Professional Documents

Culture Documents

Pipe Lax Ob Ps

Pipe Lax Ob Ps

Uploaded by

Lucie ChuCopyright:

Available Formats

You might also like

- 2.5 - FAT - C1574 - FAT Procedure PDFDocument7 pages2.5 - FAT - C1574 - FAT Procedure PDFGeorge Jhonson100% (2)

- Agriculture at A Glance: Daya Publishing HouseDocument7 pagesAgriculture at A Glance: Daya Publishing HousePan Smith57% (7)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Options Open Interest AnalysisDocument27 pagesOptions Open Interest Analysisgkrishnan59No ratings yet

- Sensitivity Analysis: Capital CostDocument4 pagesSensitivity Analysis: Capital CostZaini AhNo ratings yet

- Pipe Lax Env WH PsDocument3 pagesPipe Lax Env WH Psnov.maturidiNo ratings yet

- Pipe Lax W Eh PsDocument3 pagesPipe Lax W Eh PsWaleedm MariaNo ratings yet

- R-Bar Chart: 100 LCLX Rdbar Uclx Rbara Rbarb RbarcDocument11 pagesR-Bar Chart: 100 LCLX Rdbar Uclx Rbara Rbarb RbarcKamal ElumalaiNo ratings yet

- Metal Film Fixed Resistors (Rohs Compliant) MF-RC SeriesDocument4 pagesMetal Film Fixed Resistors (Rohs Compliant) MF-RC SeriesPablo ElíasNo ratings yet

- SPF CW-314-in Elastomeric Roof Coating-A - 1Document2 pagesSPF CW-314-in Elastomeric Roof Coating-A - 1jose100% (2)

- Nitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGDocument29 pagesNitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGNaveen GuptaNo ratings yet

- Xicon - XC 600046 1218702Document4 pagesXicon - XC 600046 1218702Damián PastreNo ratings yet

- O Brien How To Develop Perfect MemoryDocument7 pagesO Brien How To Develop Perfect MemoryRisty FegaridoNo ratings yet

- Expansion Tank Selection CalculatorDocument17 pagesExpansion Tank Selection Calculator185412No ratings yet

- Ullage in AirDocument52 pagesUllage in AirA. GHUZZINo ratings yet

- 170g - Flow Wrap: Vivo CostingDocument4 pages170g - Flow Wrap: Vivo Costingசரஸ்வதி சுவாமிநாதன்No ratings yet

- Waterjet PumpDocument2 pagesWaterjet PumpDaniel AustinNo ratings yet

- C) Statistical Empirical Findings: Statistic - HTMDocument3 pagesC) Statistical Empirical Findings: Statistic - HTMalexisgarefalakisNo ratings yet

- CoreLab PVT Study 1658959182Document18 pagesCoreLab PVT Study 1658959182ASKY PNo ratings yet

- C Trial 1Document1 pageC Trial 1Ariful IslamNo ratings yet

- Sublimation SupplementDocument7 pagesSublimation SupplementRAJESH SIMHADRINo ratings yet

- Chemical Thermo HW#4ADocument2 pagesChemical Thermo HW#4AbercNo ratings yet

- Light Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PDocument7 pagesLight Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PShan Adrias100% (1)

- EXSecondaryDocument83 pagesEXSecondaryMuslim Hedayet0% (1)

- Component Weight InformationDocument2 pagesComponent Weight InformationFarbod Jz.No ratings yet

- Automotive-Drain-to-source Voltage 5 V To 20 VDocument3 pagesAutomotive-Drain-to-source Voltage 5 V To 20 Vh_878236333No ratings yet

- Soil Improvement: No Description Unit QTY For New Muzairah Pumping Station (Lot 2A) Unit Rate (AED) Total Amount (AED)Document8 pagesSoil Improvement: No Description Unit QTY For New Muzairah Pumping Station (Lot 2A) Unit Rate (AED) Total Amount (AED)bejay bermudezNo ratings yet

- OREAS 203 DatapackDocument58 pagesOREAS 203 DatapackWidy macNo ratings yet

- Resistors PDFDocument1 pageResistors PDFwillian GaldinoNo ratings yet

- Pengetesan ConsolidationDocument17 pagesPengetesan ConsolidationRandi SetiawanNo ratings yet

- Simulaciones - 150CVXDocument15 pagesSimulaciones - 150CVXHelmutNolteNo ratings yet

