Professional Documents

Culture Documents

Accident/Near Miss Alert and Learning Report 2/5/2014: 3:18 AM

Accident/Near Miss Alert and Learning Report 2/5/2014: 3:18 AM

Uploaded by

juniorex773Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accident/Near Miss Alert and Learning Report 2/5/2014: 3:18 AM

Accident/Near Miss Alert and Learning Report 2/5/2014: 3:18 AM

Uploaded by

juniorex773Copyright:

Available Formats

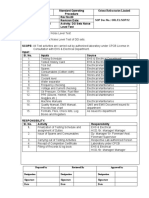

Accident/Near Miss alert and learning report 2/5/2014 : 3:18 AM

Site: Beaumont Mill Local: EAF Process: EAF Melt Shop

Potential: A Own Contractor Internal External

Responsible: Todd Concienne Phone: 409.769.1078

E-mail: Todd Concienne

NATURE TYPE SUBTYPES

Safety Actual Property Damage

Description of event

At 3:18 AM on Wednesday February 5th, an explosion happened in the Electric Arc Furnace

EAF was just in to refine at the time of explosion

Furnace operators followed the “Water in the EAF Emergency Procedure”, consistent with the Molten Metal Critical Guideline, prior to

the explosion, stopping EAF operation, raising blast shield, and evacuated the area when water was recognized

No injuries occurred

Operator stopped water flow to EAF roof, superstructure, shell, and evacuation duct but

COULD NOT stop the flow of water from the Lance Manipulator as it is not incorporated in to the EAF Emergency Water Shutoff

controls

The Evacuation Duct on the EAF was ejected from the roof on to the sump area, the EAF roof was damaged as was other auxiliary

equipment

Due to the amount of water that entered the EAF prior to, and after the explosion a refractory patch was initially done until the EAF was

cleared of steel and then an in depth refractory inspection and reline was conducted

Investigation determined that the Lance Manipulator was damaged during a reaction in the EAF and the flow of water could not be

stopped.

Injury / Loss / Damage

Damage to the EAF roof, elbow, lance manipulator, and charge machine.

Immediate Actions and Communications

Inspect EAF refractory for damage/water infiltration

Inspect EAF water cooled components for damage

Assess Mechanical and Electrical damage

Drain EAF for complete refractory inspection

Root Causes

Barrier - Physical Conditions:

Barrier - Management System:

Barrier - Behavior:

Learning

Natures: Safety

Description: There was a large amount of water entering the EAF;

- Water flow could not be immediately stopped from the Lance

The water cooled lance manipulator was damaged;

there was not a remote Emergency Water Shutoff for the lance

There was a reaction in the EAF, just behind the breast block, that damaged the lance

Emergency water shutoff controls for the lance manipulator was not considered because it is separate water system from EAF

Main Preventive Actions:

Install remote water shutoff for lance manipulator and integrate in to existing Emergency Water Controls

Review incident with all operating crews emphasizing early detection/indications of water in EAF

Look for alternative to water cooled Lance Manipulator

Evacuation elbow ejected on to sump lance manipulator, cause of explosion

Damaged lance manipulator during EAF reation Charge machine damaged

Damaged EAF without elbow

You might also like

- MIL-HDBK-23 Structural Sandwich CompositesDocument491 pagesMIL-HDBK-23 Structural Sandwich Compositeslider402114716No ratings yet

- M Schemes 02Document3 pagesM Schemes 02Pathmanathan Nadeson22% (9)

- DewateringDocument1 pageDewateringChandruNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- HRM Case Study (Nayatel Pakistan)Document12 pagesHRM Case Study (Nayatel Pakistan)mariam.irshadNo ratings yet

- SAFETY ALERT - Failure of The Steel Wire Rope of Gripper System - 18 May 2021Document1 pageSAFETY ALERT - Failure of The Steel Wire Rope of Gripper System - 18 May 2021Rinto Antony KannampillyNo ratings yet

- Case M Stank FireDocument4 pagesCase M Stank FireDeepak KumarNo ratings yet

- Near Miss - OCIMF Definition: Working AloftDocument10 pagesNear Miss - OCIMF Definition: Working AloftНина РыбкинаNo ratings yet

