Professional Documents

Culture Documents

Concrete Work Forming and Pouring

Concrete Work Forming and Pouring

Uploaded by

Michael VeneerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Work Forming and Pouring

Concrete Work Forming and Pouring

Uploaded by

Michael VeneerCopyright:

Available Formats

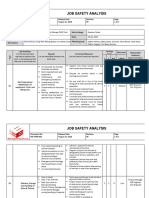

CONCRETE WORK (FORMING AND POURING)

Date Revised: March 2020 Overall Task Risk Rating: B

Description: The forming and pouring of concrete curb and sidewalks.

Location(s): Construction Projects

Associated Documents: Hazardous Agents WTS, Noise WTS, Traffic Control WTS, Equipment and Machinery Operation WTS, Night Work

WTS

RED FLAGS (HOLD WORK UNTIL CORRECTED):

Note:

- Do not commence work if there is inadequate Traffic Protection

PERSONAL PROTECTIVE EQUIPMENT (CSA COMPLIANT)

Head Foot High-Vis Hearing Hand Eye Respiratory Skin Face Fall

Protection Protection Protection Protection Protection Protection Protection Protection Protection Protection

Note:

- Additional PPE may be required based on project specific hazards - saw cutting will require eye, face and respiratory protection, hand

protection when pouring and finishing concrete

- The noise level exceeds 85 dB in the production area. Hearing protection should be worn during prolonged exposure

- Workers must wear all PPE listed in the MSDS / SDS for the specific hazardous products that they are to handle

SAFE WORK PRACTICES (SWP)

General Concrete Work Practices:

• Start the work only when you are certain that you understand the work, the hazards and you have implemented the appropriate controls

• Unsafe conditions and situations must be reported to Foreman/Superintendents immediately (and stop work until the hazard is controlled)

• Never operate a curb machine at speeds which will cause ground personnel to work carelessly - if production requirements demand it,

assign more personnel to the pouring operations

• Use the ‘buddy system’ and watch out for co-workers who may be unaware of a hazard or unsafe work activity

• Use three-point contact when mounting / dismounting machines

Traffic Control:

• The Superintendent/Foreman will complete a Traffic Protection Plan and ensure that traffic protection measures are in place and in

accordance with Ontario Traffic Manual Book 7 when workers have the potential to be endangered by vehicle traffic

• Workers will stay out the Path of Travel of vehicles and mobile equipment

• Workers and equipment operators will follow the Safe Limit of Approach practices (3m and 10m)

• Refer to the Traffic Control WTS for more information

Signalers:

• Signalers are required for backing vehicles when the operator’s view of the path of travel is obstructed

Night Work:

• Ensure lighting is adequate for visibility of the workers and for the workers to complete the task at hand

• Lighting used to illuminate the worksite shall not be aimed at drivers (making it more difficult for them to see their intended path)

• Refer to Night Work WTS for more details

Manual Material Handling:

Gazzola Paving Limited PAGE 1 OF 3

CONCRETE WORK (FORMING AND POURING)

• When possible, workers should rotate between repetitive job tasks as Repetitive Strain Injuries (RSI) can result from repeating the same

actions / movements

• If an object or material appears to be awkward in shape or too heavy, it may require additional help to be handled safely

• When handling hazardous materials (i.e. cement - which is corrosive) use the controls (i.e. hand protection) appropriate for the task

• Refer to the applicable MSDS / SDS and the Manual Material Handling WTS for more information

Inspections:

• A pre-operational safety inspection and Gazzola Daily Equipment Inspection Form is to be completed prior to using equipment

• Do not use defective equipment or machinery, inform your foreman / superintendent - they will arrange for the equipment to be serviced

• Before starting machines or equipment, ensure guards and safety devices are in place, adjusted and functioning properly

Training:

• Employee Orientations (including roles, responsibilities, applicable workplace task standards, WHMIS, etc.)