- Weight Calculations - Steel Tube - Thyssenkrupp AerospaceDocument4 pagesWeight Calculations - Steel Tube - Thyssenkrupp AerospacewinasharNo ratings yet

- MDM Frame Ex 2Document7 pagesMDM Frame Ex 2jerico mangalindanNo ratings yet

- Problem 1: Differential Vaporization at T 229 FDocument16 pagesProblem 1: Differential Vaporization at T 229 Fperiya salehNo ratings yet

- Consolidation RizwanDocument14 pagesConsolidation RizwanNouman KhalidNo ratings yet

- Metrados de CargasDocument8 pagesMetrados de CargasEdwin Rodríguez PlasenciaNo ratings yet

- Six Benchmarks of US Treasury YieldsDocument8 pagesSix Benchmarks of US Treasury YieldsATANU ROYCHOUDHURYNo ratings yet

- Memoria Cajon VertedorDocument17 pagesMemoria Cajon VertedorCesar TossNo ratings yet

- StreamDocument4 pagesStreamNARAYAN DESAINo ratings yet

- Fugacidade - Termodinmica IIDocument5 pagesFugacidade - Termodinmica IIGiovanna BolinaNo ratings yet

- Hari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisDocument17 pagesHari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisMus TakimNo ratings yet

- Sr. No. Particular Tie BeamDocument12 pagesSr. No. Particular Tie BeamHarsh BhavsarNo ratings yet

- Oedinary G1 Blended 3 - 4Document1 pageOedinary G1 Blended 3 - 4Eljoy C. AgsamosamNo ratings yet

- Diesel Fuel Storage Tank Vent Sizing CalculationDocument2 pagesDiesel Fuel Storage Tank Vent Sizing Calculationbassam hasanNo ratings yet

- Diesel Fuel Storage Tank Vent Sizing CalculationDocument2 pagesDiesel Fuel Storage Tank Vent Sizing CalculationKrishnamoorthyNo ratings yet

- Oxygen - Weight and Volume EquivalentsDocument2 pagesOxygen - Weight and Volume EquivalentsDebajyoti BarmanNo ratings yet

- AB AB BA BC BC CD CB CD DC: Bending MomentDocument3 pagesAB AB BA BC BC CD CB CD DC: Bending MomentSengoli MolutsoaneNo ratings yet

- Sulphuric Acid Simulation Part 2 - PDFDocument3 pagesSulphuric Acid Simulation Part 2 - PDFachik realNo ratings yet

- CompoundsDocument1 pageCompoundsJian MinNo ratings yet

- Ra RB RB RB RC RCDocument46 pagesRa RB RB RB RC RCJohn GonzalesNo ratings yet

- Reservoir Engineering I (Pdb2023) Assignment: Vle Due Date: Total: 10 MarksDocument1 pageReservoir Engineering I (Pdb2023) Assignment: Vle Due Date: Total: 10 MarksZain NNo ratings yet

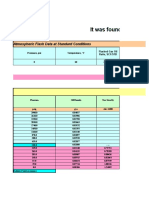

- It Was Found That The PB Is 500 Not 348 From Production PerformanceDocument41 pagesIt Was Found That The PB Is 500 Not 348 From Production PerformanceMario HuasasquicheNo ratings yet

- Weber 32 TLF - OcrDocument7 pagesWeber 32 TLF - Ocrmohamed lamine elbiskriNo ratings yet

- Stratigraphic 16 LithDocument1 pageStratigraphic 16 LithHeiman Alfredo Paz OrtegaNo ratings yet

- Workbook: Case (Main) : Material StreamsDocument1 pageWorkbook: Case (Main) : Material StreamsAnonymous hRxjRU7juNo ratings yet

- PDF Pract4 PDFDocument1 pagePDF Pract4 PDFAnonymous hRxjRU7juNo ratings yet

- PDF Pract4 PDFDocument1 pagePDF Pract4 PDFAnonymous hRxjRU7juNo ratings yet

- Ejercicio de ArmadurasDocument8 pagesEjercicio de ArmadurasLuis PoloNo ratings yet

- Nama: Ibnu Muntaha NIM: 19108010113: RissiDocument6 pagesNama: Ibnu Muntaha NIM: 19108010113: RissiIbnu MuntahaNo ratings yet

