Professional Documents

Culture Documents

Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater Samplers

Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater Samplers

Uploaded by

mickyfelixCopyright:

Available Formats

You might also like

- Abrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method ForDocument7 pagesAbrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method FormickyfelixNo ratings yet

- Concrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForDocument9 pagesConcrete Made by Volumetric Batching and Continuous Mixing: Standard Specification Formickyfelix100% (2)

- Astm D 5030 - 04Document13 pagesAstm D 5030 - 04Pierre Moro VigoNo ratings yet

- Using Density To Determine The Sugar Content in Commercial BeveragesDocument12 pagesUsing Density To Determine The Sugar Content in Commercial BeveragesMax DornelesNo ratings yet

- Using The Seismic-Reflection Method For Shallow Subsurface InvestigationDocument26 pagesUsing The Seismic-Reflection Method For Shallow Subsurface InvestigationmickyfelixNo ratings yet

- Estimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsDocument5 pagesEstimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsmickyfelixNo ratings yet

- De Alba Et Al. - Determination of Soil Liquefaction Characteristics From Large Scale Laboratory TestsDocument169 pagesDe Alba Et Al. - Determination of Soil Liquefaction Characteristics From Large Scale Laboratory TestsAshishBastolaNo ratings yet

- (Field Procedure) For Instantaneous Change in Head (Slug) Tests For Determining Hydraulic Properties of AquifersDocument4 pages(Field Procedure) For Instantaneous Change in Head (Slug) Tests For Determining Hydraulic Properties of AquifersIngrid MoraNo ratings yet

- Part 2. Suggested Method For Determining Deformability of Rock Materials in Uniaxial CompressionDocument3 pagesPart 2. Suggested Method For Determining Deformability of Rock Materials in Uniaxial CompressionHatemNo ratings yet

- Measurement of Soil Potential (Suction) Using Filter Paper: Standard Test Method ForDocument8 pagesMeasurement of Soil Potential (Suction) Using Filter Paper: Standard Test Method ForDiego Lizana OlarteNo ratings yet

- Volpe 1979 - Physical and Engineering Properties of Copper Tailings (1979 Edition) - Open LibraryDocument2 pagesVolpe 1979 - Physical and Engineering Properties of Copper Tailings (1979 Edition) - Open LibraryRICARDO ANDRES MORGADO PIZARRONo ratings yet

- Triaxial Compression Test 1978Document5 pagesTriaxial Compression Test 1978Alejandro425No ratings yet

- RAM Instruction ManualDocument144 pagesRAM Instruction Manualsercopetrol100% (4)

- Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Ground Water SamplersDocument14 pagesField Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Ground Water SamplersJohnCarlosGilNo ratings yet

- Density of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsDocument7 pagesDensity of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsIonut VasilescuNo ratings yet

- Astm D2573 D2573M 15Document8 pagesAstm D2573 D2573M 15Wilson KoNo ratings yet

- In-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Document10 pagesIn-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Ramal ColeNo ratings yet

- Astm D 7070-04Document6 pagesAstm D 7070-04Pamela SanabriaNo ratings yet

- X-Field DataDocument49 pagesX-Field Datathe luminousNo ratings yet

- AstmDocument2 pagesAstmluchitopadilla100% (2)

- 2019 - 20 - B41FG - MSC OGT FDP - Design Basis PDFDocument16 pages2019 - 20 - B41FG - MSC OGT FDP - Design Basis PDFShamsiNo ratings yet

- Influence of Vane Size and Equipment On The Results in The Vane Shear TestDocument7 pagesInfluence of Vane Size and Equipment On The Results in The Vane Shear TestNabucodonosor1980No ratings yet

- Radial Basis Functions and Kriging - A Gold Case StudyDocument8 pagesRadial Basis Functions and Kriging - A Gold Case StudyHamid KorNo ratings yet

- Cyclic TriaxialDocument2 pagesCyclic TriaxialnkotiaNo ratings yet

- D2845-Withdrawn 13696 PDFDocument7 pagesD2845-Withdrawn 13696 PDFeduardo bonillaNo ratings yet

- Peso Unitario SuelosDocument7 pagesPeso Unitario SuelossergioNo ratings yet

- Subsurface Flow and Transport Modeling: Standard Guide ForDocument6 pagesSubsurface Flow and Transport Modeling: Standard Guide ForGeotecnia PerúNo ratings yet

- SUniaxial Compression Test 1979Document4 pagesSUniaxial Compression Test 1979Alejandro425No ratings yet

- Astm D421-1985 (2007)Document2 pagesAstm D421-1985 (2007)Bruno SantosNo ratings yet

- Astm D4083 - 1 (En)Document6 pagesAstm D4083 - 1 (En)Amm MarakataNo ratings yet

- An Improved Method of Matching Response Spectra of Recorded Earthquake Ground Motion Using Wavelets PDFDocument23 pagesAn Improved Method of Matching Response Spectra of Recorded Earthquake Ground Motion Using Wavelets PDFAnonymous 7lnR7QkssNo ratings yet

- ASTM D4943 Dterminación Del Límite de ContracciónDocument6 pagesASTM D4943 Dterminación Del Límite de ContracciónDiego Castillo JaramilloNo ratings yet

- Load Controlled Cyclic Triaxial Strength of Soil: Standard Test Method ForDocument10 pagesLoad Controlled Cyclic Triaxial Strength of Soil: Standard Test Method ForROHITNo ratings yet

- ResGeo202MOOC HW3Document1 pageResGeo202MOOC HW3Muhammad HanifNo ratings yet

- EXPERIMENT No 11Document18 pagesEXPERIMENT No 11Gashaw AbebawNo ratings yet

- Astm D427-Contracción MercurioDocument4 pagesAstm D427-Contracción MercurioDaniel Villagomez SilvaNo ratings yet

- Particle-Size Distribution (Gradation) of Fine-Grained Soils Using The Sedimentation (Hydrometer) AnalysisDocument27 pagesParticle-Size Distribution (Gradation) of Fine-Grained Soils Using The Sedimentation (Hydrometer) AnalysisCRISTHIAN JESUS NEGRETE TASAYCONo ratings yet

- Direct Shear Test of Soils Under Consolidated Drained ConditionsDocument9 pagesDirect Shear Test of Soils Under Consolidated Drained ConditionsKoppolu SrinivasuluNo ratings yet

- Rock Physics Cambrige PDFDocument10 pagesRock Physics Cambrige PDFzeeshan225No ratings yet

- D653-14 Standard Terminology Relating To Soil, Rock, and ContainedDocument46 pagesD653-14 Standard Terminology Relating To Soil, Rock, and ContainedFaten Abou ShakraNo ratings yet

- Applying Rock Physics From Cutting Samples and Integration With Geology, Petrophysics and Geophysics.Document5 pagesApplying Rock Physics From Cutting Samples and Integration With Geology, Petrophysics and Geophysics.Muhammad Rafly AndraNo ratings yet

- Permeability of Granular Soils (Constant Head) : Standard Test Method ForDocument5 pagesPermeability of Granular Soils (Constant Head) : Standard Test Method ForbudiNo ratings yet

- Calculating in Situ Equivalent Elastic Moduli of Pavement Materials Using Layered Elastic TheoryDocument7 pagesCalculating in Situ Equivalent Elastic Moduli of Pavement Materials Using Layered Elastic TheoryKevin Darly Chavez ChuzonNo ratings yet

- Astm D 7263 09Document9 pagesAstm D 7263 09Irna PrasticaNo ratings yet

- Recent Developments in The Techniques of Controlling and Measuring Suction in Unsaturated SoilsDocument20 pagesRecent Developments in The Techniques of Controlling and Measuring Suction in Unsaturated SoilsAmal BhlNo ratings yet

- D 4647 - 93 R98 RDQ2NDCDocument11 pagesD 4647 - 93 R98 RDQ2NDCJonathan Chacón100% (1)

- Rotating Vane Rheometry-AreviewDocument14 pagesRotating Vane Rheometry-AreviewgoldennanukNo ratings yet

- Post-Liquefaction Volumetric Strain of Gravel-Sand Mixtures in Constant Volume Simple ShearDocument12 pagesPost-Liquefaction Volumetric Strain of Gravel-Sand Mixtures in Constant Volume Simple ShearJiaer Wu0% (1)

- D427Document4 pagesD427Nouman KhalidNo ratings yet

- Rock PhysicsDocument42 pagesRock PhysicsMark MaoNo ratings yet

- Aqtesolv Manual 5Document1 pageAqtesolv Manual 5Kevin Tang0% (1)

