Professional Documents

Culture Documents

Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main Motor

Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main Motor

Uploaded by

Ricardo NapitupuluOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main Motor

Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main Motor

Uploaded by

Ricardo NapitupuluCopyright:

Available Formats

JOB TITLE : LPG Train-4 Project CONTRACT NO.

CA/CSPD/0009

OWNER : Kuwait National Petroleum Company DIC JOB NO. : 090768

VP-15-109-001-A01-P-237-

VENDOR : DONGYANG CHEMICAL PUMP CO., LTD. DOC. NO. :

004A/B/C-D-008

P/O NO. : 090768-15-109-001-A01 ITEM NO. : P-237-004A/B/C

KNPC LPG Train-4 Project at MAA Refinery

DOCUMENT TITLE : DATA SHEET FOR MAIN MOTOR

ISSUED

JUL.09, 2012

FOR APPROVAL DONDYANG

CHEMICAL

PUMP CO.LTD.

DAELIM INDUSTRIAL CO., LTD.

JOB NO. : 090768

A1 - APPROVED

A2 - APPROVED AS NOTED

A3 - RETURN FOR CORRECTION

NA - NOT APPLICABLE

SIGNED BY : DATE

DAELIM PERMISSION TO PROCEED OR REVIEW TAKEN ON VENDOR

PRINTS SHALL NOT RELIEVE VENDOR FROM ITS RESPONSIBILITIES

OR LIABILITIES UNDER THE PURCHASE ORDER.

TOTAL 5 PAGES

1 Jul. / 09/ 12 For Approval PARK NAMGUNG MIN

0 Jul / 01/ 11 For Approval HWANG NAMGUNG MIN

REV. DATE DESCRIPTION PREPARED REVIEWED APPROVED

Page 1 OF 4

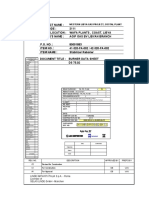

LPG TRAIN - 4 PROJECT Project No. 090768

Data / requisition sheet for Unit No. 237

Induction Motors Cage Type Revision No. 3

Doc. No. S090768.237-3.58-504-A-E

1 Applicable To : Proposal 5 Unit : 237 3

Purchase Final 6 Quantity : ONE(1) 3

2 Driven Equipment : PUMP 7 Item No. : P-237-00C-M 3

3 Site : Kuwait

4 Motor Manufacturer : ABB 3

NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER ; BY MANUFACTURER

MOTOR DESIGN DATA INSTALLATION DATA

9 Capacity : 1153 Nameplate HP (860kW) 28 Installation : Indoor Outdoor 3

10 Supply : Volts 3300 Phase 3 Hertz 50 29 Atmosphere : Corrosive

11 Speed : 3000 Synchronous RPM Other

2981 Full load RPM 30 Ambient Temperature :

12 Rotation Sense: CCW Max 82 oC (under shade 54.5 °C) Min -3 o

C

Facing opposite drive end CW 31 Area Classification :

13 Working Duty: Non-classified Cl. T3

Intermittent Continuous Gr IIA Div. Zone 2 (NEC-500)

14 Service factor 1.0 32 Maximum noise level 80(+3) dB (A)

15 Degree of Protection IP 55 33 Unusual condition : Dust Fumes 3

16 Motor Type: 34 Coupling Type: Direct Belt drive

Squirrel cage Wound rotor Reduction gear Others

17 Insulation class :F NEMA IEC Half-coupling supplied by: 3

Temperature rise :B above 35 3

18 Locked rotor current 5.9 MOTOR MANUFACTURER'S DATA

and/or code letter (not more than) G 36 Type/model offered : AMI 450

19 Locked rotor starting time 3.8 sec 37 Manufacturer Purchase Order no. :

CONSTRUCTION DATA 38 Serial no. :

20 Mounting Horizontal 39 Motor Dwg. no. :

Vertical 40 Standard/norms : IEC

21 Enclosure TEFC TENAC 41 Frame size : 450(IEC) NEMA Design

Explosion-proof TECAC CACA (TEAAC) 42 Load (Rated Volts) 1/2 3/4 FL SF

Forced ventilated Open-drip proof Efficiency 94 1

94.1 95 2

95.2 95 5

95.5

Weather protected Power factor 0.78 0.85 0.87

1

22 Bearing type Sleeve bearing - self lubricated Current 103 A 140 A 181 A A

43 Starting Condition:

23 Lubrication system: Direct Auto-transformer 3

Forced Independent Other Star-delta

Lubricating material: 44 Torques Lb-ft:

Grease Oil Full load 2754Nm Locked rotor 0.6 3

Characteristic or type: Breakdown 2.6 Pull-up 0.6

Pressure PSIG Flow GPM 45 Vibration NEMA Std.

