Professional Documents

Culture Documents

Schindler Drive Chain Maintenance

Schindler Drive Chain Maintenance

Uploaded by

Kevin aliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schindler Drive Chain Maintenance

Schindler Drive Chain Maintenance

Uploaded by

Kevin aliCopyright:

Available Formats

7 Maintenance of Drive & Brakes Drive Chain – Q 409 452

7.3 Drive Chain – Q 409 452

1 Description and Mode of Operation

The drive chain (1) is a duplex chain that transmits the driving torque to the main shaft (2).

The drive chain (1) is tensioned by longitudinally shifting the entire drive unit with the pinion (11) by

means of threaded spindles.

The chain strand is guided via chain deflectors (5) with a plastic guide.

Fig. 452-01

1) Drive chain 5) Chain deflector

2) Main shaft 11) Pinion

Foggy Bottom Station Operation & Maintenance Manual 7-13

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain – Q 409 452

2 Maintenance

2.1 Chain Tension

2.1.1 Checking the Tension

Optimum chain tension is achieved when the return strand of the chain has a sag X of 40 mm.

Retension the chain when the sag equals or exceeds 70 mm.

Fig. 452-02

2.1.2 Retensioning the Chain

Shift the drive unit until the sag X = 40 mm.

Distribute the sag X to both chain strands.

Warning: Overtensioning on one side!

Otherwise, one of the chain strands might be overtensioned.

The drive unit can be shifted within the range of the slots in the base frame.

Measure the chain elongation between two far-off chain links on a straight chain strand.

Hint!

When the max. permissible chain elongation of 2% is reached, the chain has to be replaced!

Foggy Bottom Station Operation & Maintenance Manual 7-14

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain – Q 409 452

2.2 Lubrication

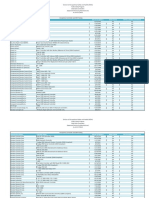

Use the following lubricants to lubricate the drive chain:

Warning: Outdoor installation & ambient temperature!

With automatic lubrication system, uncovered outdoor installaton and ambient temperatures

< 10 °C, only oils indicated below may be used!

Lubrication

BP ESSO KLÜBER MOBIL SHELL ZEPF

Method

Mineral oil Synthetic oil

Automatic Klüberoil

– – – – Ultrafit-Synthex

1 lubrication GEM 1-46N

system Only use these particular, water-repellent oils.

These oils are not suited for manual lubrication.

For more detailed information, see Maintenance Instructions Q 409 924, Automatic Lubrication

System

Foggy Bottom Station Operation & Maintenance Manual 7-15

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain Contact – Q 409 453

7.4 Drive Chain Contact – Q 409 453

1 Description and Mode of Operation

1.1 Description

With escalators of the Schindler 9700 product line, the drive chain contact is installed as standard.

The oil- and abrasion-resistant chain glider is mounted on a pivoted lever and rests on the drive chain.

When the chain breaks or slackens beyond the permissible value, the safety brake is actuated via a contact

and stops the escalator.

This safety device is mainly installed for chain breaks, since the drive brake is inactive in this case.

Fig. 453-01

1) Drive chain 4) Trigger

2) Chain glider 5) Contact

3) Lever D) Pivot points

1.2 Mode of Operation

When the drive chain (1) breaks or slackens beyond the permissible value (wear and tear), the chain

glider (2) and the lever (3) resting on the chain tilt down.

The trigger (4) which is firmly attached to the lever, swivels upward and actuates the contact (5) which in

turn actuates the safety brake.

Foggy Bottom Station Operation & Maintenance Manual 7-16

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain Contact – Q 409 453

2 Maintenance

2.1 Functional Check

Connect the maintenance operating panel.

Hint!

With the maintenance operating panel connected, the safety brake is always disengaged.

Actuate the contact manually.

– The solenoid immediately drops out and the pawl engages.

Error code: "E_19" electronically interlocked

Reset the error.

