Professional Documents

Culture Documents

Polymer Coating Material GSS

Polymer Coating Material GSS

Uploaded by

sujal jha0 ratings0% found this document useful (0 votes)

21 views26 pagesThe document discusses polymer coating materials. It notes that polymers are resistant to corrosion, lightweight, nonconductive, and have low maintenance costs. It also discusses how polymer coatings can protect metals from corrosion. The document then provides details on different types of polymer coatings like acrylics, alkyds, polyurethanes, phenolics, nylon, and fluorocarbons. It explains their properties and common applications. Various coating methods are also outlined like spraying, dipping, rolling, and wire coating.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses polymer coating materials. It notes that polymers are resistant to corrosion, lightweight, nonconductive, and have low maintenance costs. It also discusses how polymer coatings can protect metals from corrosion. The document then provides details on different types of polymer coatings like acrylics, alkyds, polyurethanes, phenolics, nylon, and fluorocarbons. It explains their properties and common applications. Various coating methods are also outlined like spraying, dipping, rolling, and wire coating.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

21 views26 pagesPolymer Coating Material GSS

Polymer Coating Material GSS

Uploaded by

sujal jhaThe document discusses polymer coating materials. It notes that polymers are resistant to corrosion, lightweight, nonconductive, and have low maintenance costs. It also discusses how polymer coatings can protect metals from corrosion. The document then provides details on different types of polymer coatings like acrylics, alkyds, polyurethanes, phenolics, nylon, and fluorocarbons. It explains their properties and common applications. Various coating methods are also outlined like spraying, dipping, rolling, and wire coating.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 26

Polymer Coating Material

By

Gowri Shankari S

ICT-IOC

March 2021 ICT-IOC GOWRI S 1

Polymer Characteristics

Corrosion resistance: Polymers are resistant to corrosion.

Lightweight

Electrical properties: Polymers are nonconductive

Low maintenance cost: Polymer is easy to maintain because it

does not rust, is easily cleaned, and requires minimal protection

from the environment.

Less Energy & Cost to fabricate

Low Heat transfer

March 2021 ICT-IOC GOWRI S 2

Metal Corrosion &

Replacement

March 2021 ICT-IOC GOWRI S 3

Coating needed !

March 2021 ICT-IOC GOWRI S 4

Coating needed !

March 2021 ICT-IOC GOWRI S 5

What Is Polymer Coating….?

Polymeric coatings are coatings or paint made with polymers that

provide superior adherence and protection from corrosion.

Examples of polymeric coatings include:

Natural and synthetic rubber

Urethane

Polyvinyl chloride

Acrylic

Phenolic resins

March 2021 ICT-IOC GOWRI S 6

Why We Need PCM ….?

• Corrosion

• Aesthetic

• Fluid Contamination

• Cost

Functions :

Protective & Decorative

March 2021 ICT-IOC GOWRI S 7

Properties of Polymer Coating

Temperature-resistant up to high

temperature).

Resistance to heat/moisture/UV and

chemical.

Wear resistance

High Toughness.

Fire retardant

Waterproof Coat(hydrophobic)

Resist microbial attack

March 2021 ICT-IOC GOWRI S 8

Coating Methods

Basic Coating Sheet Coating Methods

Methods • Rolling

• Painting • Calendering

• Spraying • Wire Coating

• Dipping • Extrusion

March 2021 ICT-IOC GOWRI S 9

Spraying Methods

•Paint is applied to an object through the use

of an air-pressurized spray gun.

March 2021 ICT-IOC GOWRI S 10

Dipping Method

A substrate is dipped into a liquid coating solution and get

coated. Coating thickness generally increases with

faster withdrawal speed

March 2021 ICT-IOC GOWRI S 11

Rolling Methods

In this process polymer solution is rolled

onto the fabric/film/sheet by a roller

suspended in the coating solution.

A – Backup roll

B –Gravure roll

C- Blade

D- Paint bath

March 2021 ICT-IOC GOWRI S 12

Wire Coating Method

•Steel cable can be jacketed

with a number of plastics,

and a variety of wall

thicknesses.

•Commonly used plastics

includes PVC, Nylon,PE or

PP.

Insulating material is used as a protective

coating on electrical wire

March 2021 ICT-IOC GOWRI S 13

Electrocoating or E-coat

•Electrocoating is an immersion

painting process in which charged paint

particles are attracted to an oppositely

charged metallic surface.

• As the paint is deposited, it forms a

finish which begins to insulate the metal

from the surrounding charged solution.

Deposition continues until the coating

thickness becomes sufficient to form a

barrier against further paint attraction.

