Professional Documents

Culture Documents

Revo Max

Revo Max

Uploaded by

hasan shoaib0 ratings0% found this document useful (0 votes)

10 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views2 pagesRevo Max

Revo Max

Uploaded by

hasan shoaibCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

REVOMAX"

N-IBR Instant Steam Generator

THERMAX

Heating Business

Improving your business is our business

Thermax is an engineering major providing sustainable

solutions in the areas of energy and environment. Spanning

over 86 countries, clients make use of Thermax’s business-to

business solutions for heating, cooling, power and

cogeneration plants; waste heat recovery units; systems for

water & wastewater management and air pollution control;

performanceimproving chemicals.

‘Thermax’s operations are supported by ongoing Research &

Development, tie-ups with global technology majors, an

international sales & service network spread over 27

countries and state-of-the-art manufacturing facilities In 14

locations including India, Indonesia, China, Poland, Denmark

and Germany.

Asa part of Thermax, Heating business - strategic business

Unit offers packaged boilers, thermal oil heaters, waste heat

recovery boilers, hot water and air generators. These are

available in modular construction as a standard package

configuration or a custom design for specific requirements.

Innovated by a strong R&D that focuses on customer

applications, we offer a range of heating systems designed to

combust widerange of solid oll & gas fuels including biomass

and heavy liquid fuels. Heating SBU helps small and medium

firms & fortune 500 companies to reduce energy cost with 2

‘worldwide presence of oil& gas based systems in Middle East

and Europe, biomass and solid fuel fired equipment in South

East Asia and Arica.

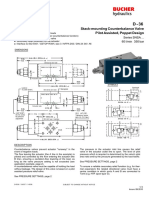

Engineered for Consistent Performance

N-IBR plug & play unit, with multi-fuel firing options (one at a time)

viz. FO, LDO, HSD, NG and LPG, itis the most efficient instant steam

Bumer

Ceramic Woo

generator in its class, preferred by process industries and the Proteted Ar

hospitality segmentfor decades.

Unique Design Features vot coi prnea

TB] * Reverse Flame Technology Deaeated —>!

~ Provides ample residence time Gases Outer Jacket

= Ensures complete combustion

SJ} Maincains consistent high thermal rurnae

efficiency “

+ Unique Membrane Coil Design sressur Pat

~ Uniform heat transfer leading to

enhanced coillife

+ Economiser-Optimiser Combination

ri Tansparent

~ Helps oxygen scavenging, reducing ite

pitting corrosion

~ Ensures reduction in heat loss

+ Cyclonic Steam Separator

= ssures steam dryness up to 92%

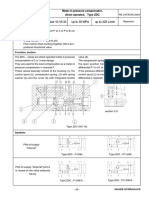

Technical Specifications

Ea ST TT

Gapediy (FRAT kg 200 500 a0 500 00 0 00 0

Design Pressure SVLOP) kg /emg tasa/175

tficency ‘AsPer 85845 Part 1 NCV Bass

Oil/Gas * 88/875

fuel 180/100 NC FO/NG/ UG

fuel Fring Stem Pressure let- Reverse, Du loc

Fuel Consumption

180 ko/e 11697532338 8223533850

100 kg/hr 120318052406 30083510 M0B_ = 361A

fo ko/he NA Wat SIS 5

Ne Nmjhe 1452717892630 SHES GTI

Us Notte 495 72 390 1237 as 390 Mss 2108

Connected lec Load

tigheo| ew 180 2a 207 275 235 27 an 307

ce v1.80 180 190 25 275 120 275 350

Light o/s waar 217 27 an an 27 an ar

Heary Gas wv NA 517 612 sar

Dimensions & Weight ‘without Separator

Lenath wm 13001500 1500 4500" 15001170 1350170

Wty M1080 1280 1280 4oo 14001480 1350120

Hegtt wm i6i0—_2iso 2150 zo 2402550 2402890

Chimney Tp Diameter wm 180 25 250 775 30 250 300 350

DiyWeght ig 950 11001100 100010001100 000 __100

THERMAX

www.thermaxglobal.com

Beam)

Registered Office

Pune 411019, India

[7] ethermarglobal

[Bl ethermaxinted

D-13, MIDC Industrial Area, RD Aga Road, Chinchwad,

lenguiryathermaxglobalcom

Thermax Business Portfolio

© estas

Customer Care: 1800-209-0115

1 cooing

Terrermax lobo! 6 paver

theraxaobal

Eiovemns © Aran cond

& @thermaxmedia

= © Chemica

(© Water and Wastewater Solutions

© Solar

© Specialised Services

Ths brochure presents nly some of aur product and we reserve the ight to amend any produc deals without