- Slope Paper 279Document12 pagesSlope Paper 279rNo ratings yet

- Specific Gravity of Soil Solids by Water Pycnometer: Standard Test Methods ForDocument8 pagesSpecific Gravity of Soil Solids by Water Pycnometer: Standard Test Methods ForMon QuinolNo ratings yet

- Gea 24 UKDocument2 pagesGea 24 UKSocrates Palomino GamboaNo ratings yet

- Environmental Isotopes in The Hydrological Cycle Vol 1 PDFDocument185 pagesEnvironmental Isotopes in The Hydrological Cycle Vol 1 PDFNoreida PRIETO MILLAN100% (1)

- Permeabilidad en Celda TriaxialDocument7 pagesPermeabilidad en Celda TriaxialLuis Lemus MondacaNo ratings yet

- Subsidence and Thermal HistoryDocument28 pagesSubsidence and Thermal Historyalbert mwairwa100% (1)

- ISRM-EUROCK-2010-012 - Determination of Direct Tensile Strength and Stiffness of Intact RocksDocument4 pagesISRM-EUROCK-2010-012 - Determination of Direct Tensile Strength and Stiffness of Intact Rocksamy75No ratings yet

- Seismic Refraction Surveyingg GEOMETRIKSDocument20 pagesSeismic Refraction Surveyingg GEOMETRIKSAltinK78No ratings yet

- D 4767 Test Method For Consolidated Undrained Triaxial Compression Test For Cohesive Soils PDFDocument13 pagesD 4767 Test Method For Consolidated Undrained Triaxial Compression Test For Cohesive Soils PDFjairoNo ratings yet

- Geology of Carbonate Reservoirs: The Identification, Description and Characterization of Hydrocarbon Reservoirs in Carbonate RocksFrom EverandGeology of Carbonate Reservoirs: The Identification, Description and Characterization of Hydrocarbon Reservoirs in Carbonate RocksNo ratings yet

- Tectonics of Sedimentary Basins: Recent AdvancesFrom EverandTectonics of Sedimentary Basins: Recent AdvancesCathy BusbyRating: 4.5 out of 5 stars4.5/5 (3)

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcretemickyfelixNo ratings yet

- Fiber-Reinforced Concrete: Standard Specification ForDocument7 pagesFiber-Reinforced Concrete: Standard Specification FormickyfelixNo ratings yet

- In-Place Density of Unhardened and Hardened Concrete, Including Roller Compacted Concrete, by Nuclear MethodsDocument5 pagesIn-Place Density of Unhardened and Hardened Concrete, Including Roller Compacted Concrete, by Nuclear MethodsmickyfelixNo ratings yet

- Coal Fly Ash and Raw or Calcined Natural Pozzolan For Use in ConcreteDocument5 pagesCoal Fly Ash and Raw or Calcined Natural Pozzolan For Use in ConcretemickyfelixNo ratings yet

- Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesChemical Admixtures For Use in Producing Flowing Concretemickyfelix100% (1)

- Determining Density of Structural Lightweight Concrete: Standard Test Method ForDocument4 pagesDetermining Density of Structural Lightweight Concrete: Standard Test Method FormickyfelixNo ratings yet

- Splitting Tensile Strength of Cylindrical Concrete SpecimensDocument5 pagesSplitting Tensile Strength of Cylindrical Concrete SpecimensmickyfelixNo ratings yet

- Total Evaporable Moisture Content of Aggregate by Drying: Standard Test Method ForDocument3 pagesTotal Evaporable Moisture Content of Aggregate by Drying: Standard Test Method FormickyfelixNo ratings yet

- Lightweight Aggregates For Concrete Masonry UnitsDocument4 pagesLightweight Aggregates For Concrete Masonry UnitsmickyfelixNo ratings yet

- Packaged, Dry, Combined Materials For Concrete and High Strength MortarDocument5 pagesPackaged, Dry, Combined Materials For Concrete and High Strength MortarmickyfelixNo ratings yet

- Lightweight Aggregates For Structural ConcreteDocument4 pagesLightweight Aggregates For Structural ConcretemickyfelixNo ratings yet

- Astm C 215Document7 pagesAstm C 215mickyfelixNo ratings yet

- Sampling and Testing Fly Ash or Natural Pozzolans For Use in Portland-Cement ConcreteDocument10 pagesSampling and Testing Fly Ash or Natural Pozzolans For Use in Portland-Cement ConcretemickyfelixNo ratings yet

- Determination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionDocument8 pagesDetermination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionmickyfelixNo ratings yet

- Standard Guide For The Evaluation, and Calibration, Continuous Friction Measurement Equipment (CFME)Document6 pagesStandard Guide For The Evaluation, and Calibration, Continuous Friction Measurement Equipment (CFME)mickyfelixNo ratings yet

- Active Soil Gas Sampling For Direct Push or Manual-Driven Hand-Sampling EquipmentDocument14 pagesActive Soil Gas Sampling For Direct Push or Manual-Driven Hand-Sampling EquipmentmickyfelixNo ratings yet

- Consolidated Drained Triaxial Compression Test For SoilsDocument11 pagesConsolidated Drained Triaxial Compression Test For SoilsmickyfelixNo ratings yet

- Measuring Deflections Using A Portable Impulse Plate Load Test DeviceDocument5 pagesMeasuring Deflections Using A Portable Impulse Plate Load Test Devicemickyfelix100% (1)

- Air-Entraining Admixtures For ConcreteDocument4 pagesAir-Entraining Admixtures For ConcretemickyfelixNo ratings yet

- Preformed Polychloroprene Elastomeric Joint Seals For BridgesDocument4 pagesPreformed Polychloroprene Elastomeric Joint Seals For BridgesmickyfelixNo ratings yet

- GSM 24 Qutiotion Fore Sale in PakistanDocument7 pagesGSM 24 Qutiotion Fore Sale in PakistanFly ash BricksNo ratings yet

- Service Letter: Date: Sep 20, 2018 Ref. No.: Hgs-Bwts-Sl-18-0001 Subject: Trouble Shooting Manual Type: HiballastDocument129 pagesService Letter: Date: Sep 20, 2018 Ref. No.: Hgs-Bwts-Sl-18-0001 Subject: Trouble Shooting Manual Type: HiballastMd Azharul IslamNo ratings yet

- Hydraulic Ram PumpDocument24 pagesHydraulic Ram PumpLeoni FrancNo ratings yet

- SWIWAR SURYA Dry-Dock Specification 2019Document110 pagesSWIWAR SURYA Dry-Dock Specification 2019NMHa100% (2)

- CATALOG M19 Marine RangeDocument41 pagesCATALOG M19 Marine RangeDanielNo ratings yet

- Fire Fighting BomDocument6 pagesFire Fighting BomVishal TiwariNo ratings yet

- 12 HOberDocument4 pages12 HOberAhmad YaniNo ratings yet

- 01 CurveDocument1 page01 CurveEngineering Rotech PumpsNo ratings yet

- Training Report: The Open Univeersity of Sri LankaDocument61 pagesTraining Report: The Open Univeersity of Sri LankaJanaka ChathurangaNo ratings yet

- Acumuladores de BexigaDocument8 pagesAcumuladores de BexigaCristiane Ramos GrieblerNo ratings yet

- Spa Quick Start Guide Balboa VS/GS100 System For VL 200 Topside ControlDocument2 pagesSpa Quick Start Guide Balboa VS/GS100 System For VL 200 Topside Control薛泽绵No ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- 9976 Implement Pump A10VO100DFR1-31R-PSC62K07 R910911026 PDFDocument12 pages9976 Implement Pump A10VO100DFR1-31R-PSC62K07 R910911026 PDFmorusNo ratings yet

- Study of Identifying Liquid Loading in Gas Wells and Deliquification Techniques IJERTV8IS060708 PDFDocument12 pagesStudy of Identifying Liquid Loading in Gas Wells and Deliquification Techniques IJERTV8IS060708 PDFMani BansalNo ratings yet

- INNOVAIR VM Blutec Condenser Service Manual 2nd GenDocument46 pagesINNOVAIR VM Blutec Condenser Service Manual 2nd GenEdgard Martin Mejia Solano100% (1)

- 0909-GS-R-VA-25005 - A1 - Manufacturing Records - LP Separator Produced Water Pumps (920-PA-003AB) PDFDocument285 pages0909-GS-R-VA-25005 - A1 - Manufacturing Records - LP Separator Produced Water Pumps (920-PA-003AB) PDFchuminhNo ratings yet

