Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

3 viewsMaterial Specification Sheet Saarstahl - C15E2C (Cq15)

Material Specification Sheet Saarstahl - C15E2C (Cq15)

Uploaded by

aaeThis document provides material specification details for Saarstahl C15E2C steel. Some key details include:

1. The steel is a plain carbon steel intended for cold extrusion of screws and bolts.

2. It has a carbon content between 0.14-0.15% and is suitable for cold extrusion according to DIN EN 10263.

3. Various heat treatments and mechanical properties are provided for different processing routes like spheroidized annealing, cold drawing, and stretch reducing. Tensile strengths and reductions of area are specified within given diameter ranges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Industrial Visit ReportDocument106 pagesIndustrial Visit ReportRushi GaikwadNo ratings yet

- 20160302015150-0214 - C10C EnglischDocument2 pages20160302015150-0214 - C10C EnglischjayalakshmivinothNo ratings yet

- 20171123111141-0303 - C4C EnglischDocument2 pages20171123111141-0303 - C4C Englischharis osmanagicNo ratings yet

- 32CrB4Document2 pages32CrB4Sergio Munguia RiveraNo ratings yet

- 20160401103255-1149 1151 C22e C22RDocument2 pages20160401103255-1149 1151 C22e C22RShabanali Omrani100% (1)

- 20160323010710-C40E (Ck40)Document2 pages20160323010710-C40E (Ck40)Hans GoetheNo ratings yet

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984No ratings yet

- Material Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationDocument2 pagesMaterial Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: Applicationshankarjb100% (1)

- Material Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationDocument2 pagesMaterial Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationErdinc BayatNo ratings yet

- 20160323010627-C45E (Ck45) - C45R (Cm45) PDFDocument2 pages20160323010627-C45E (Ck45) - C45R (Cm45) PDFNikolat84No ratings yet

- Material-Datasheet Saarstahl - C15Document1 pageMaterial-Datasheet Saarstahl - C15Rohit GadekarNo ratings yet

- 20160323093138-51CrV4 (50CrV4)Document1 page20160323093138-51CrV4 (50CrV4)P NAVEEN KUMARNo ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- 1.7225 enDocument0 pages1.7225 enPavle StevanovicNo ratings yet

- Material Specification Sheet Saarstahl - 51Crv4 (50Crv4)Document3 pagesMaterial Specification Sheet Saarstahl - 51Crv4 (50Crv4)anilNo ratings yet

- C45Document2 pagesC45Marko DobrisavljevicNo ratings yet

- 20160331071021-6541 23MnNiCrMo52Document1 page20160331071021-6541 23MnNiCrMo52rusf123No ratings yet

- 34 CR Ni Mo 6Document1 page34 CR Ni Mo 6Bogdan CraciunNo ratings yet

- Mechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesDocument4 pagesMechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesJarek CieslakNo ratings yet

- VCMO140Document3 pagesVCMO140samsul hudaNo ratings yet

- Asaab 8407 - 2MDocument11 pagesAsaab 8407 - 2MPrabath MadusankaNo ratings yet

- Dilli Max 690Document4 pagesDilli Max 690Fernando Alonso Troncos MendivesNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Buderus 7225Document4 pagesBuderus 7225Ajeng GaleriNo ratings yet

- 20160323011855-41Cr4 - 41CrS4 PDFDocument1 page20160323011855-41Cr4 - 41CrS4 PDFMarius ZenoagaNo ratings yet

- 20160323110156-11SMnPb37 (9SMnPb36)Document1 page20160323110156-11SMnPb37 (9SMnPb36)Богдан ЛекарьNo ratings yet

- Material Specification Sheet Saarstahl - 27Mncrb5-2Document1 pageMaterial Specification Sheet Saarstahl - 27Mncrb5-2rakeshNo ratings yet

- 20160323110453-11SMn30 (9SMn28)Document1 page20160323110453-11SMn30 (9SMn28)novkovic1984No ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- 20160401112452-7228 50CrMo4Document1 page20160401112452-7228 50CrMo4JonathanNo ratings yet

- S235JR Sau OL 37Document1 pageS235JR Sau OL 37Pișta GonzalesNo ratings yet

- S355J2+N Steel PlateDocument2 pagesS355J2+N Steel PlateAmanNo ratings yet

- 20200618100734-11SMnPb30 EnglischDocument1 page20200618100734-11SMnPb30 EnglischTuff qualityNo ratings yet