- Project: Panorama Cinema: U G O D U TDocument1 pageProject: Panorama Cinema: U G O D U TTalal HaNo ratings yet

- Product Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008Document9 pagesProduct Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008N.J. PatelNo ratings yet

- Lumina Homes PDFDocument1 pageLumina Homes PDFDestre Tima-anNo ratings yet

- Effects of Diet On Blood Glucose LevelDocument9 pagesEffects of Diet On Blood Glucose LevelKaneeshma Saran100% (1)

- Ijct 1 (5) 305-307Document46 pagesIjct 1 (5) 305-307Anonymous v5uipHNo ratings yet

- Babar Abbasi C VDocument10 pagesBabar Abbasi C VmimrantajNo ratings yet

- 1986 GT CatalogDocument16 pages1986 GT CatalogtspinnerNo ratings yet

- Samsung dvd-sh873 874 875 876 877Document130 pagesSamsung dvd-sh873 874 875 876 877Chema Don GarNo ratings yet

- Australian Mining ClusterDocument34 pagesAustralian Mining ClusterKumar Subrahmanya MankalaNo ratings yet

- UEFA B - Technical InformationDocument85 pagesUEFA B - Technical InformationILO 007No ratings yet

- Aivanhov - Angels and Other Mysteries of The Tree of LifeDocument208 pagesAivanhov - Angels and Other Mysteries of The Tree of LifebrentupdegraffNo ratings yet

- The Tangents Drawn at The Ends ofDocument6 pagesThe Tangents Drawn at The Ends ofpjojibabu100% (2)

- 011CMEDDocument13 pages011CMEDphilip xeroNo ratings yet

- SPD - List of AnnexuresDocument1 pageSPD - List of AnnexuresadheesNo ratings yet

- Almost 40years Airframe Noise ResearchDocument37 pagesAlmost 40years Airframe Noise ResearchMaurizio BernasconiNo ratings yet

- Ord2021082419220163Document1 pageOrd2021082419220163bujjishaikNo ratings yet

- AKG-2 Gate 4 Review Package Rev 0Document19 pagesAKG-2 Gate 4 Review Package Rev 0pvpallasigui3126100% (1)

- Printmaking Unit Plan - Amy Robertson Revised By: Deanna Plested GradeDocument47 pagesPrintmaking Unit Plan - Amy Robertson Revised By: Deanna Plested Gradeapi-264279988No ratings yet

- Countrys ClimateDocument20 pagesCountrys ClimateErika Jayne100% (1)

- J.saintifika Uji Bioavailabilitas Dan BioekivalensiDocument8 pagesJ.saintifika Uji Bioavailabilitas Dan BioekivalensiAhmad MujahidinNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- An Epistle of JeremiahDocument3 pagesAn Epistle of JeremiahBenson MuimiNo ratings yet

- Pro Tip Catalogue 4 07Document28 pagesPro Tip Catalogue 4 07notengofffNo ratings yet

- 1 Soal PrediksiDocument371 pages1 Soal PrediksiJanuar IrawanNo ratings yet

- FAQ Lecture 1Document5 pagesFAQ Lecture 1Richard De Medeiros Castro100% (1)

- Design and Performance Analysis of 2Document24 pagesDesign and Performance Analysis of 2Dilip Kumar100% (1)

- A Survey of One of The Most Important Pressure Pipe CodesDocument3 pagesA Survey of One of The Most Important Pressure Pipe CodesnerioalfonsoNo ratings yet

- The Scientific WorkDocument24 pagesThe Scientific WorkhumanNo ratings yet

- Coleção Da Taverna - Parte 2Document364 pagesColeção Da Taverna - Parte 2Physis Asclepius100% (2)

Pipe Lax Ob Ps

Pipe Lax Ob Ps

Uploaded by

Lucie ChuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Lax Ob Ps

Pipe Lax Ob Ps

Uploaded by

Lucie ChuCopyright:

Available Formats

Pipe-Lax OB

Pipe-Lax OB* additive is a spotting fluid designed to free stuck drillstrings

when using invert emulsion drilling fluids.

Pipe-Lax OB additive frees the drillstring by penetrating and cracking the filter cake to free differentially stuck pipe.