24 Cooling system: Natural Other Reduced vibration

w/ Fan Forced 46 Locked rotor power factor : later

Cooling fluids : Air Water 47 Number of consecutive starts; nos./hr (cold) : 2

Temperatures : Inlet deg C 48 Number of consecutive starts; nos./hr (hot) : 3

Outlet deg C 49 Recommended cool-down time later

Pressure PSIG after third start : later sec

Flow GPM 50 Rotor moment of inertia (wk 2) : 11kgm

Heat exchanger : Yes No 51 Locked rotor withstand time:

25 Cable Type Gland Motor cold (50oC ambient) : later sec

Cable Size Please inform Motor hot (full load temp) : later sec

26 Stator winding: Delta Star 52 Locked rotor current at: 3

Series/parallel 50% voltage : later A

27 Finish color Light Gray (Munsel No. 7) 75% voltage : later A

100% voltage : later A

ITEM NO. P-237-004C-M SERVICE Motor for P-237-004C

NO. OF REQUIREMENT ONE(1)

Page 2 OF 4

LPG TRAIN - 4 PROJECT Project No. 090768

Data / requisition sheet for Unit No. 237

Induction Motors Cage Type Revision No. 3

Doc. No. S090768.237-3.58-504-A-E

MOTOR MANUFACTURER'S DATA (CONTINUED)

OTHER REQUIREMENTS

53 Acceleration time: 76 Shaft design for torsional analysis

Motor only rated volts : 3.8 sec 77 Axial tolerance

Motor load 80% volts : 8.4 sec 78 Stress: Axial Lb Radial Lb

54 Proposed temperature class : T3 79 Terminal box thread size:

55 Maximum noise level proposed : 80+3 dB (A) 80 Curves required based on motor

56 Dimensions: saturation at rated voltage

Shaft Dia. later inches Key later inches Speed vs torque (also rated voltage)

57 Weight total 4120 Rotor 780 Speed vs power factor

58 Maximum moment on base later Lb-ft. Speed vs current

59 End play later Speed vs time (acceleration)

60 Terminal box fault withstand MVA/sec later Time vs current (heating curve)

ACCESSORY EQUIPMENT SHOP INSPECTION & TESTS

o Required Witness

61 Space heaters Max. sheath C 81

400 watts 230 volts 3 phase 50 hertz Yes No 1

62 Main terminal box size for: High voltage test plus

Main motor load later insulation resistance test

Stress cones later Measurement of:

63 Winding temperature detectors - No-load current

RTD: 6pcs PT100 No./phase 2 - Locked rotor current

PT:100 ohms at oC - Winding resistance

64 Thermocouple No./phase - Slip at load

Type - Torque at load

65 Thermistors No./phase - Starting torque

66 Thermal temperature switch: No./phase - Efficiency & power

N.O. contact factor

N.C. contact - Power factor at starting

67 Bearing temperature devices RTD's - Heat run test

Thermocouple type Alarm contacts - Vibration test at

Dial type thermometers full speed

o o

Set later C Alarm later C S/D - Noise level test

68 Differential protection NOTE

Neutral terminal box sized for CT 1. Inspection and Tests shall meet the requirements of “General

CT (by others) description Inspection requirement LPG4-PGP-007” as a minimum.

69

70 Vibration devices

Process drilling only

Process Installed: Type

Switch Manual reset

Electrical reset

71

72

73

74

75

ITEM NO. P-237-004C-M SERVICE Motor for P-237-004C

NO. OF REQUIREMENT ONE(1)

You might also like

- Boiler Performance Test Report Rev0Document73 pagesBoiler Performance Test Report Rev0mvrk19650% (1)

- 1005 0 Installation ManualDocument65 pages1005 0 Installation ManualKhaledNo ratings yet

- Lube Oil Flushing ProcedureDocument18 pagesLube Oil Flushing ProcedureKevin Chen100% (2)

- Visual Inspection ReportDocument5 pagesVisual Inspection ReportOmar WardehNo ratings yet

- Vv216a-109-A-808 - 07 - 0001 - Bolt Tightening ProcedureDocument17 pagesVv216a-109-A-808 - 07 - 0001 - Bolt Tightening Proceduretonful143No ratings yet

- Pompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM BatulicinDocument124 pagesPompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM Batulicinmuh_akbar2451No ratings yet

- Gulf Oil Corporate Presentation PPTDocument34 pagesGulf Oil Corporate Presentation PPTdpomah100% (1)

- Vp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpDocument9 pagesVp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpRicardo NapitupuluNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDocument3 pagesVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNo ratings yet

- Vp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Document2 pagesVp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Ricardo NapitupuluNo ratings yet

- TP-WMS-05969-DAS-A4-D1-K - Demulsifier DatasheetDocument9 pagesTP-WMS-05969-DAS-A4-D1-K - Demulsifier Datasheetbmanojkumar16No ratings yet

- MAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)Document16 pagesMAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)fendi zulfiantoNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDocument4 pagesVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.ADocument5 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.Asumit kumarNo ratings yet

- FLS 2290 Me Das 002 - 1 DDocument16 pagesFLS 2290 Me Das 002 - 1 Dcristiangarrido1984No ratings yet

- DatasheetDocument71 pagesDatasheetRhadityo Shakti BudimanNo ratings yet

- Vendor Document Epc CPF Phase 2Document9 pagesVendor Document Epc CPF Phase 2Mohammed AbdallaNo ratings yet

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNo ratings yet

- 16 Vacuum Pump System DescriptionDocument9 pages16 Vacuum Pump System DescriptionnodalpcrktpsNo ratings yet

- P-09 CurveDocument3 pagesP-09 CurvemohamedNo ratings yet

- Qc-Sop-0 - Drilling of PoleDocument7 pagesQc-Sop-0 - Drilling of PoleAmeerHamzaWarraichNo ratings yet

- Volume3A Mech PDFDocument321 pagesVolume3A Mech PDFSayee Krishnan100% (1)

- Standard Inspection and Test Plan ITP No: 904 Emergency Diesel GeneratorDocument5 pagesStandard Inspection and Test Plan ITP No: 904 Emergency Diesel GeneratorZaid RNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- Discipline: Rev. No.: Size: Document No.: Unit / Area NameDocument5 pagesDiscipline: Rev. No.: Size: Document No.: Unit / Area NameRishabh VermaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Data Sheet For Transfer Pump Motor For Vacuum Deaeration PackageDocument10 pagesData Sheet For Transfer Pump Motor For Vacuum Deaeration PackageHashmi ShahidNo ratings yet

- MC 10171648 9999Document3 pagesMC 10171648 9999Toni SalonenNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Test Report - Coating Thickness Measurement: Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.LDocument3 pagesTest Report - Coating Thickness Measurement: Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.Lm.aliNo ratings yet

- Heat Loss Calculation-R0Document5 pagesHeat Loss Calculation-R0Omar Mostafa Hussien ヅNo ratings yet

- 2979 - API 677DATA SHEET - HRSG BFP Gear Box Data Sheet - GGSR - Approved - dt100909Document3 pages2979 - API 677DATA SHEET - HRSG BFP Gear Box Data Sheet - GGSR - Approved - dt100909Krishnan NatarajanNo ratings yet

- Compressor Data Sheet Rev3 - Updated by EFXDocument9 pagesCompressor Data Sheet Rev3 - Updated by EFXmanuNo ratings yet

- QAP With Covering Letter - 29112022Document4 pagesQAP With Covering Letter - 29112022PRASHANTNo ratings yet

- 17 CHEMICAL fEED sYSTEMDocument13 pages17 CHEMICAL fEED sYSTEMnodalpcrktpsNo ratings yet

- 3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedDocument2 pages3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedFomaa ElsayedNo ratings yet

- PM210012 LTG520 OI3 00012 - Rev04Document11 pagesPM210012 LTG520 OI3 00012 - Rev04Pandiaraj VNo ratings yet

- Siemens MotorDocument7 pagesSiemens MotorsajidkaleemNo ratings yet

- Zi Gam02 U4839 Dts en 001 WiproDocument4 pagesZi Gam02 U4839 Dts en 001 Wiprosantoshkumarnavik264No ratings yet

- 094135-VP-N2-GE-DAS-001-001 DatasheetDocument4 pages094135-VP-N2-GE-DAS-001-001 Datasheetphuoc leNo ratings yet

- PDI_TAFE_MF_241_B1_715_PT_No.-1421P00403Document32 pagesPDI_TAFE_MF_241_B1_715_PT_No.-1421P00403dvijayan004No ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- Code A: West Qurna I Section 1Document6 pagesCode A: West Qurna I Section 1jacksonbello34No ratings yet

