Professional Documents

Culture Documents

EWLC 74 $fpeng0001121997

EWLC 74 $fpeng0001121997

Uploaded by

Iulian Dobrin0 ratings0% found this document useful (0 votes)

33 views3 pagesEWLC 74 is a microprocessor-based instrument developed to control refrigerated units. It has two relay outputs to control the compressor and defrost system, and two inputs for temperature probes. It can be configured through invisible parameters programmed via serial port to control temperature according to the application's needs, with options for defrost type, interval, and temperatures.

Original Description:

Eliwell

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEWLC 74 is a microprocessor-based instrument developed to control refrigerated units. It has two relay outputs to control the compressor and defrost system, and two inputs for temperature probes. It can be configured through invisible parameters programmed via serial port to control temperature according to the application's needs, with options for defrost type, interval, and temperatures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

33 views3 pagesEWLC 74 $fpeng0001121997

EWLC 74 $fpeng0001121997

Uploaded by

Iulian DobrinEWLC 74 is a microprocessor-based instrument developed to control refrigerated units. It has two relay outputs to control the compressor and defrost system, and two inputs for temperature probes. It can be configured through invisible parameters programmed via serial port to control temperature according to the application's needs, with options for defrost type, interval, and temperatures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

EWLC 74 rel.

12/97 ing

blind controller for refrigerated units

GENERAL DESCRIPTION sor is working.

EWLC 74 is a microprocessor based in- Power-on Led: line led (green), indicates

strument developed to control refrigerated the instrument is powered.

WHAT IT IS units. It is provided with an internal trans- Defrost Led: led (yellow) related top de-

former (230/12 Vac), two relay outputs to frost, on when defrost is in progress, blink-

EWLC 74 is a microprocessor drive the compressor and the defrost sys- ing in case of manual defrost.

based instrument developed to tem, and two inputs for NTC probes to The power-on led turns on when the in-

control refrigerated units. control the room temperature and the end strument is started and the lamp-test is

of defrost. performed by the defrost led only for about

A series of parameters (invisible and facto- 5 seconds.

HOW IT IS MADE ry programmable through the serial port

only) allows to configure the instrument ac- PARAMETERS DESCRIPTION

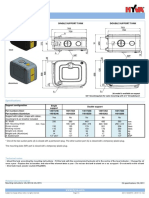

• Housing: resin PC+ABS plastic cording to the application. diF: diFferential.

with V0 extinguishing grade EWLC 74 is available in the 32x74 Eliwell Setpoint intervention differential. In refriger-

• Size: front 76x34 mm, depth standard format. ated applications temperature control is

62 mm carried out with the differential set to posi-

• Mount: panel on 71x29 mm hole OPERATION tive values; the compressor stops when

• Protection: a shed (tile) for dap In refrigerated applications temperature the Setpoint is reached (condition detect-

mount on the back of the instru- control is carried out with the differential ed by the regulation probe) and restarts

ment is available on request to set to positive values; the compressor when the temperature reaches Setpoint

protect the screw terminal block stops when the Setpoint is reached and plus the differential.

• Connections: on screw terminal restarts when the temperature reaches dit1: defrost interval time 1 (jumper ON):

block for wires max 2.5 mm2 (one Setpoint plus the differential. The Setpoint Defrost initiation frequency, in hours.

wire only per contact in compli- can be set through the trimmer on the front dit2: defrost interval time 2 (jumper OFF):

ance with VDE regulations) panel. Defrost initiation frequency, in hours.

• Commands: on front and side Two accessible jumpers located on the doh: defrost offset hour.

(through 2 jumpers) side of the instrument allow to select two Delay time for defrost start, in minutes.

• Outputs: 1 output on N.O. relay for defrost types: electrical (the compressor is dEt: defrost Endurance time-out.

compressor 8(3)A 250V AC and 1 stopped) or cycle inversion (warm gas; the Defrost time-out; after this time defrost is

exchange output on relay 8(3)A compressor keeps on operating); it is also stopped even if the defrost end tempera-

250V AC for the defrost system possible to select the number of daily de- ture is not reached; in minutes.

• Analogue inputs: two NTC probe frosts (two or four daily defrosts can be dSt: defrost Stop temperature.

for temperature control and de- chosen in the standard version, see para- Defrost end temperature.

frost management meters “dit1” and “dit2”). dnt: defrost enable temperature.

• Consumption: 1.5 VA max A series of invisible parameters - which Temperature value below which the defrost

• Power supply: 230 Vac. Others on can only be programmed in factory call is enabled.

request through the serial port - allows to set the POS: POStpone defrost.

defrost start temperature (below which th When active it allows to delay defrost at

defrost call is enabled), the defrost stop the end of the defrost interval until suitable

temperature and a maximum time (time- conditions for defrost occur.

out) after which defrost is always stopped. n = no; y = yes.

A series of “safety systems” (delay in acti- cPS: compressor Probe Set.

vation, minimum disable time, minimum End of scale value for the Setpoint trimmer.

time between two activations) protects the cPo: compressor Probe offset.

compressor from close starts. Start of scale value for the Setpoint trim-

Other parameters make the instrument mer.

configurable for different applications. dt: drainage time.