• Only trained, authorized personnel are allowed to operate vehicles / machinery / equipment

•

PPE:

• Workers on construction projects must wear, at a minimum, head, foot and high visibility protection. Eye protection as necessary

• The noise level exceeds 85 dB in the production area. Hearing protection should be worn during prolonged exposure

• Eye Glasses and Face Shield is required when completing tasks that may cause debris / objects to dislodge or become airborne

• All workers must wear the required personal protective equipment set out in applicable MSDS / SDS (i.e. hand protection)

• When saw cutting concrete where a full-face respirator to protect against inhalation of silica in dust

• At night, increase the visibility of workers (Leg Bands are provided for night work on construction projects)

• If machines are equipped with seatbelts, they must be worn by operators

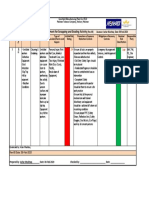

A High risk of injury or equipment / property damage.

RISK RATING

JOB HAZARD AND RISK ANALYSIS SYSTEM

B

C

Medium risk of injury or equipment / property damage.

Low risk of injury or equipment / property damage.

TASK HAZARDS TASK CONTROLS RATING

• Lack of, or Improper, Training and Education • Machine Operators must be authorized and trained

C

•

• Poor Housekeeping • Keep a clean working area, remove any tripping hazards

• Ensure that tools are neatly and safely stowed on equipment

C

• Equipment / vehicles should be cleared daily of any garbage

so as not to obstruct brakes, accelerator pedals, etc.

• Lack of Spotter • Signalers are required for backing vehicles when the

operator’s view of the path of travel is obstructed

B

• Signallers are required when equipment is within the safe

limits of approach to overhead powerlines

• Musculoskeletal disorders (MSD) & Repetitive Strain • If an object or material appears to be awkward in shape or

Injuries (RSI) too heavy, it may require additional help to be handled safely

C

• Heat Stress • Refer to Hazardous Agents WTS

• Drink water throughout the day (don’t wait until you’re thirsty)

B

• If you think someone has heat stroke or heat exhaustion: call

911, inform the foreman / superintendent and begin First Aid

• Lack of / improper PPE • Workers are to wear a respirator when saw cutting (as fine

dust is being created)

• Workers are to wear eye protection and gloves when using C

circular saws and concrete saws

•

Gazzola Paving Limited PAGE 2 OF 3

CONCRETE WORK (FORMING AND POURING)

• Lack of Inspection • A pre-operational safety inspection is to be completed

• Do not use defective equipment or machinery, inform your C

foreman / superintendent

• Improper Chemical Use/Storage • Products such as diesel will be stored in appropriate

containers and labelled indicating the contents

B

SAFE JOB PROCEDURES (SJP)

Pre-Task Commencement:

1. Gather and wear the required PPE for the task - on construction sites, all employees must wear head, foot and high visibility protection.

Eye protection when necessary

2. Ensure the site-specific workplace violence assessment is complete

3. Complete the Daily GAZZ Card and review with all workers the shift’s tasks with any associated hazards and control strategies

4. Ensure all workers understand the GAZZ Card contents, and sign off in acknowledgement

5. Ensure controls are in place prior to commencing work so risks are mitigated / eliminated

6. Ensure adequate traffic control measures are in place prior to the start of work (refer to Traffic Control WTS for more detail)

7. Determine what equipment / machinery / tools and material, are required for the completion of the task

8. Inspect all equipment / machinery / tools prior to use and document the inspections on appropriate forms when required

9. Ensure preventative maintenance activities have been completed where required, prior to using equipment / machinery / tools

10. If equipment / machinery / tools are observed to be damaged, remove it from use and notify the Foreman / Superintendent

11. Install fencing and hoarding where needed

12. Locate utilities – Call Before You Dig

13. Overhead hazards (i.e. powerlines) will be identified, signs posted and a signal person appointed as required

During Task:

1. Traffic control to be present and spotters will be in place

2. Set up forms in preparation to pour concrete

3. When the ordered material arrives, coordination of truck off loading as required

4. Mix concrete and cement if required for specified concrete pour

5. Pour the concrete

6. Smooth and finish the concrete using a variety of hand and power tools

Task Completion:

1. Inspect equipment and report malfunctions to foreman / superintendents

2. Ensure all equipment / machinery / tools are maintained and stored appropriately in the designated locations

3. Implement any housekeeping or maintenance as required

Gazzola Paving Limited PAGE 3 OF 3

You might also like

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (3)

