Professional Documents

Culture Documents

HSE Alert 21-16 Mast Collapse During Rig Move Operations

HSE Alert 21-16 Mast Collapse During Rig Move Operations

Uploaded by

曹庆园Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE Alert 21-16 Mast Collapse During Rig Move Operations

HSE Alert 21-16 Mast Collapse During Rig Move Operations

Uploaded by

曹庆园Copyright:

Available Formats

Saudi Aramco

Drilling & Workover Organization

Mast Collapse during Rig Move Operations

March 2016

The Alerts are provided to all Drilling and Workover Operations Foremen and Liaisonmen so that we all learn from the

experiences of others. The knowledge of this incident could prevent similar ones from happening in the future.

Saudi Aramco policy requires the information in this Alert to be communicated to all crew members and documented on

morning reports.

What happened?

March 2016. During rig move operations while lowering the mast, when it reached

the angle of approximately 40 degrees from the ground the drillers side hydraulic

cylinder (dragon piston) was noticed to be leaking oil. The drilling crew decided to

continue lowering the mast since this was regarded as the best option at this point.

As the mast continued to be lowered to the point of approximately 25 to 30 degrees

the driller’s side hydraulic cylinder piston fell out of the retaining section of the mast

where it is normally supported by the mast retainer pin, triggering the uncontrollable

failure and the mast fell rapidly to the ground causing excessive damage upon

impact.

Fig. 1: The mast on the ground after its collapse

Consequences

Significant damage to the equipment; the mast suffered major deformations.

Fortunately, there was no injury to rig personnel, however the incident had

the potential to escalate to a major human injury event (LTI/FAT)

Operation suspended, down time incurred for investigation and repairs

Saudi Aramco: Company General Use

T

Why did it happen?

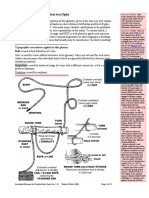

The cylinder pin was not properly

installed in the piston head eye.

Refer to Figure 2.

The hydraulic cylinder piston

heads were not visually verified

correctly to be locked into position

through the piston head eyes.

The JSA implemented was

inadequate as did not cover

sufficiently how to verify that the

cylinder pins were in place

correctly as established in the

contractor operating procedure.

The supervision from senior rig

management was inadequate

during this critical task.

What should be done to prevent recurrence?

Contractors to develop and implement suitable JSAs for raising and lowering

the specific types of masts based on OEM recommendations.

Specific instructions in line with the procedures shall be communicated and

supervised by senior rig personnel to verify that cylinder piston pins are fully

installed before raising and lowering the mast.

Senior management shall reinforce the expected supervisory responsibilities

especially for critical tasks to its rig line management.

Senior management shall reinforce and encourage the Safe Work

Authorization on all rig operations.

Saudi Aramco: Company General Use

2 Saudi Aramco: Company General Use

You might also like

- Elementary Statistics Picturing The World 8e Ebook PDFDocument23 pagesElementary Statistics Picturing The World 8e Ebook PDFcatherine.bussey794No ratings yet

- Allison Transmission Service Manual PDFDocument326 pagesAllison Transmission Service Manual PDFMitul Patel96% (27)

- Service Manual #37Document163 pagesService Manual #37CharlesWhite100% (1)

- Risk Assesment Towing 14sep10Document3 pagesRisk Assesment Towing 14sep10Haldar BishwajitNo ratings yet

- OIMDocument37 pagesOIMNaveen TripuraneniNo ratings yet

- 7.021 Operating Requirements For Lifesaving Appliances at Offshore InstallationsDocument6 pages7.021 Operating Requirements For Lifesaving Appliances at Offshore InstallationsAhmed TrabelsiNo ratings yet

- Safe Fueling ProcedureDocument16 pagesSafe Fueling Procedurerana qamarNo ratings yet

- 0002 400Document11 pages0002 400Buddharaju KiranNo ratings yet

- HSE Alert 76-20 Property Damage - ClampDocument2 pagesHSE Alert 76-20 Property Damage - ClampaswinNo ratings yet

- HSE Alert 07-16 Damage To Drilling Mast IncidentDocument1 pageHSE Alert 07-16 Damage To Drilling Mast IncidentSajid HussainNo ratings yet