- 010 - CAT-6040 - Hydraulik Cooling SystemDocument10 pages010 - CAT-6040 - Hydraulik Cooling SystemWillian Ticlia Ruiz100% (1)

- 22b - Water and Oil Based Fluids Motor Pump Unit XWH BFD54 August 11Document12 pages22b - Water and Oil Based Fluids Motor Pump Unit XWH BFD54 August 11Hatef KhorramNo ratings yet

- Goulds Pumps HSC Multi Stage Centrifugal Pump Technical BrochureDocument4 pagesGoulds Pumps HSC Multi Stage Centrifugal Pump Technical BrochureEstefanía SernaNo ratings yet

- BOM - Fastraq. Pacific WYC SN - 39370Document5 pagesBOM - Fastraq. Pacific WYC SN - 39370Juan David Triana SalazarNo ratings yet

- Building Maintenance Checklist 2023Document2 pagesBuilding Maintenance Checklist 2023Caesar A. AlesnaNo ratings yet

- Atlas Dema CatalogDocument2 pagesAtlas Dema Catalogpinny73No ratings yet

- Isuzu 4HK-4JJDocument67 pagesIsuzu 4HK-4JJveronica franciscoNo ratings yet

- Technical Service Manual: Heavy-Duty Bracket Mounted Pumps SERIES 125 AND 4125 Sizes G-LLDocument16 pagesTechnical Service Manual: Heavy-Duty Bracket Mounted Pumps SERIES 125 AND 4125 Sizes G-LLCarlos AvalosNo ratings yet

- SIMIT ChemBasic Doc enDocument40 pagesSIMIT ChemBasic Doc enraffaelloNo ratings yet

- Midea 10 HP CatalogueDocument10 pagesMidea 10 HP Cataloguethanh longNo ratings yet

- Nocchi RJetinox LDocument2 pagesNocchi RJetinox LAlvaro MejiaNo ratings yet

- IFS Training For PAM May-11 To 14-2010 - CADocument134 pagesIFS Training For PAM May-11 To 14-2010 - CAAnonymous cuOIjrLINo ratings yet

- Grasso Screw Compressor Package Pi - tcm11 38504Document84 pagesGrasso Screw Compressor Package Pi - tcm11 38504Twfeek AhmedNo ratings yet

Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater Samplers

Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater Samplers

Uploaded by

mickyfelixOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater Samplers

Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater Samplers

Uploaded by

mickyfelixCopyright:

Available Formats

Designation: D7242/D7242M − 06 (Reapproved 2013)´1

Standard Practice for

Field Pneumatic Slug (Instantaneous Change in Head) Tests

to Determine Hydraulic Properties of Aquifers with Direct

Push Groundwater Samplers1

This standard is issued under the fixed designation D7242/D7242M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε1 NOTE—Designation was editorially corrected to match units information in December 2013.

1. Scope* be applicable in all circumstances. This ASTM standard is not

1.1 This standard practice covers the field methods used to intended to represent or replace the standard of care by which

conduct an instantaneous change in head (slug) test when the adequacy of a given professional service must be judged,

pneumatic pressure is used to initiate the change in head nor should this document be applied without consideration of

pressure within the well or piezometer. While this practice a project’s many unique aspects. The word “standard” in the

specifically addresses use of pneumatic initiation of slug tests title means that the document has been approved through the

with direct push tools these procedures may be applied to wells ASTM consensus process.

or piezometers installed with rotary drilling methods when 2. Referenced Documents

appropriate.

2.1 ASTM Standards:3

1.2 This standard practice is used to obtain the required field D653 Terminology Relating to Soil, Rock, and Contained

data for determining hydraulic properties of an aquifer or a Fluids

specified vertical interval of an aquifer. Field data obtained D2434 Test Method for Permeability of Granular Soils

from application of this practice are modeled with appropriate (Constant Head)

analytical procedures (Test Methods D4104, D5785, D5881, D3740 Practice for Minimum Requirements for Agencies

D5912, Ref (1)2). Engaged in Testing and/or Inspection of Soil and Rock as

1.3 The values stated in either SI units or inch-pound units Used in Engineering Design and Construction

are to be regarded separately as standard. The values stated in D4104 Test Method (Analytical Procedure) for Determining

each system may not be exact equivalents; therefore, each Transmissivity of Nonleaky Confined Aquifers by Over-

system shall be used independently of the other. Combining damped Well Response to Instantaneous Change in Head

values from the two systems may result in non-conformance (Slug Tests)

with the standard. D5084 Test Methods for Measurement of Hydraulic Con-

1.4 This standard does not purport to address all of the ductivity of Saturated Porous Materials Using a Flexible

safety concerns, if any, associated with its use. It is the Wall Permeameter

responsibility of the user of this standard to establish appro- D5092 Practice for Design and Installation of Groundwater

priate safety and health practices and determine the applica- Monitoring Wells

bility of regulatory limitations prior to use. D5521 Guide for Development of Groundwater Monitoring

1.5 This practice offers a set of instructions for performing Wells in Granular Aquifers

one or more specific operations. This document cannot replace D5785 Test Method for (Analytical Procedure) for Deter-

education or experience and should be used in conjunction mining Transmissivity of Confined Nonleaky Aquifers by

with professional judgment. Not all aspects of this practice may Underdamped Well Response to Instantaneous Change in

Head (Slug Test)

D5856 Test Method for Measurement of Hydraulic Conduc-

1

This practice is under the jurisdiction of ASTM Committee D18 on Soil and tivity of Porous Material Using a Rigid-Wall,

Rock and is the direct responsibility of Subcommittee D18.21 on Groundwater and Compaction-Mold Permeameter

Vadose Zone Investigations.

Current edition approved Dec. 1, 2013. Published January 2014. Originally

3

approved in 2006. Last previous edition approved in 2006 as D7242 – 06. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D7242-06R13. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

D7242/D7242M − 06 (2013)´1

D5881 Test Method for (Analytical Procedure) Determining 2)) of the well or groundwater sampling device slug tests may

Transmissivity of Confined Nonleaky Aquifers by Criti- yield biased data. Field quality control may be monitored by

cally Damped Well Response to Instantaneous Change in conducting replicate tests after development and visually

Head (Slug) comparing the replicate data sets.

D5912 Test Method for (Analytical Procedure) Determining

Hydraulic Conductivity of an Unconfined Aquifer by 4.3 Aquifer response data obtained from the pneumatic slug

Overdamped Well Response to Instantaneous Change in tests are modeled with the appropriate analysis method (Test

Head (Slug) (Withdrawn 2013)4 Methods D4104, D5785, D5881, D5912, Refs (1, 3)) to

D6001 Guide for Direct-Push Groundwater Sampling for calculate the transmissivity and/or hydraulic conductivity of

Environmental Site Characterization the screened formation.

D6282 Guide for Direct Push Soil Sampling for Environ-

mental Site Characterizations (Withdrawn 2014)4 5. Significance and Use

D6724 Guide for Installation of Direct Push Groundwater 5.1 Combining slug test methods with the use of direct push

Monitoring Wells installed groundwater sampling devices provides a time and

D6725 Practice for Direct Push Installation of Prepacked cost-effective method that was previously not available for

Screen Monitoring Wells in Unconsolidated Aquifers evaluating spatial variations of hydraulic conductivity (K) in

3. Terminology unconsolidated aquifers. Current research (Ref (4)) has found

that small (decimeter) scale variations in hydraulic conductiv-

3.1 Terminology used within this practice is in accordance ity may have significant influence on solute transport and

with Terminology D653 with the addition of the following:

therefore design of groundwater remediation systems. Other

3.2 Definitions: investigators (Ref (5)) report that spatial variation in K is

3.2.1 direct-push (DP) sampling—sampling devices that are believed to be the main source of uncertainty in the prediction

directly inserted into the soil without drilling or borehole of contaminant transport in aquifers. They found that increas-

excavation. D6001 ing the data density for K in model input noticeably reduced

3.2.2 two-tube system—a system whereby inner and outer the uncertainty of model prediction. Because of increased

tubes are advanced simultaneously into the subsurface strata to efficiency and reduced costs, the combination of slug test

collect a soil sample, sometimes referred to as dual-tube. The methods with DP groundwater sampling devices makes it

outer tube is used for borehole stabilization. The inner tube for possible to obtain the additional information required to reduce

sampler insertion and recovery. D6282 uncertainty in contaminant transport models and improve

