Professional Documents

Culture Documents

IPG 1500W (Single-Module) Sheets Cutting Parameters

IPG 1500W (Single-Module) Sheets Cutting Parameters

Uploaded by

mojtaba ranjbarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IPG 1500W (Single-Module) Sheets Cutting Parameters

IPG 1500W (Single-Module) Sheets Cutting Parameters

Uploaded by

mojtaba ranjbarCopyright:

Available Formats

IPG 1500W Sheet Cutting Parameter

Material Thickness Assisted Gas Speed(m/min)

1.0 28.0-38.0

Nitrogen

2.0 7.0-9.0

1.0 6.0-11.0

2.0 5.0-6.6

3.0 3.0-3.6

4.0 2.0-3.0

Carbon Steel 5.0 1.8-2.4

6.0 Oxygen 1.5-2.0

8.0 1.0-1.3

10.0 0.7-1.2

12.0 0.6-1.0

14.0 0.6-0.8

16.0 0.5-0.7

1.0 30.0-40.0

2.0 8.0-9.6

3.0 3.0-4.0

Stainless steel 4.0 2.0-3.0

5.0 1.0-1.5

6.0 0.5-0.8

8.0 0.2-0.3

Nitrogen

1.0 18.0-25.0

2.0 5.0-6.0

Brass

3.0 1.4-1.8

4.0 1.0-1.2

1.0 9.0-12.0

Copper 2.0 2.8-3.6

3.0 1.0-1.5

Aluminum 1.0 Oxygen 15.0-30.0

2.0 6.0-9.0

3.0 1.4-3.0

4.0 1.0-1.5

(Above parameter is for reference only. The quality of materials, pressure during cutting,

and profile designing, etc. will affect cutting speed.)

Cost Analysis

Cutting of stainless steel Cutting of carbon steel

Items

(1mm) (5mm)

Electricity expenses RMB 12/h RMB 12/h

Expenses of cutting auxiliary gas RMB 16/h(N2) RMB 10/h(O2)

Expenses of protective lens and

RMB 0.4/h RMB 0.5/h

nozzle

Total expenses RMB 28.4/h RMB 22.5/h

If the assisted cutting gas is the dried compressed air, expenses are the actual operation

expenses of the air compressor plus expenses of electricity consumed by the machine

tool and consumables like protective mirror and nozzle).

Notes:

1.The electricity expense and gas expense in the table above are based on the price in

Foshan, China and prices in different areas will be various;

2.When the machine is cutting other thickness or different metal sheet, consumption of

the assisted gas may be different.

You might also like

- Laser Cutting ParametersDocument55 pagesLaser Cutting ParametersQasim Ali100% (3)

- BOOK1 - The High Pressure Die Casting ProcessDocument178 pagesBOOK1 - The High Pressure Die Casting Processecemre367386% (36)

- AAMA 611-20: Voluntary Specification For Anodized Architectural AluminumDocument12 pagesAAMA 611-20: Voluntary Specification For Anodized Architectural AluminumAluminio KingtomNo ratings yet

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- Material Steel StandardsDocument25 pagesMaterial Steel StandardssamadhankadamNo ratings yet

- Paint Coatings Resistance To The Action of Mechanical Wash BrushesDocument14 pagesPaint Coatings Resistance To The Action of Mechanical Wash Brushesclaudio5475No ratings yet

- ScrapingDocument24 pagesScrapingRohith Ravindranath0% (3)

- Brosure DB Laser DB-FM3015ADocument11 pagesBrosure DB Laser DB-FM3015Asarjono.pws03No ratings yet

- ParametersDocument3 pagesParametersfireball9877No ratings yet

- Laser Cutting Process Parameters - O2&N2: Material Thickness Speed M/min Speed M/min Speed M/minDocument2 pagesLaser Cutting Process Parameters - O2&N2: Material Thickness Speed M/min Speed M/min Speed M/minbeemasundarNo ratings yet

- Parametros Generales de Corte LaserDocument43 pagesParametros Generales de Corte LaserAgustin Daker100% (1)

