Professional Documents

Culture Documents

Hy 5XLT1

Hy 5XLT1

Uploaded by

FabioCopyright:

Available Formats

You might also like

- Yellow FeverDocument1 pageYellow FeverajithpakNo ratings yet

- KahnemanDocument11 pagesKahnemanMatt Pauls17% (18)

- Insert - PreciControl Anti-SARS-CoV-2 S.ms - 09289313190.v1.enDocument2 pagesInsert - PreciControl Anti-SARS-CoV-2 S.ms - 09289313190.v1.enLilik IndrawatiNo ratings yet

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiNo ratings yet

- XLCT 14Document2 pagesXLCT 14carlosNo ratings yet

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriqueNo ratings yet

- Tabla STEALTH 14Document2 pagesTabla STEALTH 14luz_cuellar_15No ratings yet

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikNo ratings yet

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoNo ratings yet

- 0,5 XLTDocument2 pages0,5 XLTFranciscoJSilvaNo ratings yet

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiNo ratings yet

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraNo ratings yet

- MXTP 01 Torque Conversion ChartDocument2 pagesMXTP 01 Torque Conversion ChartjavhirNo ratings yet

- Standard Torque Chart: Tool Model: MXT 1Document2 pagesStandard Torque Chart: Tool Model: MXT 1Wahyu WidiyantoNo ratings yet

- 1XLT TR2Document2 pages1XLT TR2FranciscoJSilvaNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilNo ratings yet

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86No ratings yet

- RTX04 Torque ChartDocument1 pageRTX04 Torque ChartYang Kyo OhNo ratings yet

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinNo ratings yet

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07No ratings yet

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirreNo ratings yet

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuiceNo ratings yet

- Sitio WebDocument15 pagesSitio WebRoberto RodriguezNo ratings yet

- HighTensileFastners PDFDocument24 pagesHighTensileFastners PDFMallika SahniNo ratings yet

- Polycab Price List 16th October 2021Document2 pagesPolycab Price List 16th October 2021Kushal DixitNo ratings yet

- Satuan GDocument1 pageSatuan GWoro IndrianiNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftNo ratings yet

- PH Hydraulic Torque Wrench Instruction ManualDocument23 pagesPH Hydraulic Torque Wrench Instruction ManualLikLiek WahahaNo ratings yet

- Partial Horizontal Tank Volumes: ParametersDocument4 pagesPartial Horizontal Tank Volumes: ParametersSagar DhuriNo ratings yet

- FLOWTITE Handling and StorageDocument13 pagesFLOWTITE Handling and StorageMohammed khaleelNo ratings yet

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzNo ratings yet

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Document7 pagesKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniNo ratings yet

- Indice IntraindustrialDocument17 pagesIndice IntraindustrialJuan Camilo ArboledaNo ratings yet

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyNo ratings yet

- catchment area to runoff yield 2 ١Document1 pagecatchment area to runoff yield 2 ١Ahmed NabilNo ratings yet

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaNo ratings yet

- Test 11Document3 pagesTest 11shinjuvijayNo ratings yet

- RR KABEL Price List - LT HT Cables - 01st February 2023Document4 pagesRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNo ratings yet

- Laboratory Exercise No. 5 Rheological PropertiesDocument16 pagesLaboratory Exercise No. 5 Rheological PropertiesANIME CHANNo ratings yet

- Measurements For Anchor-Chain and AccessoriesDocument4 pagesMeasurements For Anchor-Chain and AccessoriesOzata TersanesiNo ratings yet

- Phone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Document2 pagesPhone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Akhila kumarNo ratings yet

- MEIZON GUTU DDocument7 pagesMEIZON GUTU DlevisontawandaNo ratings yet

- Apy ChartDocument1 pageApy ChartTechnology GamerNo ratings yet

- Apy ChartDocument1 pageApy ChartPRANAV MUKTIBODHNo ratings yet

- Apy ChartDocument1 pageApy Chartvmcon kkl 2020No ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFSHUBHAJIT NANDINo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFPravrutti DahiwaleNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFavinash1987100% (1)

- Apy ChartDocument1 pageApy ChartUday GopalNo ratings yet

- Apy ChartDocument1 pageApy ChartMohit PathaniaNo ratings yet

- APY Chart PDFDocument1 pageAPY Chart PDFRahul TadeNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFchannel SNo ratings yet

