Professional Documents

Culture Documents

Raiseboring in Difficult Rock Conditions

Raiseboring in Difficult Rock Conditions

Uploaded by

www.di_stefano70Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raiseboring in Difficult Rock Conditions

Raiseboring in Difficult Rock Conditions

Uploaded by

www.di_stefano70Copyright:

Available Formats

Ground Support 2019 - J Hadjigeorgiou & M Hudyma (eds)

© 2019 Australian Centre for Geomechanics, Perth, ISBN 978-0-9876389-4-6

doi:10.36487/ACG_rep/1925_11_Edelbro

Raiseboring in difficult rock conditions

C Edelbro Itasca Consultants AB, Sweden

R Brummer Itasca Consulting Canada Inc., Canada

M Pierce Pierce Engineering, USA

D Sandström Boliden Mineral AB, Sweden

J Sjöberg Itasca Consultants AB, Sweden

Abstract

Virtually all long ventilation shafts and orepasses in the Boliden mines in Sweden are excavated using

raiseboring. With increasing mining depths and hence, increased virgin rock stresses, it has become difficult

to keep the shafts intact after boring and until reinforcement or other stabilising measures have been

implemented.

This paper contains a review of literature and case studies of raiseboring in difficult rock conditions. The focus

is on design, pre-reinforcement, excavation methods, and final outcomes. The cases range from long

ventilation raises to short stope slots. The data was used to further develop raisebore design charts relating

to the ratio of maximum tangential stress and uniaxial compressive strength (UCS) to raisebore length and

diameter. This enabled establishing limits for initiation of failure and problem-free boring that can be

achieved using current technology.

For problematic shafts, remedial measures such as different types of pre-reinforcement or lining the raise

while pulling out the muck are presented. Good experiences using rings of reinforced piles to allow raiseboring

through the deep weathered surface were available from Australia. However, there were no case studies with

pre-reinforcement in rock conditions similar to those of the Boliden mines. Nevertheless, vertically drilled and

pre-reinforced perimeter holes around the eventual raisebore diameter is one suggested possible action.

Based on industry experience, strategies to be considered for raiseboring in difficult rock condition are also

presented.

Keywords: raise, shaft, pre-reinforcement

1 Introduction

Virtually all long ventilation shafts and orepasses in the Boliden mines are excavated using raiseboring. Shaft

dimensions vary from 25 to 650 m in length and with diameters between 2.0 and 6.5 m. With increasing

mining depths and hence, increased virgin rock stresses, it has become difficult to keep the shafts intact after

boring, and until reinforcement or other stabilising measures have been implemented. Typical problems

during reaming and pilot drilling include:

• Convergence in the pilot hole or in the shaft (Figure 1).

• Stability problems at the face and/or in the wall.

• Stability problems in nearby drifts.

• Hard rock – uneven load on the reaming head.

Ground Support 2019, Sudbury, Canada 185

Raiseboring in difficult rock conditions C Edelbro et al.

Figure 1 Stability problem after reaming, with difficulty to take down the reaming head and change

cutters due to large convergence

This paper comprises a review of literature and case studies of raiseboring in difficult rock conditions,

focusing on design approaches, pre-reinforcement, excavation methods, and final outcomes. Moreover,

remedial measures to reduce the potential for instability during raiseboring were evaluated based on the

literature review and gained experiences.

2 Methodology and data sources

A comprehensive literature review has been conducted using internet searches in Google, online literature

databases (Scopus, Web of Science, Google Scholar etc.) and publications available at Swedish universities.

Industry experience with developing raisebores in difficult ground has been summarised. Input from 13

international clients was solicited and the data and, in particular, the experience on managing raiseboring in

ground that is overstressed, heavily jointed, or very weak and schistose, was consolidated. The majority of

the industry clients operate deep mines, and this is reflected in the collected data. Clients were provided with

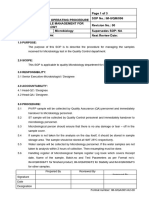

an introductory letter and a set of blank data sheets (Figure 2). Replies were received from seven client

organisations, and over 60 completed data sheets were returned. Not all of the completed data sheets

included the required stress and rock strength data, and many of the raisebores described were completed

without problems. The data obtained from clients was supplemented with data based on personal

experience as well as similar previous projects.

186 Ground Support 2019, Sudbury, Canada

Ground support in challenging conditions

Itasca/Boliden Raisebore Project

Case History Summary Data Sheet

Mine: Engineer: email:

Raisebore Name: Dip deg Dip Direction deg

From (top level): ft 0 m Depth below surface (top) ft 0 m

To (bot level): ft 0 m Depth below surface (bot) ft 0 m

Total Length: 0 ft 0 m Diameter of Raisbore ft 0,0 m

Rocktype:

From (top level): ft 0 m ft 0 m ft 0 m

To (bot level): ft 0 m ft 0 m ft 0 m

Rock Strength

σC = MPa σC = MPa σC = MPa

Rock Mass Quality RMR(ave) = Q' (ave) = RMR(ave) = Q' (ave) = RMR(ave) = Q' (ave) =

Joints/m (ave) #/m 1 #/m #/m

Field Stress at top (MPa)

σ E-W = σ N-S = σ E-W = σ N-S = σ E-W = σ N-S =

Field Stress at bot (MPa)

σ E-W = σ N-S = σ E-W = σ N-S = σ E-W = σ N-S =

Deviatoric Stess

Support?

