet

- Adhesives Technology for Electronic Applications: Materials, Processing, ReliabilityFrom EverandAdhesives Technology for Electronic Applications: Materials, Processing, ReliabilityNo ratings yet

- Etching OpperDocument8 pagesEtching OpperAnil SharmaNo ratings yet

- Carbohydrate Metabolism The RuminantDocument12 pagesCarbohydrate Metabolism The RuminantJuni ClaudiaNo ratings yet

- CDC Vaccine IngredientsDocument6 pagesCDC Vaccine IngredientsAndrea Coulter100% (1)

- Aerobic Anaerobic RespirationDocument15 pagesAerobic Anaerobic RespirationTing Ming ChanNo ratings yet

- Training Report On Bio-FetilizerDocument22 pagesTraining Report On Bio-FetilizerAnanya SatuluriNo ratings yet

- Nutrient ManagementDocument37 pagesNutrient Managementasl33% (3)

- Microbial Lecture 6Document6 pagesMicrobial Lecture 6Tri WiyonoNo ratings yet

- Vaishali Randive, Et AlDocument8 pagesVaishali Randive, Et AlOENDRIL DASNo ratings yet

- 9.GOC & IsomerismDocument37 pages9.GOC & IsomerismVinod AgrawalNo ratings yet

- M.Sc. Part 1 Sem 1 (Wef 2021-22)Document22 pagesM.Sc. Part 1 Sem 1 (Wef 2021-22)Shifa ChaudhariNo ratings yet

- Chem Yellow PresentDocument12 pagesChem Yellow PresentChris MazisNo ratings yet

- Colorants Textiles PDFDocument2 pagesColorants Textiles PDFKatNo ratings yet

- Spsc-Testing Service-Umerkot, 4TH Self - Assessment (Mcat)Document45 pagesSpsc-Testing Service-Umerkot, 4TH Self - Assessment (Mcat)Ab Hadi100% (1)

- Poster ATExDocument1 pagePoster ATExmarius_brkt6284No ratings yet

- World/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisDocument3 pagesWorld/Gmp Grade Isopropyl Alcohol, 99%: Certificate of AnalysisChé FeNo ratings yet

- Directory Feb 2013Document81 pagesDirectory Feb 2013Indrajit GhoshNo ratings yet

- History of Organic Chemistry 2Document2 pagesHistory of Organic Chemistry 2MiaNo ratings yet

- Heat Resistant Stoving Enamel Based On PKHWDocument1 pageHeat Resistant Stoving Enamel Based On PKHWnanoNo ratings yet

- Total Lipid Reagent Set (Colorimeyric Method) : Procedures (Manual)Document2 pagesTotal Lipid Reagent Set (Colorimeyric Method) : Procedures (Manual)Savrabh BhosaleNo ratings yet

- Roadmap For Supplier Improvement Program 2020-21Document5 pagesRoadmap For Supplier Improvement Program 2020-21shobha shelarNo ratings yet

- Chemistry As Level P 1 MCQs Classified TDocument34 pagesChemistry As Level P 1 MCQs Classified THussnain100% (3)

- 1Document1 page1yetruperkaNo ratings yet

- Permanganate Colorimetric Rapid Method For Chemical Oxygen Demand in SeawaterDocument3 pagesPermanganate Colorimetric Rapid Method For Chemical Oxygen Demand in SeawaterRika Epi SusantiNo ratings yet

- The Chemistry of LifeDocument15 pagesThe Chemistry of LifeNatalie MaskensNo ratings yet

- Epoxy Coating GuideDocument8 pagesEpoxy Coating GuideAzlan Othman100% (1)

- Final CPTDocument19 pagesFinal CPTAgha SufyanNo ratings yet

- Succinate Dehydrogenase: An Ideal Target For Fungicide DiscoveryDocument20 pagesSuccinate Dehydrogenase: An Ideal Target For Fungicide DiscoveryJoão LourençoNo ratings yet

- Comparisons of Epoxy Technology For Protective Coatings and Linings in Wastewater Facilities PDFDocument6 pagesComparisons of Epoxy Technology For Protective Coatings and Linings in Wastewater Facilities PDFarthurms325100% (1)

- A Simple Large-Scale Synthesis of Nearly Monodisperse Gold and Silver Nanoparticles With Adjustable Sizes and With Exchangeable SurfactantsDocument3 pagesA Simple Large-Scale Synthesis of Nearly Monodisperse Gold and Silver Nanoparticles With Adjustable Sizes and With Exchangeable Surfactants陈君泽No ratings yet

- Ijramt2 5 4Document6 pagesIjramt2 5 4thiri phyo waiNo ratings yet