- Apy ChartDocument1 pageApy ChartClassicaverNo ratings yet

- Apy ChartDocument1 pageApy Chartvinay chaudhariNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFAswin AbiNo ratings yet

- Apy ChartDocument1 pageApy Chartkrishna garaiNo ratings yet

- Apy ChartDocument1 pageApy ChartJai mishraNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Aqa Health and Social Care Coursework Examples GcseDocument5 pagesAqa Health and Social Care Coursework Examples Gcsekezevifohoh3100% (1)

- Hypertension and Congestive Heart FailureDocument4 pagesHypertension and Congestive Heart FailureDawn ReyaNo ratings yet

- Using The Psychopathy Checklist-Revised With Female Samples: Reliability, Validity, and Implications For Clinical UtilityDocument16 pagesUsing The Psychopathy Checklist-Revised With Female Samples: Reliability, Validity, and Implications For Clinical UtilityIsa Abu YahyaNo ratings yet

- Validation of The Lifft Risk Assessment Tool and Guidance On Its UseDocument10 pagesValidation of The Lifft Risk Assessment Tool and Guidance On Its UsehigormeNo ratings yet

- Safety Data Sheet Winsor & Newton Artist Acrylic Gloss Uv Varnish (Us MSDS)Document3 pagesSafety Data Sheet Winsor & Newton Artist Acrylic Gloss Uv Varnish (Us MSDS)zaryab khanNo ratings yet

- Abenezer PaperDocument31 pagesAbenezer Paperabayneh aberaNo ratings yet

- Parasite Images (Protozoan - Nematodes)Document15 pagesParasite Images (Protozoan - Nematodes)Kathleen BrazasNo ratings yet

- E1 Estanislao Towards The Development CASE NOTESDocument31 pagesE1 Estanislao Towards The Development CASE NOTESCarlo MagnoNo ratings yet

- Carter Procession Closure MapDocument1 pageCarter Procession Closure Mapcookiespiffey21No ratings yet

- Tax Case Compilation Ia To D 1Document19 pagesTax Case Compilation Ia To D 1Markonitchee Semper Fidelis100% (1)

- Theories and Models in Community Health NursingDocument26 pagesTheories and Models in Community Health NursingSabitha Jayakumar92% (12)

- Drug Name Mechanism of Action Indication/ Contraindication Adverse Effect Nursing ResponsibilitiesDocument1 pageDrug Name Mechanism of Action Indication/ Contraindication Adverse Effect Nursing ResponsibilitiesJohnrick VenturaNo ratings yet

- The Green Beauty GuideDocument290 pagesThe Green Beauty GuideVinot Nathan95% (19)

- Ve GL HirarcDocument34 pagesVe GL HirarcEncik AhmadNo ratings yet

- Chapter 2: Scientific Methods in PsychologyDocument111 pagesChapter 2: Scientific Methods in PsychologyZahid Khan BabaiNo ratings yet

- Orthognatic Surgery 2Document40 pagesOrthognatic Surgery 2ammarstein89No ratings yet

- Factors Influencing School Dropouts at T PDFDocument4 pagesFactors Influencing School Dropouts at T PDFArchana JadhavNo ratings yet

- Post Harvesting (Stages of Ripeness)Document3 pagesPost Harvesting (Stages of Ripeness)Mark Levi CannonNo ratings yet

- Discussion 4 EthicsDocument2 pagesDiscussion 4 Ethicspeter njovuNo ratings yet

- Reducing Test Anxiety and Improving Test Performance in America's SchoolsDocument8 pagesReducing Test Anxiety and Improving Test Performance in America's SchoolssanthigiNo ratings yet

- Worksheet #6-1Document4 pagesWorksheet #6-1Che InopiaNo ratings yet

- 19 - Suspended Scaffolding Construction Major Program Points 075Document12 pages19 - Suspended Scaffolding Construction Major Program Points 075BensonNo ratings yet

- Is Everything We Eat Associated With Cancer? A Systematic Cookbook ReviewDocument8 pagesIs Everything We Eat Associated With Cancer? A Systematic Cookbook ReviewRenan BragaNo ratings yet

