Professional Documents

Culture Documents

QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30

QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30

Uploaded by

ahmed fouadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30

QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30

Uploaded by

ahmed fouadCopyright:

Available Formats

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

6.4 TOXIC GAS

6.4.1 TheTLV for H2S is 10 ppm in air. This figure represents the maximum allowable

concentration for continuous exposure during an eight hours period. The maximum

allowable STEL is 15 ppm in air. The plant general alarm shall be initiated on detection

of gas concentrations at or above 10 ppm.

6.4.2 Hydrogen Sulphide is an extremely toxic gas and concentrations above 500 ppm are

potentially fatal. In order to provide an effective protection system to plant personnel in

case of toxic gas release, QP‟s philosophy is to initiate a general alarm on detection of

gas levels at or above 10 ppm. On hearing this alarm, plant personnel are required to

use the provided breathing apparatus and make their way to the designated muster

areas.

6.4.3 Wind socks shall be provided at such locations to ensure that all plant personnel who

may be at risk from exposure to toxic gas concentrations can readily identify the wind

direction and therefore evacuate the area by the most appropriate route, cross wind

whenever possible.

6.4.4 In general, toxic gas detectors distributed within the plant area is only to protect

personnel from getting exposed to toxic level of H2S and not to protect the equipment

or the assets; therefore, the execution actions for confirmed toxic gas detector in the

plant will initiates a general alarm and alarm in the control room with no shutdown

actions. However; some plants may require shutdown action from confirmed H2S e.g.

Sulphur Recovery Plant.

6.5 FIRE

6.5.1 The philosophy caters for only one major fire incident at a time on an operational site.

Fire can occur at any location from a variety of fuel sources. The protection philosophy

is rapid detection, elimination of the fuel sources and automatic or manual

extinguishing of the fire.

6.5.2 In evaluating potential risk to personnel and property, the characteristics of the

materials being handled, pressures and temperatures, as well as the types of

equipment being used, must be studied with regard to equipment spacing, proximity to

other process facilities, safe mechanical design and types and capacities of fire

prevention and fire protection equipment required.

6.5.3 Passive structural fire proofing, blast walls and thermal barriers to mitigate effects of

fire and explosion shall be utilised where necessary in accordance with approved

Codes and Standards.

6.5.4 Adequate fire fighting equipment and systems shall be provided, in accordance with

appropriate Codes and Standards, to enable quick and effective response to fires;

without exposing personnel to unacceptable levels of hazard.

6.6 SAFETY ANALYSIS/REVIEWS

6.6.1 A number of safety studies and reviews shall be undertaken in order to identify, qualify

and where necessary quantify the risks and establish that design and installed safety

systems provide adequate protection.

6.6.2 The safety studies shall consider single and simultaneous phases of operations such

as:-

a) Drilling and Production

b) Work-over and production

c) Wire-line operations and production

d) Partial shutdown and maintenance and production

Doc. File No.: PHL.S.001.R3 Page 15 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

6.6.3 The safety studies/reviews shall identify possible areas of equipment failure and

process upset and ensures that levels of protection are provided in accordance with

appropriate Codes and Standards. The safety studies/reviews place emphasis on the

consequences of change to operating variables; i.e. of high and low pressure,

temperatures, flow rates, level and leakage both between systems and into the

environment. The provision of protection systems to eliminate or minimise incidents

shall be studied to determine their adequacy.

6.6.4 Engineering shall undertake Hazops/ Safety studies/ reviews with representation from

Operations, Maintenance, and Engineering Loss Prevention Engineer.

6.6.5 The aim of the safety studies/reviews is to establish that an adequate level of safety is

achieved against the risk of fire or explosion and other design accident events.

6.6.6 Specific project fire and safety philosophy shall be detailed for each project.

6.6.7 For safety studies through out the project phases, refer to; Philosophy for Health and

Safety Activities In Projects (QP-PHL-S-038).

6.7 HAZARDOUS AREA CLASSIFICATION

6.7.1 The reasons for classifying the installation into hazardous areas are as follows:

a) To allow for appropriate material/ equipment selection.

b) To ensure that sources of ignition are segregated from potential sources of

flammable gas.

c) To assist in the location of clean air inlets (taken from non-hazardous area) for

ventilation systems or combustion equipment.

d) To assist in the location of flammable gas detectors.

6.7.2 The overall design philosophy should be to make the installation as safe as possible by

minimising the sources of release of flammable gas/liquid to the atmosphere.

6.7.3 The area classification will be in accordance with the IP Model Code of Safe Practice:

Part 15; latest edition.

6.7.4 The above Code involves classifying the various areas of the installation into zones

and grades the source of releases. Refer to IP 15 for definitions.

6.7.5 The extent of the hazardous zones is defined by the above mentioned code and is

dependent on the source of the hazard, the physical properties of the material released

and the ventilation of the area. These points are discussed below.

6.7.6 The various sources of release are determined from the PFD‟s and P&ID‟s and their

location on the installation from the equipment layout drawings. Continuous grades of

release giving rise to a Zone 0 area should be eliminated from installations.

6.7.7 The number of primary sources of hazard should be strictly limited. These are restricted

to continuous or frequent operations and to poorly ventilated areas where gas may

accumulate. The hazards of venting flammable gas must be appreciated and the vent

designed accordingly. The accumulation of pockets of gas should be eliminated by

efficient ventilation whether natural or mechanical.

6.7.8 Secondary sources of release occur infrequently and are typically caused by the failure

of a flanged joint or the infrequent venting of equipment to atmosphere. A fully welded

section of pipeline would not normally be considered to be a source of release. Further

items, which give rise to a secondary source of release, include filter covers and sphere

launcher doors, which are infrequently opened.

6.7.9 The extent of the hazardous area resulting from a source of release is governed by the

physical properties of the material. For most sources (except large vents) the distance

is defined in the IP Code.

Doc. File No.: PHL.S.001.R3 Page 16 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

6.7.10 A liquid will only give rise to a flammable vapour if it is at a temperature above its flash

point. Fluids with a flash point below 55°C or at a temperature above their flash point

are considered to be hazardous.

6.7.11 Sumps and pits shall be avoided or eleminated. If not possible then they shall be

classified for Zone 1.

6.7.12 Many items of equipment are potential sources of ignition. Electrical systems which

could produce a spark of sufficient energy to ignite the flammable gas must be

protected in accordance with recognised standards such as IEC 60079. Surface

temperatures of other equipment should be treated in the same way and may be

reduced by insulation or by cooling the contents of the system.

