Professional Documents

Culture Documents

AeroShell Fluid 41

AeroShell Fluid 41

Uploaded by

Pawang SingaCopyright:

Available Formats

You might also like

- Standard Operating Procedure For Signal DetectionDocument9 pagesStandard Operating Procedure For Signal Detectionboimzii100% (1)

- Sample Website Questions Frcem Sba Frcem ResourcesDocument4 pagesSample Website Questions Frcem Sba Frcem ResourcesmtogooNo ratings yet

- Polytechnic College of Davao Del Sur, Inc. Nursing DepartmentDocument58 pagesPolytechnic College of Davao Del Sur, Inc. Nursing DepartmentCA SavageNo ratings yet

- Datex-Ohmeda Tec7 - Service ManualDocument48 pagesDatex-Ohmeda Tec7 - Service ManualAlejandro Rios Lozano0% (1)

- PassportDocument2 pagesPassportAzat ZaripovNo ratings yet

- Aeroshell 41Document2 pagesAeroshell 41Farid SaadNo ratings yet

- Aeroshell Fluid 31Document2 pagesAeroshell Fluid 31mertaktayNo ratings yet

- Aeroshell Fluid 41Document2 pagesAeroshell Fluid 41S. MadaniNo ratings yet

- Aeroshell Fluid 3Document2 pagesAeroshell Fluid 3mertaktayNo ratings yet

- GPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFDocument2 pagesGPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFCesar Estrada Estrada MataNo ratings yet

- AeroShell Fluid 41 (India)Document3 pagesAeroShell Fluid 41 (India)Aaron ChanNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- AeroShell Fluid 4 Technical Datasheet - SCLDocument3 pagesAeroShell Fluid 4 Technical Datasheet - SCLabdul rehmanNo ratings yet

- Energol SHF-HV RangeDocument2 pagesEnergol SHF-HV RangeArthur Sanda LayukNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- Gulf Harmony AW 46 Data SheetDocument1 pageGulf Harmony AW 46 Data SheetRezaNo ratings yet

- Evolution Full-Tech Fe 5w-30 EngDocument1 pageEvolution Full-Tech Fe 5w-30 EngDaniel MartínNo ratings yet

- Rimula r2 0w 50Document2 pagesRimula r2 0w 50Aji WibowoNo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- HTS and HPC Specification DifferencesDocument11 pagesHTS and HPC Specification Differencesmohammed kareemNo ratings yet

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsmg kaungNo ratings yet

- Repsol Maker Hydraulico SC 46Document1 pageRepsol Maker Hydraulico SC 46ibrahim maulanaNo ratings yet

- Aero HF585BDocument2 pagesAero HF585BcarmaNo ratings yet

- PDS Castrol RLX Super 40Document2 pagesPDS Castrol RLX Super 40epesanoNo ratings yet

- 4454 Turbine Oil 46Document1 page4454 Turbine Oil 46AANo ratings yet

- 4454 Turbine Oil 46Document1 page4454 Turbine Oil 46AANo ratings yet

- Castrol Aircol SR RangeDocument2 pagesCastrol Aircol SR RangeJeremias UtreraNo ratings yet

- EfekDocument2 pagesEfekGasa RafliNo ratings yet

- Shell Turbo Oil T 100Document2 pagesShell Turbo Oil T 100Muhammad SaputraNo ratings yet

- Repsol DXR 8 - 1 v1 15w40Document1 pageRepsol DXR 8 - 1 v1 15w40thrharsrgNo ratings yet

- TDS - Advance 4T AX5 15W-40 (SLMA)Document2 pagesTDS - Advance 4T AX5 15W-40 (SLMA)hanafiajaNo ratings yet

- Shell Advance 4T AX7 10W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Advance 4T AX7 10W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsBernad BearNo ratings yet

- General: Ultra UTTO Is Manufactured From Premium Quality Hydro-Treated Base Oils, Which Contain Lower LevelsDocument2 pagesGeneral: Ultra UTTO Is Manufactured From Premium Quality Hydro-Treated Base Oils, Which Contain Lower LevelsPaul GuillaumeNo ratings yet

- Aeroshell Calibrating Fluid 2Document2 pagesAeroshell Calibrating Fluid 2Ricardo LacskoNo ratings yet