- HSE Alert 16-16 Violation To Rig Move Procedure Results in Power Line IncidentDocument2 pagesHSE Alert 16-16 Violation To Rig Move Procedure Results in Power Line Incident曹庆园No ratings yet

- HSE Alert Dropped Object - TDS Stabbing GuideDocument3 pagesHSE Alert Dropped Object - TDS Stabbing GuideaswinNo ratings yet

- STD 125Document18 pagesSTD 125Joydev GangulyNo ratings yet

- HSE Alert 63-17 Hydraulic Leak Led To FireDocument1 pageHSE Alert 63-17 Hydraulic Leak Led To Firesamy banakchaNo ratings yet

- Dropped Mast: Saudi AramcoDocument1 pageDropped Mast: Saudi AramcoAbdul Hameed OmarNo ratings yet

- ALGAITH PU&LD Machine Property DamageDocument14 pagesALGAITH PU&LD Machine Property Damageosama nasrNo ratings yet

- HSE Alert 61-20 Heavy Equipment Operator-Rigger ValidationDocument1 pageHSE Alert 61-20 Heavy Equipment Operator-Rigger ValidationaswinNo ratings yet

- Aramo1191 002Document10 pagesAramo1191 002M ElabdNo ratings yet

- Std-125 - INSPECTION OF MECHANICAL SEALSDocument15 pagesStd-125 - INSPECTION OF MECHANICAL SEALSJonas PadillaNo ratings yet

- TB018 - Guidelines On Alternating Lubes-RevDocument2 pagesTB018 - Guidelines On Alternating Lubes-Revmagadali7814No ratings yet

- Gi-2 401Document7 pagesGi-2 401ck19654840No ratings yet

- HSE Alert # 51-14 Improper Installing of CSG Tong Results in LTIDocument1 pageHSE Alert # 51-14 Improper Installing of CSG Tong Results in LTIaswinNo ratings yet

- MIM1191.001 WORK PERMIT, CARE, MAINTENANCE & REPAIR OF MARINE VESSELS & EQUIPMENT, May2015Document14 pagesMIM1191.001 WORK PERMIT, CARE, MAINTENANCE & REPAIR OF MARINE VESSELS & EQUIPMENT, May2015Grenoite GrenoiteNo ratings yet

- HSE Alert # 42-14 Genie Man-Lift Incident Leads To Multiple Injuries (Reissued)Document1 pageHSE Alert # 42-14 Genie Man-Lift Incident Leads To Multiple Injuries (Reissued)aswinNo ratings yet

- SF-34-21-January 2021Document6 pagesSF-34-21-January 2021Shivkumar JadhavNo ratings yet

- Worker's Leg Amputated by Parted Sand Line: DescriptionDocument2 pagesWorker's Leg Amputated by Parted Sand Line: Descriptiong5nbNo ratings yet

- ADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Document15 pagesADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Mohamed MostafaNo ratings yet

- Mercruiser D219 Service ManualDocument546 pagesMercruiser D219 Service ManualEerik (stnz)No ratings yet

- HSE Alert 105-21 Welder Finger InjuryDocument2 pagesHSE Alert 105-21 Welder Finger InjuryAlecs NedeaNo ratings yet

- Sopwss OperationsDocument477 pagesSopwss OperationsAarzoo JobanputraNo ratings yet

- 0002 - 400 Offshore Oil SpillsDocument11 pages0002 - 400 Offshore Oil SpillsANIRBANNo ratings yet

- Bunker Oil Spill Prevention and Control, Regulation and Best PracticeDocument4 pagesBunker Oil Spill Prevention and Control, Regulation and Best PracticeTammam Hassan100% (1)

- 305 CidDocument967 pages305 CidJason StephensNo ratings yet

- MIM1193.006 Marine Vessel Requirements For Maneuvers Withi PDFDocument7 pagesMIM1193.006 Marine Vessel Requirements For Maneuvers Withi PDFDanang PrayogiNo ratings yet

- Operation and Maintenance of Rescue Boat Outboard Motors: PurposeDocument2 pagesOperation and Maintenance of Rescue Boat Outboard Motors: Purposerjay216No ratings yet