6.7.13 The temperature classification of electrical equipment shall be “T3” (IEC 60079),

corresponding to surface temperature not exceeding 200°C.

6.7.14 For exhausts and air intakes the following shall be obtained:

Sparks from the exhausts from combustion equipment may also provide a source

of ignition. These are caused by glowing particles of carbon and to eliminate this

problem, all exhausts are to be taken to the edge of a Non-Hazardous area and

extended into this Non-Hazardous area by minimum of three metres.

The air intakes for combustion engines, air compressors and the ventilation

systems shall be located in non-hazardous areas and as remote from the process

areas and other sources of gas release as practical.

The air exhausts from non-hazardous areas and combustion engines shall be

terminated in non-hazardous areas at a minimum of 4.5 m from the air intakes to

avoid cross flow between extract and intake. All combustion exhausts shall be

fitted with a spark arrestor

6.7.15 Other ignition sources may comprise fixed equipment such as fired heaters or mobile

equipment such as plant traffic.

6.7.16 Fired equipment shall be located in non-hazardous areas. Within a hazardous area, the

maximum external surface temperature of equipment and piping systems will be limited

to 200°C. Plant roads that are around the perimeter of plots will be in non-hazardous

areas and only authorised traffic will be allowed to enter the plant location.

6.7.17 Other potential sources of ignition which may be present in hazardous areas during

operations or maintenance, such as welding or gas cutting, will be controlled by the

permit to work system. The plant area will be a “no-smoking” zone, and will be noted

as such by work instructions and by safety signs.

6.7.18 Where non-hazardous areas are located within hazardous areas, airlocks or gas tight,

self-closing doors shall be provided as necessary together with sufficient mechanical

ventilation to achieve a minimum level of pressurisation of 50 Pa above the adjacent

hazardous area.

6.7.19 The HVAC system where provided to maintain pressure differential within the lower

hazard rated area should be capable of ensuring a continuous air flow from the lower

hazard rated area to the higher hazard area when doors are open. This may be

achieved by the provision of a standby system capable of maintaining the required

pressure differential.

6.7.20 Construction of enclosures required to be pressurised shall ensure low leakage of

pressurisation air; adequate pipe or cable seals and airtight construction are essential.

6.7.21 Access openings between hazardous and non-hazardous enclosures shall be avoided;

where this is not possible the opening shall be protected by an airlock or gas tight door.

Doc. File No.: PHL.S.001.R3 Page 17 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

6.7.22 Access openings into or between Zone 1 or Zone 2 hazardous areas shall be protected

by an appropriate airlock(s) or gas tight door(s). Three alternative situations are

possible:

(i) Zone 1 area opening into a Zone 2 area;

(ii) Zone 2 area opening into a non-hazardous area;

(iii) Zone I area opening into a non-hazardous area.

6.7.23 Preference shall be given to using an airlock for each of the three alternative situations

referred to above. However, when an airlock is not practicable, gas-tight self-closing

doors may be used for situations (i) and (ii).Situation (iii) should be fitted with a double

door airlock whenever possible, but if this is not practicable the HVAC system provided

to maintain pressure differential should be upgraded. from a single fan normally used

for arrangements (i) and (ii), to include two 100% duty fans, one running and one

standby. Controls should automatically start the standby fan on failure of the duty fan or

upon prolonged loss of pressure differential, when both would run simultaneously.

6.7.24 Where practicable doors shall be positioned so that they do not face a source of

hazard.

6.7.25 The area of lower hazard rating shall be maintained at a minimum pressure differential

of 50 Pa above that of the connected higher hazard rated area.

6.7.26 Loss of pressure differential shall initiate an audible/visual alarm at a normally manned

station after a delay period not exceeding 30 seconds.

6.7.27 Loss of pressure differential in a non-hazardous space coincident with the detection of

gas at any location, shall initiate automatic disconnection and de-energising of all

electrical equipment that is not certified for operation in a hazardous atmosphere.

6.7.28 All electric equipment located within an airlock shall be certified as suitable for use in a

hazardous area of equal or greater hazard rating than that external to the airlock.

6.7.29 Should pressurisation be lost, an alarm shall annunciate in the Control Rooms. If gas is

simultaneously detected on the platform then executive action (electrical isolation) shall

be taken.

6.7.30 Hinged doors for normal access between hazardous and non-hazardous areas shall

open into the non-hazardous area: emergency hinged doors shall open in the direction

of escape. The exception to this guidance is sliding doors when fitted.

6.7.31 By design, the following areas shall be defined as “non-hazardous” by location:

a) Control rooms

b) Living quarters / offices

c) UPS Switch room/instrumentation/electrical equipment rooms

d) Telecommunications equipment room

e) Fire pump rooms

f) Emergency power generation areas

6.7.32 Battery rooms (Special considerations shall apply owing to battery venting and possible

H2 generation). If mechanical pressurisation is adopted then the room should be

negatively pressurised with respect to adjoining non-hazardous areas but positively

pressurised with respect to the external environment.).

6.7.33 All outdoor field equipment that may be required to operate under emergency

conditions shall be suitable for use within a Zone 1 area. This equipment includes all

items from the following list :-

a) Emergency shutdown system

b) Fire and gas detection system

Doc. File No.: PHL.S.001.R3 Page 18 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

c) Fire protection system

d) Emergency Escape lighting

e) General alarm and emergency communication system(s).

6.7.35 All electrical equipment which are located in Hazaradous area shall be certified for

ATEX approval.

6.7.36 During the course of area classification, particular attention shall be given to the

following:-

a) Fuel lines in non-hazardous areas

b) Chemical storage

c) Battery storage

d) Isolated flanges on hydrocarbon lines

e) Ventilation and pressurisation

f) Active or partially active drilling mud systems

g) Open tanks and containers

h) Glands of pumps

i) Sample points

j) Process vents

6.7.37 Electrical equipment installed in a hazardous area shall be certified for use in the

appropriate zone classification and comply with the requirement of IEC 60079 .

6.7.38 For consistancy the equipment shall be certified with a minimum temperature

classification of T3 (200°C maximum surface temperature).

6.7.39 The electrical equipment shall be classified for use in the presence of appropriate

group gases.

6.7.40 Inherent non-sparking motors cannot be assumed to be safe for use within a

hazardous area, this also applies to equipment which operates at less than 3.3KV. In

the event that Ex „e‟, „n‟, or „p‟ classified equipment is utilised then safety precautions

shall be required prior to energising.

6.7.41 Any electrical field equipment that is required to operate under emergency conditions

shall be Ex‟d‟ rated as a minimum.