- MDS SHELL Turbo Oil T68Document2 pagesMDS SHELL Turbo Oil T68Antonio CardosoNo ratings yet

- Shell Turbo Oil T 68Document2 pagesShell Turbo Oil T 68Muhammad SaputraNo ratings yet

- Total Quartz 7000 SN 10w40-Product SepcDocument2 pagesTotal Quartz 7000 SN 10w40-Product SepcJematan BosiNo ratings yet

- TOTAL QUARTZ 7000 SN - Product Spec PDFDocument2 pagesTOTAL QUARTZ 7000 SN - Product Spec PDFdnoaisapsNo ratings yet

- Shell Advance 4T Ultra 10W-40Document2 pagesShell Advance 4T Ultra 10W-40Anonymous oAbjbl4HNo ratings yet

- Shell Caprinus XS9 40 (En) TDSDocument2 pagesShell Caprinus XS9 40 (En) TDSAnonymous oAbjbl4HNo ratings yet

- Shell Helix Ultra 5W-30: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Helix Ultra 5W-30: Performance, Features & Benefits Main ApplicationsCristiBvNo ratings yet

- Shell Helix Ultra Professional AJ-L 0W-20: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesShell Helix Ultra Professional AJ-L 0W-20: Main Applications Specifications, Approvals & RecommendationsMuhNo ratings yet

- Manual Z Long Life 75W80 TDSDocument2 pagesManual Z Long Life 75W80 TDSVusal HasanovNo ratings yet

- Aeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsyierbNo ratings yet

- PDS Perfecto XEPDocument3 pagesPDS Perfecto XEP邢焕震No ratings yet

- Shell Advance 4T AX5 10W-30 (SL/MA) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Advance 4T AX5 10W-30 (SL/MA) : Performance, Features & Benefits Specifications, Approvals & RecommendationsandriNo ratings yet

- PisssDocument1 pagePisssMie IkanNo ratings yet

- Shell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsVimal GopalakrishnanNo ratings yet

- TDS - Advance 4T AX5 10W-30 (SLMA)Document2 pagesTDS - Advance 4T AX5 10W-30 (SLMA)hanafiajaNo ratings yet

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 pageP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaNo ratings yet

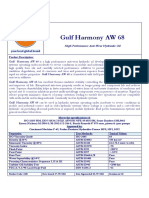

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- Techinical Data-Proton X70 DCT FluidDocument2 pagesTechinical Data-Proton X70 DCT Fluidjasonccw.pqholdingsNo ratings yet

- Total Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataDocument2 pagesTotal Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataAwais A.No ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- Castrol Alphasyn HTX Range: DescriptionDocument2 pagesCastrol Alphasyn HTX Range: DescriptionKurniawanNo ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangecarmaNo ratings yet

- Shell Rimula R2 Multi 25W-50Document2 pagesShell Rimula R2 Multi 25W-50Álgøkár ÁhmēdNo ratings yet

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsmanish mishraNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Cleaning - Condenser Module - Cooling Equipment: ReferencesDocument4 pagesCleaning - Condenser Module - Cooling Equipment: ReferencesPawang SingaNo ratings yet

- High Performance General Purpose Hydraulic OilDocument2 pagesHigh Performance General Purpose Hydraulic OilPawang SingaNo ratings yet

- BioborJF General InstructionsDocument3 pagesBioborJF General InstructionsPawang SingaNo ratings yet

- DEFSTAN 91-91-Issue 12-Sept 2020 Turbine Fuel Kerosine Type Jet A-1 NATO Code F-35 Joint Service Designation AVTURDocument51 pagesDEFSTAN 91-91-Issue 12-Sept 2020 Turbine Fuel Kerosine Type Jet A-1 NATO Code F-35 Joint Service Designation AVTURPawang SingaNo ratings yet

- TI - 02 - 01 - 00 Thermal Acoustic Insulation Blankets ReplacementDocument67 pagesTI - 02 - 01 - 00 Thermal Acoustic Insulation Blankets ReplacementPawang SingaNo ratings yet

- INTRO Level of Awarenesss of Filipino Mothers SAMPLESDocument6 pagesINTRO Level of Awarenesss of Filipino Mothers SAMPLESKathleen Joy Costales MagtanongNo ratings yet