- AISI416Document2 pagesAISI416shamsi862620No ratings yet

- C45EDocument3 pagesC45ETrương Định100% (1)

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Material 11SMnPb30 (9SMnPb28)Document1 pageMaterial 11SMnPb30 (9SMnPb28)joseocsilvaNo ratings yet

- 20160323110402-11SMnPb30 (9SMnPb28) PDFDocument1 page20160323110402-11SMnPb30 (9SMnPb28) PDFjoseocsilvaNo ratings yet

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- C53 Technical CardDocument1 pageC53 Technical CardAnonymous umabEI6No ratings yet

- Manufacturing Engineering Diploma Engineering MCQFrom EverandManufacturing Engineering Diploma Engineering MCQRating: 5 out of 5 stars5/5 (1)

- M.-Tool and Die Making Troubleshooter-Society of Manufacturing Engineers (SME) (2003) PDFDocument278 pagesM.-Tool and Die Making Troubleshooter-Society of Manufacturing Engineers (SME) (2003) PDFRuben Leal100% (1)

- Conventional Milling vs. Climb MillingDocument1 pageConventional Milling vs. Climb MillingNisar HussainNo ratings yet

- GLASSDocument5 pagesGLASSPamela SidicNo ratings yet

- BV Rule Note NR476 Approval Testing of WeldersDocument15 pagesBV Rule Note NR476 Approval Testing of Welderssmlvl01No ratings yet

- ASTM A182 Grade F22Document2 pagesASTM A182 Grade F22Oswaldo GuerraNo ratings yet

- Abrasive JetDocument16 pagesAbrasive JetganeshNo ratings yet

- SA-765/SA-765M SA-350/SA-350M: Melting Process Melting ProcessDocument2 pagesSA-765/SA-765M SA-350/SA-350M: Melting Process Melting ProcessHobinca MarianNo ratings yet

- Sheet Metal FormingDocument38 pagesSheet Metal FormingPriya ChilukuriNo ratings yet

- Tooldiesteelhandbook PDFDocument164 pagesTooldiesteelhandbook PDFRyan RafaelNo ratings yet

- 1-FprEN ISO 4210 Terms - and - DefinitionsDocument4 pages1-FprEN ISO 4210 Terms - and - Definitionsjohn michael lavidoNo ratings yet

- BE 2019 Additive ManufacturingDocument4 pagesBE 2019 Additive ManufacturingHarsha AbhichandaniNo ratings yet

- Defectos en La FundicionesDocument4 pagesDefectos en La FundicionesJulio Cesar AyalaNo ratings yet

- Durable Actuator Solutions: Centrifugal Casting Electropolishing ProcessDocument2 pagesDurable Actuator Solutions: Centrifugal Casting Electropolishing ProcessJignesh TamkeNo ratings yet

- Ta 201 A Laboratory ManualDocument22 pagesTa 201 A Laboratory ManualSunitNo ratings yet

- Cam - L7Document14 pagesCam - L7Ritik RajNo ratings yet

- Powder MetallurgyDocument9 pagesPowder MetallurgyYashvir SinghNo ratings yet

- New 4340 Alloy SteelDocument3 pagesNew 4340 Alloy Steeljimmy julian pava vargasNo ratings yet

- Flange Weld Build UpDocument2 pagesFlange Weld Build UpMohd Shafuaaz KassimNo ratings yet

- PressDocument15 pagesPressRekha HNo ratings yet

- Welding Log PipingDocument322 pagesWelding Log PipingSalman Khan100% (1)

- Thyrodur 2080Document1 pageThyrodur 2080Grafički RadoviNo ratings yet

- Material Properties and Metal FormingDocument5 pagesMaterial Properties and Metal FormingSaikat BanerjeeNo ratings yet

- Flowsheet Dan Block Diagram Pulp and Tissue: Nama: 1. Bayu Wisnu Buana Putra (M1B116001) 2. MUHAMMAD ASWARI (M1B116019)Document4 pagesFlowsheet Dan Block Diagram Pulp and Tissue: Nama: 1. Bayu Wisnu Buana Putra (M1B116001) 2. MUHAMMAD ASWARI (M1B116019)Bayu Wisnu Buana PutraNo ratings yet

- Basic Principles of Metallurgy 23.07.2020Document3 pagesBasic Principles of Metallurgy 23.07.2020Rita DesiasniNo ratings yet

- GMW14057Document19 pagesGMW14057Felipe De la cruzNo ratings yet

- European Steel and Alloy Grades: About Us EN 10248-1Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10248-1farshid KarpasandNo ratings yet