6.7.42 All mechanical equipment installed in hazardous areas shall be manufactured to

ensure that rotating parts are non sparking and adequately protected against the

generation of a static charge. Surface temperatures shall not exceed 200°C.

6.7.43 Should pressurisation be lost, an alarm shall annunciate in the Control Rooms. If gas is

simultaneously detected then executive action (electrical isolation) shall be taken.

6.7.44 In enclosed or semi-enclosed hazardous areas a minimum of 12 air changes per hour

shall be provided either from natural or mechanical ventilation. Special attention shall

be paid to void areas formed by overhead structural beams. In naturally ventilated or

sheltered areas additional mechanical ventilation may be necessary to achieve

adequate ventilation.

6.7.45 Hazardous area classification drawings showing the plan view and elevations shall be

prepared and include the following information:-

a) Identification of sources of release.

b) All ventilation inlets and outlets

c) Air intakes and exhausts of all internal combustion machinery

Doc. File No.: PHL.S.001.R3 Page 19 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

d) Location of all equipment units.

e) Points of air transfer from Modules which may affect classification, sealing gaps on

external module walls.

f) Tank or process vents

g) The classification and extent of all hazardous zones.

h) Ventilation type.

6.7.46 A hazardous area schedule shall be produced identifying as a minimum; the source of

emission, the process material its operating conditions and flash point, containment

category and fluid category, hazardous area boundary dimensions from source, source

of release grading and zone reference number.

6.8 PLANT LAYOUT

6.8.1 QP plants handle hydrocarbon vapours and liquids such as flammable and toxic gas,

NGL, LNG Crude oil etc., which if ignited following a release, have the potential to

cause a major fire or explosion. It is essential that the plant layout is configured to

minimise the possibility of an undesired event occurring. Careful attention to

equipment location improves the safety, accessibility and efficiency of a plant.

6.8.2 Land use planning for buildings and new equipments location selection shall be based

on the LSIR and the minimum separation distances mentioned in clause 6.8.18.

6.8.3 The first approach to layout is to grade each system according to the nature of the

hazard and then categorise the systems of similar grading as follows:

a) Systems which have the potential to emit flammable materials

b) Systems which may emit toxic gases

c) Systems which must be located in a Non-Hazardous area

d) Systems which are considered safe.

6.8.4 The layout of the plant or installation shall be developed to achieve the following safety

features:-

a) Maximum separation between flammable hydrocarbons and ignition sources.

b) Maximum separation between hydrocarbon and hazardous material handling areas

and emergency services, main safety equipment, accommodation areas and

means of escape.

c) Sufficient means of escape to enable efficient and protected evacuation from all

areas to designated muster and abandonment stations, under a hazard condition.

d) Maximum availability of essential services and the main safety equipment under all

foreseeable hazardous conditions.

e) Minimal risk to third parties.

f) Minimal risk of fire spread between plots, so that a fire or other emergency will be

contained in the plot of origin. This will also allow for the safe and effective isolation

of a unit from its operating neighbours when shut down for maintenance. Division

into plots will also optimise on the need for fire protection systems because the

possibility of fire spread is less.

g) Separation between hazardous and non-hazardous areas, for hazardous area

classification purposes and control of potential ignition sources.

h) Appropriate and safe access for construction, operations and maintenance.

i) Adequate access during emergency for means of escape, for emergency vehicles

and for fire fighting.

j) The location of roads that carry general traffic in non-hazardous areas, so that

vehicles are unlikely to ignite a potential hydrocarbon leak.

Doc. File No.: PHL.S.001.R3 Page 20 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

k) Fencing requirements and control of visitors.

6.8.5 Consideration shall be given to drainage from all areas taking into account the firewater

discharge rates that would be encountered.

6.8.6 Large vessels may contain high inventories of flammable material which pose a hazard

to the plant. Where possible, the capacity shall be minimised and the vessels

segregated from Non-Hazardous areas.

6.8.7 Consideration shall be given to the location and height of flares and cold vent stacks

which discharge flammable and toxic hydrocarbon materials and combustion products

to the atmosphere.

6.8.8 Arrangement of flares, vents, drains and exhausts shall be in accordance with QP

environmental standards.

6.8.9 The separation distances for offshore plant layout shall be determined on a case by

case basis and in accordance with the relevant Codes and Standards.

6.8.10 The installation shall be orientated as far as is practicable to ensure that:

a) Prevailing winds direct any fire, smoke and/or escaping hydrocarbon gas/vapour

clouds away from the installation generally and the accommodation/ temporary

refuge in particular;

b) Support vessels can operate adequately in an emergency;

c) Helicopter approach flight paths conform to the regulations and are free of

interference from cranes, flare tower, drilling derrick, and hazardous vents;

d) Stationing/mooring of supply boats, and the launching of survival crafts has the

lowest possible risk of collision with any part of the installations.

6.8.11 It is normal for an offshore installation to be designed to withstand extreme 100 year

environmental conditions such as wind, current and waves, air and sea temperature

extremes, seabed characteristics and marine growth.

6.8.12 The structure should be designed to withstand all foreseeable combinations of forces

arising from environmentally imposed forces, helicopter landing and take-off, erection,

alteration, dismantling and removal of secondary structure or equipment.

6.8.13 Any structures located in the wave/splash zone should be capable of withstanding the

forces imposed by wave impact.

6.8.14 The minimum jacket impact absorption criteria should be not less than 4 MJ.

6.8.15 Preference shall be given to the use of inherently corrosion resistant material. Any

material not inherently corrosion resistant or adequately protected be of sufficient mass

to allow for corrosion losses during the service life of the installation. Noting that a

Service life of 30 years is a quite normal requirement for both the structure and

topsides equipment.

6.8.16 The use of aluminium or aluminium alloys shall be restricted; particularly in hazardous

areas due to the possibility of generation of incentive sparks.

6.8.17 Where the use of aluminium is unavoidable, the material may be allowed following

approval from QP Materials and Loss Prevention engineers. Where zinc is used in

proximity to stainless steels there is a risk of metal embrittlement and in such cases

precautions must be taken to protect against the surface of the stainless steel from

contact with flaking or molten zinc.

Doc. File No.: PHL.S.001.R3 Page 21 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

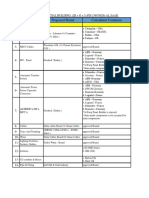

6.8.18 Onshore Plant Minimum Separation Distances

Factor Minimum Separation

(metres)

Between process equipment / piping systems and 7.5

edge of plant road.