Problems experienced

during or after raiseboring

Solution or steps taken

to overcome problems

Comments/Sketches/Diagrams Any other notes

Figure 2 Raisebore data sheet. Items in yellow were completed by clients

Ground Support 2019, Sudbury, Canada 187

Raiseboring in difficult rock conditions C Edelbro et al.

3 Case studies of raisebored shafts

Based on the available collected information, a selection of well-described cases (vertical shafts) are

presented in this chapter. A summary of studied cases, which have had problems during raising and before

commission, is presented in Table 1.

3.1 Mine A – ventilation raise

At Mine A a 750 m long ventilation raise with bottom at 1,300 m depth was raisebored in heavily veined

Quartz Monzodiorite. The diameter of the raise was 3 m. The reaming stopped after 35 m due to poor ground

conditions. Subsequent mucking produced significantly more tonnes than expected. A remote loader was

used to clear the raise several times, however the raise would fail again within hours. After a short period of

stability, the raise was fully mucked and the reamer head removed, with 10 cutters found to be missing, see

Figure 3. The raise failed again after removal of the reamer and was left choked to help with rehab grouting.

Probe drilling was carried out to determine the shape of the overbreak. These holes were then used to grout

a 3‒4 m high plug in the raise base. The remaining grout placement was done from the collar with lean mix

in an attempt to fill void. The pilot hole was re-drilled once grouting was completed, and 2.4 m (as opposed

to 3 m) diameter reaming recommenced. The overbreak was attributed to locally low rock block strength

from intense veining/microdefecting relative to high in situ horizontal stress.

In terms of characterisation, the main learning from the experience was to better account for the influence

of veins and microdefects on the rock block strength when estimating raise stability. In terms of placement,

the main learning was to use shorter raises to lower the risk. Moreover, the raises should be repositioned if

core from the characterisation hole suggests weak ground that may lead to raise instability at a specific locale

(e.g. move bottom up if needed and bore separate leg below).

(a) (b)

Figure 3 Reamer head before (a) and after (b) 35 m reaming

188 Ground Support 2019, Sudbury, Canada

Table 1 Vertical raisebored shafts

Mine and type Total length/ Vertical depth In situ stress Main UCS Rock mass Joints and Problems

of raise Diameter (m) at bottom of at bottom geological unit (MPa) behaviour weakness

shaft (m) level (MPa) and/or quality zones

Mine A, 750/ 1,300 σH = 58 Quartz 95 (27–161) GSI = 38 Joint spacing Stopped after

ventilation 3 σh = 27 Monzodiorite (26–52) 0.25 m 35 m

case 1 σv = 34

Mine A, slot 48/ 1,300 As above Andesite 136 (± 24) GSI = 40–45 Joint spacing Spalling along

case 2 2.4 0.3 m entire length

of raise

Mine C, 82/ 2,473 σH = 1.6σv = Granite/ 210 RMR = 90 1 joint/m Reamer was

ventilation 2.4 107 Gabbro stuck

Mine K 1 stope 36.1/ 2,296 σH, σh = 125 Rhyolite 110‒130 Rhyolite Rhyolite Squeezing,

slot raise 1.2 copper, copper Copper seismic event

sulphide zinc RMR = 65 and 2 joints/m

Sulphide zinc = Sulphide Zinc

79 3 joints/m

Mine K 2 stope 33/ 2,335 σH = σh = 95 As above As above As above As above Accelerating

slot raise 1.2 deformation

Mine K 3 stope 37/ 2,936 σH = σh = 150 Rhyolite 110 RMR = 65 3 joints/m Pilot bit stuck

slot raises 3 1.2 copper and reamer

stringer ore jammed

Lucky Friday 15–30/ 2,990 σH = 1.5σv Thinly bedded 70–110 Not applicable Vertical Overbreak,

orepasses 1.8–3.0 σh = 1.25σv Argillite, Siltite (Argillite) to highly foliation with buckling,

100–125 anisotropic spacing less deforming of

(Siltite) rock than 0.15 m, liners

bedding in

Argillite

Ground Support 2019, Sudbury, Canada 189

Table 1 (continued) Vertical raisebored shafts

Mine and type Total length/ Vertical depth In situ stress Main UCS Rock mass Joints and Problems

of raise Diameter (m) at bottom of at bottom geological unit (MPa) behaviour weakness

shaft (m) level (MPa) and/or quality zones

Neves-Corvo 1, 227/ 816 σH = 26 Shales 50–120 RMR = 59–64 5–7 joints/m Decreased

ventilation 3.1 σh = 22 reaming rate

Neves-Corvo 2, 220/ 816 As above Shales, 50–240 RMR = 38–59 4–20 joints/m Huge cavity

ventilation 3.1 volcanics,

massive ore

Neves-Corvo 3, 150/ 760 σH = 25 Shales, breccia 50–240 RMR = 54–64 4–12 joints/m Instable

ventilation 2.1 σh = 21 sidewalls

Neves-Corvo 8, 345/ 630 σH = 20 Volcanics, 50–160 RMR = 54–63 1–5 joints/m Constant fall

ventilation 3.1 σh = 17 black and of material

siliceous from raise

shales, sidewalls

greywacke

UCS – uniaxial compressive strength. GSI – Geological Strength Index. RMR – Rock Mass Rating.