- Gi-0002 401Document7 pagesGi-0002 401malika_00100% (1)

- SF 26 23Document6 pagesSF 26 23Shivkumar JadhavNo ratings yet

- GDN 218Document25 pagesGDN 218Vasant Kumar Varma100% (1)

- IMCASF - Oct 20Document6 pagesIMCASF - Oct 20Shivkumar JadhavNo ratings yet

- 600168898-2-1 Low CaseDocument1 page600168898-2-1 Low CaseRahul KrishnanNo ratings yet

- SF 21 21Document6 pagesSF 21 21Natraj RamanNo ratings yet

- Fatality Contractor WelderDocument1 pageFatality Contractor WelderMohammedNo ratings yet

- SF 19 22Document6 pagesSF 19 22Shivkumar JadhavNo ratings yet

- IMCASF - Oct 17Document6 pagesIMCASF - Oct 17Shivkumar JadhavNo ratings yet

- MIM1201.009 REPORTING PROCEDURES FOR VESSELS ON INTERNATIONAL VOYAGES, Dec2017Document8 pagesMIM1201.009 REPORTING PROCEDURES FOR VESSELS ON INTERNATIONAL VOYAGES, Dec2017Grenoite GrenoiteNo ratings yet

- Hydraulic Telescopic Cylinder FailureDocument1 pageHydraulic Telescopic Cylinder FailureMohammedNo ratings yet

- MercruiserDocument268 pagesMercruiserJoe Pudlak100% (1)

- Taiko Three-Rotor Screw PumpsDocument20 pagesTaiko Three-Rotor Screw PumpsYaman YalçınNo ratings yet

- Saudi Aramco: Drilling & Workover Organization Offshore Gas Drilling Engineering DepartmentDocument1 pageSaudi Aramco: Drilling & Workover Organization Offshore Gas Drilling Engineering DepartmentaswinNo ratings yet

- Scaffolding For LifeDocument27 pagesScaffolding For LifeSameer Kulkarni100% (1)

- MIM1201.007 MARINE SAFE WORKING PRACTICES, Jan2016Document11 pagesMIM1201.007 MARINE SAFE WORKING PRACTICES, Jan2016Grenoite GrenoiteNo ratings yet

- Hanbell Compressor Installation and Startup GuideDocument40 pagesHanbell Compressor Installation and Startup Guidehasbullah mariahNo ratings yet

- Aramo1186 512Document4 pagesAramo1186 512M ElabdNo ratings yet

- Road Safety Alert 03-22 Fatal MVADocument2 pagesRoad Safety Alert 03-22 Fatal MVAMalik Muhammad Nauman ZiaNo ratings yet

- SF 07 24Document6 pagesSF 07 24Shivkumar JadhavNo ratings yet

- Iss 094 PDFDocument31 pagesIss 094 PDFAhmed yousefNo ratings yet

- Deepwater Horizon AccidentDocument36 pagesDeepwater Horizon AccidentVishnu PanickerNo ratings yet

- MIM1187.003 MARINE DEPARTMENT INCIDENT CATEGORIZATION AND INCIDENT INVESTIGATION, Dec2017Document22 pagesMIM1187.003 MARINE DEPARTMENT INCIDENT CATEGORIZATION AND INCIDENT INVESTIGATION, Dec2017Grenoite GrenoiteNo ratings yet

- Fall of Travelling BlockDocument5 pagesFall of Travelling BlockParesh NayakNo ratings yet

- MANUAL FOR REACTORS - v2Document7 pagesMANUAL FOR REACTORS - v2narendradounde143No ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- MV Willy: Report On The Investigation of The Grounding ofDocument33 pagesMV Willy: Report On The Investigation of The Grounding ofLyubomir IvanovNo ratings yet

- No. 39 Safe Use of Rafts or Boats For Survey No.39Document3 pagesNo. 39 Safe Use of Rafts or Boats For Survey No.39Ainul YaqienNo ratings yet

- SEAM5 WEEK1 CME Official Deadweight - DisplacementDocument15 pagesSEAM5 WEEK1 CME Official Deadweight - DisplacementDarkxeiDNo ratings yet