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- Job Hazard Analysis of Site SURVEYINGDocument1 pageJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- JSA Transformer Installations, Testing, Commissioning.Document6 pagesJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt75% (4)

- Vorderman C. - Computer Coding For Kids. A Unique Step-By-Step Visual Guide, From Binary Code To Buildings Game - 2019 PDFDocument226 pagesVorderman C. - Computer Coding For Kids. A Unique Step-By-Step Visual Guide, From Binary Code To Buildings Game - 2019 PDFGaurav100% (2)

- Filipino Sa Piling Larangan (4.1)Document43 pagesFilipino Sa Piling Larangan (4.1)Lalisa Ameler67% (24)

- SMEDA Green House Farm (Export of Fresh Cut Roses)Document27 pagesSMEDA Green House Farm (Export of Fresh Cut Roses)Babar RaisNo ratings yet

- Rethinking Sexism Gender and SexualityDocument2 pagesRethinking Sexism Gender and SexualityKarmenNo ratings yet

- Case Report Grant Funding ApplicationDocument2 pagesCase Report Grant Funding ApplicationGlobal Advances in Health and MedicineNo ratings yet

- Badri Rai v. State of Bihar, AIR 1958 SC 953: FactsDocument5 pagesBadri Rai v. State of Bihar, AIR 1958 SC 953: FactsDrsika100% (2)

- R F (H W C) :: ED Lags OLD Ork Until OrrectedDocument4 pagesR F (H W C) :: ED Lags OLD Ork Until OrrectedtusharDJNo ratings yet

- SWP For Asphalt Road WorksDocument4 pagesSWP For Asphalt Road WorksKalisha RavelloNo ratings yet

- R F (H W C) :: Crushing & Screening Operations BDocument5 pagesR F (H W C) :: Crushing & Screening Operations Bkmohamedkeita906No ratings yet

- Night WorkDocument3 pagesNight Workkessery koivoguiNo ratings yet

- R F (H W C) :: Operations & Screening CrushingDocument7 pagesR F (H W C) :: Operations & Screening Crushingkmohamedkeita906No ratings yet

- Risk Assessment - Erection of LP Heater 2Document5 pagesRisk Assessment - Erection of LP Heater 2Hanu JemberNo ratings yet

- JSA-control Panel Final Reviwed AVCDocument5 pagesJSA-control Panel Final Reviwed AVCSubhash Chekka SEC 115KV ProjectNo ratings yet

- Paint Work Using Mobile Crane PSO FSD.Document5 pagesPaint Work Using Mobile Crane PSO FSD.fiazhussaindbxNo ratings yet

- RA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFDocument8 pagesRA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFIbrahim EsmatNo ratings yet

- Fencing and HordingDocument2 pagesFencing and HordingAsad RazaNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Screening and Crushing Operations 2016 VersionDocument4 pagesScreening and Crushing Operations 2016 Versionkmohamedkeita906No ratings yet

- Lesson Learned RegisterDocument2 pagesLesson Learned Registernasir habibNo ratings yet

- Jsa Steel ErectionDocument9 pagesJsa Steel Erection01095902062ahmedNo ratings yet

- Job Safety Analysis FABCONDocument8 pagesJob Safety Analysis FABCONGladyNo ratings yet

- RA 1 CocacolaDocument5 pagesRA 1 CocacolaIbrahim EsmatNo ratings yet

- Dewatering Risk Assessment (0075) - Rev-02Document16 pagesDewatering Risk Assessment (0075) - Rev-02Muhammad OsamaNo ratings yet

- Ehv SWP Form Tower AssemblyDocument4 pagesEhv SWP Form Tower AssemblySn AhsanNo ratings yet

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Solar PV Modules Loading On Roof Top: Project: Seaworld Abu Dhabi - 8.368Mwp Solar PV Project OperationDocument3 pagesSolar PV Modules Loading On Roof Top: Project: Seaworld Abu Dhabi - 8.368Mwp Solar PV Project OperationKarimo KilaniNo ratings yet

- Tool Box Talks ConstructionDocument12 pagesTool Box Talks Constructiontexas_peteNo ratings yet