Between process equipment / piping systems and 15.0

fired heater

Between process equipment/ piping systems and 100.0

control room (Note: Refer further to sections 8.10)

Between process equipment/ piping system and 250.0

normally manned utility buildings such as workshop,

office, laboratory and gate house. Note: Refer further

to sections 8.10.3)

Between process equipment/ piping system and 30.0

unmanned electrical utilities such as substations,

transformers.

Between process equipment /piping system and 30.0

boundary fence

Between two main process units on the same plot 20.0

Between air cooled heat exchangers and fired heaters 20.0

(to minimise the possibility of circulation of hot air).

Notes: Other than all welded pipe work (welded pipe will be reviewed in case by case

basis).

6.8.19 Separation distances for vents and flares need to be calculated, using internationally

accepted and validated methodology, when the vent and flare flow rates are known.

6.8.20 Separation distance from any bulk storage of hydrocarbon material shall be in

accordance with IP3 and IP19.

6.8.21 Separation distance from any open separator ponds (if there are any) needs to be

calculated.

6.8.22 Dedicated access ways within each plant unit will be provided for operations,

emergency escape and fire fighting. These access ways will run to the plant roads.

6.8.23 Roads and access ways will be arranged so as to avoid 'dead ends'. To allow for the

possibility of one road or access way being blocked e.g. by an accident, there will

generally be at least two separate routes to any location on the site.

6.8.24 The site will itself be accessed by a 'normal' and an 'emergency' road.

6.8.25 Roads will as far as practicable be located in non-hazardous areas so that vehicles are

unlikely to be a source of ignition.

6.8.26 The minimum width of roads will allow for access by plant vehicles such as cranes, and

emergency vehicles such as fire tenders. The width of major roads will allow two

vehicles to pass each other.

Doc. File No.: PHL.S.001.R3 Page 22 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

6.8.27 The minimum width of access ways and roads will be as follows:

Minimum width of access ways and roads width

a. Major roads around each plot 6.0 m

b. All other roads 4.0 m

c. Pedestrian access within plot limits 1.0 m

d. Stairways on tanks 750 mm

e. Pedestrian access receiving traffic from two or more routes 1.2 m

f. Maintenance access around individual items of equipment 1.0 m

6.8.28 The required headroom over the full width of roads will be 5.5 metres minimum to allow

the passage of emergency vehicles, cranes and other tall vehicles.

6.8.29 All areas of the plant, where emergency vehicles may require access, shall be provided

with roadways of six metres width. This is to permit two large vehicles to pass each

other in safety and to deploy to affected areas.

6.8.30 There will be two means of escape to safety from any normal working area of the site,

except for small platforms or rooms where the distance of a single means of escape is

less than five meter nominal.

6.8.31 Emergency entrances/exits will be located in perimeter fencing as needed to ensure

the minimum two routes to safety. Consideration will be given to the escape

requirements from any platforms on the process columns.

6.8.32 Escape routes will be directed away from possible hazards and will terminate at a

designated muster area that will be in a safe location by the site entrance.

6.8.33 Emergency escape lightning shall be provided with a proper signage.

6.8.34 Where practical, two or more means of escape from raised platforms shall be provided.

Interconnections between overhead platforms shall be provided where reasonable.

6.8.35 Escape route philosophy for buildings shall be in accordance with NFPA 101.Tank

bund walls shall be provided with steps cast into the walls at pre-determined intervals.

7.0 FIRE & GAS DETECTION SYSTEMS

7.1 The protection of personnel, the plant and the environment from the effects of toxic

gas, fire and explosion is prime objective to ensure that an acceptable level of safety is

achieved.

7.2 The basic requirements of the fire and gas detection systems are as follows:

Rapid detection of the undesired event; toxic or flammable gas release and fire

On confirmed detection, simultaneously:

Raise Alarm

Isolate the source of fuel/gas

Isolate sources of ignition

Exclude air where possible

Apply extinguishant where appropriate

Protect adjacent equipment to prevent escalation of the incident

Doc. File No.: PHL.S.001.R3 Page 23 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

7.3 ESSENTIAL FEATURES

7.3.1 All outdoor field equipment associated with fire and gas detection/control shall be

suitable for operation within a Zone 1 hazardous area and the environmental conditions

prevailing.

7.3.2 All components shall be accessible for maintenance and testing without disruption to

routine operation of the plant, interruption of overall protection monitoring or undue

degradation of the system (Including sensors, through logic and annunciation to

activation).

7.3.3 Upon detection of an alarm condition, suitable audible and visual alarms shall be initiated

at the Fire and Gas Panel.

7.3.4 Identify the type and location of the detection device activated at the main fire and gas

panel and at any other defined control point or repeater station.

7.3.5 Visual alarms at the alarm panel and any annunciation panels shall meet the approved

colour coding as identified below.

7.3.6 Minimum SIL requirement for F&G panel shall be SIL-2.

7.3.7 Typical loops of F&G system shall be assessed in the SIL study.

7.3.8 All F&G system shall be FM approved UL listed or equivalent.

7.3.9 Video display colours adopted in QP Status Display Systems

GRAPHIC ELEMENT ASSOCIATED COLOURS

Any Inhibit Brown

Any Fault White

Any Fire Alarm Red

Flammable Gas Symbol Magenta

High Alarm(1ooN) Alarm lists will be White Text on Magenta background

Flammable Gas Border turns Magenta.

High Alarm (2ooN) Alarm lists will be Black Text on Magenta background.

(Confirmed gas)

Flammable Gas symbol Orange.

Low Alarm (1ooN) Alarm lists will be white text on orange background.

Flammable gas Border turns orange.

Low alarm (2ooN) Alarm lists will be black text on orange background.

(Confirmed Gas)

Toxic gas alarm Yellow.

symbol(1ooN) Alarm lists will be white text on yellow background.

Toxic gas (2ooN) Border turns yellow.

Alarm lists will be black text on yellow background.

Detector Tag nos. Normal Light Grey

condition

System Status Area/Zone Green

identifiers

Symbols Normal condition Black

Graphic display Back cloth Black

General symbols Dark grey

Graphic titles, page No. Green text

System date and time Cyan text.

Doc. File No.: PHL.S.001.R3 Page 24 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

7.3.10 All information from sub-systems shall be available to the operator in the master CCR.

Any sub-system providing information at other plant locations shall be for indication only.

Thus while the master CCR maintains the control functions, slave information systems

on the same plant provide information only with no executive control features on

associated distributed plants (e.g. gas distribution system) with designated secondary

control centres, control facilities may be enabled either by cascade or password control.