March 2021 ICT-IOC GOWRI S 14

Different Polymer Coatings

Acrylics and alkyds :

Acrylics are esters of acrylic acid.

Alkyds are synthetic resins made by reacting alcohols and fatty acids

Alkyd resins benefits are: good weathering characteristics and ease of

application with low-cost, low-toxicity, Abrasion resistance, Good

adhesion.

March 2021 ICT-IOC GOWRI S 15

Acrylics and alkyds :

Used in marine vessel, bridge, dryer ambient

temperature curing, rust preventative paint

Silicone modification of organic resins

improves overall weatherability & durability

March 2021 ICT-IOC GOWRI S 16

The colors of the paints were identical when

applied. After 15 years of weathering, the

appearance of the alkyds has changed

dramatically.

Alkyd

Acrylic

March 2021 ICT-IOC GOWRI S 17

Polyurethane enamels:

Characterized by excellent toughness,

durability, and corrosion resistance.

Used in conveyor equipment, aircraft, boats,

road-building machinery, and motorcycle

parts.

March 2021 ICT-IOC GOWRI S 18

Air plane Coating with Polyurethane

March 2021 ICT-IOC GOWRI S 19

Coating with Polyurethane

March 2021 ICT-IOC GOWRI S 20

Phenolic (Epoxy):

Better adhesion to metal substrates than do most other

organic material.

Attractive economically

Used in corrosive chemicals or abrasive materials.

March 2021 ICT-IOC GOWRI S 21

Coating with Phenolics

Pump Impeller Pipe Painting with Epoxy Coupling

March 2021 ICT-IOC GOWRI S 22

Nylon 11

Provide attractive appearance as well as

protection from chemicals, abrasion, and impact.

2.5 to 8 mil, nylon coatings are used on office and

outdoor furniture, hospital beds, vending-

machine parts, and building railings

Heavier coatings -- to 50 mil -- are applied to

protect, food-processing machinery, farm and

material-handling equipment, and industrial

equipment such as pipe, fittings, and valves

March 2021 ICT-IOC GOWRI S 23

Coating with Nylon

March 2021 ICT-IOC GOWRI S 24

Fluorocarbons (PTFE)

More nearly inert to chemicals and solvents than

all other polymers

The major application of PTFE, consuming about

50% of production, is for wiring in aerospace and

computer applications

Its frictionless qualities allow improved flow of

highly viscous liquids.

March 2021 ICT-IOC GOWRI S 25

THANK YOU !

March 2021 ICT-IOC GOWRI S 26

You might also like

- VP - PSV SEA VEGA REV.0 (New Logo) r2Document4 pagesVP - PSV SEA VEGA REV.0 (New Logo) r2Sugiman LayantoNo ratings yet

- PFT - 253 LEAF GREEN BaruDocument4 pagesPFT - 253 LEAF GREEN Barueva andriana putriNo ratings yet

- Dale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Document7 pagesDale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Luz Mary OrtegaNo ratings yet

- Polymer Coating Material GSSDocument26 pagesPolymer Coating Material GSSsujal jhaNo ratings yet

- Polymer Coating Material GSSDocument26 pagesPolymer Coating Material GSSsujal jhaNo ratings yet

- Waste Delivery Receipt Form For The Vessels Calling Romania's PortsDocument13 pagesWaste Delivery Receipt Form For The Vessels Calling Romania's Portssuiramamid79No ratings yet

- LDocument5 pagesLKatherine NaveaNo ratings yet

- Time Sheet TantoDocument4 pagesTime Sheet TantoFatra FirdianNo ratings yet

- Atmospheric Stability Classes Rev 1 PDFDocument33 pagesAtmospheric Stability Classes Rev 1 PDFDJSeidel100% (1)

- CP ParandowskiDocument8 pagesCP ParandowskiДмитрий ПлясунNo ratings yet

- Silsilah Kesultanan Turki UsmaniDocument2 pagesSilsilah Kesultanan Turki UsmaniSidik cahaya saputraNo ratings yet

- 9 14 Pages Mcqs Cswip 31 Question Answers Solved Past Papers Cswip 31 PDF FreeDocument14 pages9 14 Pages Mcqs Cswip 31 Question Answers Solved Past Papers Cswip 31 PDF Freekihal zohirNo ratings yet

- Laporan Harian Bongkar / Muat: Jam 06:00 S/D 06:00 (24 Jam)Document2 pagesLaporan Harian Bongkar / Muat: Jam 06:00 S/D 06:00 (24 Jam)Faisal MartianaNo ratings yet