190 Ground Support 2019, Sudbury, Canada

Ground support in challenging conditions

3.2 Mine C – Ventilation raise

Many shafts have been raisebored in Mine C and this example is illustrative of the sort of problems

experienced. An approximately 80 m fresh air raise (ventilation) was bored between depths of 2,473 m and

2,390 m below collar in a granite/gabbro with a uniaxial compressive strength (UCS) of about 210 MPa. The

raise location was selected to avoid known geological units comprising shear zones, jointing, and ductile

biotite.

No problems were experienced during pilot hole drilling, and reaming went relatively well, with only minor

seismicity recorded, until approaching breakthrough. The plan was to pull the reamer through rather than to

lower it in order to avoid blasting the breakthrough. The day shift raise crew stopped near breakthrough with

no shift coming on in the afternoon. The next day the reamer was stuck. A plan of action was put together to

release the reamer by blasting. After a couple of unsuccessful smaller blasts, it was decided to remove the

raisebore off the platform before continuing. To do so, the pilot stem needed to be removed. Extra hitches

were installed to hold the remaining stem as to not drop the reamer after release. This all resulted in project

delays and a lot of additional work, as well as risk to equipment. The solution to overcome the issue is to

'hot-seat' the raise and have a continuous reaming ongoing upon approach to a breakthrough.

3.3 Mine K – stope slot raises

Mine K is a very deep blasthole mine that raisebores the slots for their blasthole stopes. Because of the

sequence used, it is unavoidable that raisebores need to be developed in highly stressed ground. As an

example, a raise was developed in a location where the major principal stress was roughly 150 MPa in a

rhyolite copper ore with UCS of about 110 MPa. Clearly this ground was highly overstressed before pilot

drilling began.

The raise pilot hole began to squeeze on the rods during downdrilling. Operators had to trip rods multiple

times to maintain pilot hole diameter, prior to attaching the reamer. During reaming, due to anticipated high

rates of closure, the reamer was lowered out of the raise between afternoon and day shifts, and then

‘reamed’ back up to the ‘face’ to ensure the reamer would not be stuck in the raise. Multiple surveys were

done in the raise, which showed large pockets of caving approximately 2 to 3 m below the overcut elevation.

The orientation of where crushing occurred (Figure 4) was mapped to estimate the stress field orientation

for future model updates during mining. Multiple seismic events with local magnitudes up to 2.8 during

mining of the stope resulted in badly damaged rock mass around the raise, complicating drilling and mining

processes.

3.4 Lucky Friday mine – orepasses and ventilation raises

At the Lucky Friday Mine raise lengths vary but orepasses are typically limited to 30 m length and vent raises

limited to 15 m length. These are relatively deep raises, with most production currently conducted at 2,100

to 2,290 m depth (shaft bottom is at 2,990 m depth). The host rock is primarily a thinly-bedded argillite (UCS

70–110 MPa) which can, depending on the sand content, be siltite (100–125 MPa). The primary fractures in

the rock are vertically-oriented foliation and bedding in the argillite. The spacing of the foliation varies, but

is typically less than about 15 cm. There is some widely-spaced horizontal jointing, but the vertical foliation

dominates the rock mass response. Water seepage is minimal. The major principal in situ stress is horizontal,

equal to 1.5 times the vertical stress and trends N40W. The intermediate principal stress is horizontal as well

and is 1.25 times the vertical stress.

Raises sometimes experience overbreak during reaming. Significant excavation interaction can occur when

the vent raises are driven too close to the downward-direction, adjacent vein mining. Sometimes operators

have to drop the reamer several times to keep the raise going. Instability typically includes buckling of the

thin foliation into the raise and deforming of liners. The remedial measures on how to maintain wall stability

for the Lucky Friday mine are presented in Section 5.

Ground Support 2019, Sudbury, Canada 191

Raiseboring in difficult rock conditions C Edelbro et al.

Figure 4 Views down slot raise soon after completion, showing severe crushing and squeezing close of

raisebore

3.5 Neves-Corvo Mine – ventilation raise

Based on a comprehensive stability study work for shafts, orepasses and ventilation raises, data for a total of

11 ventilation raises and two orepasses was summarised by Somincor for this work. The diameters of the

raises were 2.1, 3.1, and 4.1 m and with lengths of 66‒345 m. Unstable sidewalls (some loose blocks or

instability during the initial part of the excavation) were observed for six of the raises during reaming. In

general, no support was installed in the raises, with the exception of lining used in weaker rock sections. No

severe problems during reaming occurred for the raises in Neves-Corvo Mine. However, there were some

issues regarding spalling, falling of material etc.