7.3.11 The following essential aspects of Human Machine Interface (HMI) for control systems

shall be considered in design:

a) Construction and hierarchy of graphics

b) Definition and operation of major graphics

c) Adopted colour representations

d) Alarm processing and reporting

e) Matrix and Mimic panels including indications and controls

7.3.12 The system shall be self-monitoring to detect faults that may affect the operation of the

system. Detection of a fault shall register an appropriate signal at the alarm panel and

any annunciation panels or system displays.

7.3.13 Signals from the fire and gas detection system may be used to initiate operation of fire

fighting equipment or systems, and initiate plant shutdown and blowdown systems.

7.3.14 The alarm system shall be supplied power from the essential power supply and shall

include battery back-up with a dedicated battery charger. The back-up battery capacity

shall not be less than 60 minutes maximum load.

7.3.15 The fire and gas system shall be based on the provision of suitable field detector

devices, which alarm to the fire and gas control panel.

7.3.16 The fire and gas detection system shall be physically arranged so that a single failure in

it is unlikely to cause critical impairment of the system‟s safety function.

7.3.17 Cables to field detectors shall be fire resistant to IEC 60331.

7.3.18 Detection modes that are arranged to cause plant shutdown shall be generally on a two

out of N voting arrangement to reduce the possibility of spurious shutdowns; where N is

a minimum of three detectors.

A revealed fault condition shall be arranged to vote as an alarm condition; in the other

hand, it shall not cause tripping the plant. For example, one detector in fault mode and

another detector in confirmed mode shall trip the plant; but, two detectors in fault

condition shall not trip the plant.

Nevertheless, any one pneumatic detection system will each operate as a single loop.

7.3.19 Field detector types shall be selected on the basis of the following:

a) The type which gives the earliest detection of the event

b) Freedom from spurious operation

c) Suitability for the ambient environmental conditions

d) An optimum design and limitation of the number of detectors

e) Proven operation in similar situations

f) Inherent reliability

g) Low maintenance requirements

Doc. File No.: PHL.S.001.R3 Page 25 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

7.4 FLAMMABLE GAS DETECTION

7.4.1 All areas containing potential sources of gas emission shall be monitored for ambient

flammable gas.

7.4.2 Within process areas the gas detectors will be arranged so that detection is based on a

nominal five metre two-dimensional staggered matrix. This dimension is based on

consideration by QP that at least three detectors are within the detectable range of a gas

release within a plant area. Detailed detector locations will be based on relative

buoyancy of the gas or vapour to be detected. 3D model review to be used in order to

indentify leak sources and thereby deciding suitable distribution of gas detectors.

7.4.3 Gas detector selection (Depending upon the area being protected) shall be IR point / IR

Open path/ Ultrasonic gas detectors.

7.4.4 The detector alarm settings will be:

a) Point type :

20% LEL (low level alarm) and 50% LEL (high level alarm) of methane in air.

Areas where flammable gas has been excluded under normal operating

conditions; 10% LEL (low level alarm) and 20% LEL (high level alarm) of

methane in air.

HVAC intake for buildings in safe area; 10% (low level alarm) and 20% (high

level alarm).

Ventilation air intakes to gas turbine enclosures; 15% LEL (low level alarm)

and 25% LEL (high level alarm)

b) Beam type :

One LEL metre (low level alarm) and 2.5 LEL metres (high level alarm)

Note: Executive control action shall be taken on confirmed high level alarm.

7.5 TOXIC GAS DETECTION

7.5.1 On plants producing, treating or using hydrocarbons contain toxic gas, a fixed automatic

toxic gas detection system shall be provided. The system will monitor those parts of the

plant where a toxic gas (H2S) hazard may arise. On detection a general alarm shall be

raised and plant control room personnel automatically alerted to the existence and

location of the condition. Detector locations shall be determined by means of case by

case examination of the plant layout and may be placed either peripherally around the

plot, at suitable intervals or placed to cover areas with a leak potential, or both.

7.5.2 Activation of one detector at 10 ppm will raise an alarm. Further executive actions (if

needed) shall be detailed in the project specific philosophy and identified on the plant

cause and effect chart.

7.5.3 Within process areas the toxic gas detectors will be arranged so that detection is based

on a nominal 10 metre two-dimensional staggered matrix. This dimension is based on

consideration by QP that at least three detectors are within the detectable range of a gas

release within a plant area. Detailed detector locations will be based on relative

buoyancy of the gas or vapour to be detected. 3D model review to be used in order to

indentify leak sources and thereby deciding suitable distribution of gas detectors.

7.6 FIRE DETECTION

7.6.1 Fires within the hydrocarbon plants predominantly involve:

Leaking hydrocarbon material; from a failure of the process equipment; OR

Doc. File No.: PHL.S.001.R3 Page 26 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

Electrical and instrument equipment and cabling such as that contained in the switch

room or local equipment room: OR

Other combustible material such as paper, rag, lubricating oil and grease that may

be contained in a workshop or materials store.

7.6.2 Detector types shall be selected to detect the predominant characteristics of the fire

behaviour, and shall be provided in sufficient numbers and suitably located to provide

effective monitoring.

7.6.3 Due consideration shall be given to the specification and design of fire detection systems

to minimise the incidence of false or spurious alarms.

7.6.4 Fire detector selection shall be from the following types (Depending upon the area being

protected):

a) Smoke detection - Ionisation, Optical and Air sampling (HSSD)

b) Heat detection - Pneumatic (frangible bulb / fusible plug / fusible tube)

Electrical (rate of rise / rate compensated / fixed temp).

c) Flame detection - IR.

7.6.5 Linear Heat Detector Cable for fire detection in the cable trenches and cable cellars shall

be provided

7.7 SMOKE DETECTION

7.7.1 Smoke detectors sense combustion products and should be used within enclosed

spaces that are not subject to extremes of temperature, humidity, dust or wind.

7.7.2 Detection is achieved in the smouldering stage before flames and high temperature

occurs. Areas of selection include accommodation, ceiling void spaces, auxiliary and

switch gear rooms with false floors and ceilings, where high density of electrical cables

are installed.

7.7.3 Where detection is required in false floors and ceilings, remote indicating lamps shall be

provided.

7.7.4 Detection in areas of electrical risk, where historically gaseous fire protection systems

have been employed, and detection in not normally manned buildings on remote not

normally manned plants shall be by HSSD which is likely to give an alarm of a fire at an

early stage.

7.7.5 Consideration should also be given to using HSSD systems in not normally manned

buildings on manned plants; where the risk and consequential loss deems it appropriate.

