Professional Documents

Culture Documents

Compact Cyclone Multiphase Meter (CCM) : Phase Dynamics

Compact Cyclone Multiphase Meter (CCM) : Phase Dynamics

Uploaded by

Jose MarquezCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lab 4 (Flowmeter Demonstration)Document24 pagesLab 4 (Flowmeter Demonstration)bae72% (18)

- Warman 14x12 AHDocument1 pageWarman 14x12 AHGabriel MarinoNo ratings yet

- In Normal Operation Two Pumps Are in Operation With The Third One On Standby, Which Will Start in Case Any One of The TwoDocument4 pagesIn Normal Operation Two Pumps Are in Operation With The Third One On Standby, Which Will Start in Case Any One of The TwoRajeshSahuNo ratings yet

- Tercera Asignación Control de Procesos 2021 - IIDocument7 pagesTercera Asignación Control de Procesos 2021 - IIBrayanNo ratings yet

- Lecture 22012Document28 pagesLecture 22012John Kevin NocheNo ratings yet

- Double Suction Centrifugal PumpDocument8 pagesDouble Suction Centrifugal PumpBilal WaseemNo ratings yet

- 26-Reservoir Engineering Self-TestDocument9 pages26-Reservoir Engineering Self-TestThắng NguyễnNo ratings yet

- FM FPMDocument25 pagesFM FPMBhawani Pratap Singh PanwarNo ratings yet

- CatDocument7 pagesCathamda100% (1)

- CFD in Launch Vehicle ApplicationsDocument6 pagesCFD in Launch Vehicle ApplicationsaeroalanNo ratings yet

- Kappa Dda Book 5.30.01Document852 pagesKappa Dda Book 5.30.01LAURA CATALINA CARDENAS RODRIGUEZ0% (1)

- Topic T1: Mass, Momentum and Energy AUTUMN 2013Document32 pagesTopic T1: Mass, Momentum and Energy AUTUMN 2013Aziful AiemanNo ratings yet

- Manush Kumar - Fluid Mechanics and Hydraulic Machines (2019, Pearson Education) PDFDocument993 pagesManush Kumar - Fluid Mechanics and Hydraulic Machines (2019, Pearson Education) PDFYumilka Alarcon100% (1)

- Annubar Transmissor de Vazão PrincípioDocument8 pagesAnnubar Transmissor de Vazão PrincípioDouglas HenriqueNo ratings yet

- The Burke-Schumann Spray Diffusion Flame in A PDFDocument12 pagesThe Burke-Schumann Spray Diffusion Flame in A PDFricljrNo ratings yet

- EntryLevel1-Hydraulic-English AssessmentAndAnswer SheetDocument30 pagesEntryLevel1-Hydraulic-English AssessmentAndAnswer SheetTrevor BurnettNo ratings yet

- A New Automotive Air Conditioning System Simulation Tool Developed in MATLAB/SimulinkDocument15 pagesA New Automotive Air Conditioning System Simulation Tool Developed in MATLAB/SimulinkPrashant IngaleNo ratings yet

- Gas-Liquid: Two-Phase ConvectionDocument8 pagesGas-Liquid: Two-Phase ConvectionForcus onNo ratings yet

- An Experimental Study of Air-Entraining VorticesDocument22 pagesAn Experimental Study of Air-Entraining VorticesBharath kumarNo ratings yet

- FADZXcv SXDocument1 pageFADZXcv SXMohamed SelimNo ratings yet

- Solver Settings and Output File: 16.0 ReleaseDocument42 pagesSolver Settings and Output File: 16.0 ReleaseFilip StojkovskiNo ratings yet

- Single and Double Volute Casing - RodeltaDocument3 pagesSingle and Double Volute Casing - Rodeltamasood_me60No ratings yet

- D155AX-5 Chapter 6 Hydraulic Fan CircuitDocument12 pagesD155AX-5 Chapter 6 Hydraulic Fan Circuithaimay118No ratings yet

- Control ValveDocument12 pagesControl ValvenerioalfonsoNo ratings yet

- Serv1852 TXT6Document38 pagesServ1852 TXT6Noel Olvera100% (2)

- មេរៀនChapter3Document10 pagesមេរៀនChapter3Yves JuniorNo ratings yet

- B.tech 4th Sem CE Final 2Document15 pagesB.tech 4th Sem CE Final 2Medalson RonghangNo ratings yet

- Tutorials Report Computational Fluid Dynamics - CH5101: Tutorial 1: - Problem Statement - Fluid Flow in A 2D PipeDocument3 pagesTutorials Report Computational Fluid Dynamics - CH5101: Tutorial 1: - Problem Statement - Fluid Flow in A 2D PipeDavis ArkelNo ratings yet

- CH 8 PDFDocument61 pagesCH 8 PDFGaurav Kumar100% (1)

- Module 3 Aircraft Propulsion NotesDocument30 pagesModule 3 Aircraft Propulsion NotesPratham M JariwalaNo ratings yet

Compact Cyclone Multiphase Meter (CCM) : Phase Dynamics

Compact Cyclone Multiphase Meter (CCM) : Phase Dynamics

Uploaded by

Jose MarquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compact Cyclone Multiphase Meter (CCM) : Phase Dynamics

Compact Cyclone Multiphase Meter (CCM) : Phase Dynamics

Uploaded by

Jose MarquezCopyright:

Available Formats

Phase Dynamics, Inc.