- Bowel Incontinence ConstipationDocument3 pagesBowel Incontinence ConstipationMatty-b AskalaniNo ratings yet

- Locater UpdateDocument46 pagesLocater UpdatenovaaputryNo ratings yet

- HIRARC Healthcare Linen 01Document8 pagesHIRARC Healthcare Linen 01Don McleanNo ratings yet

- Hyperthyroidism in PregnancyDocument5 pagesHyperthyroidism in PregnancyOhazurike EphraimNo ratings yet

Hy 5XLT1

Hy 5XLT1

Uploaded by

FabioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hy 5XLT1

Hy 5XLT1

Uploaded by

FabioCopyright:

Available Formats

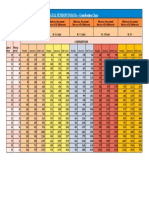

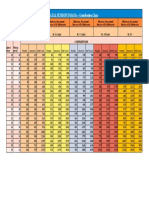

HYTORC

TOOL MODEL: HY-5XLT

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN TORQUE IN PRESSURE IN

PSI FT. LBS. KGM NM BAR

1500 835 115 1132 104

1600 890 123 1206 110

1800 1000 138 1356 124

2000 1110 154 1505 138

2200 1222 169 1657 152

2400 1334 184 1808 165

2600 1446 200 1960 179

2800 1558 215 2112 193

3000 1670 231 2264 207

3200 1782 246 2416 220

3400 1894 262 2568 234

3600 2006 277 2719 248

3800 2118 293 2871 262

4000 2230 308 3023 276

4200 2342 324 3175 290

4400 2454 339 3327 303

4600 2566 355 3478 317

4800 2678 370 3630 331

5000 2790 386 3782 345

5200 2902 401 3934 358

5400 3014 417 4086 372

5600 3126 432 4238 386

5800 3238 448 4389 400

6000 3350 463 4541 414

6200 3462 479 4693 427

6400 3574 494 4845 441

6600 3686 510 4997 455

6800 3798 525 5149 468

7000 3910 541 5300 482

7200 4022 556 5452 496

7400 4134 572 5604 510

7600 4246 587 5756 524

7800 4358 603 5908 538

8000 4470 618 6060 552

8200 4582 634 6211 565

8400 4694 649 6363 579

8600 4806 665 6515 593

8800 4918 680 6667 607

9000 5030 696 6819 620

9200 5142 711 6970 634

9400 5254 727 7122 648

9600 5366 742 7274 662

9800 5478 758 7426 676

10000 5590 773 7578 690

* ISO DOCUMENT 9000 REV. 09/1993

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions should be

observed to avoid accidents or personal injury. The following tips will assist you.

• READ ALL INSTUCTIONS.

• KEEP WORK AREA CLEAN AND WELL LIT.

• CONSIDER WORK AREA ENVIRONMENT. Electrical Pumps should never be used in an atmosphere which can be

considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact can cause sparks, precautions

should be taken.

• AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

• STAY CLEAR DURING OPERATION. In most cases, the tool will allow “hands free” operation. If the tool must be held or steadied

during operation, use alternative means of securing the tool to the application

• GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being used.

• STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

• USE RIGHT TOOL. Don’t force small tools or attachments to do the job of a larger tool. Don’t use a tool for purposes not intended.

• PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety shoes and other

applicable clothing.

• USE SAFETY GLASSES.

• MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of moving the equipment.

• MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual damage frequently and

always prior to use. Always follow instruction for proper tool and pump maintenance. Refer to the Operations Maintenance Section for

further clarification

• STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the influence of any mood altering

substances.

• PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

• PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to “ride up” or to “creep”, stop and re-adjust the reaction arm to a more solid and

secure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and reaction surfaces.

• ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are the correct size and

fully engage the nut. Hidden flaws, however, remain a possibility which could cause breakage, so stay clear of sockets during operation

• DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)

NOTE: Hytorc Pumps are designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

You might also like

- Yellow FeverDocument1 pageYellow FeverajithpakNo ratings yet

- KahnemanDocument11 pagesKahnemanMatt Pauls17% (18)

- Insert - PreciControl Anti-SARS-CoV-2 S.ms - 09289313190.v1.enDocument2 pagesInsert - PreciControl Anti-SARS-CoV-2 S.ms - 09289313190.v1.enLilik IndrawatiNo ratings yet

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiNo ratings yet

- XLCT 14Document2 pagesXLCT 14carlosNo ratings yet

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriqueNo ratings yet

- Tabla STEALTH 14Document2 pagesTabla STEALTH 14luz_cuellar_15No ratings yet

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikNo ratings yet

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoNo ratings yet

- 0,5 XLTDocument2 pages0,5 XLTFranciscoJSilvaNo ratings yet

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiNo ratings yet

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraNo ratings yet

- MXTP 01 Torque Conversion ChartDocument2 pagesMXTP 01 Torque Conversion ChartjavhirNo ratings yet

- Standard Torque Chart: Tool Model: MXT 1Document2 pagesStandard Torque Chart: Tool Model: MXT 1Wahyu WidiyantoNo ratings yet

- 1XLT TR2Document2 pages1XLT TR2FranciscoJSilvaNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilNo ratings yet

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86No ratings yet

- RTX04 Torque ChartDocument1 pageRTX04 Torque ChartYang Kyo OhNo ratings yet

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinNo ratings yet

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07No ratings yet

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirreNo ratings yet

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuiceNo ratings yet

- Sitio WebDocument15 pagesSitio WebRoberto RodriguezNo ratings yet

- HighTensileFastners PDFDocument24 pagesHighTensileFastners PDFMallika SahniNo ratings yet

- Polycab Price List 16th October 2021Document2 pagesPolycab Price List 16th October 2021Kushal DixitNo ratings yet

- Satuan GDocument1 pageSatuan GWoro IndrianiNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftNo ratings yet

- PH Hydraulic Torque Wrench Instruction ManualDocument23 pagesPH Hydraulic Torque Wrench Instruction ManualLikLiek WahahaNo ratings yet

- Partial Horizontal Tank Volumes: ParametersDocument4 pagesPartial Horizontal Tank Volumes: ParametersSagar DhuriNo ratings yet

- FLOWTITE Handling and StorageDocument13 pagesFLOWTITE Handling and StorageMohammed khaleelNo ratings yet

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzNo ratings yet

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Document7 pagesKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniNo ratings yet

- Indice IntraindustrialDocument17 pagesIndice IntraindustrialJuan Camilo ArboledaNo ratings yet

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyNo ratings yet

- catchment area to runoff yield 2 ١Document1 pagecatchment area to runoff yield 2 ١Ahmed NabilNo ratings yet

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaNo ratings yet

- Test 11Document3 pagesTest 11shinjuvijayNo ratings yet

- RR KABEL Price List - LT HT Cables - 01st February 2023Document4 pagesRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNo ratings yet

- Laboratory Exercise No. 5 Rheological PropertiesDocument16 pagesLaboratory Exercise No. 5 Rheological PropertiesANIME CHANNo ratings yet

- Measurements For Anchor-Chain and AccessoriesDocument4 pagesMeasurements For Anchor-Chain and AccessoriesOzata TersanesiNo ratings yet

- Phone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Document2 pagesPhone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Akhila kumarNo ratings yet

- MEIZON GUTU DDocument7 pagesMEIZON GUTU DlevisontawandaNo ratings yet

- Apy ChartDocument1 pageApy ChartTechnology GamerNo ratings yet

- Apy ChartDocument1 pageApy ChartPRANAV MUKTIBODHNo ratings yet

- Apy ChartDocument1 pageApy Chartvmcon kkl 2020No ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFSHUBHAJIT NANDINo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFPravrutti DahiwaleNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFavinash1987100% (1)

- Apy ChartDocument1 pageApy ChartUday GopalNo ratings yet

- Apy ChartDocument1 pageApy ChartMohit PathaniaNo ratings yet

- APY Chart PDFDocument1 pageAPY Chart PDFRahul TadeNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFchannel SNo ratings yet

- Apy ChartDocument1 pageApy ChartClassicaverNo ratings yet

- Apy ChartDocument1 pageApy Chartvinay chaudhariNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFAswin AbiNo ratings yet

- Apy ChartDocument1 pageApy Chartkrishna garaiNo ratings yet

- Apy ChartDocument1 pageApy ChartJai mishraNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Aqa Health and Social Care Coursework Examples GcseDocument5 pagesAqa Health and Social Care Coursework Examples Gcsekezevifohoh3100% (1)