As an example, issues during reaming and developed cavities (based on filming the raise) were observed for

a 220 m long ventilation raise (presented as Neves-Corvo 2 in Table 1) with a diameter of 3.1 m. The rock

types in the area were siliceous shales, volcanics, greywacke and massive ore. The UCS varied from 50 to

240 MPa and the Rock Mass Rating (RMR) varied between 38 and 59. Shotcrete lining was performed for the

first 56 m. After 56 m it was not possible to shotcrete due to a huge cavity which the lining equipment could

not cross. Hence, constant monitoring of the raise stability was performed. However, after the lining

application the raise was stable.

4 Design approach

The empirical McCracken and Stacey method (McCracken & Stacey 1989) is commonly used for first-pass

designs of shafts. Design of, and methods for determining the life of, orepasses was reviewed and compiled

by Brummer (1998). The McCracken and Stacey method addresses the initial stability of a shaft, but this

method requires detailed geomechanics data that for many case studies is not available (Brummer 1998). In

Brummer (1998) a survey of primarily Canadian industry mines in brittle, strong rocks was performed and a

192 Ground Support 2019, Sudbury, Canada

Ground support in challenging conditions

stability index was developed relating the laboratory intact UCS to the maximum tangential (σmax = 3σH - σh)

stress around circular orepasses.

The data obtained from the previous study (long-term stability) by Brummer (1998) together with data from

the current study (short-term stability) allowed the further development of a Raisebore Design Chart relating

the maximum tangential stress (σmax = 3σH - σh) to UCS. It was apparent that this ratio could be plotted against

the size of the raisebore (Figure 5) as well as the length of the raisebore (Figure 6). This enabled establishing

what appeared to be limits for what can be achieved using today’s technology. One of the important limits is

the stress ratio at which the perimeter of the raise or pilot starts to fail because of the induced tangential

stress around the raisebore. Based on failure observations this occurs at a σmax/UCS ratio of about 0.3, see

Figure 5. The next limit, when severe spalling and crushing occurs, is at a σmax/UCS ratio of about 1.2‒1.5,

based on industry experience. It can be further noted that for low σmax/UCS ratios, in particular for the chart

in Figure 6, the length of the shaft has less influence on the results. This is neither unreasonable, nor

unexpected; however, for high ratios, the opposite is true, and both length and diameter are strongly

restricted by the stress-strength conditions.

All cases presented in Table 1 are plotted in the charts together with cases which had no problems during

raising. The problem-free raises are marked with green triangles and the cases with severe problems are

marked with red squares. These charts can be applied to all type of raises as they consider the short-term

condition. Like other empirical geomechanical design techniques these charts are intended to provide an

indication of the potential for problem-free raising.

Figure 5 Raisebore design chart relating σmax/UCS ratio to raisebore diameter. Red squares represent

severe problems, green triangles no problems and black squares some problems. The black

dashed curve defines the approximate limit for problem-free raising

Ground Support 2019, Sudbury, Canada 193

Raiseboring in difficult rock conditions C Edelbro et al.

Figure 6 Raisebore design chart relating σmax/UCS ratio to raisebore length. Red squares represent

severe problems, green triangles no problems and black squares some problems. The black

dashed curve defines the approximate limit for problem-free raising

5 Remedial measures and ideas for the future

The motivation for mining engineers is to improve the ground condition so that raises can be back-reamed

full face and personnel do not have to work in shafts. Three different ways to support the walls or use pre-

reinforcement are:

1. Lining the raise while pulling out the muck helps suppress failure as evidenced at the Lucky Friday

Mine (see Section 3.4). If the hole behind the reamer is filled with muck, which supports the walls

temporarily, a plastic pipe or steel conduit can float down from the top as the muck is pulled out.

When complete, the annulus is backfilled with grout.

2. As presented in Vervoorn (2005), ground freezing has been used, for example, by the mining

companies North Selby Coalfield (Yorkshire in UK), White County Coal (Illinois in USA), and Potash

Mining (Saskatchewan in Canada). The purpose with freezing as a remedial measure is to increase

the strength of a broken and fractured rock mass.

3. Pre-reinforcement by using rings of reinforced piles has been installed and trialled in mines such

as the Bendigo Gold Mines, Callie Gold Mine, Cadia East, Mt Isa Mine, Olympic Dam, and Wattle

Dam Gold mine (Marlow et al. 2013).