2.2 Checking the Condition of the Chain Glider

Fig. 453-02

2) Chain glider

7) Fastening screws (AM5x20)

Minimum height of chain glider (2): 13 mm

Warning: Pay attention to screw heads!

The heads of the screws (7) must not glide on the chain rollers!

Replace the chain glider (2) as soon as it equals or falls short of the minimum height.

Foggy Bottom Station Operation & Maintenance Manual 7-17

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain Contact – Q 409 453

2.3 Adjusting the Contact

Hint!

A setting check is only required during commissioning or upon replacement of the proximity

switch.

Fig. 453-03

3) Lever

4) Trigger

5) Contact

7) Base plate

With the lever (3) tilted down, the contact roller and the trigger (4) should overlap by 3.5+0.5 mm.

The length of the spring should measure between 215 and 230 mm.

Foggy Bottom Station Operation & Maintenance Manual 7-18

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain Deflector – Q 409 453A

7.5 Drive Chain Deflector – Q 409 453A

1 Description and Mode of Operation

1.1 Description

The drive chain deflector is installed to guide the drive chain and to prevent improper vibration of the drive

chain.

1.2 Mode of Operation

Oil- and abrasion-resistant chain gliders are mounted on the drive chain deflector.

The drive chain (1) is supported by drive the chain deflector (2) which is moved via a threaded rod (3).

Fig. 453A-01

1) Drive chain

2) Drive chain deflector

3) Threaded rod

D) Pivot points

Foggy Bottom Station Operation & Maintenance Manual 7-19

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain Deflector – Q 409 453A

2 Maintenance

2.1 Functional Check

Check the guidance of the drive chain (1) by the drive chain deflector (2) during inspection operation of

the escalator.

Check the vibration behavior of the drive chain (1) during inspection operation of the escalator.

2.2 Checking the Condition of the Chain Guides

Fig. 453A-02

8) Chain guide

Minimum permissible depth of the chain guide groove: 8.5 mm

Replace the chain guide (8) as soon as the groove equals or falls short of the minimum permissible depth.

Foggy Bottom Station Operation & Maintenance Manual 7-20

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

7 Maintenance of Drive & Brakes Drive Chain Deflector – Q 409 453A

2.3 Adjusting the Deflector

Hint!

A setting check is only required during commissioning or upon replacement of the deflector.

Fig. 453A-03

2) Drive chain deflector

3) Threaded rod

4) Lock nuts

Adjust the drive chain deflector with the threaded rod (3) by means of the lock nut (4).

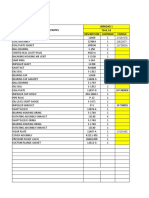

2.4 Lubrication

Lubricate the pivot points (D) (see Fig. 453A-01) with mineral oil.

Use extreme-pressure mineral oils, viscosity VG 460:

BP ESSO KLÜBER MOBIL SHELL

Energol GR-XP Spartan Klüberoil Oil Omala

460 EP 460 GEM 1-460N DTE24 460

Foggy Bottom Station Operation & Maintenance Manual 7-21

Washington Metropolitan Area Transit Authority Schindler 9700™ Escalators

You might also like

- Method Statement For Door and Window Installation PDFDocument13 pagesMethod Statement For Door and Window Installation PDFpp100% (2)

- K609711 MM STM PV30 InstallationDocument24 pagesK609711 MM STM PV30 InstallationAli Diab100% (1)

- Planetary Geared Machine P420 / 450: Technical CatalogDocument29 pagesPlanetary Geared Machine P420 / 450: Technical CatalogAli DiabNo ratings yet

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 pagesTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- Fermator Car Door CD30 Maintenance Manual Premium - 09.18Document76 pagesFermator Car Door CD30 Maintenance Manual Premium - 09.18alfrelia0% (1)

- Gen2™ Comfort Lift. Taking Ride Quality To A Higher LevelDocument10 pagesGen2™ Comfort Lift. Taking Ride Quality To A Higher LevelJitendra DwivediNo ratings yet

- 3300 AP ReportDocument14 pages3300 AP ReportWiratama PutraNo ratings yet

- En Synergy Jan 2015Document72 pagesEn Synergy Jan 2015anh trong100% (1)