Typical Physical Properties

Physical appearance.......................................................................................................................................................................................................... Liquid

Odor.........................................................................................................................................................................................................................................Slight

Solubility in water...................................................................................................................................................................................................... Dispersible

Specific gravity.................................................................................................................................................................................................................. 0.98-1.0

Flash point..............................................................................................................................................................................................................220° F (104° C)

Applications

Success in freeing differentially stuck pipe is greatest when the spotting fluid is applied as soon as possible after the pipe becomes

stuck. A fluid that can be mixed and spotted quickly often frees the drillstring before fishing operations are required. Because Pipe-Lax

OB additive is a singly-packaged, liquid blend made for fast mixing it is ideal for spotting situations.

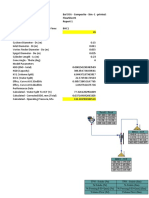

Mixing Formulation (per final barrel or per final m3)

Density Pipe-Lax OB Pipe-Lax OB Pipe-Lax OB

M-I Bar* Fer-Ox M-I Wate*

lb/gal (s.g.) additive additive additive

lb (kg) lb (kg) lb (kg)

bbl (m3) bbl (m3) bbl (m3)

9.0 (1.08) 0.975 (0.155) 37 (16.8) 0.980 (0.156) 35 (15.9) 0.974 (0.155) 37 (16.8)

10.0 (1.20) 0.938 (0.15) 92 (41.7) 0.950 (0.151) 87 (39.5) 0.936 (0.149) 93 (42.2)

11.0 (1.32) 0.900 (0.143) 147 (66.7) 0.920 (0.146) 140 (63.5) 0.897 (0.143) 148 (67.1)

12.0 (1.44) 0.863 (0.137) 202 (91.6) 0.890 (0.141) 192 (87.1) 0.858 (0.136) 204 (92.5)

13.0 (1.56) 0.825 (0.131) 257 (116.6) 0.860 (0.137) 245 (111.1) 0.819 (0.13) 259 (117.5)

14.0 (1.68) 0.788 (0.125) 312 (141.5) 0.830 (0.132) 297 (134.7) 0.781 (0.124) 315 (142.9)

15.0 (1.80) 0.750 (0.12) 367 (166.5) 0.800 (0.127) 350 (158.8) 0.742 (0.118) 370 (167.8)

16.0 (1.92) 0.713 (0.113) 423 (191.9) 0.770 (0.122) 402 (182.3) 0.703 (0.112) 426 (193.2)

Mixing Procedure

1. Calculate the volume of spotting fluid required and add at least 10% to compensate for any washout. In addition, include 25 bbl (3.97 m3)

to remain in the drillstring.

2. In a clean, dry tank, mix the required amount of Pipe-Lax OB additive determined from the Mixing Formulation Chart.

3. If the slurry is to be weighted, add the correct amount of M-I Bar*, M-I Wate* or Fer-Ox* weighting materials until thoroughly blended.

4. Displace the slurry to the zone where the differential sticking is suspected. Leave 25 bbl (3.97 m3) inside the pipe to displace at an

hourly rate into the openhole.

5. Work the pipe while the spotting fluid is soaking. Pump 0.5–1.0 bbl (0.08 – 0.16 m3) every ½ hour to assure fresh soak solution is being

displaced into the openhole.

6. Allow at least 24 hr for the Pipe-Lax OB additive to free stuck pipe. Unweighted spotting fluids are generally effective in a shorter period

of time.

Note: When using Pipe-Lax OB additive in deviated wells with angles greater than 35°, the spotting fluid should be weighted 0.5 lb/gal

(0.06 s.g.) heavier than the original fluid in the well to encourage the spotting fluid to migrate to the lower side of the hole.

Advantages

■■ Effective at cracking the filter cake in NAF systems

■■ Temperature-stable to >350° F (>177° C)

■■ Pipe-Lax OB additive is compatible with invert fluids; it can be incorporated to the system (1-5% V/V final concentration) without

adversely affecting mud properties. Pilot testing to confirm compatibility is recommended

■■ Can be easily weighted with M-I Bar, M-I Wate or Fer-Ox products

Limitations

■■ Addition of this product to a synthetic fluid may cause the system to fail bioassay testing

Toxicity and Handling

Bioassay information is available upon request.

Handle as an industrial chemical, wearing protective equipment and observing the precautions described in the Material Safety Data

Sheet (MSDS).

Packaging and Storage

Pipe-Lax OB additive is packaged in 55 gal (208 l) drums.