- Hypertension and Congestive Heart FailureDocument4 pagesHypertension and Congestive Heart FailureDawn ReyaNo ratings yet

- Using The Psychopathy Checklist-Revised With Female Samples: Reliability, Validity, and Implications For Clinical UtilityDocument16 pagesUsing The Psychopathy Checklist-Revised With Female Samples: Reliability, Validity, and Implications For Clinical UtilityIsa Abu YahyaNo ratings yet

- Validation of The Lifft Risk Assessment Tool and Guidance On Its UseDocument10 pagesValidation of The Lifft Risk Assessment Tool and Guidance On Its UsehigormeNo ratings yet

- Safety Data Sheet Winsor & Newton Artist Acrylic Gloss Uv Varnish (Us MSDS)Document3 pagesSafety Data Sheet Winsor & Newton Artist Acrylic Gloss Uv Varnish (Us MSDS)zaryab khanNo ratings yet

- Abenezer PaperDocument31 pagesAbenezer Paperabayneh aberaNo ratings yet

- Parasite Images (Protozoan - Nematodes)Document15 pagesParasite Images (Protozoan - Nematodes)Kathleen BrazasNo ratings yet

- E1 Estanislao Towards The Development CASE NOTESDocument31 pagesE1 Estanislao Towards The Development CASE NOTESCarlo MagnoNo ratings yet

- Carter Procession Closure MapDocument1 pageCarter Procession Closure Mapcookiespiffey21No ratings yet

- Tax Case Compilation Ia To D 1Document19 pagesTax Case Compilation Ia To D 1Markonitchee Semper Fidelis100% (1)

- Theories and Models in Community Health NursingDocument26 pagesTheories and Models in Community Health NursingSabitha Jayakumar92% (12)

- Drug Name Mechanism of Action Indication/ Contraindication Adverse Effect Nursing ResponsibilitiesDocument1 pageDrug Name Mechanism of Action Indication/ Contraindication Adverse Effect Nursing ResponsibilitiesJohnrick VenturaNo ratings yet

- The Green Beauty GuideDocument290 pagesThe Green Beauty GuideVinot Nathan95% (19)

- Ve GL HirarcDocument34 pagesVe GL HirarcEncik AhmadNo ratings yet

- Chapter 2: Scientific Methods in PsychologyDocument111 pagesChapter 2: Scientific Methods in PsychologyZahid Khan BabaiNo ratings yet

- Orthognatic Surgery 2Document40 pagesOrthognatic Surgery 2ammarstein89No ratings yet

- Factors Influencing School Dropouts at T PDFDocument4 pagesFactors Influencing School Dropouts at T PDFArchana JadhavNo ratings yet

- Post Harvesting (Stages of Ripeness)Document3 pagesPost Harvesting (Stages of Ripeness)Mark Levi CannonNo ratings yet

- Discussion 4 EthicsDocument2 pagesDiscussion 4 Ethicspeter njovuNo ratings yet

- Reducing Test Anxiety and Improving Test Performance in America's SchoolsDocument8 pagesReducing Test Anxiety and Improving Test Performance in America's SchoolssanthigiNo ratings yet

- Worksheet #6-1Document4 pagesWorksheet #6-1Che InopiaNo ratings yet

- 19 - Suspended Scaffolding Construction Major Program Points 075Document12 pages19 - Suspended Scaffolding Construction Major Program Points 075BensonNo ratings yet

- Is Everything We Eat Associated With Cancer? A Systematic Cookbook ReviewDocument8 pagesIs Everything We Eat Associated With Cancer? A Systematic Cookbook ReviewRenan BragaNo ratings yet

- Bowel Incontinence ConstipationDocument3 pagesBowel Incontinence ConstipationMatty-b AskalaniNo ratings yet

- Locater UpdateDocument46 pagesLocater UpdatenovaaputryNo ratings yet

- HIRARC Healthcare Linen 01Document8 pagesHIRARC Healthcare Linen 01Don McleanNo ratings yet

- Hyperthyroidism in PregnancyDocument5 pagesHyperthyroidism in PregnancyOhazurike EphraimNo ratings yet