- Grand Tour: Start YourDocument9 pagesGrand Tour: Start YourCeneJNo ratings yet

- QS Prop GuideDocument112 pagesQS Prop GuideRoberto ImplatiniNo ratings yet

- 5.7L EFI 5.7LX EFI 350 Magnum EFI Gen+ Alpha One: Operation & Maintenance ManualDocument136 pages5.7L EFI 5.7LX EFI 350 Magnum EFI Gen+ Alpha One: Operation & Maintenance ManualErman GÖGENNo ratings yet

- Document Analysis: First Voyage Around The World: By: Antonio PigafettaDocument5 pagesDocument Analysis: First Voyage Around The World: By: Antonio Pigafettapheobe saludesNo ratings yet

- The Paquete Habana, 175 U.S. 677 (1900)Document1 pageThe Paquete Habana, 175 U.S. 677 (1900)IntifadaJjangNatangcopNo ratings yet

- PCGA Flotilla Handbook - Web VersionDocument10 pagesPCGA Flotilla Handbook - Web VersionLyel LimNo ratings yet

- Pirate Weapons: Name Skill DAM Crit Range Encum Price Rarity SpecialDocument4 pagesPirate Weapons: Name Skill DAM Crit Range Encum Price Rarity SpecialkdtomposNo ratings yet

- Lampiran Usulan Penghapusan 2022Document4 pagesLampiran Usulan Penghapusan 2022Aristiya MayasariNo ratings yet

- Cluster4 Papsel Fakfak 20221125Document208 pagesCluster4 Papsel Fakfak 20221125Nando FernandoNo ratings yet

- Form 21-Work Rest Hours Record ECDocument2 pagesForm 21-Work Rest Hours Record ECArafatul AlamNo ratings yet

- IADC - West Ariel - 17 Mar 08Document69 pagesIADC - West Ariel - 17 Mar 08Them Bui XuanNo ratings yet

- The Battle of Winchelsea, 1350 "Les Espagnols Sur Mer"Document3 pagesThe Battle of Winchelsea, 1350 "Les Espagnols Sur Mer"AIM Investor JournalNo ratings yet

- Ffe PpeDocument12 pagesFfe Ppecaptainphihung100% (1)

- ECM GD-08 - Placards Required On Board-USDocument1 pageECM GD-08 - Placards Required On Board-USguoterryNo ratings yet

- Captain Vartul DixitDocument40 pagesCaptain Vartul DixitAman GautamNo ratings yet

- Framework of On-Board Team e Ffectiveness: A Qualitative Study of Shipping IndustryDocument21 pagesFramework of On-Board Team e Ffectiveness: A Qualitative Study of Shipping IndustrySantoso WahyudiNo ratings yet

- Knot Glossary Robert-BirchDocument19 pagesKnot Glossary Robert-BirchAutumn HammNo ratings yet

- A Sixteen Question Multiple-Choice Question Assessment For - Big Things Come in Small Packages by Eleanora E. Tate - Answer Key Is ProvidedDocument8 pagesA Sixteen Question Multiple-Choice Question Assessment For - Big Things Come in Small Packages by Eleanora E. Tate - Answer Key Is Providedive14_No ratings yet

- Information Required For Emergency Towing BookletDocument7 pagesInformation Required For Emergency Towing BookletAamir SirohiNo ratings yet

- Daily Report Deme Project 26-10-2022Document1 pageDaily Report Deme Project 26-10-2022alamNo ratings yet

- Annual Ed 2022Document64 pagesAnnual Ed 2022Gourab EonNo ratings yet

- Vittorio Veneto 1941 350 NewDocument14 pagesVittorio Veneto 1941 350 NewpilletNo ratings yet

- Asd Tug - SpecDocument2 pagesAsd Tug - SpecLazaros Karapou100% (1)

- When Thoughts and Ideas Are Expressed Clearly and Succinctly in WritingDocument15 pagesWhen Thoughts and Ideas Are Expressed Clearly and Succinctly in WritingOm Prakash RajNo ratings yet

- Barrios v. Go Thong, 7 SCRA 535Document5 pagesBarrios v. Go Thong, 7 SCRA 535JMae MagatNo ratings yet