- Fontes 2017Document10 pagesFontes 2017Larissa RezendeNo ratings yet

- Disaster Readiness and Risk Reduction: Quarter 1 - Module 3: Disasters and Its EffectsDocument16 pagesDisaster Readiness and Risk Reduction: Quarter 1 - Module 3: Disasters and Its EffectsKrystin DiamosNo ratings yet

- Basic Principles in Plastic Surgery (Surgical FlapsDocument17 pagesBasic Principles in Plastic Surgery (Surgical FlapsMs. Priya MahtoNo ratings yet

- Alternative Mod Ali Ties of CareDocument13 pagesAlternative Mod Ali Ties of Caremanu sethiNo ratings yet

- Human Capital NcertDocument17 pagesHuman Capital NcertYuvika BishnoiNo ratings yet

- Tomorrows Food, Tomorrows FarmsDocument16 pagesTomorrows Food, Tomorrows FarmsEmir DžinoNo ratings yet

- Homeroom Guidance Q4 - Module 15Document27 pagesHomeroom Guidance Q4 - Module 15Teacher Lii-Anne MagnoNo ratings yet

- DD Env 14237-2002Document24 pagesDD Env 14237-2002phuonghdNo ratings yet

- Timeline Kerja Tongkang Hull 139 (SM 339)Document1 pageTimeline Kerja Tongkang Hull 139 (SM 339)aditya kristantoNo ratings yet

- Operating Instruction DD 200 DD 250 02 EN Operating Instruction PUB 5245929 000Document39 pagesOperating Instruction DD 200 DD 250 02 EN Operating Instruction PUB 5245929 000Biprojit HoreNo ratings yet

- Animal Tissue Notes NiruDocument18 pagesAnimal Tissue Notes NirujnbjinjinNo ratings yet

- LIDZ THEODORE - A Psicosocial Orientation To Schizophrenic DisordersDocument9 pagesLIDZ THEODORE - A Psicosocial Orientation To Schizophrenic DisordersRodrigo G.No ratings yet

- Assessment of Dietary Pattern and Nutritional Status of Undergraduate Students in A Private University in Southern NigeriaDocument8 pagesAssessment of Dietary Pattern and Nutritional Status of Undergraduate Students in A Private University in Southern NigeriaSunita KarkiNo ratings yet

- Filtek Supreme XTEDocument6 pagesFiltek Supreme XTEOral CareNo ratings yet

- InsertDocument1 pageInsertAhmad Shafiq ZiaNo ratings yet

- Diagnosis and TreatmentDocument6 pagesDiagnosis and TreatmentVadim BulbakNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesMary Grace Delos SantosNo ratings yet

- Inclusive EducationDocument118 pagesInclusive EducationBelay KassahunNo ratings yet

- SMC Training Manual A4Document32 pagesSMC Training Manual A4vishal rohillaNo ratings yet

- Manav Mangal High School, Chandigarh Holiday Home Engagement AssignmentDocument46 pagesManav Mangal High School, Chandigarh Holiday Home Engagement AssignmentArshdeep singhNo ratings yet

- For Submission Research 1 BSOA A Group 4Document47 pagesFor Submission Research 1 BSOA A Group 4グレゴリオ ギナフェNo ratings yet

- 05 Maret 2020 UpDocument42 pages05 Maret 2020 UpMichelle Chia JungNo ratings yet

- DyslipidemiaDocument2 pagesDyslipidemiaapi-607717122No ratings yet

- Teen Sex Trafficking & Sexual Exploitation Awareness Brochure For School AdministrationDocument6 pagesTeen Sex Trafficking & Sexual Exploitation Awareness Brochure For School AdministrationmccaininstituteNo ratings yet

- Police Abolition 101Document40 pagesPolice Abolition 101Salome Cortes RoblesNo ratings yet

AeroShell Fluid 41

AeroShell Fluid 41

Uploaded by

Pawang SingaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AeroShell Fluid 41

AeroShell Fluid 41

Uploaded by

Pawang SingaCopyright:

Available Formats

Technical Data Sheet

AeroShell Fluid 41 (EU)

AeroShell Fluid 41 is a mineral hydraulic oil manufactured to a very high level of cleanliness, and possesses

improved fluid properties. AeroShell Fluid 41 contains additives which provide excellent low temperature fluidity

as well as exceptional anti-wear, oxidation - corrosion inhibition and shear stability. In addition metal de-activators

and foam inhibitors are included in this high viscosity index fluid to enhance performance in hydraulic

applications. AeroShell Fluid 41 is capable of wide temperature range operation.