- SOP For Breakdown Maintenance - 1Document6 pagesSOP For Breakdown Maintenance - 1Pandu BirumakovelaNo ratings yet

- Incident Report - Aux BlowerDocument3 pagesIncident Report - Aux BlowerPrinceSadhotraNo ratings yet

- Investigation Report of Electrical Fire at Camp CharlieDocument3 pagesInvestigation Report of Electrical Fire at Camp CharlieEneyo VictorNo ratings yet

- FORMG-222-01.00.E00 - N16319 - Tripping Incident - 220kV Lines - 1Document14 pagesFORMG-222-01.00.E00 - N16319 - Tripping Incident - 220kV Lines - 1antaryamisinghNo ratings yet

- Near Miss Bulletin 4Q 2016Document5 pagesNear Miss Bulletin 4Q 2016randhir mahadikNo ratings yet

- SOP-02for Breakdown MaintenanceDocument4 pagesSOP-02for Breakdown MaintenancePandu BirumakovelaNo ratings yet

- Johwar Fire Incident ReportDocument2 pagesJohwar Fire Incident ReportOBINo ratings yet

- Accident and Incident Report Feb 3 2022 Cable CuttingDocument7 pagesAccident and Incident Report Feb 3 2022 Cable CuttingCharles DoriaNo ratings yet

- Craig Lamar Presentation Permission To Post PubliclyDocument18 pagesCraig Lamar Presentation Permission To Post PubliclypelayaranpejuangNo ratings yet

- Electrical Marine Thermal Imaging Survey Sample ReportDocument14 pagesElectrical Marine Thermal Imaging Survey Sample ReportRachit SharmaNo ratings yet

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal Pattanayak100% (2)

- Steam Turbine StartupDocument17 pagesSteam Turbine StartupRahul ChoubeyNo ratings yet

- Effluent Discharge Mock Emergency and Evalaution ReportDocument3 pagesEffluent Discharge Mock Emergency and Evalaution Reportremember0% (1)

- Collision With Wharf and Barge After Steering Power Loss: (1) PrefaceDocument5 pagesCollision With Wharf and Barge After Steering Power Loss: (1) PrefaceFazle RabbiNo ratings yet

- IMCASF - Jan 18Document5 pagesIMCASF - Jan 18Shivkumar JadhavNo ratings yet

- 01 SOP Preventive Maintenance - MachineDocument4 pages01 SOP Preventive Maintenance - MachinePandu Birumakovela100% (1)

- IMCASF - Jul 18Document6 pagesIMCASF - Jul 18Shivkumar JadhavNo ratings yet

- 5-Star Safety and Health Management SystemDocument5 pages5-Star Safety and Health Management SystemSn Ahsan100% (1)

- IMCASF - Dec 17Document6 pagesIMCASF - Dec 17Shivkumar JadhavNo ratings yet

- Initial Incident Notification (IIN) ReportDocument1 pageInitial Incident Notification (IIN) ReportAns RasheedNo ratings yet

- SOP Doc No.: ORL/EM/SOP/01: ST STDocument9 pagesSOP Doc No.: ORL/EM/SOP/01: ST STPandu BirumakovelaNo ratings yet

- PTTP ProcessSafetyFundamentalsDocument12 pagesPTTP ProcessSafetyFundamentalsAnonymous q2iHVfNo ratings yet

- The Red Jacket UMP: Quick Troubleshooting GuideDocument5 pagesThe Red Jacket UMP: Quick Troubleshooting GuideBrandon CatronNo ratings yet

- Potential Fatal Event Advisory: (As Applicable - E.G. Make/model of Equipment)Document2 pagesPotential Fatal Event Advisory: (As Applicable - E.G. Make/model of Equipment)angel_machacaNo ratings yet

- Imca Findings-S.vivienneDocument6 pagesImca Findings-S.vivienneWiddy IriandiNo ratings yet

- Safety Bulletin Vol 1 Issue 02 Draftl 2Document4 pagesSafety Bulletin Vol 1 Issue 02 Draftl 2api-185453632No ratings yet

- 4orange Stripe # 04 EnglishDocument2 pages4orange Stripe # 04 EnglishShahid RazaNo ratings yet