3.2.3 single-tube system—a system whereby single remedial action design.

extension/drive rods with samplers attached are advanced into 5.2 The data obtained from application of this practice may

the subsurface strata to collect a soil sample. D6282 be modeled with the appropriate analytical method to provide

3.2.4 slug test—a single well test to measure aquifer prop- information on the transmissivity and hydraulic conductivity of

erties such as transmissivity and hydraulic conductivity. A slug the screened formation in a timely and cost effective manner.

test is conducted by inducing a near instantaneous change in

the static water level in a well and observing the recovery of 5.3 The appropriate analytical method selected for analysis

the water level to static condition over time. Also called an of the data will depend on several factors, including, but not

instantaneous change in head test. limited to, the aquifer type (confined, unconfined, leaky) well

construction parameters (partially or fully penetrating), and the

4. Summary of Practice type of aquifer response observed during the slug test (over-

4.1 This practice describes the field procedures used to damped or underdamped). Some of the appropriate methods

conduct an instantaneous change in head (slug) test in a direct may include Test Methods D4104, D5785, D5881 and D5912.

push (DP) installed groundwater sampling device or monitor- A thorough review of many slug test models and analytical

ing well using air pressure to cause a sudden change in the methods is provided in Ref (1).

water level. A pneumatic manifold is installed on a developed

5.4 Slug tests may be conducted in materials of lower

well or DP installed device to control the pressure in the

hydraulic conductivity than are suitable for pumping tests. Slug

wellhead. Positive pressure or vacuum may be applied with the

tests may be used to obtain estimates of K for aquitards

pneumatic manifold to induce a rising head test or falling head

consisting primarily of silts and clays. Special field procedures

test, respectively. The changing water level in the well is

may be required.

monitored with a transducer and data acquisition device and

the data is saved for curve fitting and analysis. 5.5 The pneumatic slug test provides some advantages when

4.2 Appropriate well design and construction is necessary to compared to pumping tests or slug tests conducted by other

obtain representative slug test results. Furthermore, without methods.

adequate development (Practice D6725, Guide D5521, Refs (1, 5.5.1 Some of the advantages relative to pump tests include:

5.5.1.1 No water added to or removed from the well. An

4

The last approved version of this historical standard is referenced on important consideration when water quality must not be altered

www.astm.org. for purposes of environmental sampling.

Copyright by ASTM Int'l (all rights reserved); 2

D7242/D7242M − 06 (2013)´1

5.5.1.2 Large volumes of water not removed from the well 5.6.2 Several types of temporary groundwater monitoring

as during a pumping test. An important consideration if the devices may be installed by DP methods (Guide D6001). These

groundwater is contaminated and will require disposal as a tools may be installed at various depths and various locations

regulated waste. for slug testing and groundwater sampling in unconsolidated

5.5.1.3 Slug tests usually require only a fraction of the time materials. Most of these tools are extracted for decontamina-

needed to complete a pump test. tion and multiple re-use, and can minimize the need for

5.5.1.4 No large diameter pumping well or down well pump permanent well installations.

required. 5.6.3 Short screens may be used to slug test discrete depth

5.5.1.5 Slug tests provide information on K for the forma- intervals to document vertical and lateral variations of K within

tion in the vicinity of the well. an aquifer in a cost and time effective manner.

5.5.2 Some advantages relative to slug tests using water or 5.6.4 Equipment required to install DP wells and temporary

a mechanical slug include: groundwater samplers are often smaller and more mobile than

5.5.2.1 No water added to or removed from the well or DP conventional rotary drilling equipment. This can make site

sampler to conduct the test. Generally does not change water access easier and more rapid.

quality for sampling. Use of vacuum to induce a falling head 5.6.5 Other direct push screening and sampling methods, for

test could result in loss of volatiles from water in the well example Guide D6282 on soil sampling, can be used to detect

column. Additional purging may be required before sampling test zones in advance of slug testing, which helps with

for volatile contaminants. knowledge of test location.

5.5.2.2 Pneumatic initiation of the slug test provides clean, 5.6.6 Direct push tests are minimally intrusive.

high quality data with minimal noise, especially important in 5.6.7 Direct push tests are generally more rapid and less

high hydraulic conductivity formations and small diameter expensive than other drilling methods.

wells. 5.7 Some disadvantages of DP methods as compared to

5.5.2.3 In small diameter DP tools, inserting a mechanical conventional rotary drilling include:

slug or adding water may be difficult or even preclude accurate 5.7.1 DP methods generally provide a smaller diameter bore

measurement of changing water levels. hole than traditional rotary drilling. This may limit the size of

5.5.3 Some disadvantages of slug tests as compared to equipment than can be placed down hole.

pumping tests include: 5.7.2 Direct push tools are designed to penetrate unconsoli-

5.5.3.1 Slug tests provide information on K for the forma- dated materials only. Other rotary drilling methods will be

tion only in the vicinity of the well, not a large scale average required to penetrate consolidated rock.

value as obtained from a pumping test. 5.7.3 Some subsurface conditions may limit the depth of

5.5.3.2 Most slug test analytical methods can provide infor- penetration of DP methods and tools. Some examples include

mation only on aquifer transmissivity and hydraulic conduc- thick caliche layers, cobbles or boulders, or very dense

tivity. Pumping test analysis can provide additional informa- materials, such as high density glacial tills.

tion on aquifer parameters such as specific storage, etc.

5.5.4 Some disadvantages of the pneumatic slug test relative NOTE 1—The quality of the result produced by this standard is

dependent on the competence of the personnel performing it, and the

to slug tests using water or a mechanical slug include: suitability of the equipment and facilities used. Agencies that meet the

5.5.4.1 Airtight seals needed on the well casing or drive criteria of Practice D3740 are generally considered capable of competent

rods. and objective testing/sampling/inspection/etc. Users of this standard are

5.5.4.2 The screen must remain below the water level cautioned that compliance with Practice D3740 does not in itself assure

reliable results. Reliable results depend on many factors; Practice D3740

throughout the slug test. Wells screened across the water table provides a means of evaluating some of those factors. Practice D3740 was

cannot be slug tested with the pneumatic method. developed for agencies engaged in the testing or inspection of soils and

5.5.4.3 Pressure transducers and electronic acquisition rock, or both. As such, it is not totally applicable to agencies performing

methods usually required for pneumatic slug testing. Not this practice. However, users of this practice should recognize that the

framework of Practice D3740 is appropriate for evaluating the quality of

always needed for manual methods. an agency performing this practice. Currently there is no known qualify-

5.5.4.4 Equilibration of water level after pressure (or ing national authority that inspects agencies that perform this practice.

vacuum) applied to the wellhead increases time required to

complete the slug test, especially important in low-K forma- 6. Apparatus

tions.

6.1 General—The following discussion provides descrip-

5.6 Direct push methods provide some advantages as com- tions and details for one pneumatic slug test system. Many

pared to conventional drilling methods for the installation of geologists and hydrologists have fabricated their own pneu-

wells and temporary groundwater monitoring devices to be matic slug test equipment. While the descriptions below are

used for slug testing. Some of the advantages include: specific to one particular system other pneumatic systems may

5.6.1 DP methods minimize generation of soil cuttings be suitable if they can provide appropriate data quality and data

reducing waste handling and disposal costs at contaminated density for the aquifer response to be monitored in the field.

sites during the installation of permanent wells (Guide D6724, Professional experience and judgment should be used to

Practice D6725) and temporary groundwater monitoring de- evaluate whether the pneumatic slug test system is adequate for

vices (Guide D6001). the aquifer and well conditions to be tested. Not all wells or

Copyright by ASTM Int'l (all rights reserved); 3

D7242/D7242M − 06 (2013)´1

temporary groundwater monitoring devices are appropriate for range of pressure change to be monitored. Pressure transducers

pneumatic slug testing. rated at 35 to 70 kPa [5 to 10 psi] are generally suitable because

6.2 Pneumatic Manifold—The pneumatic manifold is an the transducer is placed approximately 1 to 1.5 m [3 to 5 ft]

airtight system to allow for control of air pressure inside the below the water level for most test conditions. Pressure ratings

wellhead. The primary features of a pneumatic manifold are of 140 kPa [20 psi] or higher may be acceptable, but if small

depicted in Fig. 1 and include: head changes are used, resolution of higher pressure transduc-