AeroShell Fluid 41 is dyed red.

Main Applications Chlorinated solvents should not be used for cleaning

AeroShell Fluid 41 is intended as an hydraulic fluid in all hydraulic components which use AeroShell Fluid 41. The

modern aircraft applications requiring a mineral hydraulic residual solvent contaminates the hydraulic fluid and may

fluid. AeroShell Fluid 41 is particularly recommended where lead to corrosion.

use of a "superclean" fluid can contribute to improvements Due to its properties, it is also used in several industrial

in component reliability, and can be used in aircraft applications.

0 0

systems operating unpressurised between –54 C to 90 C

Specifications, Approvals & Recommendations

·

and pressurised between –540C to 1350C.

MIL-PRF-5606J

·

AeroShell Fluid 41 should be used in systems with

DEF STAN 91-48 Grade Superclean

synthetic rubber components and must not be used in

systems incorporating natural rubber. · COMAC QPL-CMS-OL-104

AeroShell Fluid 41 is compatible with AeroShell Fluids 4, · DCSEA 415/A (French)

31, 51, 61 and 71 and SSF/LGF. Meets DEF STAN 91-48 Grade Normal*

· Analogue to AMG-10 (Russian)

· NATO Code H-515 (equivalent H-520 normal grade)

· Joint Service Designation OM-15* (equivalent OM-18)

For a full listing of equipment approvals and

recommendations, please consult your local Shell Technical

Helpdesk.

Typical Physical Characteristics

Properties Method MIL-PRF-5606 J Typical

Oil Type Mineral Mineral

Kinematic viscosity @1000C mm2/s ASTM D445 4.90 minimum 5.30

Kinematic viscosity 0

@40 C mm /s2 ASTM D445 13.2 minimum 14.3

Kinematic viscosity @–40 C 0

mm /s2 ASTM D445 600 maximum 460

Kinematic viscosity @–54 C 0

mm /s2 ASTM D445 2 500 maximum 2 200

Flashpoint 0

C ASTM D93 82 minimum 95

Pour point 0

C ASTM D97 –60 maximum –60 maximum

Total acid number mgKOH/g ASTM D664 0.2 maximum 0.02

Evaporation loss 6 hrs 0

@71 C %m ASTM D972 20 maximum 15.4

Water content mg/kg ASTM D6304 100 maximum 75 maximum

Page 1 of 2 AeroShell Fluid 41 (EU), v 1.4 23.07.2021.07.31

Properties Method MIL-PRF-5606 J Typical

Relative density @15.6/15 ASTM D4052 Report 0.873

.60C

Colour ASTM D1500 Red Red

Particulate contamination, 5 to 15 µm FED-STD-791- 8 000 maximum 1 000

number of particles per 100 ml 3012

in size range

Particulate contamination, 16 to 25 µm FED-STD-791- 1425 maximum 1 000 maximum

number of particles per 100 ml 3012

in size range

Particulate contamination, 26 to 50 µm FED-STD-791- 253 maximum 150 maximum

number of particles per 100 ml 3012

in size range

Particulate contamination, 51 to 100 FED-STD-791- 45 maximum 20 maximum

number of particles per 100 ml µm 3012

in size range

Particulate contamination, over 100 FED-STD-791- 8 maximum 5 maximum

number of particles per 100 ml µm 3012

in size range

Particle Count Number SAE AS4059 5 5 maximum

Copper corrosion ASTM D130 2e maximum 2b

Steel on steel wear, scar diam mm ASTM D4172 1.0 maximum 0.6

Rubber swell, L rubber 168hrs % ASTM D4289 19.0 to 30.0 Passes

Low temperature stability 72 @–540C FED-STD-791- Must Pass Passes

hrs 3458

Gravimetric analysis mg/100mL ASTM D4898 1.0 maximum 0.2

Foaming tendency ASTM D892 Must Pass Passes

Barium content mg/kg ASTM D5185 10 maximum Nil

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,

variations in these characteristics may occur.