- Microsoft PowerPoint - Materi Dasar Pengenalan Kapal-PrintoutDocument28 pagesMicrosoft PowerPoint - Materi Dasar Pengenalan Kapal-Printoutdian.yudistiro8435No ratings yet

- Kuliah Tamu ITB 2010 FinalDocument32 pagesKuliah Tamu ITB 2010 FinalbarconNo ratings yet

- CSWIP 3.0 Visual Inspection RevisedDocument136 pagesCSWIP 3.0 Visual Inspection RevisedquyennqNo ratings yet

- QSOP - Install Solid Control Equipment (SO)Document5 pagesQSOP - Install Solid Control Equipment (SO)harry mulyafitNo ratings yet

- Pemeriksaan Kecelakaan Kapal Imdg & MarpolDocument35 pagesPemeriksaan Kecelakaan Kapal Imdg & MarpolVino Telo100% (1)

- LPK DGDocument24 pagesLPK DGsubrascNo ratings yet

- Chap 0.3 Waste Water TreatmentDocument12 pagesChap 0.3 Waste Water Treatmentrrjm_24No ratings yet

- Welding Inspector Question and Answer According CSWIP 3.1-1Document76 pagesWelding Inspector Question and Answer According CSWIP 3.1-1Mahmoud HagagNo ratings yet

- Loading Operation 2Document21 pagesLoading Operation 2Subir BairagiNo ratings yet

- Liebherr SC OverviewDocument11 pagesLiebherr SC Overviewnicolasq francescaNo ratings yet

- Authorised Gas Tester Training Level 1 Gas Testing Including Confined Space Testing PDFDocument42 pagesAuthorised Gas Tester Training Level 1 Gas Testing Including Confined Space Testing PDFahmedNo ratings yet

- Send Perhitungan Ritase Driver 2018-08Document19 pagesSend Perhitungan Ritase Driver 2018-08Asep KingNo ratings yet

- Accident Investigation 1Document19 pagesAccident Investigation 1arulazzikriNo ratings yet

- Pertemuan X Penanganan Proses Berlabuh JangkarDocument24 pagesPertemuan X Penanganan Proses Berlabuh JangkarRani TribuanaNo ratings yet

- Daftar Singkatan Dalam Istilah PelayaranDocument6 pagesDaftar Singkatan Dalam Istilah Pelayaranbagas maheswaraNo ratings yet

- BARQI BROTHERS Company Profile - 2022Document25 pagesBARQI BROTHERS Company Profile - 2022Muljono MolNo ratings yet

- Co2dh20 - 22B - 204 - IsocontenedorDocument5 pagesCo2dh20 - 22B - 204 - IsocontenedorLuis CortezNo ratings yet

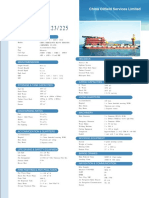

- COSL 221/222/223/225: China Oilfield Services LimitedDocument1 pageCOSL 221/222/223/225: China Oilfield Services LimitedSanty SantyNo ratings yet

- Form For Cargo InformationDocument1 pageForm For Cargo InformationHenny SulastriNo ratings yet

- Ship Particular Blue Marlin 02Document2 pagesShip Particular Blue Marlin 02Hermawan NathanaelNo ratings yet

- Fasilitas Pelabuhan Dan FungsinyaDocument98 pagesFasilitas Pelabuhan Dan FungsinyaDiego Maradona Maharduta100% (1)

- Reefer ContainerDocument23 pagesReefer ContainertholeNo ratings yet

- Materi Dasar Pengenalan Kapal-PrintoutDocument28 pagesMateri Dasar Pengenalan Kapal-Printoutdian.yudistiro8435100% (1)

- Marine Insurance - Niko LukumDocument59 pagesMarine Insurance - Niko LukumNapol 09No ratings yet

- LPT - Question and AnswerDocument3 pagesLPT - Question and Answerdanish.khan80206040No ratings yet

- Checklist - Annual Special Hull - SubmersibleDocument8 pagesChecklist - Annual Special Hull - SubmersibleGene LoConteNo ratings yet

- MarlawDocument1 pageMarlawEko Novianto0% (1)

- RTOG Module 6 - Vehicle Management PDFDocument42 pagesRTOG Module 6 - Vehicle Management PDFsukarno agustoNo ratings yet

- Nondestructive Examination (NDE)Document82 pagesNondestructive Examination (NDE)HashirNo ratings yet

- Control ValveDocument39 pagesControl ValvewirawansatriaNo ratings yet

- Ship Shore Safety Check ListDocument3 pagesShip Shore Safety Check ListRoberto StepicNo ratings yet