1251 Columbia Drive

Phase Dynamics Richardson, TX 75081 USA

E-Mail sales@phasedynamics.com

Technology for Precision Measurements Tel: 972-680-1550

Fax: 972-680-3262

Compact Cyclone Multiphase Meter (CCM)

• Compact And Simple to Repair

by Local Personnel

• 2 Phase Separation Assures

Measurement Quality

• Unique Swirl Elements Assure

Separation & Control of Slugging

Conditions

• Highest Quality Components Fisher

Valves/Actuators & MicroMotion

Coriolis

• Control and Measurement Electronics

in One Package

• Fast Well Testing Typically

4 Hours per Well or Less

• Turn Down Is Primarily Line Size

& Instrumentation Dependent

The system is a modern version of display well test results. There are no after the control valves.

a traditional 2 phase separator. extra transmitters, PLC’s or PC’s The separated liquid is routed

Standard industry methods for water required. The CCM can be used as a through a full-range microwave water

cut and gas/liquid flow measurement stand-alone system using the local cut analyzer forming an integral part of

are used. operator interface, control and display, the CCM. There are no issues with

Well testing can be done quickly or remotely using the digital interface salinity affecting the measurement

and accurately. This is due to the via Modbus. because of Phase Dynamics’ ability to

small liquid volume and short time The first stage of gas liquid properly handle salinity based on the

required to establish equilibrium. separation has a swirl element to measurement physics.

Finite element analysis of well create tangential velocity for Coriolis flow meters for the gas and

conditions and fluid parameters is separation. This creates a force of liquid measurement are used for mass

performed to optimize the CCM’s more than 50 g’s on the 3 phase flow. flow and density. Observing the

design. This provides assurance of Unlike other systems, which use a density allows determination of the

the product’s operational envelope at simple nozzle to impart the tangential quality of the overall performance of

delivery. velocity. the system. The user then knows that

An integrated control system has The second stage completes the the measurement uncertainty is

been designed by Phase Dynamics to separation of liquids from the gas by minimized.

simplify and improve performance for using additional swirl elements. This The CCM system has been

maximum system reliability. Simple provides for very dry outlet gas. The accepted for fiscal well testing in

operator commands start, stop and gas is then recombined with the liquid Alaska.

© Phase Dynamics, Inc.

CCM Literature 0105

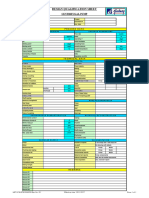

TECHNICAL SPECIFICATIONS - COMPACT CYCLONE MULTIPHASE METER (CCM)

The CCM meter is an engineered product to the specific customer requirements. The following is a general

description of the system specifications.

General

Inlet & Outlet Pipe dimensions 2 – 6 inch Available

Materials 316L Stainless steel typical, skid is painted black iron

Wetted parts 316L Stainless steel, restricted to instrument specifications

Pressure range 0 to 100 bar

o

Flowing Temperature range 0 to +100 C Standard – other Temperatures available

o

Instrument Temperature 0 to +55 C ambient

Installation Skid mounted in horizontal or vertical pipe

Power supply 120 VAC, 230 VAC 50/60 Hz or 24 VDC

Power consumption Approximately 160 Watts

Pressure drop Typically 1 bar (15 psi), depends on flow rates

Weight and size Dependent on design flow rates

Performance

Measuring range

Water Cut 0 to 100%

GVF at operating conditions 0 to 100% GVF: Gas Void Fraction

The configuration of flow meters and instruments to be

Liquid and gas flow rates

designed according to the actual flow rates and specifications

All, but for some special conditions, such as severe slugging

Flow regimes

flow, contact manufacturer

Individual flow meters

Gas flow meter Coriolis

Liquid flow meter Coriolis

Water Cut Analyzer Phase Dynamics Inc. Microwave Water Cut Analyzer

Typical overall uncertainties

Liquid flow rate Relative uncertainty of +/- 5 %

Gas flow rate Relative uncertainty of +/- 5 %

Water Cut Absolute uncertainty of +/- 3 to 5 %, depending on application

Signal Interfaces

Inputs

Digital ModBus RTU

Outputs

Digital Total Oil, Water & Gas, Water Cut, Pressure, Temperature,

Level, Initiate Test, more

ModBus RTU, other options available

Approvals and Compliance

European standard Zone 1 and 2, EEx de IIC T6, GOST Standard

Class I, Div. 1, Groups,C,D

Factory Mutual & CSA

Class II,Div. 1, Groups E,F,G

Electromagnetic radiation EMC

Installation and site requirements

Calibration (not required in the field) Standard calibration procedures for single phase flow meters

Pneumatic air valve controls Typical instrument air @ 7 barg (100psi)

Visit our Website at WWW.PHASEDYNAMICS.COM

© Phase Dynamics, Inc.