- FM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetDocument8 pagesFM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetAmr TarekNo ratings yet

- Attachmnet-7 Vendor-Coversheet QAPDocument2 pagesAttachmnet-7 Vendor-Coversheet QAPPRASHANTNo ratings yet

- RFX 2332301326Document2 pagesRFX 2332301326Mena KamelNo ratings yet

- 75kw Bom Train A - A1, A2 Train-B b1, b2 - Revb1Document8 pages75kw Bom Train A - A1, A2 Train-B b1, b2 - Revb1projectNo ratings yet

- 03.23 - ME & AE FO Supply PumpDocument2 pages03.23 - ME & AE FO Supply PumpKANISHK KOHLINo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Vendor PrintDocument3 pagesVendor PrintEurotech Tra TranNo ratings yet

- PE-D-ROPJD124227008-IN-DAS-003-05-E - Flow Counter - DatasheetsDocument2 pagesPE-D-ROPJD124227008-IN-DAS-003-05-E - Flow Counter - Datasheetstravel for photoNo ratings yet

- Fire Pump Proposal Summary: WeightDocument3 pagesFire Pump Proposal Summary: WeightDerkung Benowat100% (1)

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- ATA 79 ENG MCD Installation ProcedureDocument6 pagesATA 79 ENG MCD Installation Procedureanarko arsipelNo ratings yet

- 2.1 Mechanical Datasheet For Air Compressor SkidDocument8 pages2.1 Mechanical Datasheet For Air Compressor SkidTrung Trinh BaoNo ratings yet

- Pipes Backfilling Release Check List 2inch Air LineDocument1 pagePipes Backfilling Release Check List 2inch Air LineAnwar QaisNo ratings yet

- Test Package - 0063-003Document24 pagesTest Package - 0063-003qamar qateebNo ratings yet

- Idg PDFDocument8 pagesIdg PDFKunwar SinghNo ratings yet

- BFW Cooler Datasheet Rev 2Document3 pagesBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNo ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- It - PT - Asme - 01 - Rev 00Document16 pagesIt - PT - Asme - 01 - Rev 00Ricardo NapitupuluNo ratings yet

- Vp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Document2 pagesVp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Ricardo NapitupuluNo ratings yet

- Leak Test Procedure of Atmospheric VesselDocument9 pagesLeak Test Procedure of Atmospheric VesselRicardo NapitupuluNo ratings yet

- Daily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographDocument1 pageDaily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographRicardo NapitupuluNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpDocument9 pagesVp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpRicardo NapitupuluNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDocument4 pagesVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDocument3 pagesVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNo ratings yet

- MKM-PM-PID-02 - Piping Instrument Diagram Evaporator - R0Document1 pageMKM-PM-PID-02 - Piping Instrument Diagram Evaporator - R0Ricardo NapitupuluNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvDocument3 pagesVp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvRicardo NapitupuluNo ratings yet

- SN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Document4 pagesSN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Ricardo NapitupuluNo ratings yet

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Document7 pagesAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNo ratings yet

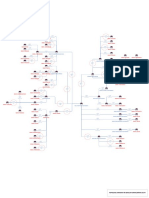

- Topologi Jaringan 49 Sekolah Sman/Smkn Se DiyDocument2 pagesTopologi Jaringan 49 Sekolah Sman/Smkn Se DiyRicardo NapitupuluNo ratings yet

- S Curve Instrument CepuDocument1 pageS Curve Instrument CepuRicardo NapitupuluNo ratings yet

- 6 BLP Spesifikasi Teknis 49 SMA 14920Document6 pages6 BLP Spesifikasi Teknis 49 SMA 14920Ricardo NapitupuluNo ratings yet

- PLD - Shelter - 30 11 2020Document3 pagesPLD - Shelter - 30 11 2020Ricardo NapitupuluNo ratings yet

- Support and Non Pressure Part Calculation of Foul ProductionDocument34 pagesSupport and Non Pressure Part Calculation of Foul ProductionRicardo NapitupuluNo ratings yet

- Eng - M - Lifting Lug Cal - 2Document6 pagesEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNo ratings yet

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceDocument1,274 pagesThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceRicardo NapitupuluNo ratings yet

- Nm-Dairy Planning Data SheetDocument16 pagesNm-Dairy Planning Data SheetRicardo NapitupuluNo ratings yet

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandDocument295 pagesThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandRicardo NapitupuluNo ratings yet

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainDocument228 pagesThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainRicardo NapitupuluNo ratings yet

- API Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsDocument5 pagesAPI Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsRicardo NapitupuluNo ratings yet

- B-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantDocument3 pagesB-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantRicardo NapitupuluNo ratings yet

- Chapter 13. Fire Severity Calculations: Input ParametersDocument20 pagesChapter 13. Fire Severity Calculations: Input ParametersRicardo NapitupuluNo ratings yet

- Chapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeDocument6 pagesChapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeRicardo NapitupuluNo ratings yet

- AT03081Document11 pagesAT03081Jackson PhinniNo ratings yet

- Details of Purchase Orders Placed On Limited / Single Tender Basis From 01.07.2020 To 30.09.2020Document8 pagesDetails of Purchase Orders Placed On Limited / Single Tender Basis From 01.07.2020 To 30.09.2020Atul GuptaNo ratings yet

- Jawaharlal Nehru Technological University HyderabadDocument45 pagesJawaharlal Nehru Technological University HyderabadKAMESWARARAO DOMMETINo ratings yet

- Design and Analysis of A Ladder Frame ChassisDocument10 pagesDesign and Analysis of A Ladder Frame ChassisJuan Sebastian CameroNo ratings yet

- Hyundai Motor Company Online Report 3033Document133 pagesHyundai Motor Company Online Report 3033catalan.andNo ratings yet

- MLRH 1994 4 432Document4 pagesMLRH 1994 4 432Shidah RafiqeNo ratings yet

- 2-8 Especifiaciones Mayores ComponentesDocument4 pages2-8 Especifiaciones Mayores Componenteslevinton jose tobias genesNo ratings yet

- Owner'S Manual: BK175 & BK215Document38 pagesOwner'S Manual: BK175 & BK215Brock LynamNo ratings yet

- Suzuki Super Carry BrochureDocument4 pagesSuzuki Super Carry BrochureAlieNo ratings yet

- Fgtech Driver List MotorbikeDocument4 pagesFgtech Driver List MotorbikeАНДРЕЙNo ratings yet

- For Highest Concrete Qualities: Ring-Pan MixerDocument8 pagesFor Highest Concrete Qualities: Ring-Pan MixerGeetesh Makadia100% (1)

- Grand Cherokee 2008 5.7LDocument254 pagesGrand Cherokee 2008 5.7LlefontNo ratings yet

- Akshata Black BookDocument81 pagesAkshata Black BookAishwarya NairNo ratings yet

- Interview Questions For Engineers-1512639929Document11 pagesInterview Questions For Engineers-1512639929Andrii100% (2)

- Starting PDFDocument1 pageStarting PDFANH LÊNo ratings yet

- DIAMEC Smart6Document210 pagesDIAMEC Smart6Alexander Perez100% (2)

- Eventos Autos Clasicos TunjaDocument10 pagesEventos Autos Clasicos TunjaDenis Tatiana Salazar MartínezNo ratings yet

- Stock AnalysisDocument545 pagesStock AnalysisWRSAOBUDGETNo ratings yet

- Hitachi Zaxis 145WDocument28 pagesHitachi Zaxis 145WAndrea797No ratings yet

- KD Series Engines: For Industrial Power SystemsDocument20 pagesKD Series Engines: For Industrial Power SystemsMaximiliano Sanchez0% (1)

- 0 - Aditya MNC Assignment PDFDocument22 pages0 - Aditya MNC Assignment PDFAshish pariharNo ratings yet

- Engine Mechanical - 5.7LDocument426 pagesEngine Mechanical - 5.7LjisuuuNo ratings yet

- Brookville Catalog 2018 Reduced X2Document112 pagesBrookville Catalog 2018 Reduced X2attila77.gajdosNo ratings yet

- Manuals 7 3L Power Stroke ManualDocument78 pagesManuals 7 3L Power Stroke Manualurieal100% (1)

- Catalogo H1P 89 - 100Document177 pagesCatalogo H1P 89 - 100THIAGO COMERCIO DE PECAS E SERVICOS LTDAHIDRAULICOSNo ratings yet

- M104 WolverineDocument3 pagesM104 WolverinerameshNo ratings yet

- Goodyear Racing Drag CatalogDocument8 pagesGoodyear Racing Drag CatalogAdriano CavalheiroNo ratings yet

- Manual Mtto 793DDocument111 pagesManual Mtto 793DAndres Julian Guerrero VanegasNo ratings yet

- J23 Power PressDocument8 pagesJ23 Power PressLASMI Multi ServicesNo ratings yet