- IE496 Industrial Engineering Internship: Dr. Barnes March 17, 2008 Lecture # 8Document36 pagesIE496 Industrial Engineering Internship: Dr. Barnes March 17, 2008 Lecture # 8Mochamad Teguh SubarkahNo ratings yet

- Fire IncidentDocument1 pageFire IncidentAntay KorakotNo ratings yet

- 14-08-2020 - 2200 Hrs - LS 4G1 - DO - Fire Fighting PVC Pipe - DraftDocument12 pages14-08-2020 - 2200 Hrs - LS 4G1 - DO - Fire Fighting PVC Pipe - DraftJohn Vincent Macatangay CleofeNo ratings yet

- Thermal Runaway Incident FormDocument9 pagesThermal Runaway Incident Formroyal motorsNo ratings yet

- Doc. No. Page No: 1 OF 2: Integrated Departmental Manual Caustic Soda Unit Sop/Elect /10Document2 pagesDoc. No. Page No: 1 OF 2: Integrated Departmental Manual Caustic Soda Unit Sop/Elect /10Ravi Shankar ChakravortyNo ratings yet

- 02 SOP Preventive Maintenance of DG SetsDocument4 pages02 SOP Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- 7 - Bus Bar & Ducts - YearlyDocument3 pages7 - Bus Bar & Ducts - Yearlyrishimaran100% (1)

- IMCASF - Sept 16Document4 pagesIMCASF - Sept 16Shivkumar JadhavNo ratings yet

- MS05-Installation of Sanitary ProductsDocument2 pagesMS05-Installation of Sanitary ProductsAndrei VNo ratings yet

- Human Factors - Module2Document7 pagesHuman Factors - Module2Sudarsan PrathipatiNo ratings yet

- Case Study - Fire Incident Due To Leakage of MS From Insulating Joint 200520 PDFDocument4 pagesCase Study - Fire Incident Due To Leakage of MS From Insulating Joint 200520 PDFMainak GhoshNo ratings yet

- MME Standard Operating Procedure (SOP)Document10 pagesMME Standard Operating Procedure (SOP)hardi05No ratings yet

- IMCASF - Mar 17Document5 pagesIMCASF - Mar 17Shivkumar JadhavNo ratings yet

- Incident Report: A. General InformationDocument3 pagesIncident Report: A. General InformationHarman SandhuNo ratings yet

- SOP Noise Testing of DG SetsDocument2 pagesSOP Noise Testing of DG SetsPandu Birumakovela100% (1)

- Lesson Learned-HIPO Near Miss - Energy IsolationDocument1 pageLesson Learned-HIPO Near Miss - Energy IsolationMukeshNo ratings yet

- IMCA Safety Flashes 2009 07Document6 pagesIMCA Safety Flashes 2009 07Francisco TajúNo ratings yet

- Efact55 Fishing VesselsDocument12 pagesEfact55 Fishing VesselsamasrurNo ratings yet

- ES&H Site Visit Report WeldingDocument3 pagesES&H Site Visit Report Weldingmuhammad.younisNo ratings yet

- Technicalbulletin060 EngineroomFloodingDocument4 pagesTechnicalbulletin060 EngineroomFloodingAbhijith Sreevalsan PillaiNo ratings yet

- ObservationsDocument4 pagesObservationsER S AtramNo ratings yet

- Imcasf 10 18Document6 pagesImcasf 10 18Shola EshoNo ratings yet

- School of Mechanical Engineering: Battery SafetyDocument19 pagesSchool of Mechanical Engineering: Battery SafetyVadim RiabovNo ratings yet

- OSER For UtilitiesDocument20 pagesOSER For UtilitiesMuhammad Haris HamayunNo ratings yet

- F.No.11-NT (23) /2005 Dated 5th April 2005: Sub: Fire On Passenger VesselDocument2 pagesF.No.11-NT (23) /2005 Dated 5th April 2005: Sub: Fire On Passenger VesselAjay SinghNo ratings yet

- TBT 200 Incidents and General Precautions - 02Document4 pagesTBT 200 Incidents and General Precautions - 02AhamedNo ratings yet

- Job Safety AnalysisDocument1 pageJob Safety AnalysisAdamuNo ratings yet

- Air Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811From EverandAir Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811No ratings yet