6.2.1 Inlet valve connecting to an air or vacuum source. ers may be inadequate. The diameter of the transducer and

6.2.2 Pressure regulator to modulate the rate of pressuriza- cable should allow its insertion down hole without interfer-

tion of the well head. ence. Dark cables on pressure transducers are subject to

6.2.3 Pressure/vacuum gauge to monitor pressure in the heating when exposed to sunlight. This may cause fluctuations

wellhead. May be graduated in centimetres [inches] of water in transducer response (Ref (6)) and errors in slug test data

pressure. Used for leak testing and monitoring the amount of analysis. Minimize exposure of transducer cables to sunlight.

water level change in the wellhead. Also allow pressure transducer to equilibrate to ambient water

6.2.4 Air tight fitting (transducer port) that allows the temperature as specified by manufacturer before initiating slug

transducer and cable to move up and down for placement at tests.

various depths within the well. An additional airtight fitting 6.4 Data Logger/Analog to Digital Inverter—Several por-

may be available for a second transducer to monitor the air table data loggers are commercially available that may be used

pressure inside the wellhead. to capture the transducer signal and store it for later down load

6.2.5 Release valve that may be opened rapidly to allow for to a computer for plotting and analysis. Some systems use an

quick exchange of air between the wellhead and ambient analog to digital inverter to acquire the analog signal from the

atmosphere. The release valve opening should be approxi- pressure transducer and convert it to digital format for direct

mately the same diameter or larger than the well casing to be upload to a portable computer. Some data acquisition systems

tested. This will provide for unhampered airflow and minimize allow the user to observe the slug test response as the test is

generation of any noise as the pressure in the wellhead changes conducted in the field. Be sure the data acquisition system will

rapidly. provide for sufficient sampling rate to capture fast recovering

6.2.6 Casing adapter that will allow the pneumatic manifold water levels or oscillatory responses if these conditions are

to attach to the well casing with an airtight connection. The anticipated. Sampling rates of 5 to 10 Hz may be needed when

casing adapter should attach to the well casing or drive rod in oscillatory responses occur.

such a way as not to reduce the ID below that of the ID of the 6.5 Air/Vacuum Supply—As the pressure inside the well

casing to be tested. head required to depress the water level a sufficient amount to

6.3 Pressure Transducer—Several pressure transducers suit- conduct a slug test is not more than 3 to 7 kPa [1 to 2 psi], a

able for use in slug testing are commercially available. Pres- large compressor is usually not required, especially for wells of

sure ratings may be reported in kiloPascal (kPa) [pounds per 50 mm [2-in.] diameter or less and the smaller DP tools. For

square inch (psi)]. Be sure that baseline noise levels and larger diameter wells and wells with deep water levels a

hysteresis characteristics of the transducer are suitable for the compressor or other clean gas supply may be preferred. In the

NOTE 1—Various rod and casing adapters are used to connect to

different size casing or DP drive rods. Inside diameter of the release valve

should be the same or larger than the diameter of the well casing to be

tested.

FIG. 1 Example of a Pneumatic Manifold Used to Conduct Slug

Tests on DP Groundwater Samplers or Conventional PVC Wells

Copyright by ASTM Int'l (all rights reserved); 4

D7242/D7242M − 06 (2013)´1

smaller wells and tools, a foot-operated pump or manually 6.7 Miscellaneous Supplies and Accessories—Various hand

operated pump can be used to provide sufficient air pressure or tools, supplies and accessories will make field activities more

vacuum with minimal effort. Small 12 Volt electric pumps are efficient and easier. Plumber’s tape and O-rings may be

available and may be used if desired. Some field technicians required to make up airtight fittings. A soapy liquid to conduct

prefer to use cylinders of compressed gas. This is suitable, but leak testing on exposed fittings and connections will help if

does present some additional safety hazards for transportation system leaks do occur.

of the compressed gas cylinders. Whatever the source of air for

pressurization of the wellhead, ensure the air is clean and will 7. Preparation/Conditioning

not contain potential contaminants. If a compressor is required, 7.1 Well construction (Practice D5092, Guide D6725) and

use an oil-less compressor. DP groundwater sampler installation (Guide D6001, Refs (7,

6.6 Casing Adapters—Verify the pneumatic manifold is 8)) must be completed appropriately to assure that representa-

specifically designed to provide an airtight fitting for the casing tive data is obtained from slug tests. In general, PVC monitor-

diameter on the well(s) to be tested. Adapters may be used to ing wells with filter packs are installed and developed some

attach the pneumatic head to larger or smaller casing sizes if time before slug testing is conducted. Alternatively, DP

necessary. Be sure the adapters do not obstruct the ID of the groundwater sampling tools (Fig. 2) may be installed and

well casing. developed immediately before slug tests are conducted. If the

NOTE 1—Screen is protected with a sheath during advancement. Small extension rods inserted after driving (a) to expose screen desired amount for

slug testing and sampling. Development must be conducted (b) to assure that natural flow is established between the formation and sampling device.

Simple inertial pump often effective for surging and purging to develop the sampler.

FIG. 2 Direct Push Installed Single Tube Groundwater Sampling Device

Copyright by ASTM Int'l (all rights reserved); 5

D7242/D7242M − 06 (2013)´1

well screen and/or filter pack are improperly designed for the thin-walled sampler should be used to core the formation

formation monitored it may be difficult or impossible to beneath the dual tube rods. A brush or other suitable means is

achieve good well development. Boring logs and well con- then used to relieve smearing on the core hole wall in cohesive

struction diagrams should be reviewed prior to mobilization to formations. Relief of smearing is comparable to development

evaluate possible well design problems. Alternatively, cone in coarse-grained materials. A screen is then inserted into the

penetration test (CPT) or coring logs could be performed near cored hole in preparation for slug testing. A small casing (for

the well to verify subsurface conditions. One common problem example, 13-mm [0.5-in.] PVC riser pipe) may be used to

is that the filter media and screen slot size are too large for the connect the screen to the surface. The smaller casing will help

natural formation conditions. This may result in continued reduce the recovery time required for the slug tests in fine-

movement of fines into the well even after significant devel- grained materials. An alternative to use of the screen is to fill

opment is conducted. Such movement of fines may cause the cored and brushed hole with sand having a much higher

erratic recovery rate in the well or curvature of normalized data permeability and K than the formation.

plots. This will hinder accurate modeling of the slug test 7.3 Well Development—Slug test results in granular forma-

response and calculation of aquifer parameters. Clearly note tions are particularly susceptible to well development. If the

any suspected well design problems in the field log book and well or temporary groundwater sampling tool is not adequately

later reporting. developed before slug tests are conducted the observed re-

7.2 When slug tests are to be conducted in fine-grained sponse will be biased and inaccurate. Use adequate well

formations special procedures may be required to minimize development methods (Guide D5521, Guide D6724, Practice

compression and damage to the natural formation. DP Dual D6725, Refs (1, 2)) to assure that natural flow has been

tube methods (Fig. 3) may provide an effective means to access established between the well and granular aquifer so that

the formation and conduct slug tests under these conditions. A representative slug test results are obtained. Some basic well

NOTE 1—Dual tube soil sampling procedures may be combined with simple groundwater sampling devices to conduct sampling and slug testing at

multiple depths in one boring. After removal of the soil sample or center rod a simple slotted screen may be installed through the open bore of the casing

(a). In coarse grained sediments the rods are retracted to expose the screen (b). Following development an adapter attaches the pneumatic manifold (c)

to the large drive rods for slug testing. In fine grained materials a thin walled tube may be used to core below the outer rods to minimize compression

of the formation (d). The screen is then set in the open core hole below the drive rods.

FIG. 3 DP Dual Tube Methods for Pneumatic Slug Tests

Copyright by ASTM Int'l (all rights reserved); 6

D7242/D7242M − 06 (2013)´1

development procedures for sandy formations include over 7.6 Documentation of Well and Aquifer Parameters —To

pumping, surging with a surge block followed by purging, facilitate accurate modeling of the slug test results well

surging and purging with an inertial pump. Older wells may construction details must be known. These include parameters

require redevelopment prior to slug testing to obtain accurate such as casing diameter, screen diameter and screen length.

results. In fine-grained formations any purging for develop- Well construction logs may provide much of this data. In

ment should be gentle and surging should be avoided to addition, boring logs and water level data must be reviewed to

prevent damage. In cohesive formations brushing the core hole determine the thickness of the aquifer and whether the aquifer

to relieve smearing from core sampling may be an integral part is confined or unconfined. An easy way to assure that all of the

of the development process. required data is recorded is to prepare a diagram (Appendix

7.4 Static Water Levels—Measure and record the water level X1) or list of the pertinent data to be gathered in the field for

in the well to be slug tested before starting the tests. When each well tested. This will assure that consistent and complete

possible, monitor the water level over a period of time similar records are maintained.

to the duration of the slug test recovery. Measure and record 8. Procedures

the water level after testing is complete.