- Squeeze CastingDocument18 pagesSqueeze CastingFebri Ramdani NugrahaNo ratings yet

- Page 270Document1 pagePage 270tito3007No ratings yet

- Damascus SteelDocument7 pagesDamascus SteelMichael MichaelNo ratings yet

Material Specification Sheet Saarstahl - C15E2C (Cq15)

Material Specification Sheet Saarstahl - C15E2C (Cq15)

Uploaded by

aae0 ratings0% found this document useful (0 votes)

3 views2 pagesThis document provides material specification details for Saarstahl C15E2C steel. Some key details include:

1. The steel is a plain carbon steel intended for cold extrusion of screws and bolts.

2. It has a carbon content between 0.14-0.15% and is suitable for cold extrusion according to DIN EN 10263.

3. Various heat treatments and mechanical properties are provided for different processing routes like spheroidized annealing, cold drawing, and stretch reducing. Tensile strengths and reductions of area are specified within given diameter ranges.

Original Description:

Original Title

20160323015120-C15E2C (Cq15)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides material specification details for Saarstahl C15E2C steel. Some key details include:

1. The steel is a plain carbon steel intended for cold extrusion of screws and bolts.

2. It has a carbon content between 0.14-0.15% and is suitable for cold extrusion according to DIN EN 10263.

3. Various heat treatments and mechanical properties are provided for different processing routes like spheroidized annealing, cold drawing, and stretch reducing. Tensile strengths and reductions of area are specified within given diameter ranges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views2 pagesMaterial Specification Sheet Saarstahl - C15E2C (Cq15)

Material Specification Sheet Saarstahl - C15E2C (Cq15)

Uploaded by

aaeThis document provides material specification details for Saarstahl C15E2C steel. Some key details include:

1. The steel is a plain carbon steel intended for cold extrusion of screws and bolts.

2. It has a carbon content between 0.14-0.15% and is suitable for cold extrusion according to DIN EN 10263.

3. Various heat treatments and mechanical properties are provided for different processing routes like spheroidized annealing, cold drawing, and stretch reducing. Tensile strengths and reductions of area are specified within given diameter ranges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

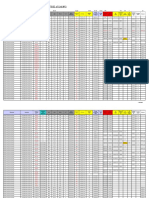

Material specification sheet

Saarstahl - C15E2C (Cq15)

Material No.: Former brand name: International steel grades:

1.1132 RKS15 BS:

AFNOR:

SAE:

Material group: Steel for cold extrusion according to DIN EN 10263

Chemical C Si Mn P S Cu

composition:

(Typical analysis in %) 0,14 0,15 0,40 <0,025 <0,025 <0,25

Application: Plain carbon steel for cold extrusion of screws and bolts

Hot forming and Soft annealing: 650 - 700°C

heat treatment: Hardening: 870 - 900°C/water

Tempering: 530 - 670°C

Mechanical

Properties:

Untreated (+U) or untreated + as hot rolled (+PE)

Diameter d [mm] >2-5 > 5 - 10 > 10 - 40 > 40 - 100

Tensile strength Rm [N/mm²] - max. 480 max. 480 max. 480

Reduction of area Z [%] - min. 58 min. 58 min. 58

Spheroidized annealed (+AC) or spheroidized annealed + peeled

(+AC+PE)

Diameter d [mm] >2-5 > 5 - 10 > 10 - 40 > 40 - 100

Tensile strength Rm [N/mm²] - max. 430 max. 430 max. 430

Reduction of area Z [%] - min. 65 min. 65 min. 65

untreated + cold drawn (+U+C)

Diameter d [mm] >2-5 > 5 - 10 > 10 - 40 > 40 - 100

Tensile strength Rm [N/mm²] - max. 570 max. 560 -

Reduction of area Z [%] - min. 56 min. 56 -

untreated + cold drawn + spheroidized annealed (+U+C+AC)

Diameter d [mm] >2-5 > 5 - 10 > 10 - 40 > 40 - 100

Tensile strength Rm [N/mm²] max. 420 max. 410 max. 410 -

Reduction of area Z [%] min. 67 min. 67 min. 67 -

Untreated + cold drawn + spheroidized annealed + stretch reduced by

roll drawing (+U+C+AC+LC)

Diameter d [mm] >2-5 > 5 - 10 > 10 - 40 > 40 - 100

Tensile strength Rm [N/mm²] max. 460 max. 450 max. 450 -

Reduction of area Z [%] min. 65 min. 65 min. 65 -

Spheroidized annealed + cold drawn (+AC+C)