- Risk Assessment - Pipe Fit Up - Hot WorkDocument7 pagesRisk Assessment - Pipe Fit Up - Hot WorkHanu JemberNo ratings yet

- JHA Crushing OperationsDocument3 pagesJHA Crushing Operationsabdullah ashrafNo ratings yet

- CM3 Reviewer - L3Document3 pagesCM3 Reviewer - L3A.GNo ratings yet

- Construction by Ohio DOTDocument21 pagesConstruction by Ohio DOTSantosh GokarnNo ratings yet

- Al - Osais Contracting Company Haradh Area Power Reliability EnhancementDocument3 pagesAl - Osais Contracting Company Haradh Area Power Reliability EnhancementREHAN IQBAL100% (3)

- Trampoline Centre Safety Information: Identifying The RisksDocument2 pagesTrampoline Centre Safety Information: Identifying The RisksVasile NodisNo ratings yet

- JSA - Working at HeightDocument5 pagesJSA - Working at HeightSampath Kumar KandasamyNo ratings yet

- Screening and Crushing Operations 2016 VersionDocument3 pagesScreening and Crushing Operations 2016 Versionmohamedkeita0880No ratings yet

- Motor Grader Safe Work ProcedureDocument12 pagesMotor Grader Safe Work ProcedureScribdTranslationsNo ratings yet

- Use of 110v Tools B 05Document1 pageUse of 110v Tools B 05cardyNo ratings yet

- JSA Installation of GearboxDocument2 pagesJSA Installation of GearboxDaniel TOMBENo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Site Specific Safety OrientationDocument39 pagesSite Specific Safety OrientationBernard AmooNo ratings yet

- Dewatering Risk Assessment (0075) - Rev-00Document15 pagesDewatering Risk Assessment (0075) - Rev-00Muhammad OsamaNo ratings yet

- 1-Machine SafetyDocument59 pages1-Machine Safetyᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔100% (3)

- TBT LogDocument9 pagesTBT LogfatehNo ratings yet

- Construction MachineriesDocument3 pagesConstruction MachineriesJoyce MarananNo ratings yet

- Ehv SWP Form Tower ErectionDocument4 pagesEhv SWP Form Tower ErectionSn AhsanNo ratings yet

- Ehv SWP Form Scaffolding RemovalDocument2 pagesEhv SWP Form Scaffolding RemovalSn AhsanNo ratings yet

- Heavy Equipment Safety TrainingDocument26 pagesHeavy Equipment Safety Trainingarnold arayataNo ratings yet

- JSA Tie in ActivitiesDocument15 pagesJSA Tie in ActivitiesQADEER SHANNo ratings yet

- THE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4Document21 pagesTHE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4RosalyNo ratings yet

- COSH Handout Nov 2022 (EERC)Document4 pagesCOSH Handout Nov 2022 (EERC)JOHN CARLO DE GUZMAN AMBAY (JCDGA)No ratings yet

- Risk Assessment - Erection Portal Reclaimer - FinalDocument5 pagesRisk Assessment - Erection Portal Reclaimer - FinalHanu JemberNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Unit GC2 Element 4 - InternationalDocument14 pagesUnit GC2 Element 4 - InternationalSatya NaiduNo ratings yet

- Job Safety Analysis & Risk Assessment For Scrapping and Grading ActivityDocument1 pageJob Safety Analysis & Risk Assessment For Scrapping and Grading ActivityAzhar Mushtaq100% (1)

- JSA - Structural Steel Errection Anerrection and DismantlingDocument5 pagesJSA - Structural Steel Errection Anerrection and DismantlingSwaroop CherryNo ratings yet

- Se SF Activity HW TRNDocument24 pagesSe SF Activity HW TRNElvyn Fabellore HerreraNo ratings yet

- 5.module 21-26 FRROHS COSH Manual 2020 Rev1Document44 pages5.module 21-26 FRROHS COSH Manual 2020 Rev1camlbassigNo ratings yet

- 12 Life Saving RulesDocument15 pages12 Life Saving RulesVăn Trần ĐìnhNo ratings yet

- Safe Lifting and Rigging TrainingDocument84 pagesSafe Lifting and Rigging Trainingfaroz khan100% (2)