- Fiber Laser Cutting ParametersDocument25 pagesFiber Laser Cutting ParametersKerry Saintz100% (1)

- Raycus CW Fiber Laser 500-20000W Cutting ParametersDocument58 pagesRaycus CW Fiber Laser 500-20000W Cutting ParametersAsdf100% (1)

- Ficha Tecnica de SF3015H-4000WDocument19 pagesFicha Tecnica de SF3015H-4000WOscar FlorezNo ratings yet

- Astm A269 A269mDocument5 pagesAstm A269 A269mwataneta valveNo ratings yet

- Astm A493 16Document2 pagesAstm A493 16wongNo ratings yet

- 1 s2.0 S0956053X20305110 mmc1Document37 pages1 s2.0 S0956053X20305110 mmc1emzzNo ratings yet

- 316 316L Technical Information SheetDocument5 pages316 316L Technical Information SheetfejlongNo ratings yet

- Metallography and Microstructures of Stainless Steel Vandervoort Met-Of-SS-Vol-9Document31 pagesMetallography and Microstructures of Stainless Steel Vandervoort Met-Of-SS-Vol-9Andrea CalderaNo ratings yet

- Bahru Stainless Product Catalogue (5th Rev, 10 Feb 2017)Document35 pagesBahru Stainless Product Catalogue (5th Rev, 10 Feb 2017)JonNo ratings yet

- A 53 - A 53m - 00 QtuzltawDocument7 pagesA 53 - A 53m - 00 QtuzltawPablo CzNo ratings yet

- Austenitic Stainless SteelsDocument23 pagesAustenitic Stainless SteelsAndrea VieyraNo ratings yet

- Asme 0387.1Document9 pagesAsme 0387.1Servando LozanoNo ratings yet

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDocument1 pageSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNo ratings yet

- Direct Determination of Lime With EDTA Banerjee1976 - 2Document4 pagesDirect Determination of Lime With EDTA Banerjee1976 - 2Khalid JavedNo ratings yet

- Sa 240Document9 pagesSa 240ismaelarchilacastilloNo ratings yet

- The US Particle Accelerator School Materials, Fabrication Techniques, and Joint DesignsDocument46 pagesThe US Particle Accelerator School Materials, Fabrication Techniques, and Joint Designsgangappa birajadarNo ratings yet

- BAS Castings - Ni Resist CA..Document3 pagesBAS Castings - Ni Resist CA..vijay2bhagyaNo ratings yet

- Bảng Độ Dày CắtDocument11 pagesBảng Độ Dày Cắta.lifelong.partner4392No ratings yet

- Review of Industrial Engineering Letters: Hydrogen Sulphide, Corrosion Rate, Stainless Steel. Nickel, Water, EnvironmentDocument9 pagesReview of Industrial Engineering Letters: Hydrogen Sulphide, Corrosion Rate, Stainless Steel. Nickel, Water, EnvironmentPrasad ChakkrapaniNo ratings yet

- Stainless 316, 316L, 317, 317L: Element Percent by Weight Maximum Unless Range Is Specified 316 316L 317 317LDocument3 pagesStainless 316, 316L, 317, 317L: Element Percent by Weight Maximum Unless Range Is Specified 316 316L 317 317LAvijit SharmaNo ratings yet

- Metalography and Microstructures of Stainless Steels and Maraging SteelsDocument32 pagesMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraNo ratings yet

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- Studytheme 2.24 - Other Metals and AlloysDocument14 pagesStudytheme 2.24 - Other Metals and AlloysMarno PrinslooNo ratings yet

- Alternative Fuels For Cement Industry: A ReviewDocument5 pagesAlternative Fuels For Cement Industry: A ReviewAnonymous Ja3jvaXNo ratings yet

- SCRM BrochureDocument6 pagesSCRM BrochureRizwan TonoyNo ratings yet

- B 150 - B 150m - 02 - Qje1mc9cmtuwts1sruqDocument11 pagesB 150 - B 150m - 02 - Qje1mc9cmtuwts1sruqHimanshu KashyapNo ratings yet