CCM Literature 0205

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lab 4 (Flowmeter Demonstration)Document24 pagesLab 4 (Flowmeter Demonstration)bae72% (18)

- Warman 14x12 AHDocument1 pageWarman 14x12 AHGabriel MarinoNo ratings yet

- In Normal Operation Two Pumps Are in Operation With The Third One On Standby, Which Will Start in Case Any One of The TwoDocument4 pagesIn Normal Operation Two Pumps Are in Operation With The Third One On Standby, Which Will Start in Case Any One of The TwoRajeshSahuNo ratings yet

- Tercera Asignación Control de Procesos 2021 - IIDocument7 pagesTercera Asignación Control de Procesos 2021 - IIBrayanNo ratings yet

- Lecture 22012Document28 pagesLecture 22012John Kevin NocheNo ratings yet

- Double Suction Centrifugal PumpDocument8 pagesDouble Suction Centrifugal PumpBilal WaseemNo ratings yet

- 26-Reservoir Engineering Self-TestDocument9 pages26-Reservoir Engineering Self-TestThắng NguyễnNo ratings yet

- FM FPMDocument25 pagesFM FPMBhawani Pratap Singh PanwarNo ratings yet

- CatDocument7 pagesCathamda100% (1)

- CFD in Launch Vehicle ApplicationsDocument6 pagesCFD in Launch Vehicle ApplicationsaeroalanNo ratings yet

- Kappa Dda Book 5.30.01Document852 pagesKappa Dda Book 5.30.01LAURA CATALINA CARDENAS RODRIGUEZ0% (1)

- Topic T1: Mass, Momentum and Energy AUTUMN 2013Document32 pagesTopic T1: Mass, Momentum and Energy AUTUMN 2013Aziful AiemanNo ratings yet

- Manush Kumar - Fluid Mechanics and Hydraulic Machines (2019, Pearson Education) PDFDocument993 pagesManush Kumar - Fluid Mechanics and Hydraulic Machines (2019, Pearson Education) PDFYumilka Alarcon100% (1)

- Annubar Transmissor de Vazão PrincípioDocument8 pagesAnnubar Transmissor de Vazão PrincípioDouglas HenriqueNo ratings yet

- The Burke-Schumann Spray Diffusion Flame in A PDFDocument12 pagesThe Burke-Schumann Spray Diffusion Flame in A PDFricljrNo ratings yet

- EntryLevel1-Hydraulic-English AssessmentAndAnswer SheetDocument30 pagesEntryLevel1-Hydraulic-English AssessmentAndAnswer SheetTrevor BurnettNo ratings yet

- A New Automotive Air Conditioning System Simulation Tool Developed in MATLAB/SimulinkDocument15 pagesA New Automotive Air Conditioning System Simulation Tool Developed in MATLAB/SimulinkPrashant IngaleNo ratings yet

- Gas-Liquid: Two-Phase ConvectionDocument8 pagesGas-Liquid: Two-Phase ConvectionForcus onNo ratings yet

- An Experimental Study of Air-Entraining VorticesDocument22 pagesAn Experimental Study of Air-Entraining VorticesBharath kumarNo ratings yet

- FADZXcv SXDocument1 pageFADZXcv SXMohamed SelimNo ratings yet

- Solver Settings and Output File: 16.0 ReleaseDocument42 pagesSolver Settings and Output File: 16.0 ReleaseFilip StojkovskiNo ratings yet

- Single and Double Volute Casing - RodeltaDocument3 pagesSingle and Double Volute Casing - Rodeltamasood_me60No ratings yet

- D155AX-5 Chapter 6 Hydraulic Fan CircuitDocument12 pagesD155AX-5 Chapter 6 Hydraulic Fan Circuithaimay118No ratings yet

- Control ValveDocument12 pagesControl ValvenerioalfonsoNo ratings yet

- Serv1852 TXT6Document38 pagesServ1852 TXT6Noel Olvera100% (2)

- មេរៀនChapter3Document10 pagesមេរៀនChapter3Yves JuniorNo ratings yet

- B.tech 4th Sem CE Final 2Document15 pagesB.tech 4th Sem CE Final 2Medalson RonghangNo ratings yet

- Tutorials Report Computational Fluid Dynamics - CH5101: Tutorial 1: - Problem Statement - Fluid Flow in A 2D PipeDocument3 pagesTutorials Report Computational Fluid Dynamics - CH5101: Tutorial 1: - Problem Statement - Fluid Flow in A 2D PipeDavis ArkelNo ratings yet

- CH 8 PDFDocument61 pagesCH 8 PDFGaurav Kumar100% (1)

- Module 3 Aircraft Propulsion NotesDocument30 pagesModule 3 Aircraft Propulsion NotesPratham M JariwalaNo ratings yet