7.7.6 Point type, optical smoke detectors may only be used in accommodation type risk areas

where there is minimal air movement.

7.7.7 Point type, ionisation smoke detectors may be installed, if the Authority having

jurisdiction, permits their use in any appropriate enclosed space that does not require to

be provided with an HSSD system.

7.8 HEAT AND FLAME DETECTION

7.8.1 Heat detection shall be used when it is not practical to utilise smoke detection i.e. high

temperature, high humidity, dust etc.

7.8.2 In areas protected by sprinkler or deluge system fusible plugs or frangible quartzoid will

generally be chosen for heat detection/activation with the system being designed in

accordance with NFPA Code 13 for sprinkler system and NFPA 15 for deluge system. In

Doc. File No.: PHL.S.001.R3 Page 27 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

certain areas protected such as floating tank roofs, plastic tube may be considered as an

option.

7.8.3 In open areas, such as process area, fires may show heat radiation and flames.

Therefore appropriate detector types shall be selected using a case by case examination

of the plant equipment and plant layout. This will be detailed in the specific plant project.

3D model review to be used for location of flame detectors in order to identify possible

obstruction and to ensure clear line of sight.

Note: Operating efficiency of the detection system shall remain at a maximum at all

times. Prevailing environmental conditions shall be taken into account in establishing the

locations of detectors with attention paid to detrimental vibration effects and moist salt-

laden air. The detectors shall be protected against accidental damage or tampering

where necessary.

7.9 MANUAL ALARM CALL POINTS

7.9.1 Onshore plants shall be provided with a manual alarm call point system throughout the

plant area. At the entry/exit points to buildings and along escape routes such that the

distance from any part of the process or utilities plant areas to the nearest call point shall

not exceed 30 metres.

7.9.2 Offshore plants shall be provided with a manual emergency alarm call point system

throughout the plant area and at the entry/exit points, at bridge access points and

stairways.

7.9.3 Call points shall be double action type e.g. lift flap “break-glass”.

7.9.4 Manual alarm call points shall activate audible and visual alarms on the central and local

fire and gas panels, start the firewater pumps and operate the general plant alarm and

plant status lights.

7.10 PRE-DISCHARGE AUDIBLE ALARMS

Enclosed areas protected by fixed gaseous fire protection shall be provided with a pre-

discharge alarm within the protected space, operating in conjunction with the status light.

This is to warn personnel of the imminent discharge of gaseous extinguishant into the

area. Duration of the alarm shall be 30 seconds.

7.11 EXECUTIVE ACTION

7.11.1 Executive action of the fire and gas systems shall be determined on a case by case

basis and shall be detailed in the cause and effect of the specific plant project.

However, in general, the executive action philosophy is as outlined below.

7.11.2 The fire and gas detection system shall automatically initiate executive actions as

follows:

a) FIRE DETECTED

Air sampling type high sensitivity smoke detection

Fire detected (level 1) ALERT 1

Alarm to Control Room

Initiate local panel alarm

Fire detected (level 2) ALERT 2

Alarm to Control Room

Initiate local panel alarm

Doc. File No.: PHL.S.001.R3 Page 28 of 82 Custodian Dept.: ST

QP PHILOSOPHY FOR FIRE AND SAFETY

DOC. No. QP-PHL-S-001 Rev. 3

Initiate plant general alarm

Fire detected (level 3) FIRE 1

Alarm to Control Room

Initiate local fire panel alarm

Initiate plant general alarm

Fire pump start ( where applicable)

Alarm to fire station /security office

Fire detected (level 4) FIRE 2

Alarm to Control Room

Initiate local fire panel alarm

Initiate plant general alarm

Fire pump start ( where applicable)

Alarm to fire station /security office

Shutdown ventilation

Close fire dampers

Isolate power feeder supply to affected area.

Operation of a single point type smoke detector:

Because of the sensitivity of point type smoke detectors and the potential for false

alarms, activation of a single detector shall

Alarm to Control Room

Start fire pumps

Initiate local alarm

Operation of two point type smoke detectors.

Alarm to Control Room

Start fire pumps

Initiate local alarm

Initiate plant General Alarm

Isolate power feeder supply to affected area

Shutdown ventilation system to affected area

Close fire dampers if provided

Release fixed extinguishing system (if provided)

Operation of a single flame detector or electrical heat detector:

Alarm to Control Room

Initiate plant General Alarm

Start duty firewater pump

Operation of two flame or two electrical heat detectors:

Alarm to Control Room

Initiate plant general alarm

Shutdown ventilation system

Close fire dampers (if provided)

Isolate power feeder supply to affected area.

Start fire pumps

Initiate the shutdown and blowdown systems

Release fixed extinguishing system

Doc. File No.: PHL.S.001.R3 Page 29 of 82 Custodian Dept.: ST

You might also like

- Victorian Case Study SolutionDocument3 pagesVictorian Case Study Solutionfaraz ahmad khan100% (2)

- Poster2 Arrhythmia Recognition eDocument1 pagePoster2 Arrhythmia Recognition eItharshan IndreswaranNo ratings yet

- QP 2170at 1 Fire Services FF FaDocument25 pagesQP 2170at 1 Fire Services FF Faahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 1-15Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 1-15ahmed fouadNo ratings yet

- Avoiding Explosions by Means of Inerting SystemsDocument14 pagesAvoiding Explosions by Means of Inerting SystemsRicky Menon100% (1)

- ANalyzer Shelter Tool Box TalkDocument1 pageANalyzer Shelter Tool Box TalkhomesxxxNo ratings yet

- PTS 20185Document48 pagesPTS 20185ronelbarafaeldiegoNo ratings yet

- Mole Concept-Jee (Main+advanced)Document61 pagesMole Concept-Jee (Main+advanced)Resonance Dlpd87% (173)

- The Criteria To Be Applied in The Process and Other Facilities Design AreDocument5 pagesThe Criteria To Be Applied in The Process and Other Facilities Design AreMohamed KamelNo ratings yet

- Confined Spaces ProcedureDocument10 pagesConfined Spaces Procedurezam110No ratings yet

- Wet BenchDocument29 pagesWet BenchAnurag KiroriwalNo ratings yet

- Fume Hood Manual Final 20150909Document33 pagesFume Hood Manual Final 20150909hazc5666No ratings yet

- Toxic and Flammable Gases in Research LabDocument7 pagesToxic and Flammable Gases in Research LabjeyalaljNo ratings yet