The most well documented cases on how to improve the shaft stability are from pre-reinforcement by using

rings of reinforced piles. Therefore, this approach is further described for two cases. The first case is a 4.5 m

diameter and 27 m long ventilation shaft which was raised in the Athena Gold Mine (Marlow et al. 2013). The

site profile comprised an extremely weak upper zone (the top 10 m) and a moderately weak lower zone

(10‒27 m depth). The stability of the raisebore shaft was assessed using two approaches: (i) the McCracken

and Stacey method and (ii) the maximum stable unsupported span estimate. Results for both methods clearly

showed that a conventional 4.5 m diameter raisebore would not be successful in this ground, with a

194 Ground Support 2019, Sudbury, Canada

Ground support in challenging conditions

probability of failure exceeding 50% over much of the length of the raise. A ring of 24 bored piles, nominally

27 m deep and with a pile diameter of 200 mm, was installed around the shaft position. Since the pile length

was close to the raise length, some piles were bedded into rock below the floor of the underground drive.

Old drill rod reinforcement was grouted into the holes. The drill rods were linked and centralised in the holes

by means of spacers at the collars. However, during reaming the reaming head hit some of the drill rods/piles,

which required a change to a smaller reamer diameter.

Another example is the two 150 m deep ventilation shafts of 3 and 4 m diameter which were raisebored

through to the surface in the Trident mine in 2007. Site investigation drilling confirmed about 50 m of weak

weathered rock at both locations of the shafts, with sharp contacts to strong competent rocks. A 5 m thick

zone of soft clay, located 25 m below surface, was found at the site with the 4 m diameter shaft. The

excavation and reinforcement of the 4 m diameter shaft is presented in Sexton et al. (2008). A total of 20

non-contiguous, cable reinforced grouted minipiles were designed to be installed from surface down to fresh

rock (55 m depth) before back-reaming. The layout was in the form of two rings of piles, the outer ring at

0.5 m standoff and with steel reinforcement, and the inner ring at 0.15 m standoff being grouted, see

Figure 7. The piles were designed with 270 mm diameter and with a spacing less than 1.47 m (which required

at least 11 piles in the outer ring and 10 piles in the inner ring).

Figure 7 Layout of the vertical reinforced piles at the Trident Mine (Marlow et al. 2013)

Pile drilling problems was a major practical issue for the 4 m shaft in the Trident Mine. Only two holes were

successful in the outer ring and the first cycle of holes, see cycle 1 in Figure 7. Hence, a second set of piles

was designed, this time using 140 mm diameter reverse circulation (RC) drilling. A new inner ring was drilled

and grouted in order to backfill the washouts from the original drilling in the outer ring. Subsequently, an

outer ring of cable reinforced piles was constructed. The raise was then successfully reamed through to the

surface. Some pieces of the inner piles were recovered from the cuttings. The excavated volume was 95 m3

more than expected over the full shaft length. This roughly equated to the observed overbreak of the raise

walls, in one location extending out to the piles, which implied that the piles inhibited a larger collapse.

Factors to consider regarding pile planning and design (Marlow et al. 2013) are:

• Maximum allowable spacing or aperture between piles.

• Pile diameter.

• Standoff distance, which is the clear space between the bored edge of the raisebore and the edge

of the piles.

• Expected verticality of the pile boreholes.

Ground Support 2019, Sudbury, Canada 195

Raiseboring in difficult rock conditions C Edelbro et al.

There were no published case studies with pre-reinforcement in rock conditions with a combination of high

stresses and weak and strong rock, similar to those of the Boliden mines. However, as vertical pre-reinforced

holes have been trialled with success in many other mines, a ring along the whole length of the shaft is

suggested as an idea for the future for the Boliden mines (Figure 8). The inner ring can be complemented

with an outer ring (or several rings) with shorter holes, in the top and bottom of the shaft (Figure 9).

The holes could be reinforced using, for example, bolts (which are linked) or cable bolts and concrete

(i.e. components with high tensile capacity as not to fail due to lateral movements). This set-up may work

well also under high-stress conditions, but it may be questioned whether it could also sustain large strain

bursts. For such conditions, additional studies, for example using numerical modelling, would be required.

Figure 8 Example of layout of the vertical reinforced piles along the whole length of raise

Figure 9 Example of layout using an inner and outer ring in the top and bottom of raise

6 Concluding remarks

Cases regarding raiseboring in difficult conditions have been summarised in this work. The raises vary in

diameter (1.2‒6.1 m) and length (15‒750 m) and were developed in different ground conditions. Based on

the information and experience reviewed during this study, the following strategies for raiseboring in difficult

ground should be considered:

• Keep the reamer/cutter moving by ‘hot change at the face’ in order to avoid it to get stuck. This

was the solution for the mine C case in Section 3.2.

• If continuous drilling or reaming cannot be performed, then lower the head or pilot to the bottom

and re-raise as for the mine K case in Section 3.3.

196 Ground Support 2019, Sudbury, Canada

Ground support in challenging conditions

• Reduce size of cutterhead if conditions become problematic and if a reduced diameter can be

tolerated, as for the mine A case in Section 3.1.

• Use shorter raises to lower the risk and reposition raises if examination of rock cores from the

characterisation holes suggests weak ground will lead to raise instability at a specific locale. This

was concluded for the mine A case in Section 3.1.