- Overview Q595500Document1 pageOverview Q595500Asif Abbasov100% (1)

- Schindler Escalator 9700AE - Brake MaintenanceDocument4 pagesSchindler Escalator 9700AE - Brake MaintenanceHùng VĩNo ratings yet

- Schindler Drive MaintenanceDocument5 pagesSchindler Drive MaintenanceDanta Rover ScoutNo ratings yet

- Schindler Brake Maintenance PDFDocument7 pagesSchindler Brake Maintenance PDFSantosh Kumar100% (1)

- Schlndler: 1 Replacement and Adjustment of Brake Contacts KB and KDocument8 pagesSchlndler: 1 Replacement and Adjustment of Brake Contacts KB and KallbsforakNo ratings yet

- Schindler 5500 Layout Data Sheet Seismic PDFDocument4 pagesSchindler 5500 Layout Data Sheet Seismic PDFน๊อกคิโอ้ ฅนพันช่างNo ratings yet

- 6300 & SGB InformationDocument6 pages6300 & SGB InformationPio Rodolfo0% (1)

- Schindler Escalator 9300AE InstallationVDocument23 pagesSchindler Escalator 9300AE InstallationVHùng Vĩ100% (1)

- Schindler Modular Gearless Machines FMR355Document2 pagesSchindler Modular Gearless Machines FMR355Kar Keong LewNo ratings yet

- (Mech. Safety System) K 602673-07Document38 pages(Mech. Safety System) K 602673-07Ali Diab100% (1)

- Planning Data According To EN81-20: Schindler 5500Document4 pagesPlanning Data According To EN81-20: Schindler 5500NgocHoanTranNo ratings yet

- Modu-Tool Basic Operating Instructions PDFDocument2 pagesModu-Tool Basic Operating Instructions PDFAliRouyouNo ratings yet

- Atlas Basic SP Instalation Manual enDocument39 pagesAtlas Basic SP Instalation Manual enISHAQNo ratings yet

- Technical Information and Configuration: Progressive Safety Gear G01Document16 pagesTechnical Information and Configuration: Progressive Safety Gear G01Ali DiabNo ratings yet

- 104 Door Control Board PM-SSCDocument16 pages104 Door Control Board PM-SSCKevin SilvaNo ratings yet

- Pre-Wiring, Car BottomDocument3 pagesPre-Wiring, Car BottomAli DiabNo ratings yet

- K 604194 - 02 - Varidor 30AP T2 PDFDocument36 pagesK 604194 - 02 - Varidor 30AP T2 PDFTaufik Hidayat KurniansyahNo ratings yet

- User Guide, Global Drive Loader ToolDocument5 pagesUser Guide, Global Drive Loader ToolPio RodolfoNo ratings yet

- Controller With EMIDocument11 pagesController With EMIMohammed Qaid AlathwaryNo ratings yet

- Hoisting Motor FMP 160: Motors For Planetary GearsDocument8 pagesHoisting Motor FMP 160: Motors For Planetary GearsAli DiabNo ratings yet

- Preventive Maintenance Instruction For V3F16R Drive MODULE KM870400GDocument14 pagesPreventive Maintenance Instruction For V3F16R Drive MODULE KM870400GMarta Silva VenturaNo ratings yet

- Traccion EscalerasDocument16 pagesTraccion EscalerasRafael BrunoNo ratings yet

- 9300AE 10-30kseis LDN 2005 PDFDocument2 pages9300AE 10-30kseis LDN 2005 PDFDoina ClichiciNo ratings yet

- ESC - Orinoco Spare Parts List - 2012-08-17 (V.a01-Xxxx)Document29 pagesESC - Orinoco Spare Parts List - 2012-08-17 (V.a01-Xxxx)Israel IslasNo ratings yet

- Schindler 7000 MaintainDocument16 pagesSchindler 7000 MaintainMahmoud MagdyNo ratings yet