‘©Thermax Linvted, Dec. 2019

atic The photons wed nthe brochure erence and ny nt match the stu lant

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Handheld Hydraulic Readouts & DataloggersDocument5 pagesHandheld Hydraulic Readouts & Dataloggersnemi90No ratings yet

- VFS - Float SwitchDocument4 pagesVFS - Float Switchnemi90No ratings yet

- Portable Oil and Fuel Cleanliness Monitor: Technical DatasheetDocument12 pagesPortable Oil and Fuel Cleanliness Monitor: Technical Datasheetnemi90No ratings yet

- Electronic Temperature Transmitter With HSI Sensor Recognition ETS 4548-HDocument2 pagesElectronic Temperature Transmitter With HSI Sensor Recognition ETS 4548-Hnemi90No ratings yet

- Coal Mine: Tel Fax Email MobileDocument25 pagesCoal Mine: Tel Fax Email Mobilenemi90No ratings yet

- Applied Sciences: Grousers Effect in Tracked Vehicle Multibody Dynamics With Deformable Terrain Contact ModelDocument19 pagesApplied Sciences: Grousers Effect in Tracked Vehicle Multibody Dynamics With Deformable Terrain Contact Modelnemi90No ratings yet

- Stack-Mounting Counterbalance Valve Pilot Assisted, Poppet DesignDocument4 pagesStack-Mounting Counterbalance Valve Pilot Assisted, Poppet Designnemi90No ratings yet

- EN3302 SK-Hochdruck KatalogversionDocument6 pagesEN3302 SK-Hochdruck Katalogversionnemi90No ratings yet

- rd14028 - 2019 05 13Document48 pagesrd14028 - 2019 05 13nemi90No ratings yet

- Single Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - ZDocument2 pagesSingle Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - Znemi90No ratings yet

- 01 Check Valve Mini CatalogDocument50 pages01 Check Valve Mini Catalognemi90No ratings yet

- Series TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 HDocument4 pagesSeries TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 Hnemi90No ratings yet

- Hydraulic Excavator: Engine Power Operating Weight - North America Operating Weight - Europe/Australia and New ZealandDocument16 pagesHydraulic Excavator: Engine Power Operating Weight - North America Operating Weight - Europe/Australia and New Zealandnemi90No ratings yet

- SAE Flanged ConnectionDocument2 pagesSAE Flanged Connectionnemi90No ratings yet

- Nominal Pipe Size: Navigation SearchDocument5 pagesNominal Pipe Size: Navigation Searchnemi90No ratings yet

- Z2FS 10 New Series... 30BDocument8 pagesZ2FS 10 New Series... 30Bnemi90No ratings yet

- RAL Classic Colour Chart: Wednesday March 23rd 2011Document5 pagesRAL Classic Colour Chart: Wednesday March 23rd 2011nemi90No ratings yet

- DBETR - Proportional Pressure Relief ValveDocument5 pagesDBETR - Proportional Pressure Relief Valvenemi90No ratings yet

- Fabrication: Socket Head Cap ScrewsDocument3 pagesFabrication: Socket Head Cap Screwsnemi90No ratings yet

- Z2FS 6, 16, 22 Modular Throttle Check ValveDocument6 pagesZ2FS 6, 16, 22 Modular Throttle Check Valvenemi90No ratings yet

- ButtWeld Swivel Flange - ISO 6164Document1 pageButtWeld Swivel Flange - ISO 6164nemi90No ratings yet

- ZDC-16, 25, 32 Meter-In Pressure Compensator, Direct OperatedDocument7 pagesZDC-16, 25, 32 Meter-In Pressure Compensator, Direct Operatednemi90No ratings yet

- ButtWeld Solid Flange - ISO-6162Document2 pagesButtWeld Solid Flange - ISO-6162nemi90No ratings yet

- Size 10 and 16 Up To 31.5mpa Up To 160 L/Min: 2-Way Flow Control Valve, Type 2FrmDocument6 pagesSize 10 and 16 Up To 31.5mpa Up To 160 L/Min: 2-Way Flow Control Valve, Type 2Frmnemi90No ratings yet

- Z2FS 6 New Series... 40BDocument6 pagesZ2FS 6 New Series... 40Bnemi90No ratings yet

- ButtWeld Solid Flange - ISO-6164Document1 pageButtWeld Solid Flange - ISO-6164nemi90No ratings yet

- Blind Flange-ISO 6164Document1 pageBlind Flange-ISO 6164nemi90No ratings yet

- Blind Flange-ISO 6162Document1 pageBlind Flange-ISO 6162nemi90No ratings yet

- ButtWeld Swivel Flange - ISO-6162Document2 pagesButtWeld Swivel Flange - ISO-6162nemi90No ratings yet