The developed design charts can be used for any type of raise considering short-term stability. The charts

can provide an indication of the likelihood of stress related problems during raising. For cases where severe

spalling and crushing are likely to occur, further investigations regarding geology and rock mechanics are

suggested. The main experience gained from the mine A case (Section 3.1), was to better account for the

influence of veins and microdefects on the rock block strength when estimating raise stability. Hence, the

focus should be on variation in rock strength, weakness zones, foliations, veins and microdefects, and also

quantifying these.

Based on different methods to support the shaft walls, pre-reinforcement by using reinforced vertical holes

is a suggested possible action. There is still uncertainty regarding for which conditions and for what potential

failure mechanisms that this type of pre-reinforcement works. This should be further investigated, which

may be done through numerical analysis.

Acknowledgement

We acknowledge all clients and mines who have shared information. A special thanks goes to João Gabriel

(Mining Engineer at Somincor) who shared his experience and data from ventilation raises and orepasses in

the Neves-Corvo mine.

References

Brummer, R 1998, Design of Orepasses: Methods for Determining the Useful Life of Orepasses Based on Previous Experience and Case

Studies, submitted to CAMIRO Mining Division Limited, Sudbury, January 1998.

Marlow, P, Webber, S, Mikula, PA & Lee, M 2013, ‘Bored reinforced piles for raisebore support: four case studies, and guidelines

developed from lessons learnt’, Mining Technology, vol. 122, iss. 3, pp. 159–165.

McCracken, A & Stacey, TR 1989, ‘Geotechnical risk assessment for large‐diameter raise‐bored shafts’, Proceedings of the Second

International Conference on Shaft Design and Construction, Institute of Materials, Minerals and Mining, London.

Sexton, M, Mikula, PA & Lee, MF 2008, ‘Trident mine raise bore – a bored pile case study, Proceedings of the 1st Southern Hemisphere

International Rock Mechanics Symposium, Australian Centre for Geomechanics, Perth, pp. 137‒148.

Vervoorn, R 2005, Wall Support for Raise Bored Shafts, master thesis, Delft University of Technology, Delft.

Ground Support 2019, Sudbury, Canada 197

Raiseboring in difficult rock conditions C Edelbro et al.

198 Ground Support 2019, Sudbury, Canada

You might also like

- I/A Series A Hardware Model P92 Workstation: Windows XP Professional Operating SystemDocument4 pagesI/A Series A Hardware Model P92 Workstation: Windows XP Professional Operating SystemThomas BORNEYNo ratings yet

- Circle Theorems Exam QuestionsDocument4 pagesCircle Theorems Exam QuestionsglennNo ratings yet

- Geotechnical Solutions For Unstable Rock Mass at Sg. Buloh AreaDocument8 pagesGeotechnical Solutions For Unstable Rock Mass at Sg. Buloh Areajinwook75No ratings yet

- The Q-Slope Method For Rock Slope EngineeringDocument17 pagesThe Q-Slope Method For Rock Slope EngineeringThiago MarquesNo ratings yet

- Mechanical Behaviour of Laterally Loaded Large-Diameter Steel Tubular Piles Embedded in Soft RockDocument39 pagesMechanical Behaviour of Laterally Loaded Large-Diameter Steel Tubular Piles Embedded in Soft Rock649358666No ratings yet

- Model 01Document27 pagesModel 01hailegmichael31No ratings yet

- The Q-Slope Method For Rock Slope EngineeringDocument17 pagesThe Q-Slope Method For Rock Slope EngineeringmehdiNo ratings yet

- ArmstrongDocument9 pagesArmstrongronan2000No ratings yet

- Structural ElementsDocument157 pagesStructural ElementsDidi Chekwube NnamdiNo ratings yet

- Nara PPT PDocument55 pagesNara PPT PEswara PrasadNo ratings yet

- The Q-Slope Method For Rock Slope EngineeringDocument17 pagesThe Q-Slope Method For Rock Slope EngineeringSebastian Jorquera HenriquezNo ratings yet

- 0pile Load Test - 1Document39 pages0pile Load Test - 1rushikeskNo ratings yet

- ECE 3127 Advanced Hydraulic structures-DAMSDocument44 pagesECE 3127 Advanced Hydraulic structures-DAMSSam KaburuNo ratings yet

- 09 GrenonDocument14 pages09 GrenonseniNo ratings yet

- Part 10 - Design ParameterDocument7 pagesPart 10 - Design ParameterAfendi AriffNo ratings yet

- Lab 4CDocument5 pagesLab 4CRuzengulalebih ZEta's-ListikNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument5 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringFabián Arquín BolañosNo ratings yet

- A Load-Transfer Function For The Side Resistance of Drilled Shafts in Soft RockDocument19 pagesA Load-Transfer Function For The Side Resistance of Drilled Shafts in Soft RocklsfletiNo ratings yet

- Design & Supervision Consulting (DSC) Services For Melamchi Phase 1Document28 pagesDesign & Supervision Consulting (DSC) Services For Melamchi Phase 1Ujala ShahNo ratings yet

- Observed Behaviour of Laterally Expanded PDFDocument14 pagesObserved Behaviour of Laterally Expanded PDFJuan Camilo PinedaNo ratings yet