- Error VD DC K604409en - 02 - NopwDocument16 pagesError VD DC K604409en - 02 - NopwLuis Alejandro SanchezNo ratings yet

- Modu SoftDocument2 pagesModu Softhabibulla100% (1)

- Schindler 5500 - Schindler - PDF Catalogs - Documentation - BrochuresDocument1 pageSchindler 5500 - Schindler - PDF Catalogs - Documentation - BrochuresJati SasangkaNo ratings yet

- MLI Otis MCS220M (VEC01-OT01) - Manuel D'installation - GB - Du 31 10 02 (7669)Document56 pagesMLI Otis MCS220M (VEC01-OT01) - Manuel D'installation - GB - Du 31 10 02 (7669)phil johnsNo ratings yet

- 6300 Safety Componants Maint'Document14 pages6300 Safety Componants Maint'Pio Rodolfo100% (1)

- PRECISION - EscalatorParts 800 233 0838 SCHINDLER EscalatorPartsDocument16 pagesPRECISION - EscalatorParts 800 233 0838 SCHINDLER EscalatorPartsChristian Córdoba GamboaNo ratings yet

- Q 41313697 Idd Dor Drive SystemDocument53 pagesQ 41313697 Idd Dor Drive SystemYasmin QuintelaNo ratings yet

- 100-170 ManualDocument59 pages100-170 ManualReza KühnNo ratings yet

- Schindler 3300 Ca Product Family Brochure PDFDocument32 pagesSchindler 3300 Ca Product Family Brochure PDFjorge barrerNo ratings yet

- Lift Monitoring & Diagnostics: SystemDocument53 pagesLift Monitoring & Diagnostics: SystemMohd Abu AjajNo ratings yet

- BẢN VẼ MX-GCDocument52 pagesBẢN VẼ MX-GCPhù MỹNo ratings yet

- OBJ - DOKU-3332-00.fm Brake System FM280Document33 pagesOBJ - DOKU-3332-00.fm Brake System FM280Mustafa Malhas100% (1)

- k604522 MX Basic Fixtures Mantto PDFDocument49 pagesk604522 MX Basic Fixtures Mantto PDFBenjamin Gonzalez100% (1)

- DT-5 Analyzer: Core Learning GuideDocument40 pagesDT-5 Analyzer: Core Learning GuideСакенNo ratings yet

- Elevator Spare Parts: ThyssenkruppDocument28 pagesElevator Spare Parts: ThyssenkruppBeldescuRobertNo ratings yet

- Error 94 Schindler Hydra 330aDocument3 pagesError 94 Schindler Hydra 330aIJGUNo ratings yet

- Ej41902030 1Document19 pagesEj41902030 1Dennis Notenboom100% (1)

- Schindler Actionboard User Manual v5Document30 pagesSchindler Actionboard User Manual v5Josue GomezNo ratings yet

- 10 Aaa21700xDocument17 pages10 Aaa21700xasdf100% (1)

- Adjusting The E311MV E411MV LMCSS Ward-Leonard Modernization ControllerDocument19 pagesAdjusting The E311MV E411MV LMCSS Ward-Leonard Modernization ControllerSamuel Acevedo100% (2)

- Entrance CPSI Test - Ver 2Document10 pagesEntrance CPSI Test - Ver 2Ali DiabNo ratings yet

- Schindler PMS420 Brake Adjustment, Test and ReplacementDocument16 pagesSchindler PMS420 Brake Adjustment, Test and ReplacementStuart Baron100% (2)

- TK-50 Installation Manual Rev 1.1 - EVO1Document20 pagesTK-50 Installation Manual Rev 1.1 - EVO1anh trong0% (1)

- Elevator Mechanic's Helper: Passbooks Study GuideFrom EverandElevator Mechanic's Helper: Passbooks Study GuideNo ratings yet

- RW Manual SKDocument4 pagesRW Manual SKKaushaveer GhooraNo ratings yet

- Kone Step ChainDocument6 pagesKone Step Chaindaniel cooperNo ratings yet

- Comandos Basicos Base Band ERICSSON - CleanedDocument4 pagesComandos Basicos Base Band ERICSSON - CleanedMichelle Alves de JesusNo ratings yet