Health, Safety & Environment

· Health and Safety

This product is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Safety Data Sheet, which can be obtained from

https://www.epc.shell.com

· Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

· Advice

Advice on applications not covered here may be obtained from your Shell representative.

· *Superclean grades

The British specification DEF STAN 91-48 covers two grades (normal and superclean) of mineral hydraulic fluid which differ

only in their cleanliness limits. AeroShell Fluid 41 is manufactured to meet the superclean requirements and thus it also

meets the requirements of the normal grade.

Page 2 of 2 AeroShell Fluid 41 (EU), v 1.4 23.07.2021.07.31

You might also like

- Standard Operating Procedure For Signal DetectionDocument9 pagesStandard Operating Procedure For Signal Detectionboimzii100% (1)

- Sample Website Questions Frcem Sba Frcem ResourcesDocument4 pagesSample Website Questions Frcem Sba Frcem ResourcesmtogooNo ratings yet

- Polytechnic College of Davao Del Sur, Inc. Nursing DepartmentDocument58 pagesPolytechnic College of Davao Del Sur, Inc. Nursing DepartmentCA SavageNo ratings yet

- Datex-Ohmeda Tec7 - Service ManualDocument48 pagesDatex-Ohmeda Tec7 - Service ManualAlejandro Rios Lozano0% (1)

- PassportDocument2 pagesPassportAzat ZaripovNo ratings yet

- Aeroshell 41Document2 pagesAeroshell 41Farid SaadNo ratings yet

- Aeroshell Fluid 31Document2 pagesAeroshell Fluid 31mertaktayNo ratings yet

- Aeroshell Fluid 41Document2 pagesAeroshell Fluid 41S. MadaniNo ratings yet

- Aeroshell Fluid 3Document2 pagesAeroshell Fluid 3mertaktayNo ratings yet

- GPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFDocument2 pagesGPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFCesar Estrada Estrada MataNo ratings yet

- AeroShell Fluid 41 (India)Document3 pagesAeroShell Fluid 41 (India)Aaron ChanNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- AeroShell Fluid 4 Technical Datasheet - SCLDocument3 pagesAeroShell Fluid 4 Technical Datasheet - SCLabdul rehmanNo ratings yet

- Energol SHF-HV RangeDocument2 pagesEnergol SHF-HV RangeArthur Sanda LayukNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- Gulf Harmony AW 46 Data SheetDocument1 pageGulf Harmony AW 46 Data SheetRezaNo ratings yet

- Evolution Full-Tech Fe 5w-30 EngDocument1 pageEvolution Full-Tech Fe 5w-30 EngDaniel MartínNo ratings yet

- Rimula r2 0w 50Document2 pagesRimula r2 0w 50Aji WibowoNo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- HTS and HPC Specification DifferencesDocument11 pagesHTS and HPC Specification Differencesmohammed kareemNo ratings yet

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsmg kaungNo ratings yet

- Repsol Maker Hydraulico SC 46Document1 pageRepsol Maker Hydraulico SC 46ibrahim maulanaNo ratings yet

- Aero HF585BDocument2 pagesAero HF585BcarmaNo ratings yet

- PDS Castrol RLX Super 40Document2 pagesPDS Castrol RLX Super 40epesanoNo ratings yet

- 4454 Turbine Oil 46Document1 page4454 Turbine Oil 46AANo ratings yet

- 4454 Turbine Oil 46Document1 page4454 Turbine Oil 46AANo ratings yet

- Castrol Aircol SR RangeDocument2 pagesCastrol Aircol SR RangeJeremias UtreraNo ratings yet

- EfekDocument2 pagesEfekGasa RafliNo ratings yet

- Shell Turbo Oil T 100Document2 pagesShell Turbo Oil T 100Muhammad SaputraNo ratings yet

- Repsol DXR 8 - 1 v1 15w40Document1 pageRepsol DXR 8 - 1 v1 15w40thrharsrgNo ratings yet

- TDS - Advance 4T AX5 15W-40 (SLMA)Document2 pagesTDS - Advance 4T AX5 15W-40 (SLMA)hanafiajaNo ratings yet

- Shell Advance 4T AX7 10W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Advance 4T AX7 10W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsBernad BearNo ratings yet