- Caustic Soda Liquid 48-50%Document12 pagesCaustic Soda Liquid 48-50%wongpengchiong7205No ratings yet

- MARPOL Presentation (Final Version)Document61 pagesMARPOL Presentation (Final Version)soner0004100% (1)

- Draft, Trim, Hog-Sag & Density Correction - AISI - PresentationDocument20 pagesDraft, Trim, Hog-Sag & Density Correction - AISI - PresentationAnugrah Putra RaNo ratings yet

- Dong-Kyu Choi PDFDocument33 pagesDong-Kyu Choi PDFParthiban NagarajanNo ratings yet

- Report Sample - Pre-Shipment Inspection-ThermometerDocument30 pagesReport Sample - Pre-Shipment Inspection-ThermometerCarlosSánchezNo ratings yet

- CONTAINER TYPES SIZE AND DIMENTIONS - Export Import DatabaseDocument11 pagesCONTAINER TYPES SIZE AND DIMENTIONS - Export Import DatabaseMaria Gabriela BusteloNo ratings yet

- Grounding and Bonding For Oil and Gas Drilling orDocument8 pagesGrounding and Bonding For Oil and Gas Drilling orMadhusudhana RajuNo ratings yet

- LNG Imo FamiliarizationDocument32 pagesLNG Imo FamiliarizationAustin UdofiaNo ratings yet

- Arti Nomor ContainerDocument7 pagesArti Nomor ContainerDennis SetiawanNo ratings yet

- Introduction To Load Line Survey PDFDocument70 pagesIntroduction To Load Line Survey PDFinfraNo ratings yet

- PORT AND WAREHOUSE - Edit 10 Januari 2019Document14 pagesPORT AND WAREHOUSE - Edit 10 Januari 2019Ali HasyimiNo ratings yet

- Requirements. Problems. Solutions A Shipowner's PerspectiveDocument66 pagesRequirements. Problems. Solutions A Shipowner's PerspectivePham Tất TiệpNo ratings yet

- APS Company Profile Presentation To KSO PTM EP Telaga Said March 11 2014Document26 pagesAPS Company Profile Presentation To KSO PTM EP Telaga Said March 11 2014Nik AbduhNo ratings yet

- Peralatan A - F (Update)Document33 pagesPeralatan A - F (Update)AnnisaNo ratings yet

- Wooden Pallet 1200 X 1000 MMDocument1 pageWooden Pallet 1200 X 1000 MMPokemon HienaNo ratings yet

- Awareness ISO 45001Document97 pagesAwareness ISO 45001kresna suryadiNo ratings yet

- Acoustic Doppler Current ProfilerDocument20 pagesAcoustic Doppler Current Profilerashish chauhanNo ratings yet

- LED Depensing 5070Document12 pagesLED Depensing 5070Anonymous 0tqzNTWyyNo ratings yet

- Cat EpoxyDocument12 pagesCat Epoxymohamed Salah klaiNo ratings yet

- 10.4 Degradation of Cotton During Alkaline ScouringDocument3 pages10.4 Degradation of Cotton During Alkaline Scouringsujal jhaNo ratings yet

- Improve Your Finance KnowledgeDocument12 pagesImprove Your Finance Knowledgesujal jhaNo ratings yet

- Introduction To Dyeing of TextilesDocument75 pagesIntroduction To Dyeing of Textilessujal jhaNo ratings yet

- PolyestersDocument6 pagesPolyesterssujal jhaNo ratings yet

- How Behavior Affects Financial Decisions.Document12 pagesHow Behavior Affects Financial Decisions.sujal jhaNo ratings yet

- Printing IntroductionDocument40 pagesPrinting Introductionsujal jhaNo ratings yet

- Introduction To BlowroomDocument21 pagesIntroduction To Blowroomsujal jha100% (1)

- Driyng Zone 6Document7 pagesDriyng Zone 6sujal jhaNo ratings yet

- Introduction To Melt SpinningDocument7 pagesIntroduction To Melt Spinningsujal jha100% (1)

- Numerical WindingDocument12 pagesNumerical Windingsujal jhaNo ratings yet

- 152 809 2 PBDocument12 pages152 809 2 PBsujal jhaNo ratings yet

- Winding: 2.2 Classification of Winding PrinciplesDocument4 pagesWinding: 2.2 Classification of Winding Principlessujal jha0% (1)

- Textile WastewaterDocument43 pagesTextile Wastewatersujal jhaNo ratings yet

- Functional FinishingDocument31 pagesFunctional Finishingsujal jhaNo ratings yet