Store in a dry, well-ventilated area. Keep container closed. Keep away from heat, sparks and flames. Store away from incompatibles.

Follow safe warehousing practices regarding palletizing, banding, shrink-wrapping and/or stacking.

This information is supplied solely for informational purposes and M-I SWACO makes no guarantees or

P.O. Box 42842

warranties, either expressed or implied, with respect to the accuracy and use of this data. All product Houston, Texas 77242-2842

warranties and guarantees shall be governed by the Standard Terms of Sale. Nothing in this document

is legal advice or is a substitute for competent legal advice.

www.miswaco.slb.com

Email: questions@miswaco.slb.com

©2011 M-I L.L.C. All rights reserved. *Mark of M-I L.L.C.

FPB.1622.1106.R1 (E) Litho in U.S. A.

You might also like

- 2.5 - FAT - C1574 - FAT Procedure PDFDocument7 pages2.5 - FAT - C1574 - FAT Procedure PDFGeorge Jhonson100% (2)

- Agriculture at A Glance: Daya Publishing HouseDocument7 pagesAgriculture at A Glance: Daya Publishing HousePan Smith57% (7)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Options Open Interest AnalysisDocument27 pagesOptions Open Interest Analysisgkrishnan59No ratings yet

- Sensitivity Analysis: Capital CostDocument4 pagesSensitivity Analysis: Capital CostZaini AhNo ratings yet

- Pipe Lax Env WH PsDocument3 pagesPipe Lax Env WH Psnov.maturidiNo ratings yet

- Pipe Lax W Eh PsDocument3 pagesPipe Lax W Eh PsWaleedm MariaNo ratings yet

- R-Bar Chart: 100 LCLX Rdbar Uclx Rbara Rbarb RbarcDocument11 pagesR-Bar Chart: 100 LCLX Rdbar Uclx Rbara Rbarb RbarcKamal ElumalaiNo ratings yet

- Metal Film Fixed Resistors (Rohs Compliant) MF-RC SeriesDocument4 pagesMetal Film Fixed Resistors (Rohs Compliant) MF-RC SeriesPablo ElíasNo ratings yet

- SPF CW-314-in Elastomeric Roof Coating-A - 1Document2 pagesSPF CW-314-in Elastomeric Roof Coating-A - 1jose100% (2)

- Nitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGDocument29 pagesNitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGNaveen GuptaNo ratings yet

- Xicon - XC 600046 1218702Document4 pagesXicon - XC 600046 1218702Damián PastreNo ratings yet

- O Brien How To Develop Perfect MemoryDocument7 pagesO Brien How To Develop Perfect MemoryRisty FegaridoNo ratings yet

- Expansion Tank Selection CalculatorDocument17 pagesExpansion Tank Selection Calculator185412No ratings yet

- Ullage in AirDocument52 pagesUllage in AirA. GHUZZINo ratings yet

- 170g - Flow Wrap: Vivo CostingDocument4 pages170g - Flow Wrap: Vivo Costingசரஸ்வதி சுவாமிநாதன்No ratings yet

- Waterjet PumpDocument2 pagesWaterjet PumpDaniel AustinNo ratings yet

- C) Statistical Empirical Findings: Statistic - HTMDocument3 pagesC) Statistical Empirical Findings: Statistic - HTMalexisgarefalakisNo ratings yet

- CoreLab PVT Study 1658959182Document18 pagesCoreLab PVT Study 1658959182ASKY PNo ratings yet

- C Trial 1Document1 pageC Trial 1Ariful IslamNo ratings yet

- Sublimation SupplementDocument7 pagesSublimation SupplementRAJESH SIMHADRINo ratings yet

- Chemical Thermo HW#4ADocument2 pagesChemical Thermo HW#4AbercNo ratings yet

- Light Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PDocument7 pagesLight Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PShan Adrias100% (1)

- EXSecondaryDocument83 pagesEXSecondaryMuslim Hedayet0% (1)

- Component Weight InformationDocument2 pagesComponent Weight InformationFarbod Jz.No ratings yet

- Automotive-Drain-to-source Voltage 5 V To 20 VDocument3 pagesAutomotive-Drain-to-source Voltage 5 V To 20 Vh_878236333No ratings yet