- General: Ultra UTTO Is Manufactured From Premium Quality Hydro-Treated Base Oils, Which Contain Lower LevelsDocument2 pagesGeneral: Ultra UTTO Is Manufactured From Premium Quality Hydro-Treated Base Oils, Which Contain Lower LevelsPaul GuillaumeNo ratings yet

- Aeroshell Calibrating Fluid 2Document2 pagesAeroshell Calibrating Fluid 2Ricardo LacskoNo ratings yet

- MDS SHELL Turbo Oil T68Document2 pagesMDS SHELL Turbo Oil T68Antonio CardosoNo ratings yet

- Shell Turbo Oil T 68Document2 pagesShell Turbo Oil T 68Muhammad SaputraNo ratings yet

- Total Quartz 7000 SN 10w40-Product SepcDocument2 pagesTotal Quartz 7000 SN 10w40-Product SepcJematan BosiNo ratings yet

- TOTAL QUARTZ 7000 SN - Product Spec PDFDocument2 pagesTOTAL QUARTZ 7000 SN - Product Spec PDFdnoaisapsNo ratings yet

- Shell Advance 4T Ultra 10W-40Document2 pagesShell Advance 4T Ultra 10W-40Anonymous oAbjbl4HNo ratings yet

- Shell Caprinus XS9 40 (En) TDSDocument2 pagesShell Caprinus XS9 40 (En) TDSAnonymous oAbjbl4HNo ratings yet

- Shell Helix Ultra 5W-30: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Helix Ultra 5W-30: Performance, Features & Benefits Main ApplicationsCristiBvNo ratings yet

- Shell Helix Ultra Professional AJ-L 0W-20: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesShell Helix Ultra Professional AJ-L 0W-20: Main Applications Specifications, Approvals & RecommendationsMuhNo ratings yet

- Manual Z Long Life 75W80 TDSDocument2 pagesManual Z Long Life 75W80 TDSVusal HasanovNo ratings yet

- Aeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsyierbNo ratings yet

- PDS Perfecto XEPDocument3 pagesPDS Perfecto XEP邢焕震No ratings yet

- Shell Advance 4T AX5 10W-30 (SL/MA) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Advance 4T AX5 10W-30 (SL/MA) : Performance, Features & Benefits Specifications, Approvals & RecommendationsandriNo ratings yet

- PisssDocument1 pagePisssMie IkanNo ratings yet

- Shell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsVimal GopalakrishnanNo ratings yet

- TDS - Advance 4T AX5 10W-30 (SLMA)Document2 pagesTDS - Advance 4T AX5 10W-30 (SLMA)hanafiajaNo ratings yet

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 pageP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaNo ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- Techinical Data-Proton X70 DCT FluidDocument2 pagesTechinical Data-Proton X70 DCT Fluidjasonccw.pqholdingsNo ratings yet

- Total Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataDocument2 pagesTotal Quartz 5000 SN 10W-40 15W-40 15W-50 20W50: Key DataAwais A.No ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- Castrol Alphasyn HTX Range: DescriptionDocument2 pagesCastrol Alphasyn HTX Range: DescriptionKurniawanNo ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangecarmaNo ratings yet

- Shell Rimula R2 Multi 25W-50Document2 pagesShell Rimula R2 Multi 25W-50Álgøkár ÁhmēdNo ratings yet

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsmanish mishraNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Cleaning - Condenser Module - Cooling Equipment: ReferencesDocument4 pagesCleaning - Condenser Module - Cooling Equipment: ReferencesPawang SingaNo ratings yet

- High Performance General Purpose Hydraulic OilDocument2 pagesHigh Performance General Purpose Hydraulic OilPawang SingaNo ratings yet

- BioborJF General InstructionsDocument3 pagesBioborJF General InstructionsPawang SingaNo ratings yet

- DEFSTAN 91-91-Issue 12-Sept 2020 Turbine Fuel Kerosine Type Jet A-1 NATO Code F-35 Joint Service Designation AVTURDocument51 pagesDEFSTAN 91-91-Issue 12-Sept 2020 Turbine Fuel Kerosine Type Jet A-1 NATO Code F-35 Joint Service Designation AVTURPawang SingaNo ratings yet