- Phosphorous CompoundsDocument36 pagesPhosphorous Compoundssujal jhaNo ratings yet

- Polymer CompositeDocument39 pagesPolymer Compositesujal jhaNo ratings yet

- What's The Difference Between Micro, Ultra & Nano Filtration - MembraconDocument6 pagesWhat's The Difference Between Micro, Ultra & Nano Filtration - MembraconJimmy Hend KhratNo ratings yet

- Heavy MetalDocument11 pagesHeavy MetalMwemezi RwizaNo ratings yet

- Nutritional and Bioactive Compounds in Dried Tomato Processing WasteDocument9 pagesNutritional and Bioactive Compounds in Dried Tomato Processing WasteOliviaNo ratings yet

- Aditya SharmaDocument12 pagesAditya SharmaAnish kumarNo ratings yet

- Hydro CarbonsDocument10 pagesHydro CarbonsLok Jun Hao100% (1)

- Ventós: 1. Identification of The Substance/Mixture and The Company/UndertakingDocument5 pagesVentós: 1. Identification of The Substance/Mixture and The Company/UndertakingOctavian CoifanNo ratings yet

- Recycle. Process EngineeringDocument20 pagesRecycle. Process EngineeringDarel WilliamsNo ratings yet

- 3b - Serway - MillikanDocument7 pages3b - Serway - Millikanalejandro1rs1orNo ratings yet

- ReddDocument183 pagesReddXQNo ratings yet

- Libro - Funcional Genomics - DNA, RNA and Protein Analysis - Springer ProtocolsDocument385 pagesLibro - Funcional Genomics - DNA, RNA and Protein Analysis - Springer ProtocolsDiana López López100% (3)

- Common Organic Compounds: Properties and Uses: Redeveloped Division Initiated Self-Learning ModuleDocument21 pagesCommon Organic Compounds: Properties and Uses: Redeveloped Division Initiated Self-Learning ModuleMaribeth Q. AdierNo ratings yet

- Module 5Document13 pagesModule 5let's skip this100% (1)

- Technical - Manual El - Zinc MetalTech 2012Document158 pagesTechnical - Manual El - Zinc MetalTech 2012RICARDO GIERKENo ratings yet

- 2001 04 14 Malossa eDocument4 pages2001 04 14 Malossa eJorge GómezNo ratings yet

- neodisher-IP-Spray MB en PN4304 2015-08-01 240205 152138Document1 pageneodisher-IP-Spray MB en PN4304 2015-08-01 240205 152138Lukas WijayantoNo ratings yet

- 08 - Water and SolutionsDocument32 pages08 - Water and Solutionsayulg2100% (2)

- Heat and Mass Transfer Laboratory Manual PDFDocument59 pagesHeat and Mass Transfer Laboratory Manual PDFKuldeep KumarNo ratings yet

- VOESTALPINE - Durostat (EN-05062019) 04 - 2019 PDFDocument3 pagesVOESTALPINE - Durostat (EN-05062019) 04 - 2019 PDFSimone PavaniNo ratings yet

- Solar Powered Desalination System Using Fresnel LensDocument7 pagesSolar Powered Desalination System Using Fresnel LensjonaNo ratings yet

- SSC Je 02-03-2017Document17 pagesSSC Je 02-03-2017vikash kumarNo ratings yet

- Hydrogen Usage in Cement Production: Opportunities & ChallengesDocument18 pagesHydrogen Usage in Cement Production: Opportunities & Challengeshoang nguyenNo ratings yet

- Biological Activities of CurcuminDocument22 pagesBiological Activities of CurcumindetiNo ratings yet

- How Chemistry Related To Other ScienceDocument1 pageHow Chemistry Related To Other SciencePRINTDESK by Dan100% (2)

- Marlex HGX 030spDocument1 pageMarlex HGX 030spErnesto CheguavaraNo ratings yet

- Seminar On Air Pollution: Submitted To: Submitted byDocument32 pagesSeminar On Air Pollution: Submitted To: Submitted byHELLO WORLDNo ratings yet

- Shrikant FeSO4 ReportDocument20 pagesShrikant FeSO4 ReportPrashant KiraveNo ratings yet

- Australia BSL Project: Start Completion Location Client Capacity ProjectDocument2 pagesAustralia BSL Project: Start Completion Location Client Capacity ProjectAmy GardnerNo ratings yet

- Thermal, Electrochemical, and Photochemical Conversion of CO2 To Fuels and Value-Added Products 18-27Document10 pagesThermal, Electrochemical, and Photochemical Conversion of CO2 To Fuels and Value-Added Products 18-27Gustavo Hdez100% (1)