- Soil Improvement: No Description Unit QTY For New Muzairah Pumping Station (Lot 2A) Unit Rate (AED) Total Amount (AED)Document8 pagesSoil Improvement: No Description Unit QTY For New Muzairah Pumping Station (Lot 2A) Unit Rate (AED) Total Amount (AED)bejay bermudezNo ratings yet

- OREAS 203 DatapackDocument58 pagesOREAS 203 DatapackWidy macNo ratings yet

- Resistors PDFDocument1 pageResistors PDFwillian GaldinoNo ratings yet

- Pengetesan ConsolidationDocument17 pagesPengetesan ConsolidationRandi SetiawanNo ratings yet

- Simulaciones - 150CVXDocument15 pagesSimulaciones - 150CVXHelmutNolteNo ratings yet

- Weight Calculations - Steel Tube - Thyssenkrupp AerospaceDocument4 pagesWeight Calculations - Steel Tube - Thyssenkrupp AerospacewinasharNo ratings yet

- MDM Frame Ex 2Document7 pagesMDM Frame Ex 2jerico mangalindanNo ratings yet

- Problem 1: Differential Vaporization at T 229 FDocument16 pagesProblem 1: Differential Vaporization at T 229 Fperiya salehNo ratings yet

- Consolidation RizwanDocument14 pagesConsolidation RizwanNouman KhalidNo ratings yet

- Metrados de CargasDocument8 pagesMetrados de CargasEdwin Rodríguez PlasenciaNo ratings yet

- Six Benchmarks of US Treasury YieldsDocument8 pagesSix Benchmarks of US Treasury YieldsATANU ROYCHOUDHURYNo ratings yet

- Memoria Cajon VertedorDocument17 pagesMemoria Cajon VertedorCesar TossNo ratings yet

- StreamDocument4 pagesStreamNARAYAN DESAINo ratings yet

- Fugacidade - Termodinmica IIDocument5 pagesFugacidade - Termodinmica IIGiovanna BolinaNo ratings yet

- Hari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisDocument17 pagesHari Ke.2 Hari Ke.3 Hari Ke.4 Hari Ke.5 Hari Ke.6: - Lab. AnalysisMus TakimNo ratings yet

- Sr. No. Particular Tie BeamDocument12 pagesSr. No. Particular Tie BeamHarsh BhavsarNo ratings yet

- Oedinary G1 Blended 3 - 4Document1 pageOedinary G1 Blended 3 - 4Eljoy C. AgsamosamNo ratings yet

- Diesel Fuel Storage Tank Vent Sizing CalculationDocument2 pagesDiesel Fuel Storage Tank Vent Sizing Calculationbassam hasanNo ratings yet

- Diesel Fuel Storage Tank Vent Sizing CalculationDocument2 pagesDiesel Fuel Storage Tank Vent Sizing CalculationKrishnamoorthyNo ratings yet

- Oxygen - Weight and Volume EquivalentsDocument2 pagesOxygen - Weight and Volume EquivalentsDebajyoti BarmanNo ratings yet

- AB AB BA BC BC CD CB CD DC: Bending MomentDocument3 pagesAB AB BA BC BC CD CB CD DC: Bending MomentSengoli MolutsoaneNo ratings yet

- Sulphuric Acid Simulation Part 2 - PDFDocument3 pagesSulphuric Acid Simulation Part 2 - PDFachik realNo ratings yet

- CompoundsDocument1 pageCompoundsJian MinNo ratings yet

- Ra RB RB RB RC RCDocument46 pagesRa RB RB RB RC RCJohn GonzalesNo ratings yet

- Reservoir Engineering I (Pdb2023) Assignment: Vle Due Date: Total: 10 MarksDocument1 pageReservoir Engineering I (Pdb2023) Assignment: Vle Due Date: Total: 10 MarksZain NNo ratings yet

- It Was Found That The PB Is 500 Not 348 From Production PerformanceDocument41 pagesIt Was Found That The PB Is 500 Not 348 From Production PerformanceMario HuasasquicheNo ratings yet

- Weber 32 TLF - OcrDocument7 pagesWeber 32 TLF - Ocrmohamed lamine elbiskriNo ratings yet

- Stratigraphic 16 LithDocument1 pageStratigraphic 16 LithHeiman Alfredo Paz OrtegaNo ratings yet

- Workbook: Case (Main) : Material StreamsDocument1 pageWorkbook: Case (Main) : Material StreamsAnonymous hRxjRU7juNo ratings yet