- RotametroDocument2 pagesRotametroCarlos Gallardo SanchezNo ratings yet

- PeraDocument2 pagesPeraKarlo PongracNo ratings yet

- I3040170817 (Grid Plate MHP66 Hammer Mill)Document1 pageI3040170817 (Grid Plate MHP66 Hammer Mill)bblacksmith29100% (1)

- ASME PCC-1 - Bolted Flange Assembly - Guidelines - 2000Document32 pagesASME PCC-1 - Bolted Flange Assembly - Guidelines - 2000brunobassottiNo ratings yet

- Bombas Centrifugas Gorman RuppDocument5 pagesBombas Centrifugas Gorman RuppmiguelNo ratings yet

- GM End MillsDocument48 pagesGM End MillsjosuecncNo ratings yet

- How To Measure The Length of A Zipper: Metal Zipper Size ChartDocument2 pagesHow To Measure The Length of A Zipper: Metal Zipper Size ChartKarlaNo ratings yet

- Crouse Hinds TMC Catalog PageDocument1 pageCrouse Hinds TMC Catalog PageYofre Moreno CobeñaNo ratings yet

- Type D17 Anchor Shackle With Oval PinDocument1 pageType D17 Anchor Shackle With Oval PinIsaacNarendraAkbarNo ratings yet

- 1 - Turbomachinery-Hydraulic Machines ClassificationDocument25 pages1 - Turbomachinery-Hydraulic Machines Classificationmedo ElrefaeyNo ratings yet

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNo ratings yet

- Stair Case Design: Schematic PlanDocument6 pagesStair Case Design: Schematic Planthanigai veluNo ratings yet

- Manual-Thruster Brush Gear Replacement InstructionDocument3 pagesManual-Thruster Brush Gear Replacement InstructiongreckeNo ratings yet

- Liquid Distributor DesignDocument3 pagesLiquid Distributor Designanon_414493592100% (1)

- Goulds IC Pump BulletinDocument24 pagesGoulds IC Pump BulletinSergio E. Marchetti Newco S. A.100% (1)

- Drill Press TableDocument11 pagesDrill Press TableWil NelsonNo ratings yet

- Schematic and Quill CreateDocument18 pagesSchematic and Quill CreateDudika 5704No ratings yet

- Theory of GearingDocument478 pagesTheory of GearingLSPI MDE1No ratings yet

- 16A PlugDocument2 pages16A Plugsrikanth NakkaNo ratings yet

- Ajay Kumar Garg Engineering College Ghaziabad Department of Civil EngineeringDocument3 pagesAjay Kumar Garg Engineering College Ghaziabad Department of Civil EngineeringAlokNo ratings yet

- Practical Introduction To Pumping Technology - Uno WahrenDocument2 pagesPractical Introduction To Pumping Technology - Uno Wahrenmach20_aardvark8064No ratings yet

- Alert Service Bulletin: EmergencyDocument13 pagesAlert Service Bulletin: EmergencyRaymond ZamoraNo ratings yet

- JGK - H - e - T - Ring ClearancesDocument1 pageJGK - H - e - T - Ring ClearancesCarlos A. Mantilla J.No ratings yet

- Pneumatic Reciprocating Hacksaw Machine: March 2016Document6 pagesPneumatic Reciprocating Hacksaw Machine: March 2016SaurabhNo ratings yet

- Vertipack 320: High Speed Zipper AttachmentDocument2 pagesVertipack 320: High Speed Zipper AttachmentkunalkakkadNo ratings yet

- Ratandeep PfizerDocument4 pagesRatandeep PfizerMukesh PanwarNo ratings yet

- General Service InformationDocument5 pagesGeneral Service InformationJuan Carlos Inga Vasquez100% (1)

- Bush Type Flexible CouplingsDocument4 pagesBush Type Flexible CouplingsNHÂN LÊ HOÀNGNo ratings yet