8.1 General—A typical field setup for pneumatic slug test-

7.5 Verify Development—Probably the most effective way to ing with a DP installed groundwater sampling tool is provided

verify that adequate development has been conducted on the in Fig. 5. Refer to this figure for clarification of the procedures

well is to run preliminary slug tests. In wells that recover discussed below.

quickly, running three preliminary slug tests performed with

the same initial head displacement are recommended. Plot the 8.2 Install Pneumatic Manifold—The pneumatic manifold is

recovery curves for visual inspection (Fig. 4) or view onscreen fitted to the well casing or DP drive rod to provide an airtight

if possible. When the well is adequately developed the initial fit. In some cases, adapters may be required to attach the

change in head (Ho) and the symmetry of the recovery curves pneumatic manifold to the casing. Use appropriate O-rings or

should be very similar. If preliminary slug tests of the same other materials to assure an airtight seal is obtained.

magnitude do not show a similar Ho and symmetry, further 8.3 Install Transducer—Insert transducer down the well or

development may be required. Verification of development in DP tool through airtight fitting on the manifold. Lower the

fine-grained formations will be time consuming. Project objec- transducer below the static water level to allow for temperature

tives and economics must be considered under these circum- equilibration. The transducer should be placed below the water

stances. level further than the water level will be lowered during the

NOTE 1—Replicate slug tests with approximately the same initial head value (Ho) performed through a single tube groundwater sampler at a depth of

28 m [91 ft] with 3 m [1 ft] of screen exposed to formation. Proportional peak height and symmetry of the recovery curves for these overdamped responses

indicate development is adequate and data quality acceptable.

FIG. 4 Replicate Slug Tests Displaying Overdamped Response

Copyright by ASTM Int'l (all rights reserved); 7

D7242/D7242M − 06 (2013)´1

NOTE 1—Appropriate development must be performed before slug tests

are conducted.

FIG. 5 Example of Field Setup Used for Performing a Pneumatic

Slug Test with a Direct Push Installed Groundwater Sampler

slug tests, usually 1 to 1.5 m [3 to 5 ft]. Critical early time data pressure (or vacuum) gauge on the pneumatic manifold to

will not be obtained if the water level is lowered below the determine when the desired water level change is obtained.

transducer during a slug test. Follow manufacturer’s recom- Adding more air (or increasing vacuum) incrementally may be

mendations to zero or set baseline on the transducer before done to obtain the desired initial head change value. Allow the

initiating tests. water level in the wellhead to stabilize before starting the slug

8.4 Data Acquisition—Attach transducer to data acquisition test. Initial head pressures that provide a water level change in

system. This system may be a simple data logger or analog- the range of 30 to 100 cm [1 to 3 ft] are generally recom-

to-digital (A-D) inverter and portable computer or other mended (Ref (1)). Larger head changes may be suitable for

appropriate system. Prepare system for acquisition of data under damped formations.

based on manufacturer’s recommendations. From preliminary

8.6 Leak Testing—Testing the pneumatic manifold and well

slug tests determine appropriate data acquisition rate to provide

acceptable data density for recovery rate of the well. For highly system for leaks is often done while conducting a preliminary

permeable aquifers, especially when oscillatory responses slug test. After pressurizing (or evacuating) the wellhead, the

occur, data acquisition rates of 5 to 10 Hz may be needed to air pressure inside the wellhead will drift back to an equilib-

provide sufficient data density for accurate modeling and curve rium point. Observe the pressure gauge on the pneumatic head

fitting. to determine when the pressure has stabilized. If the pressure in

the wellhead continues to drop (or rise) until it approaches

8.5 Pressurize (or Evacuate) Wellhead—Connect supply of

ambient air pressure then the system has a leak. Readjust

compressed air (or vacuum pump) to the inlet valve of the

pressure in the wellhead and use a suitable leak detection fluid

pneumatic manifold. Use pressure regulator or suitable valve to

regulate rate of airflow into the wellhead. Do not over to check each fitting for possible leaks. Make necessary

pressurize the wellhead. If air is injected into the formation, adjustments to eliminate leaks. Leaks may occur not only at the

non-representative results will occur during slug testing due to pneumatic head, but down hole. PVC casing joints may be

compressibility of air trapped in the formation. Observe the damaged, or O-rings may be missing. For DP tools, be sure to

Copyright by ASTM Int'l (all rights reserved); 8

D7242/D7242M − 06 (2013)´1

use O-rings on every rod connection and keep the tool string cm, 75 cm [10 in., 20 in., 30 in.] (1)). Visual inspection of peak

tightened as it is advanced to depth. height and symmetry should reveal all three to be proportional

8.7 Initiate Slug Test—Once the wellhead is pressurized (or (Fig. 7). If the peak height for the ~75 cm [~30 in.] slug test is

evacuated) to the desired level and the water level in the well proportionally small compared to the other tests, it suggests

has stabilized the pressure release valve on the pneumatic head that slug tests at the larger magnitude are not providing

is quickly and smoothly opened to start the slug test. The accurate responses. Recommend conducting a slug test of

duration required for recovery of the water level to its intermediate head (for example, 35 cm [15 in.]) to determine if

equilibrium level will depend on the transmissivity of the the slug test response over this smaller range is accurate.

screened formation, length and diameter of the screen and

8.9 Field Notes and Data Storage—Save electronic data

diameter of the casing where the water level change occurs.

files to diskettes, compact disks, etc. for storage and archival,

The duration of water level recovery is independent of the

magnitude of the initial change in the water level (Ho) used to label appropriately. Maintain complete and accurate field notes

induce the slug test. Pressurization and slug test recovery to document methods, field quality control, anomalous results

curves for a typical over damped slug test response may occur and any deviations from planned procedures.

in a matter of seconds (Fig. 4), minutes or even hours for

fine-grained formations. Under damped slug test responses 9. Report

(Fig. 6) are typical of high hydraulic conductivity formations 9.1 The following information should be included in the

and are often completed in less than a minute. field report. Much of this information is included on the

8.8 Field Quality Check—When duration of tests permit, a diagram in Appendix X1. Refer also to D5434 for further

minimum of three slug tests should be performed using the guidance and information.

same initial head displacement (for example, 50 cm [20 in.]) 9.1.1 Facility name, location and address information, site

(Ref (1)). Plot the results of the three tests, or observe contacts.

onscreen, and compare peak height and curve symmetry (Fig.

9.1.2 Well number, location, depth, and well construction

4). If all tests have very similar peak height and curve

information as listed in Appendix X1.

symmetry this suggests test results are repeatable and well

development adequate. For additional quality control in the 9.1.3 Names of drilling company, driller, helper, and field

field and during later data analysis, conduct tests with greater technician conducting the slug test.

and lesser head displacement values (for example, 25 cm, 50 9.1.4 File names of slug test data files.

NOTE 1—High hydraulic conductivity formations may yield an underdamped response to an instantaneous change in head resulting in an oscillatory

movement of water in the well. The slug tests in this figure were performed in a DP installed prepacked screen monitoring well with 13-mm [0.5-in.]

nominal casing diameter and effective screen length of 3-m [10-ft]. A sampling rate of 10 Hz was used to provide good definition of the aquifer response

so that curve fitting and determination of K could be done accurately. Visual inspection of peak height and curve symmetry for repeat tests may be used

to conduct field quality control.

FIG. 6 Slug Tests Displaying the Underdamped (Oscillatory) Response

Copyright by ASTM Int'l (all rights reserved); 9

D7242/D7242M − 06 (2013)´1

NOTE 1—A series of slug tests using different initial head values may be used in the field to provide a qualitative evaluation of the data and aquifer-well

system response. Visual inspection indicating proportional peak heights and symmetry of response curves suggests system response is linear over the

range of head values tested. See Fig. 8 for post acquisition QC measures.

FIG. 7 Proportional Response of Underdamped Slug Tests Conducted With Different Initial Head Values

9.1.5 Specifications of equipment used to conduct the slug Rc = actual measured radius of the casing (or drive rod)

test (transducer, data logger, screen specifications, DP ground- where the measured change in water level occurs

water sampler specifications, etc.). during the slug test, and

9.1.6 Rising head or falling head test, magnitude of head rt = actual measured radius of the transducer cable.

change used to initiate the test.