- IZOMBE Fire and Gas Assessment Study Report - FinalDocument26 pagesIZOMBE Fire and Gas Assessment Study Report - FinalLawrence Osuvwe OfuokuNo ratings yet

- RDM - Fume Hood Maintenance 10-25-10Document5 pagesRDM - Fume Hood Maintenance 10-25-10Ahlehadith Youth Force AttockNo ratings yet

- Understanding NFPA654 2006editionDocument2 pagesUnderstanding NFPA654 2006editionLady FonsecaNo ratings yet

- Specification FireDocument13 pagesSpecification Firedumbledoreaaaa100% (1)

- Oxygen & Nitrogen Gas Lines: Page 1 of 4Document4 pagesOxygen & Nitrogen Gas Lines: Page 1 of 4qamar sayedNo ratings yet

- Oisd RP 233Document66 pagesOisd RP 233Arunashish MazumdarNo ratings yet

- HSELeak DetectionDocument44 pagesHSELeak Detectionwlmostia100% (1)

- Safety in Petroleum IndustryDocument5 pagesSafety in Petroleum Industrymahendra patelNo ratings yet

- Imo Circulara 776 - Guidelines For The Approval of Equivalent Fixed GasDocument18 pagesImo Circulara 776 - Guidelines For The Approval of Equivalent Fixed GasradugorjNo ratings yet

- Annex A: Mable Limit (LFL)Document1 pageAnnex A: Mable Limit (LFL)Najam24No ratings yet

- Gas DetectorDocument16 pagesGas Detectoramirhosseine00100% (1)

- Assignment 01 GRANADADocument3 pagesAssignment 01 GRANADAJomar Tabios GRANADANo ratings yet

- Hazards 28 Paper 36Document8 pagesHazards 28 Paper 36민도연No ratings yet

- Protocol For Use and Maintenance of Oxygen Monitoring DevicesDocument16 pagesProtocol For Use and Maintenance of Oxygen Monitoring Devicespraveen.fahdcontractingNo ratings yet

- Chemicalfumehoods VUDocument8 pagesChemicalfumehoods VUZuhair MasedNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 31-45Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 31-45ahmed fouadNo ratings yet

- AramcoStandard PDFDocument39 pagesAramcoStandard PDFAbdul Hameed OmarNo ratings yet

- understandingNFPA654 2006 EditionDocument2 pagesunderstandingNFPA654 2006 EditionCarlos JiménezNo ratings yet

- Fire & Gas Detection and Alarm SystemsDocument17 pagesFire & Gas Detection and Alarm Systemseliud03100% (1)

- Estellito - Area ClassificationDocument7 pagesEstellito - Area ClassificationRoadieNo ratings yet

- Unit Test 2 P-7 H & E Legislation 23114Document11 pagesUnit Test 2 P-7 H & E Legislation 23114pankajsharma130No ratings yet

- Explain The Important Design Requirements For A CO Total Flooding SystemDocument5 pagesExplain The Important Design Requirements For A CO Total Flooding SystemAdarshGuptaNo ratings yet

- IMO Circular848Document5 pagesIMO Circular848nastyn176No ratings yet

- Local Exhaust VentilationDocument25 pagesLocal Exhaust Ventilationfariyashoeb100% (1)

- Safety Concept EginaDocument34 pagesSafety Concept EginaEmamokeNo ratings yet

- Safe Practices For Welding Inspectors: 8/16/2018 AWS-CWI Seminar 1Document30 pagesSafe Practices For Welding Inspectors: 8/16/2018 AWS-CWI Seminar 1Ahmed Shaban KotbNo ratings yet

- Lab VentilationDocument22 pagesLab VentilationSameer UddinNo ratings yet

- Process STD 601Document13 pagesProcess STD 601madx44100% (1)

- 2013 Ahmad Etal A Risk-Based Method For Determining Passive Fire Protection Adequacy. Fire Safety Journal 58 Pp. 160-169-LibreDocument10 pages2013 Ahmad Etal A Risk-Based Method For Determining Passive Fire Protection Adequacy. Fire Safety Journal 58 Pp. 160-169-LibrelambtranNo ratings yet

- Is 5572 - Hazardous ClassificationDocument2 pagesIs 5572 - Hazardous ClassificationMathavaraj DharmarajNo ratings yet

- 2015-Ashrae-Handbook-Hvac-Applications - LABROTARIES-8 - 06-11-2022Document1 page2015-Ashrae-Handbook-Hvac-Applications - LABROTARIES-8 - 06-11-2022eng.abdullrahmanNo ratings yet

- Anesthetic GasDocument3 pagesAnesthetic GasJuan PáezNo ratings yet

- Construction and Alteration Fire Safety Procedure HSE-FLP-P005Document12 pagesConstruction and Alteration Fire Safety Procedure HSE-FLP-P005Em NiaxNo ratings yet

- 15915s01 Fume Hoods LC-PPDDocument8 pages15915s01 Fume Hoods LC-PPDKhyle Laurenz DuroNo ratings yet

- FlareDocument10 pagesFlareAgus SuriptoNo ratings yet

- Ventilation: Outdoor LocationsDocument1 pageVentilation: Outdoor LocationsmeeNo ratings yet

- Cold Venting As API 521 To Discharge HCDocument4 pagesCold Venting As API 521 To Discharge HCkenoly123100% (1)

- Precautions For Flammable Liquids: Flash PointDocument4 pagesPrecautions For Flammable Liquids: Flash PointssdxyjNo ratings yet

- Steel Industry Gas SafetyDocument3 pagesSteel Industry Gas SafetyJaeman ParkNo ratings yet

- Ni 2914Document9 pagesNi 2914nandafontenelleNo ratings yet

- Revised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDocument18 pagesRevised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDanial Haidhar YusoffNo ratings yet

- Hydrogen HazopDocument19 pagesHydrogen HazopAdhi Sudrajat50% (2)

- Safety For Magnetic Particle Flaw DetectionDocument2 pagesSafety For Magnetic Particle Flaw DetectionHares SlalNo ratings yet

- Design of Fire and Gas Detection SystemDocument10 pagesDesign of Fire and Gas Detection SystemhenriqueNo ratings yet

- Spe 101422 MS P PDFDocument5 pagesSpe 101422 MS P PDFmsmsoft90No ratings yet

- Examples of OP in Certain Industries (Enregistré Automatiquement)Document6 pagesExamples of OP in Certain Industries (Enregistré Automatiquement)Frank BillNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- The Risks of Nuclear Energy Technology: Safety Concepts of Light Water ReactorsFrom EverandThe Risks of Nuclear Energy Technology: Safety Concepts of Light Water ReactorsNo ratings yet