- Unggulan Saintifik/Terapan Dalam Bidang Infrastruktur Dan Lingkungan Binaan Rekayasa GeoteknikDocument52 pagesUnggulan Saintifik/Terapan Dalam Bidang Infrastruktur Dan Lingkungan Binaan Rekayasa GeoteknikCandra SuryaNo ratings yet

- Creep SettlementDocument16 pagesCreep Settlementalien kilNo ratings yet

- Bar and Barton - 2017 - The Q-Slope Method For Rock Slope Engineering PDFDocument16 pagesBar and Barton - 2017 - The Q-Slope Method For Rock Slope Engineering PDFDelia PlăcintăNo ratings yet

- TP36 Geopier Vs SC Performance Dr. David WhiteDocument8 pagesTP36 Geopier Vs SC Performance Dr. David WhiteToby BobyNo ratings yet

- Pile Capacity - An Overview - ScienceDirect TopicsDocument15 pagesPile Capacity - An Overview - ScienceDirect TopicssurNo ratings yet

- Cep (2018 Ge 11,31)Document12 pagesCep (2018 Ge 11,31)Muhammad Zaka EmadNo ratings yet

- Lect 1 Pile FoundationDocument34 pagesLect 1 Pile FoundationPaulNo ratings yet

- Han 2013Document10 pagesHan 2013Benjamin GonzalezNo ratings yet

- Presentation 4Document112 pagesPresentation 4Stephanie HaynesNo ratings yet

- Presented By:, Shivam Gandhi AhmedabadDocument43 pagesPresented By:, Shivam Gandhi AhmedabaddhivyaNo ratings yet

- Rock Support Design in Mandai Project, Singapore: Chen S.G., Tan K.H. & Ong H.LDocument8 pagesRock Support Design in Mandai Project, Singapore: Chen S.G., Tan K.H. & Ong H.LHarold TaylorNo ratings yet

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Javiera MoralesNo ratings yet

- DfssssDocument14 pagesDfssssxazsdu puNo ratings yet

- 195 Micropiles - Recent Advances and Future TrendsDocument27 pages195 Micropiles - Recent Advances and Future TrendsCarlos Rafael Obregón Mimbela100% (1)

- CP4 Report On High Slope 20220914Document42 pagesCP4 Report On High Slope 20220914Mukunda DhunganaNo ratings yet

- The Stability Assessment of Arch Dams and Corresponding Reinforcement TechnologyDocument11 pagesThe Stability Assessment of Arch Dams and Corresponding Reinforcement TechnologyQingcheng YuNo ratings yet

- Silo-O - Slope Stability Analysis Report Rev B - TO REVIEWDocument13 pagesSilo-O - Slope Stability Analysis Report Rev B - TO REVIEWJulian SandovalNo ratings yet

- Open Pit Design Assignment - 2021Document9 pagesOpen Pit Design Assignment - 2021pauloreceado07No ratings yet

- z183 2003 micropilesFoundedRockDocument6 pagesz183 2003 micropilesFoundedRockPercy CasaniNo ratings yet

- Lateral Resistance of Helical Monopole Bases - SakrDocument8 pagesLateral Resistance of Helical Monopole Bases - SakrvilaneneNo ratings yet

- Empirical Slope Design For Hard and Soft Rocks Using Q-SlopeDocument8 pagesEmpirical Slope Design For Hard and Soft Rocks Using Q-SloperubenNo ratings yet

- GWW ExamplesDocument23 pagesGWW ExamplesSuthan PooranampillaiNo ratings yet

- Soft Ground Tunneling Design and Construction-NGS Fourth Monthly Lecture Series On 7th Feb 2019Document29 pagesSoft Ground Tunneling Design and Construction-NGS Fourth Monthly Lecture Series On 7th Feb 2019Bigyan UpadhayayNo ratings yet

- Deformation-Based Support Selection For Tunnels in Strainburst-Prone Ground-KaiserDocument14 pagesDeformation-Based Support Selection For Tunnels in Strainburst-Prone Ground-Kaisersuliman saadiNo ratings yet

- f094 PDFDocument4 pagesf094 PDFAnshuman SinghNo ratings yet

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Tsalis SalsabilaNo ratings yet

- Pile Foundation5640165006659842839Document33 pagesPile Foundation5640165006659842839sujan pokhrelNo ratings yet

- 158 Piles at Rainy RiverDocument9 pages158 Piles at Rainy RiverPamungkas T.No ratings yet

- OCK Hute Outlet Tability: C. E. Rice, K. C. Kadavy, K. M. Robinson, K. R. CookDocument4 pagesOCK Hute Outlet Tability: C. E. Rice, K. C. Kadavy, K. M. Robinson, K. R. CookLeonardo Rodrigues SantosNo ratings yet

- 1 Design of Tower Foundations Subramonia Book GOOD GOODDocument7 pages1 Design of Tower Foundations Subramonia Book GOOD GOODandyhr100% (1)