9.1.7 Recommend including copies of boring logs and well 10.2 Correction for Frictional Losses in High K Media—

construction logs and development logs for each well tested. Field research (Ref (8)) found that frictional losses became

9.1.8 Field notes completed as slug tests conducted. significant in smaller diameter casings (ID < 50 mm [2 in.])

9.1.9 Site-specific information relevant to the project. when under damped (oscillatory) responses were encountered.

Comparison of results with tests conducted in adjacent larger

10. Data Analysis Considerations diameter wells revealed that the frictional losses began to

10.1 Casing Radius Correction—When conducting slug appear when the formation hydraulic conductivity exceeded

tests in smaller diameter wells or DP tools (for example, ID < about 60 m/day [200 ft/day]. Additional analysis (Ref (9))

50 mm [2 in.]), the diameter of the transducer cable will resulted in development of a simple correction factor to

displace a significant proportion of the well volume. This will account for frictional losses in the smaller diameter casing. The

result in faster recovery of the water level and an error in the correction procedure for the calculation of hydraulic conduc-

determined K if the displaced volume is not corrected for tivity described therein should be followed when the casing

during calculation. To account for the volume displaced by the diameter is less than 50 mm [2 in.] and the hydraulic

transducer cable the casing radius is corrected as follows: conductivity exceeds 60 m/day [200 ft/day].

Rcc 5 ~ R 2c 2 r t2 ! 1/2 (1) 10.3 Analytical Models—Both formation conditions and the

where: type of slug test response obtained during the slug test will

determine the analytical model that should be used to calculate

Rcc = the corrected casing radius,

the formation hydraulic conductivity. Boring logs, CPT logs or

Copyright by ASTM Int'l (all rights reserved); 10

D7242/D7242M − 06 (2013)´1

similar information must be reviewed along with observed 11. Precision and Bias

water levels to determine if the aquifer is confined or uncon-

11.1 Precision—Test data on precision is not presented due

fined. Review of the slug test data plot will readily indicate if

to the nature of this test method. It is either not feasible or too

the aquifer response is over damped (for example, Fig. 4) or

costly at this time to have 10 or more agencies participate in an

under damped (for example, Fig. 6). This information is used

in situ testing program at a given site.

in conjunction with Guide D4043 to select the appropriate

analytical model for calculation of hydraulic conductivity or 11.2 The subcommittee (D18.21) is seeking any data from

transmissivity. A thorough review of analytical models used for the users of this test method that might be used to make a

determination of hydraulic conductivity is provided in Ref (1). limited statement on precision.

NOTE 1—Three slug tests were performed in the same well using

differing initial head values (see Fig. 7). Non-normalized plot (a) with

start times aligned shows time correlation of peaks and troughs with

different initial displacements. Normalized plot (b) demonstrates that for

the range of head values tested the system responds in a linear fashion and

therefore no bias of method over the range tested. These tests conducted

in a nominal 13-mm [0.5-in.] diameter PVC prepacked screen well with

3-m [10-ft] effective screen interval using pneumatic methods.

FIG. 8 Example of Post Acquisition Quality Control

Copyright by ASTM Int'l (all rights reserved); 11

D7242/D7242M − 06 (2013)´1

11.3 Slug tests conducted in situ in the field are generally field. However, some methods for qualitative evaluation of bias

regarded as providing semi quantitative estimates of transmis- may be applied, either in the field or later by comparison of

sivity and/or hydraulic conductivity. The results are usually data plots from replicate tests from the same well. Due to the

considered semi-quantitative because of the heterogeneous influence of scale (Ref (10)) it is generally not appropriate to

nature of almost all aquifers and natural formations. However, compare slug tests to pumping tests to assess bias.

methods do exist for qualitatively and quantitatively assessing Additionally, comparison of slug tests to laboratory tests for K

precision and bias for multiple slug tests conducted in a single on soil cores (for example, Test Methods D2434, D5084,

well using the same methods. D5856) is generally not effective. Again the influence of scale

11.4 Location Specific Precision—Precision of location spe- of measurement as well as laboratory and sampling procedures

cific slug tests may be evaluated on a qualitative level in the will result in differences in measured values of K between lab

field, and later, quantitatively during modeling and calcula- tests and slug tests often approaching an order of magnitude.

tions. Some lab procedures measure vertical K as compared to the

11.4.1 Precision in the Field is most often evaluated by horizontal K measured by slug tests. Other lab methods use

conducting several pneumatic slug tests initiated using the remolding of the sample that will change natural texture and

same initial head. Visual comparison is made of data plots from structure causing differences between the lab measurements

three or more slug tests initiated with the same initial head and field slug tests.

(Fig. 4). The initial change in the head for each test should be 11.5.2 A quality check may be performed for evaluation of

comparable. The rate of the water level recovery and the bias in the field by conducting three or more slug tests using

symmetry of the recovery curve should be similar for all the differing initial head values (Fig. 7, Fig. 8). Visual comparison

tests based on visual inspection of the data plots. If these of the data plots may be made in the field to determine if the

qualitative measures of precision are not met in the field, change in initial head used to start the tests results in a

corrective action should be considered. Most often the well is proportional change of response observed in the output data

redeveloped to remove a well skin or to remove mobile fines (Fig. 7). If the change in peak height from smaller to larger

from the screened interval in order to obtain repeatable results. initial head values is not proportional corrective measures

Note any anomalous slug test response in field notes and report should be considered. Additional well development may be

appropriately. required or the magnitude of head over which the tests are

11.4.2 Quantitative Precision—Precision may be quantita- conducted may need to be reduced. Use of large initial head

tively evaluated after the slug test response data are obtained. values in small diameter wells or groundwater samplers will

Results from three or more slug tests initiated with the same result in attenuation of response due to frictional losses in the

initial head may be plotted over each other for graphical well bore (Refs (8, 9)) causing a bias in the test result.

comparison. Furthermore, the appropriate analytical method

11.5.3 Results from repeat slug tests with differing initial

(Test Methods D4104, D5785, D5881, D5912, Refs (1, 3))

head values (Fig. 8a) (for example 25, 50, and 75 cm [10, 20,

should be used to calculate the hydraulic conductivity from

and 30 in.]) may be normalized (Ht/Ho) and plotted together

each repeat test conducted with the same initial head in one

well. The precision of the method may then be evaluated by (Fig. 8b) for a graphical evaluation of bias. When the aquifer

calculation of the percent relative standard deviation (%RSD) and well are responding appropriately the normalized results

between the calculated hydraulic conductivity values where: should closely overlay one another on the plot (Fig. 8b). This

indicates a lack of bias in the testing method under the existing

% RSD 5 @ $ ~ Sum~ x i 2 mean! 2 ! / ~ n 2 1 ! % /mean# 3 100 (2) aquifer and well conditions for the range of head values tested.

The percent relative standard deviation for slug tests con- Use of extremely large head values (2 to 3 m [5 to 10 ft]) will

ducted in the same well with the same initial head should not often result in nonlinear results (Ref (9)) when compared to

exceed 10 %. This assumes the slug tests are conducted over smaller head values, especially in aquifers that display oscil-

the same screen interval, applying the same method. latory responses to slug testing.

11.5 Bias—There is no accepted reference value for this test

method, therefore, bias cannot be determined. 12. Keywords

11.5.1 Unlike laboratory analytical methods, objective stan- 12.1 aquifer; direct push; hydraulic conductivity; pneu-

dards do not exist for (pneumatic) slug tests conducted in the matic; slug test

Copyright by ASTM Int'l (all rights reserved); 12

D7242/D7242M − 06 (2013)´1

APPENDIX

(Nonmandatory Information)

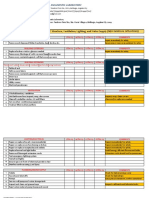

X1. SLUG TEST FIELD INFORMATION FORM FOR WELL CONSTRUCTION / WATER SAMPLER INSTALLATION

X1.1 See Fig. X1.1.

Copyright by ASTM Int'l (all rights reserved); 13

D7242/D7242M − 06 (2013)´1

Ho = Initial change in head at instant the slug test is started. For pneumatic slug tests, this may be estimated from the stabilized pressure (or vacuum)

gauge readout on the manifold just before the slug test is started.

h = Saturated thickness of aquifer.

Le = Effective screen length: This will include length of any artificial sand pack extending above the well screen.