- EHS R&O Assessment - AlmeeraDocument6 pagesEHS R&O Assessment - AlmeeraAnandu SankarNo ratings yet

- Risk Assessment Tipu-PremierDocument6 pagesRisk Assessment Tipu-PremierFahad HayatNo ratings yet

- The Passing of The Public Utility Concept PDFDocument14 pagesThe Passing of The Public Utility Concept PDFClarissa de VeraNo ratings yet

- Compliance System Checklist and Insurance Underwriting Management System ManualDocument13 pagesCompliance System Checklist and Insurance Underwriting Management System Manualsharon omashNo ratings yet

- Cowan and Van Der Ryn: Ecological DesignDocument8 pagesCowan and Van Der Ryn: Ecological DesignferozfaruqiNo ratings yet

- BDBL AssignmentDocument9 pagesBDBL AssignmentSamira IslamNo ratings yet

- Plant Manager or VP of OperationsDocument6 pagesPlant Manager or VP of Operationsapi-77811453No ratings yet

- Deped Guidelines and Procedures On The Management of Children-At-Risk (Car) and Children in Conflict With The Law (Cicl)Document13 pagesDeped Guidelines and Procedures On The Management of Children-At-Risk (Car) and Children in Conflict With The Law (Cicl)Raba BethNo ratings yet

- Red ChiefDocument17 pagesRed Chiefbholu436100% (2)

- Acko Bike Policy - DBTR00126261926 - 00Document1 pageAcko Bike Policy - DBTR00126261926 - 00harshith sbNo ratings yet

- Speech by Honourable Bahame Tom Mukirya Nyanduga, The Acting Chairperson of The African Commission On Human and Peoples' Rights at The Opening Ceremony of The 46th Ordinary SessionDocument15 pagesSpeech by Honourable Bahame Tom Mukirya Nyanduga, The Acting Chairperson of The African Commission On Human and Peoples' Rights at The Opening Ceremony of The 46th Ordinary SessionNegsNo ratings yet

- PEOPLE V GUILLEN G.R. No. L-1477 PDFDocument4 pagesPEOPLE V GUILLEN G.R. No. L-1477 PDFJM CamposNo ratings yet

- Ass#9Document3 pagesAss#9Mariel B. Dela PeñaNo ratings yet

- Hairdressing 12-3Document4 pagesHairdressing 12-3Govie Dionisios100% (1)

- Abstract Writing: Purposes, Conventions and Types: What Is An Abstract?Document8 pagesAbstract Writing: Purposes, Conventions and Types: What Is An Abstract?sman888No ratings yet

- The Role of Intensive Mentorship in EmONC - Improved Quality of CareDocument16 pagesThe Role of Intensive Mentorship in EmONC - Improved Quality of CareJhpiegoNo ratings yet

- Chap011 The Organization of International BusinessDocument20 pagesChap011 The Organization of International BusinessJaycel BayronNo ratings yet

- Smart Resume For Sales PositionDocument2 pagesSmart Resume For Sales PositionAsadur RahmanNo ratings yet

- REVISI Peta Okupasi AnimasiDocument15 pagesREVISI Peta Okupasi AnimasiHelloMotion AcademyNo ratings yet

- Taking Process Improvement Beyond The Quality DepartmentDocument4 pagesTaking Process Improvement Beyond The Quality DepartmentHassen TalebNo ratings yet

- Academic Calendar Winter 2016 17Document3 pagesAcademic Calendar Winter 2016 17Ashwin BalajiNo ratings yet

- Fevicol Ad AnalysisDocument2 pagesFevicol Ad AnalysisKaran TrivediNo ratings yet

- Giving Opinions and ArgumentDocument2 pagesGiving Opinions and ArgumentMArina MeenaNo ratings yet

- Davis Kiara Esh320 Diagnosticassessmentandunitplan 2Document19 pagesDavis Kiara Esh320 Diagnosticassessmentandunitplan 2api-293919801No ratings yet

- ISO 27001:2013 Gap AnalysisDocument8 pagesISO 27001:2013 Gap AnalysisTSANIA MAULIDIANo ratings yet

- Invitation Letter To TraineesDocument4 pagesInvitation Letter To TraineesMark Roger Huberit IINo ratings yet