- Design of Tower FoundationsDocument7 pagesDesign of Tower FoundationsGuillermo LockhartNo ratings yet

- 4) Webinar Content - DR - KMK-03.05.2020Document90 pages4) Webinar Content - DR - KMK-03.05.2020Amith Unnimadhavan UNo ratings yet

- Yeo 1993Document14 pagesYeo 1993RooyagroupNo ratings yet

- NPTEL Course: Ground ImprovementDocument35 pagesNPTEL Course: Ground ImprovementmmNo ratings yet

- ClassificationDocument105 pagesClassificationOxky Setiawan WibisonoNo ratings yet

- Chapter 9 - Rock MassDocument116 pagesChapter 9 - Rock MassZulaikha Kamal50% (2)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Bleeding Time (Final)Document6 pagesBleeding Time (Final)Darwin Cañeso Balasta100% (1)

- Dissociative Multiplicity and Psychoanal PDFDocument30 pagesDissociative Multiplicity and Psychoanal PDFDangelo AugustoNo ratings yet

- Super Combi 3000 Still Growing Super Combi 3000 Cresce Ancora Super Combi 3000 Crece Todavia MasDocument7 pagesSuper Combi 3000 Still Growing Super Combi 3000 Cresce Ancora Super Combi 3000 Crece Todavia MasCalidad CohpaflexNo ratings yet

- Sec 06-01 PDFDocument26 pagesSec 06-01 PDFtempthereNo ratings yet

- Unit 1 Lecture MaterialDocument68 pagesUnit 1 Lecture Materialparvathy.kNo ratings yet

- Manual Na3s & Na4Document164 pagesManual Na3s & Na4jhonNo ratings yet

- Use Case, Process Modeling and Process Description: Systems Analysis and DesignDocument68 pagesUse Case, Process Modeling and Process Description: Systems Analysis and DesignNaim Harith Bin ZulkifliNo ratings yet

- Finding Duplicate FilesDocument1 pageFinding Duplicate FilesSerafimNo ratings yet

- Eee-III-Analog Electronic Circuits (15ee34) - AssignmentDocument6 pagesEee-III-Analog Electronic Circuits (15ee34) - AssignmentchaitanyaNo ratings yet

- A2 Multitrac With A2 Process Controller PEI: Welding TractorsDocument5 pagesA2 Multitrac With A2 Process Controller PEI: Welding TractorsLuis Chiara LoayzaNo ratings yet

- Electrical Braking of Asynchronous Motors - EEPDocument7 pagesElectrical Braking of Asynchronous Motors - EEPnavigareeNo ratings yet

- LogDocument102 pagesLogRay01 PutraNo ratings yet

- Catalog Varvel RS RTDocument60 pagesCatalog Varvel RS RTNikola VojisavljevicNo ratings yet

- Im-Ii-Qm-006-Sample Management For MicrobiologyDocument3 pagesIm-Ii-Qm-006-Sample Management For MicrobiologyVaidyanathan KesavanNo ratings yet

- Examination-Schedule BE-Arch-BCA-B.Sc .Env - Fall-2023 AllDocument4 pagesExamination-Schedule BE-Arch-BCA-B.Sc .Env - Fall-2023 Allsandhyakhadka909No ratings yet

- Theory of Rock Breakage.BDocument15 pagesTheory of Rock Breakage.BME-MNG-11 Bandhavi mogaramNo ratings yet

- DataLog X2 Terminal X2 Installation and User GuideDocument40 pagesDataLog X2 Terminal X2 Installation and User GuideDadang KurniaNo ratings yet

- Solutions - AIATS JEE (Adv) - 2018 (CBT Mode) - Test-5A - Paper-1 - (22-04-2018) PDFDocument6 pagesSolutions - AIATS JEE (Adv) - 2018 (CBT Mode) - Test-5A - Paper-1 - (22-04-2018) PDFBHARAT CHANDWANINo ratings yet

- Unit 2 - I Input and Output v1.5Document10 pagesUnit 2 - I Input and Output v1.5Thomas MathewNo ratings yet

- Service Manual: Digital Video Camera RecorderDocument74 pagesService Manual: Digital Video Camera RecorderJuan Carlos MuñozNo ratings yet

- Azeotropic Distillation ReportDocument2 pagesAzeotropic Distillation ReportKaye CaqNo ratings yet

- High-Voltage Safety Improvement Design For ElectriDocument15 pagesHigh-Voltage Safety Improvement Design For ElectriVăn BảoNo ratings yet

- Log Cat 1706683832269Document23 pagesLog Cat 1706683832269karanpareek5898No ratings yet

- OpenELIS Lab Data - Admin Guide (For Bahmni)Document6 pagesOpenELIS Lab Data - Admin Guide (For Bahmni)Hiến LưuNo ratings yet

- WRCDocument3 pagesWRCEdson CarrascoNo ratings yet

- IsomersDocument3 pagesIsomersjaiNo ratings yet

- PHD Thesis Machine LearningDocument8 pagesPHD Thesis Machine Learningtygocixff100% (1)