- Calculo 86bDocument10 pagesCalculo 86bjuniorex773No ratings yet

- Overhead Cranes DQR Series: Mr. Skocaj Marco 013375CP020 12/12/2013Document25 pagesOverhead Cranes DQR Series: Mr. Skocaj Marco 013375CP020 12/12/2013juniorex773No ratings yet

- Irizar Forge Product Guide 2021 METRICDocument92 pagesIrizar Forge Product Guide 2021 METRICjuniorex773No ratings yet

- Investigation of The Effect of The Sling Angle and Size On The Reliability of Lifting HooksDocument13 pagesInvestigation of The Effect of The Sling Angle and Size On The Reliability of Lifting Hooksjuniorex773No ratings yet

- Ficha Técnica - CadenasDocument1 pageFicha Técnica - Cadenasjuniorex773No ratings yet

- FactoryTalk Historian SEDocument26 pagesFactoryTalk Historian SEjuniorex773No ratings yet

- Tag Heuer Movement FinishesDocument2 pagesTag Heuer Movement FinishesDevil GodNo ratings yet

- DP FourSeals ENGDocument60 pagesDP FourSeals ENGgeorgia83609No ratings yet

- Vlsi Module-5Document56 pagesVlsi Module-5Phanindra ReddyNo ratings yet

- Comparative and Superlative AdjectivesDocument5 pagesComparative and Superlative AdjectivesYoussef BrsNo ratings yet

- Research Article: ISSN: 0975-833XDocument5 pagesResearch Article: ISSN: 0975-833XAdeep MathurNo ratings yet

- Tabelas Roscas TrapezoidaisDocument49 pagesTabelas Roscas TrapezoidaisDesenvolvimento MHNo ratings yet

- Tata Motors's AchivementsDocument105 pagesTata Motors's AchivementsSunny SinghNo ratings yet

- ASX Announcement 2021 23 - CRU Conference PresentationDocument26 pagesASX Announcement 2021 23 - CRU Conference PresentationÂngelo PereiraNo ratings yet

- SuperWale Data SheetDocument8 pagesSuperWale Data SheetMagnum CompositesNo ratings yet

- Chapter 6Document24 pagesChapter 6گل میوہNo ratings yet

- CookiesDocument130 pagesCookiesNinjamuppetNo ratings yet

- Tutorial Materials SelectionDocument2 pagesTutorial Materials SelectionSyahmiNo ratings yet

- Moxon Sat AntDocument4 pagesMoxon Sat AntMaureen PegusNo ratings yet

- Harris Ts100 User ManualDocument24 pagesHarris Ts100 User ManualMiguel Alfonso Ruiz MendezNo ratings yet

- PreloadDocument21 pagesPreloadjainshani2No ratings yet

- Sika RainTiteDocument2 pagesSika RainTiteRialno TambunanNo ratings yet

- Cut Out ValveDocument64 pagesCut Out ValveHoang L A TuanNo ratings yet

- File DisksDocument22 pagesFile DisksAlana PetersonNo ratings yet

- Safety Data Sheet: Section 1 - Product and Company IdentificationDocument4 pagesSafety Data Sheet: Section 1 - Product and Company IdentificationAnnaAffandieNo ratings yet

- DS IV Unit NotesDocument29 pagesDS IV Unit NotesAlagandula KalyaniNo ratings yet

- Caserm/D: Publication Ordering InformationDocument326 pagesCaserm/D: Publication Ordering InformationjohnNo ratings yet

- Procurement PlanDocument32 pagesProcurement Planario widjaksono100% (1)

- 如何写一个简短的开场白Document6 pages如何写一个简短的开场白afmojdevnNo ratings yet

- Tunnel Engineering MCQ PDFDocument9 pagesTunnel Engineering MCQ PDFAkshayNo ratings yet

- Emc2700 AbzDocument3 pagesEmc2700 AbzDrew AlbaneseNo ratings yet

- SPE 127422 Cement-Sheath Wellbore Integrity For CO Injection and Storage WellsDocument11 pagesSPE 127422 Cement-Sheath Wellbore Integrity For CO Injection and Storage Wellsadvantage025No ratings yet

- SR Designworks: Head OfficeDocument15 pagesSR Designworks: Head Officeihameed4100% (1)