- Use of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsFrom EverandUse of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsNo ratings yet

- QP 2165at 1 AcmvDocument44 pagesQP 2165at 1 Acmvahmed fouadNo ratings yet

- 2275AT 1 IrrigationDocument13 pages2275AT 1 Irrigationahmed fouadNo ratings yet

- QP 2155at 1 PlumbingDocument22 pagesQP 2155at 1 Plumbingahmed fouadNo ratings yet

- QP 2145AT 1 SewerDocument11 pagesQP 2145AT 1 Sewerahmed fouadNo ratings yet

- QP 2150AT 1 DrainageDocument7 pagesQP 2150AT 1 Drainageahmed fouadNo ratings yet

- 2250at 1 HelicopterDocument10 pages2250at 1 Helicopterahmed fouadNo ratings yet

- 2265at 1 External WorksDocument30 pages2265at 1 External Worksahmed fouadNo ratings yet

- 2255at 1 Special RoofDocument16 pages2255at 1 Special Roofahmed fouadNo ratings yet

- 2240at 1 External Duct Qtel ElvDocument5 pages2240at 1 External Duct Qtel Elvahmed fouadNo ratings yet

- Al-Othman Design Criteria-Rev2Document13 pagesAl-Othman Design Criteria-Rev2ahmed fouadNo ratings yet

- SECTION 16721 Fire Alarm SystemDocument8 pagesSECTION 16721 Fire Alarm Systemahmed fouadNo ratings yet

- Design CRITERIA Report SAUDDocument13 pagesDesign CRITERIA Report SAUDahmed fouadNo ratings yet

- Fire Alarm Control Panal 1 & 2 Loop BrochureDocument1 pageFire Alarm Control Panal 1 & 2 Loop Brochureahmed fouadNo ratings yet

- Battery Room Ventilation Fan - Electric..Document3 pagesBattery Room Ventilation Fan - Electric..ahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 46-60Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 46-60ahmed fouadNo ratings yet

- Vendor List 02dec2021Document3 pagesVendor List 02dec2021ahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013Document23 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013ahmed fouadNo ratings yet

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 31-45Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 31-45ahmed fouadNo ratings yet

- Pathophysiology HLH 5900-Syllabus College of Health Professions Fall 2020Document14 pagesPathophysiology HLH 5900-Syllabus College of Health Professions Fall 2020Lisa100% (1)

- SAP EAM-PM - Maintenance & Operations - Main ProcessDocument2 pagesSAP EAM-PM - Maintenance & Operations - Main Processleoaug100% (1)

- Rule: Air Carrier Certification and Operations: Portable Oxygen Concentrator Devices Onboard Aircraft Use of Additional DevicesDocument4 pagesRule: Air Carrier Certification and Operations: Portable Oxygen Concentrator Devices Onboard Aircraft Use of Additional DevicesJustia.com100% (1)

- Guidelines For Human Settlement Planning and Design Redbook V2Document379 pagesGuidelines For Human Settlement Planning and Design Redbook V2Mark JacobsNo ratings yet

- 2009 Connecticut State Employee W2 SummaryDocument2,161 pages2009 Connecticut State Employee W2 SummaryRepublican-American100% (1)

- NB, NBG, TP, TPD: Installation and Operating InstructionsDocument16 pagesNB, NBG, TP, TPD: Installation and Operating Instructionshvacr061No ratings yet

- The Boy Scouts' First Camp Fire: by Herbert CarterDocument109 pagesThe Boy Scouts' First Camp Fire: by Herbert CarterGutenberg.orgNo ratings yet

- NEMA-WC 74 - ICEA S-93-639 5-46kV Shielded Power CableDocument97 pagesNEMA-WC 74 - ICEA S-93-639 5-46kV Shielded Power CableTrầnHữuHòaNo ratings yet

- Basics of Voice CultureDocument3 pagesBasics of Voice CultureNehaDesaiNo ratings yet

- CV Abdul HafeezDocument7 pagesCV Abdul HafeezAbdul Hafeez KandhroNo ratings yet

- 2020-07-16 St. Mary's County TimesDocument32 pages2020-07-16 St. Mary's County TimesSouthern Maryland OnlineNo ratings yet

- Role of Microorganisms in Petroleum IndustryDocument4 pagesRole of Microorganisms in Petroleum Industrysidraali786137No ratings yet

- Criminal Liability Lecture Notes: General Defences To Criminal LiabilityDocument24 pagesCriminal Liability Lecture Notes: General Defences To Criminal LiabilityAtamba Black100% (1)

- Summary of MovsDocument8 pagesSummary of MovsAllanSalardaAdemNo ratings yet

- Science PT Poster q2 ClerigoDocument5 pagesScience PT Poster q2 ClerigoErich Benedict ClerigoNo ratings yet

- Guide Falsework AustraliaDocument4 pagesGuide Falsework AustraliaHafizah MohdNo ratings yet

- HUDSON THREE Dessert MenuDocument6 pagesHUDSON THREE Dessert MenuDaniel LagstromNo ratings yet

- ShivSutras by H.H. Sri Sri Ravishankarji - 7 Video Sessions CoveredDocument18 pagesShivSutras by H.H. Sri Sri Ravishankarji - 7 Video Sessions Coveredorchidocean5627No ratings yet

- HEALTH 9 QUARTER2 MODULE3 WeeK5-6Document9 pagesHEALTH 9 QUARTER2 MODULE3 WeeK5-6Heidee Basas100% (3)

- Singer BangladeshDocument16 pagesSinger BangladeshMahbubur RahmanNo ratings yet

- Japan - Seaflo Neo CF PremiumDocument2 pagesJapan - Seaflo Neo CF PremiumMinh Khoa TrịnhNo ratings yet

- Blood Clinical CorellaionsDocument12 pagesBlood Clinical Corellaionssinte beyuNo ratings yet

- KGSSDocument20 pagesKGSSSrinivasan RajenderanNo ratings yet

- ZRZT 55-90 (VSD) (FF)Document25 pagesZRZT 55-90 (VSD) (FF)Erick GuzmanNo ratings yet

- 181-CEN Fire Safety in Buildings - CEN TC 127Document4 pages181-CEN Fire Safety in Buildings - CEN TC 127Perie Anugraha Wiguna100% (1)

- Anaesthesia Workstation 4Document120 pagesAnaesthesia Workstation 4john georgeNo ratings yet

- Submitted JTOIDocument10 pagesSubmitted JTOIFAHIRA RAHMA NATHANIANo ratings yet