- MaterialDocument10 pagesMaterialAnonymous w6TIxI0G8lNo ratings yet

- Compositon of Martensitic SteelDocument1 pageCompositon of Martensitic SteelMahesh PandyaNo ratings yet

- 316-316l Pipes SuppliersDocument4 pages316-316l Pipes SuppliersSvamitva Steel IndustriesNo ratings yet

- Fly Ash - An Emerging Alternative Building Material: © 1999, NMI, Jamshedpur, Pp. 59-67Document9 pagesFly Ash - An Emerging Alternative Building Material: © 1999, NMI, Jamshedpur, Pp. 59-67NikhilNo ratings yet

- What Is A Pitting Resistance Equivalent Number (PREN) - Unified AlloysDocument10 pagesWhat Is A Pitting Resistance Equivalent Number (PREN) - Unified AlloysromerobernaNo ratings yet

- Typical Materials Composition of A TireDocument3 pagesTypical Materials Composition of A TireSanjay KumarNo ratings yet

- Material CompositionsDocument8 pagesMaterial CompositionswanNo ratings yet

- Technical Center 1Document3 pagesTechnical Center 1nimeshchanchaniNo ratings yet

- Rath Sanitary Tube Uid182010340122 PDFDocument2 pagesRath Sanitary Tube Uid182010340122 PDFthanhquang1001No ratings yet

- A 249 - A 249m - 03 Qti0os9bmjq5ts1sruqDocument11 pagesA 249 - A 249m - 03 Qti0os9bmjq5ts1sruqAntonio ChangNo ratings yet

- SJC 20180606 12Document7 pagesSJC 20180606 12elkey987654321No ratings yet

- Reci 1500W Fiber Laser Cutting Data 30um)Document2 pagesReci 1500W Fiber Laser Cutting Data 30um)morteza hamishegiNo ratings yet

- Specifications For SS 316L Plates: Maximum, Unless Range or Minimum Is IndicatedDocument2 pagesSpecifications For SS 316L Plates: Maximum, Unless Range or Minimum Is IndicatedKhoirul JukiNo ratings yet

- Chloride Threshold For Various Reinforcement Steel TypesDocument21 pagesChloride Threshold For Various Reinforcement Steel Typesshameeka100% (1)

- Measurement of The Drag Coefficients of Spherical ParticlesDocument10 pagesMeasurement of The Drag Coefficients of Spherical Particlessr3shNo ratings yet

- Stainless Steel GradesDocument8 pagesStainless Steel Gradesnathan1979No ratings yet

- ★03주차 - 재료학 Ch03a - Engineering Materials and Their Properties - PartA - 재료 - 65쪽Document65 pages★03주차 - 재료학 Ch03a - Engineering Materials and Their Properties - PartA - 재료 - 65쪽littleson119119No ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- MAX Cutting Parameter (500W 15000W) 20200903Document64 pagesMAX Cutting Parameter (500W 15000W) 20200903ياسر محمد عثمان حسينNo ratings yet

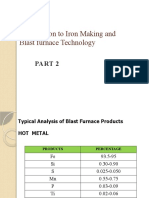

- Introduction To Iron Making and Blast Furnace TechnologyDocument24 pagesIntroduction To Iron Making and Blast Furnace TechnologyDevansh MankarNo ratings yet

- Sound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)Document50 pagesSound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)sherio amrousyNo ratings yet

- Effect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessDocument7 pagesEffect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessBoujemaa DrifNo ratings yet

- pp043-049 ms18Document6 pagespp043-049 ms18Srikanth SrikantiNo ratings yet

- SCM As Copper TailingDocument27 pagesSCM As Copper TailingSangamesh KarbariNo ratings yet

- Aerospace Materials: Aircraft Applications of Steel. Aircraft Applications of Steel. Advantages and DisadvantagesDocument55 pagesAerospace Materials: Aircraft Applications of Steel. Aircraft Applications of Steel. Advantages and DisadvantagesJASHANPREET SinghNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- BL2471 W-2020-092 - 6000x2500x15 S355J2+N (HF18701) 52102Document5 pagesBL2471 W-2020-092 - 6000x2500x15 S355J2+N (HF18701) 52102johnnyNo ratings yet