Ls = True screen length. The length of slotted or perforated screen exposed to the formation.

Lw = Length of water column in the well (Lw = TD – SWL).

Rb = Radius of filter pack or borehole over the screen interval.

Rc = Casing radius. True internal radius of casing where the water level occurs.

Note—Casing radius must be constant over the interval where water level change occurs during the slug test. If the casing radius is not constant over this

interval, the rate of water level change observed by the transducer will be distorted causing errors in modeling and determination of aquifer parameters.

Rcc = (Rc2 – rt2)1/2 (Ref (8)). For wells or DP casing less than 25-mm [1-in.] radius the casing radius must be corrected for the radius of the transducer

cable. In smaller wells, the transducer cable begins to displace a significant volume and will result in increased rate of water level recovery. If not

accounted for this will cause a systematic error in calculation of aquifer parameters.

Rs = Screen radius. Radius of the slotted or perforated casing where water enters the well during the slug test.

rt = Radius of the transducer cable. Specifically, the radius of the cable over which the water level change occurs during the slug test.

SWL = Static water level. Water level in the undisturbed well at ambient atmospheric pressure.

TD = Total depth. Depth of well screen as measured from reference point at the surface.

Ts = Depth the transducer is submerged below the static water level.

Aquifer Type—Review sample cores, well and boring logs, and/or geophysical logs to determine if the aquifer is confined or unconfined.

Formation Type—Provide a verbal description of the formation material being slug tested (for example, clay, silt, sand, gravel, silty-sand, etc.). Best if this

description is based on a sample collected from the interval being tested.

NOTE 1—Not all parameters identified here are required for use with each model to calculate hydraulic conductivity.

FIG. X1.1 Slug Test Field Information Form for Well Construction / Water Sampler Installation

Copyright by ASTM Int'l (all rights reserved); 14

D7242/D7242M − 06 (2013)´1

REFERENCES

(1) Butler, Jr., J. J., The Design, Performance, and Analysis of Slug Tests, (6) Cain, S. F., Davis, G. A., Loheide, S. P., and Butler, Jr., J. J., “Noise

Lewis Publishers/CRC Press, Boca Raton, FL, 1998. in Pressure Transducer Readings Produced by Variations in Solar

(2) U.S. Environmental Protection Agency (EPA), Handbook of Sug- Radiation,” Ground Water, Vol 42, No. 6, November-December 2004,

gested Practices for the Design and Installation of Ground-Water pp. 939–944.

Monitoring Wells, EPA/600/4-89/034, March 1991. (7) McCall, W., Butler, Jr., J. J., Healey, J. M., Lanier, A. A., Sellwood, S.

(3) Butler, Jr., J. J., and Garnett, E. J., “Simple Procedures for Analysis of M., and Garnett, E. J., “A Dual-Tube Direct-Push Method for Vertical

Slug Tests in Formations of High Hydraulic Conductivity Using Profiling of Hydraulic Conductivity in Unconsolidated Formations,”

Spreadsheet and Scientific Graphics Software,” Kansas Geological Env. & Eng. GeoScience, Vol VIII, No. 2, May 2002, pp. 75–84.

Survey Open File Report (OFR) 2000-40. (www.kgs.ukans.edu/ (8) Butler, Jr., J. J., Healey, J. M., McCall, G. W., Garnett, E. J., and

hydro/publications/ofr00_40/index.html)

Loheide, S. P., “Hydraulic Tests with Direct Push Equipment,”

(4) Zheng, C., and Gorelick, S. M., “Analysis of Solute Transport in Flow

Ground Water, Vol 40, No. 1, January-February 2002, pp. 25–36.

Fields Influenced by Preferential Flowpaths at the Decimeter Scale,”

(9) Butler, Jr., J. J., “A Simple Correction for Slug Tests in Small-

Ground Water, Vol 41, No. 2, March-April 2003, pp. 142–155.

(5) Bright, J., Wang, F., and Close, M., “Influence of the Amount of Diameter Wells,” Ground Water, Vol 40, No. 3, 2002, pp. 303–307.

Available K Data on Uncertainty About Contaminant Transport (10) Sanchez-Vila, X., Carrera, J., and Girardi, J. P., “Scale Effects in

Prediction,” Ground Water, Vol 40, No. 5, September-October 2002, Transmissivity,” Journal of Hydrology, Vol 183, 1996, pp. 1–22.

pp. 529–534.

SUMMARY OF CHANGES

Committee D18 has identified the location of selected changes to this standard since the last issue (D7242 –

06) that may impact the use of this standard. (Approved Dec. 1, 2013.)

(1) Revised the standard into a dual measurement system with (2) Deleted reference to D4750, which has been withdrawn.

the units of measurement now stated in either inch-pound units

or SI units.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 15

You might also like

- Abrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method ForDocument7 pagesAbrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method FormickyfelixNo ratings yet

- Concrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForDocument9 pagesConcrete Made by Volumetric Batching and Continuous Mixing: Standard Specification Formickyfelix100% (2)

- Astm D 5030 - 04Document13 pagesAstm D 5030 - 04Pierre Moro VigoNo ratings yet

- Using Density To Determine The Sugar Content in Commercial BeveragesDocument12 pagesUsing Density To Determine The Sugar Content in Commercial BeveragesMax DornelesNo ratings yet

- Using The Seismic-Reflection Method For Shallow Subsurface InvestigationDocument26 pagesUsing The Seismic-Reflection Method For Shallow Subsurface InvestigationmickyfelixNo ratings yet

- Estimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsDocument5 pagesEstimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsmickyfelixNo ratings yet

- De Alba Et Al. - Determination of Soil Liquefaction Characteristics From Large Scale Laboratory TestsDocument169 pagesDe Alba Et Al. - Determination of Soil Liquefaction Characteristics From Large Scale Laboratory TestsAshishBastolaNo ratings yet

- (Field Procedure) For Instantaneous Change in Head (Slug) Tests For Determining Hydraulic Properties of AquifersDocument4 pages(Field Procedure) For Instantaneous Change in Head (Slug) Tests For Determining Hydraulic Properties of AquifersIngrid MoraNo ratings yet

- Part 2. Suggested Method For Determining Deformability of Rock Materials in Uniaxial CompressionDocument3 pagesPart 2. Suggested Method For Determining Deformability of Rock Materials in Uniaxial CompressionHatemNo ratings yet

- Measurement of Soil Potential (Suction) Using Filter Paper: Standard Test Method ForDocument8 pagesMeasurement of Soil Potential (Suction) Using Filter Paper: Standard Test Method ForDiego Lizana OlarteNo ratings yet

- Volpe 1979 - Physical and Engineering Properties of Copper Tailings (1979 Edition) - Open LibraryDocument2 pagesVolpe 1979 - Physical and Engineering Properties of Copper Tailings (1979 Edition) - Open LibraryRICARDO ANDRES MORGADO PIZARRONo ratings yet

- Triaxial Compression Test 1978Document5 pagesTriaxial Compression Test 1978Alejandro425No ratings yet

- RAM Instruction ManualDocument144 pagesRAM Instruction Manualsercopetrol100% (4)

- Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Ground Water SamplersDocument14 pagesField Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Ground Water SamplersJohnCarlosGilNo ratings yet

- Density of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsDocument7 pagesDensity of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsIonut VasilescuNo ratings yet

- Astm D2573 D2573M 15Document8 pagesAstm D2573 D2573M 15Wilson KoNo ratings yet

- In-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Document10 pagesIn-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Ramal ColeNo ratings yet

- Astm D 7070-04Document6 pagesAstm D 7070-04Pamela SanabriaNo ratings yet

- X-Field DataDocument49 pagesX-Field Datathe luminousNo ratings yet

- AstmDocument2 pagesAstmluchitopadilla100% (2)

- 2019 - 20 - B41FG - MSC OGT FDP - Design Basis PDFDocument16 pages2019 - 20 - B41FG - MSC OGT FDP - Design Basis PDFShamsiNo ratings yet

- Influence of Vane Size and Equipment On The Results in The Vane Shear TestDocument7 pagesInfluence of Vane Size and Equipment On The Results in The Vane Shear TestNabucodonosor1980No ratings yet

- Radial Basis Functions and Kriging - A Gold Case StudyDocument8 pagesRadial Basis Functions and Kriging - A Gold Case StudyHamid KorNo ratings yet

- Cyclic TriaxialDocument2 pagesCyclic TriaxialnkotiaNo ratings yet