- PDF Pract4 PDFDocument1 pagePDF Pract4 PDFAnonymous hRxjRU7juNo ratings yet

- PDF Pract4 PDFDocument1 pagePDF Pract4 PDFAnonymous hRxjRU7juNo ratings yet

- Ejercicio de ArmadurasDocument8 pagesEjercicio de ArmadurasLuis PoloNo ratings yet

- Nama: Ibnu Muntaha NIM: 19108010113: RissiDocument6 pagesNama: Ibnu Muntaha NIM: 19108010113: RissiIbnu MuntahaNo ratings yet

- Project: Panorama Cinema: U G O D U TDocument1 pageProject: Panorama Cinema: U G O D U TTalal HaNo ratings yet

- Product Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008Document9 pagesProduct Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008N.J. PatelNo ratings yet

- Lumina Homes PDFDocument1 pageLumina Homes PDFDestre Tima-anNo ratings yet

- Effects of Diet On Blood Glucose LevelDocument9 pagesEffects of Diet On Blood Glucose LevelKaneeshma Saran100% (1)

- Ijct 1 (5) 305-307Document46 pagesIjct 1 (5) 305-307Anonymous v5uipHNo ratings yet

- Babar Abbasi C VDocument10 pagesBabar Abbasi C VmimrantajNo ratings yet

- 1986 GT CatalogDocument16 pages1986 GT CatalogtspinnerNo ratings yet

- Samsung dvd-sh873 874 875 876 877Document130 pagesSamsung dvd-sh873 874 875 876 877Chema Don GarNo ratings yet

- Australian Mining ClusterDocument34 pagesAustralian Mining ClusterKumar Subrahmanya MankalaNo ratings yet

- UEFA B - Technical InformationDocument85 pagesUEFA B - Technical InformationILO 007No ratings yet

- Aivanhov - Angels and Other Mysteries of The Tree of LifeDocument208 pagesAivanhov - Angels and Other Mysteries of The Tree of LifebrentupdegraffNo ratings yet

- The Tangents Drawn at The Ends ofDocument6 pagesThe Tangents Drawn at The Ends ofpjojibabu100% (2)

- 011CMEDDocument13 pages011CMEDphilip xeroNo ratings yet

- SPD - List of AnnexuresDocument1 pageSPD - List of AnnexuresadheesNo ratings yet

- Almost 40years Airframe Noise ResearchDocument37 pagesAlmost 40years Airframe Noise ResearchMaurizio BernasconiNo ratings yet

- Ord2021082419220163Document1 pageOrd2021082419220163bujjishaikNo ratings yet

- AKG-2 Gate 4 Review Package Rev 0Document19 pagesAKG-2 Gate 4 Review Package Rev 0pvpallasigui3126100% (1)

- Printmaking Unit Plan - Amy Robertson Revised By: Deanna Plested GradeDocument47 pagesPrintmaking Unit Plan - Amy Robertson Revised By: Deanna Plested Gradeapi-264279988No ratings yet

- Countrys ClimateDocument20 pagesCountrys ClimateErika Jayne100% (1)

- J.saintifika Uji Bioavailabilitas Dan BioekivalensiDocument8 pagesJ.saintifika Uji Bioavailabilitas Dan BioekivalensiAhmad MujahidinNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- An Epistle of JeremiahDocument3 pagesAn Epistle of JeremiahBenson MuimiNo ratings yet

- Pro Tip Catalogue 4 07Document28 pagesPro Tip Catalogue 4 07notengofffNo ratings yet

- 1 Soal PrediksiDocument371 pages1 Soal PrediksiJanuar IrawanNo ratings yet

- FAQ Lecture 1Document5 pagesFAQ Lecture 1Richard De Medeiros Castro100% (1)

- Design and Performance Analysis of 2Document24 pagesDesign and Performance Analysis of 2Dilip Kumar100% (1)

- A Survey of One of The Most Important Pressure Pipe CodesDocument3 pagesA Survey of One of The Most Important Pressure Pipe CodesnerioalfonsoNo ratings yet

- The Scientific WorkDocument24 pagesThe Scientific WorkhumanNo ratings yet

- Coleção Da Taverna - Parte 2Document364 pagesColeção Da Taverna - Parte 2Physis Asclepius100% (2)