- TI - 02 - 01 - 00 Thermal Acoustic Insulation Blankets ReplacementDocument67 pagesTI - 02 - 01 - 00 Thermal Acoustic Insulation Blankets ReplacementPawang SingaNo ratings yet

- INTRO Level of Awarenesss of Filipino Mothers SAMPLESDocument6 pagesINTRO Level of Awarenesss of Filipino Mothers SAMPLESKathleen Joy Costales MagtanongNo ratings yet

- Fontes 2017Document10 pagesFontes 2017Larissa RezendeNo ratings yet

- Disaster Readiness and Risk Reduction: Quarter 1 - Module 3: Disasters and Its EffectsDocument16 pagesDisaster Readiness and Risk Reduction: Quarter 1 - Module 3: Disasters and Its EffectsKrystin DiamosNo ratings yet

- Basic Principles in Plastic Surgery (Surgical FlapsDocument17 pagesBasic Principles in Plastic Surgery (Surgical FlapsMs. Priya MahtoNo ratings yet

- Alternative Mod Ali Ties of CareDocument13 pagesAlternative Mod Ali Ties of Caremanu sethiNo ratings yet

- Human Capital NcertDocument17 pagesHuman Capital NcertYuvika BishnoiNo ratings yet

- Tomorrows Food, Tomorrows FarmsDocument16 pagesTomorrows Food, Tomorrows FarmsEmir DžinoNo ratings yet

- Homeroom Guidance Q4 - Module 15Document27 pagesHomeroom Guidance Q4 - Module 15Teacher Lii-Anne MagnoNo ratings yet

- DD Env 14237-2002Document24 pagesDD Env 14237-2002phuonghdNo ratings yet

- Timeline Kerja Tongkang Hull 139 (SM 339)Document1 pageTimeline Kerja Tongkang Hull 139 (SM 339)aditya kristantoNo ratings yet

- Operating Instruction DD 200 DD 250 02 EN Operating Instruction PUB 5245929 000Document39 pagesOperating Instruction DD 200 DD 250 02 EN Operating Instruction PUB 5245929 000Biprojit HoreNo ratings yet

- Animal Tissue Notes NiruDocument18 pagesAnimal Tissue Notes NirujnbjinjinNo ratings yet

- LIDZ THEODORE - A Psicosocial Orientation To Schizophrenic DisordersDocument9 pagesLIDZ THEODORE - A Psicosocial Orientation To Schizophrenic DisordersRodrigo G.No ratings yet

- Assessment of Dietary Pattern and Nutritional Status of Undergraduate Students in A Private University in Southern NigeriaDocument8 pagesAssessment of Dietary Pattern and Nutritional Status of Undergraduate Students in A Private University in Southern NigeriaSunita KarkiNo ratings yet

- Filtek Supreme XTEDocument6 pagesFiltek Supreme XTEOral CareNo ratings yet

- InsertDocument1 pageInsertAhmad Shafiq ZiaNo ratings yet

- Diagnosis and TreatmentDocument6 pagesDiagnosis and TreatmentVadim BulbakNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesMary Grace Delos SantosNo ratings yet

- Inclusive EducationDocument118 pagesInclusive EducationBelay KassahunNo ratings yet

- SMC Training Manual A4Document32 pagesSMC Training Manual A4vishal rohillaNo ratings yet

- Manav Mangal High School, Chandigarh Holiday Home Engagement AssignmentDocument46 pagesManav Mangal High School, Chandigarh Holiday Home Engagement AssignmentArshdeep singhNo ratings yet

- For Submission Research 1 BSOA A Group 4Document47 pagesFor Submission Research 1 BSOA A Group 4グレゴリオ ギナフェNo ratings yet

- 05 Maret 2020 UpDocument42 pages05 Maret 2020 UpMichelle Chia JungNo ratings yet

- DyslipidemiaDocument2 pagesDyslipidemiaapi-607717122No ratings yet

- Teen Sex Trafficking & Sexual Exploitation Awareness Brochure For School AdministrationDocument6 pagesTeen Sex Trafficking & Sexual Exploitation Awareness Brochure For School AdministrationmccaininstituteNo ratings yet

- Police Abolition 101Document40 pagesPolice Abolition 101Salome Cortes RoblesNo ratings yet