- Product Brochure Atas Metstar New WebDocument4 pagesProduct Brochure Atas Metstar New WebAnonymous 3o4Mwew0No ratings yet

- Exercise - I: (Only One Option Is Correct)Document3 pagesExercise - I: (Only One Option Is Correct)Amudala HemashviniNo ratings yet

- LOI Scrap Copper Wire 3Document4 pagesLOI Scrap Copper Wire 3Farhan AshrafNo ratings yet

- Past Paper CHemistryDocument20 pagesPast Paper CHemistryRubén Patricio Fernández Periago YR11YNo ratings yet

- Eta-120114 Spax ScrewsDocument84 pagesEta-120114 Spax ScrewsSunnyWongNo ratings yet

- Valve Data Sheet - Gate Valve: Colves Fluid Control S.R.LDocument1 pageValve Data Sheet - Gate Valve: Colves Fluid Control S.R.LMohamed gaballa SaidNo ratings yet

- Test Bank Supervision Police Personnel 8th Edition Iannone Iannone BernsteinDocument36 pagesTest Bank Supervision Police Personnel 8th Edition Iannone Iannone Bernsteinnayword.mermaidnr1v0a100% (32)

- Shell Corrosion Under InsulationDocument16 pagesShell Corrosion Under InsulationDavide CongiuNo ratings yet

- DGS-MN-001 - Rev-3 Insulation BoxesDocument2 pagesDGS-MN-001 - Rev-3 Insulation BoxesHabibur Rehman MNo ratings yet

- Gas Cutting - JKPDocument19 pagesGas Cutting - JKPavikNo ratings yet

- Astm E18Document39 pagesAstm E18Poedyaji MawardiNo ratings yet

- ISO Chemical Process Pumps: Pump DivisionDocument28 pagesISO Chemical Process Pumps: Pump DivisionChristianReinosoNo ratings yet

- AXEVINYL Industry Co.,Ltd: Item No. Item Name Picture Item No. Item Name PictureDocument5 pagesAXEVINYL Industry Co.,Ltd: Item No. Item Name Picture Item No. Item Name PictureJuan Pablo Sanchez RojasNo ratings yet

- ACE PackerDocument4 pagesACE PackerHadi KoraniNo ratings yet

- Grain Tech Newsletter Bulk Material Handing EquipmentDocument20 pagesGrain Tech Newsletter Bulk Material Handing EquipmentAnthonyNo ratings yet

- ACS Specs GFRC1Document10 pagesACS Specs GFRC1Chrill DsilvaNo ratings yet

- Annexure-C Quality Assurance Plan (Sample) Qap NoDocument1 pageAnnexure-C Quality Assurance Plan (Sample) Qap NoRégis YannickNo ratings yet

- Literature Review On Iron and Steel IndustryDocument6 pagesLiterature Review On Iron and Steel Industrysmvancvkg100% (1)

- BS 3701-1964Document12 pagesBS 3701-1964ahmed samyNo ratings yet

- Sale and Purchase Agreement: Know All Men by These PresentsDocument4 pagesSale and Purchase Agreement: Know All Men by These PresentsBermar Saratan T.No ratings yet

- Landing Gear Weekly Change Reports Dated 02-21-2021 NSRDocument1,492 pagesLanding Gear Weekly Change Reports Dated 02-21-2021 NSRRangaNo ratings yet

- Friction Welding Usage TodayDocument15 pagesFriction Welding Usage Todaycule93No ratings yet

- Indian Standard: Copper Plate, Sheet and Strip For Industrial ?urposes - SpecificationDocument7 pagesIndian Standard: Copper Plate, Sheet and Strip For Industrial ?urposes - SpecificationMurugan PalanisamyNo ratings yet

- 2014-02 TestingCathodicProtectionSystems Slides 508Document49 pages2014-02 TestingCathodicProtectionSystems Slides 508shejin R.SNo ratings yet

- CH01 IntroductionDocument12 pagesCH01 IntroductionAbro HasanNo ratings yet