Diameter d [mm] >2-5 > 5 - 10 > 10 - 40 > 40 - 100

Tensile strength Rm [N/mm²] - max. 520 max. 510 -

Reduction of area Z [%] - min. 62 min. 62 -

You might also like

- Industrial Visit ReportDocument106 pagesIndustrial Visit ReportRushi GaikwadNo ratings yet

- 20160302015150-0214 - C10C EnglischDocument2 pages20160302015150-0214 - C10C EnglischjayalakshmivinothNo ratings yet

- 20171123111141-0303 - C4C EnglischDocument2 pages20171123111141-0303 - C4C Englischharis osmanagicNo ratings yet

- 32CrB4Document2 pages32CrB4Sergio Munguia RiveraNo ratings yet

- 20160401103255-1149 1151 C22e C22RDocument2 pages20160401103255-1149 1151 C22e C22RShabanali Omrani100% (1)

- 20160323010710-C40E (Ck40)Document2 pages20160323010710-C40E (Ck40)Hans GoetheNo ratings yet

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984No ratings yet

- Material Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationDocument2 pagesMaterial Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: Applicationshankarjb100% (1)

- Material Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationDocument2 pagesMaterial Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationErdinc BayatNo ratings yet

- 20160323010627-C45E (Ck45) - C45R (Cm45) PDFDocument2 pages20160323010627-C45E (Ck45) - C45R (Cm45) PDFNikolat84No ratings yet

- Material-Datasheet Saarstahl - C15Document1 pageMaterial-Datasheet Saarstahl - C15Rohit GadekarNo ratings yet

- 20160323093138-51CrV4 (50CrV4)Document1 page20160323093138-51CrV4 (50CrV4)P NAVEEN KUMARNo ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- 1.7225 enDocument0 pages1.7225 enPavle StevanovicNo ratings yet

- Material Specification Sheet Saarstahl - 51Crv4 (50Crv4)Document3 pagesMaterial Specification Sheet Saarstahl - 51Crv4 (50Crv4)anilNo ratings yet

- C45Document2 pagesC45Marko DobrisavljevicNo ratings yet

- 20160331071021-6541 23MnNiCrMo52Document1 page20160331071021-6541 23MnNiCrMo52rusf123No ratings yet

- 34 CR Ni Mo 6Document1 page34 CR Ni Mo 6Bogdan CraciunNo ratings yet

- Mechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesDocument4 pagesMechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesJarek CieslakNo ratings yet

- VCMO140Document3 pagesVCMO140samsul hudaNo ratings yet

- Asaab 8407 - 2MDocument11 pagesAsaab 8407 - 2MPrabath MadusankaNo ratings yet

- Dilli Max 690Document4 pagesDilli Max 690Fernando Alonso Troncos MendivesNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Buderus 7225Document4 pagesBuderus 7225Ajeng GaleriNo ratings yet

- 20160323011855-41Cr4 - 41CrS4 PDFDocument1 page20160323011855-41Cr4 - 41CrS4 PDFMarius ZenoagaNo ratings yet

- 20160323110156-11SMnPb37 (9SMnPb36)Document1 page20160323110156-11SMnPb37 (9SMnPb36)Богдан ЛекарьNo ratings yet

- Material Specification Sheet Saarstahl - 27Mncrb5-2Document1 pageMaterial Specification Sheet Saarstahl - 27Mncrb5-2rakeshNo ratings yet

- 20160323110453-11SMn30 (9SMn28)Document1 page20160323110453-11SMn30 (9SMn28)novkovic1984No ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- 20160401112452-7228 50CrMo4Document1 page20160401112452-7228 50CrMo4JonathanNo ratings yet

- S235JR Sau OL 37Document1 pageS235JR Sau OL 37Pișta GonzalesNo ratings yet

- S355J2+N Steel PlateDocument2 pagesS355J2+N Steel PlateAmanNo ratings yet

- 20200618100734-11SMnPb30 EnglischDocument1 page20200618100734-11SMnPb30 EnglischTuff qualityNo ratings yet

- AISI416Document2 pagesAISI416shamsi862620No ratings yet

- C45EDocument3 pagesC45ETrương Định100% (1)

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Material 11SMnPb30 (9SMnPb28)Document1 pageMaterial 11SMnPb30 (9SMnPb28)joseocsilvaNo ratings yet

- 20160323110402-11SMnPb30 (9SMnPb28) PDFDocument1 page20160323110402-11SMnPb30 (9SMnPb28) PDFjoseocsilvaNo ratings yet

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- C53 Technical CardDocument1 pageC53 Technical CardAnonymous umabEI6No ratings yet

- Manufacturing Engineering Diploma Engineering MCQFrom EverandManufacturing Engineering Diploma Engineering MCQRating: 5 out of 5 stars5/5 (1)

- M.-Tool and Die Making Troubleshooter-Society of Manufacturing Engineers (SME) (2003) PDFDocument278 pagesM.-Tool and Die Making Troubleshooter-Society of Manufacturing Engineers (SME) (2003) PDFRuben Leal100% (1)

- Conventional Milling vs. Climb MillingDocument1 pageConventional Milling vs. Climb MillingNisar HussainNo ratings yet

- GLASSDocument5 pagesGLASSPamela SidicNo ratings yet

- BV Rule Note NR476 Approval Testing of WeldersDocument15 pagesBV Rule Note NR476 Approval Testing of Welderssmlvl01No ratings yet

- ASTM A182 Grade F22Document2 pagesASTM A182 Grade F22Oswaldo GuerraNo ratings yet

- Abrasive JetDocument16 pagesAbrasive JetganeshNo ratings yet

- SA-765/SA-765M SA-350/SA-350M: Melting Process Melting ProcessDocument2 pagesSA-765/SA-765M SA-350/SA-350M: Melting Process Melting ProcessHobinca MarianNo ratings yet

- Sheet Metal FormingDocument38 pagesSheet Metal FormingPriya ChilukuriNo ratings yet

- Tooldiesteelhandbook PDFDocument164 pagesTooldiesteelhandbook PDFRyan RafaelNo ratings yet

- 1-FprEN ISO 4210 Terms - and - DefinitionsDocument4 pages1-FprEN ISO 4210 Terms - and - Definitionsjohn michael lavidoNo ratings yet

- BE 2019 Additive ManufacturingDocument4 pagesBE 2019 Additive ManufacturingHarsha AbhichandaniNo ratings yet

- Defectos en La FundicionesDocument4 pagesDefectos en La FundicionesJulio Cesar AyalaNo ratings yet

- Durable Actuator Solutions: Centrifugal Casting Electropolishing ProcessDocument2 pagesDurable Actuator Solutions: Centrifugal Casting Electropolishing ProcessJignesh TamkeNo ratings yet

- Ta 201 A Laboratory ManualDocument22 pagesTa 201 A Laboratory ManualSunitNo ratings yet

- Cam - L7Document14 pagesCam - L7Ritik RajNo ratings yet

- Powder MetallurgyDocument9 pagesPowder MetallurgyYashvir SinghNo ratings yet

- New 4340 Alloy SteelDocument3 pagesNew 4340 Alloy Steeljimmy julian pava vargasNo ratings yet

- Flange Weld Build UpDocument2 pagesFlange Weld Build UpMohd Shafuaaz KassimNo ratings yet

- PressDocument15 pagesPressRekha HNo ratings yet

- Welding Log PipingDocument322 pagesWelding Log PipingSalman Khan100% (1)

- Thyrodur 2080Document1 pageThyrodur 2080Grafički RadoviNo ratings yet

- Material Properties and Metal FormingDocument5 pagesMaterial Properties and Metal FormingSaikat BanerjeeNo ratings yet

- Flowsheet Dan Block Diagram Pulp and Tissue: Nama: 1. Bayu Wisnu Buana Putra (M1B116001) 2. MUHAMMAD ASWARI (M1B116019)Document4 pagesFlowsheet Dan Block Diagram Pulp and Tissue: Nama: 1. Bayu Wisnu Buana Putra (M1B116001) 2. MUHAMMAD ASWARI (M1B116019)Bayu Wisnu Buana PutraNo ratings yet

- Basic Principles of Metallurgy 23.07.2020Document3 pagesBasic Principles of Metallurgy 23.07.2020Rita DesiasniNo ratings yet

- GMW14057Document19 pagesGMW14057Felipe De la cruzNo ratings yet

- European Steel and Alloy Grades: About Us EN 10248-1Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10248-1farshid KarpasandNo ratings yet

- Squeeze CastingDocument18 pagesSqueeze CastingFebri Ramdani NugrahaNo ratings yet

- Page 270Document1 pagePage 270tito3007No ratings yet

- Damascus SteelDocument7 pagesDamascus SteelMichael MichaelNo ratings yet