Dripping time; after defrost the compres-

COMMANDS ON FRONT PANEL sor is stopped for a time set by this value

There is no display. A button is available for (in minutes).

manual activation of the defrost cycle: by dPo: defrost (at) Power on.

pressing and releasing it a defrost cycle is Allows to select or deselect defrost at

started, provided that suitable conditions startup.

are present. n = no; y = yes.

A trimmer on the front panel allows to set cPP: compressor Probe Protection.

the operation setpoint for the compressor: Allows to select the state of compressor

its range can be customised and set for faulty probe.

through two parameters. oF = relay OFF for faulty probe;

Compressor Led: led (red) related to the on = relay ON for faulty probe;

compressor relay, on when the compres- dc = duty cycle; ON and OFF times for the

DEFAULT SETTINGS - STANDARD MODELS frosts in case of manual call through de-

frost key pressure.

Parameter Description Range Default Unit n = no; y = yes.

diF diFferential -50…50 2 °C Oct: On compressor time.

dit1 defrost interval time 1 0…18 12 hours Minimum compressor on time before the

activation of the inversion valve in cycle in-

dit2 defrost interval time 2 0…18 6 hours

version defrosts, in minutes.

doh derfost offset hour 0…255 0 min

dEt defrost Endurance time 0…255 30 min MECHANICAL MOUNT

dSt defrost Stop temperature –50…50 9 °C

EWLC 74 is designed for panel mount. Drill

a 29x71 mm hole and introduce the instru-

dnt defrost enable temperature –50…50 0 °C ment fixing it with the special bracket (in-

POS POSpone defrost n/y n flag cluded).

cPS compressor Probe Set –50…50 –10 °C The operating temperature range for cor-

rect operation is from –5 to 65 °C. Do not

cPo compressor Probe offset –50…50 –30 °C

install the instrument in moist and/or dirty

dt drainage time 0…255 0 min places; it is suitable for operation in envi-

dPo defrost (at) Power-on n/y n flag ronments with an ordinary pollution level.

cPP compressor Probe Protection flag

Leave enough room for air circulation by

oF / on / dc on

the cooling holes of the instrument.

Ont On time compressor 0…255 5 min

OFt OFF time compressor 0…255 5 min ELECTRICAL CONNECTIONS

ctP compressor type Protection nP / don / doF / dbi nP flag EWLC 74 is provided with screw terminal

blocks for the connection of electrical

cdP compressor delay Protection 0…255 0 min

wires with a maximum 2.5 mm2 section

odo output delay (at) on 0…255 0 min (one wire only per terminal in compliance

drt defrost restet time n/y y flag with VDE regulations).

The instrument is provided with two out-

Oct On compressor time 0…255 0 min

puts, a N.O. contact for the compressor

and an exchange contact for the defrost

system. Outputs on the defrost relay are

free from voltage. Do not exceed the max-

CONNECTIONS imum contact capacity: 8(3)A AC 250V. In

case of heavier loads use a contactor with

a suitable power.

Ensure the voltage of the EWLC 74 power

EWLC 74 complies to requirements.

The two NTC probes do not require inser-

tion polarity and can be lengthened using

sa standard bipolar cable (please remem-

ber that too long probes imply worse in-

strument performance for the EMC

electromagnetic compatibility).

1 2 3 4 5 6 7 8 9 10

The probe cables shall be kept far from re-

lay cables and from the power supply both

thermostat for EMC and safety reasons. The European

NTC probe safety regulations state that the power

supply and relay contacts (and, generally,

defrost comp. all parts with dangerous voltage) shall be

defrost separated from very low safety voltage

NTC probe

contacts (probes) by insulations and dis-

tances suitable to guarantee at least a

POWER SUPPLY double or reinforced insulation. EMC re-

quirements for correct operation

suggest/impose to put maximum care in

this separation through the use of insulat-

ing channels separated by suitable cable

relay are set by parameters “Ont” and doF = delay at switching oFf. Minimum fixing systems.

“OFt”. time for relay deactivation.

Ont: On time (compressor). dbi = delay between two successive TECHNICAL DATA

Compressor ON time; in minutes. starts. Minimum time between two subse- Housing: resin PC+ABS plastic with V0

OFt: OFF time (compressor). quent relay activations. extinguishing grade.

Compressor OFF time; in minutes. cdP: compressor delay Protection. Size: front 76x34 mm, depth 62 mm.

ctP: compressor type Protection. Time related to the previous parameter; in Mount: panel on 71x29 mm hole.

Allows to select the type of protection from minutes. Protection: a shed (tile) for dap mount on

close compressor starts (the time is set odo: output delay (at) on. the back of the instrument is available on

through the following parameter): Activation delay for relays at instrument request to protect the screw terminal

nP = no Protection. No protection. startup; in minutes. block.

don = delay on start. Delay on relay activa- drt: defrost reset time. Connections: on screw terminal block for

tion. It allows to enable the count of timed de- wires max 2.5 mm2 (one wire only per con-

EWLC 74 12/97 ing 2

tact in compliance with VDE regulations).

Commands : on f ront and side (th rough 2

jumpers).

Data storag e : on non volatile memory

(EEPROM).

Operating temperatu re : –5…65 °C.

Storage temperatu re : –30…75 °C.

Outputs : 1 output on N.O. relay for com-

pr essor 8(3)A 250V A C and 1 exchange

output on relay 8(3)A 250V A C for the de-

f rost system.

Analogue input s : two NTC p r obe for

temperatu re cont rol and def rost manage-

ment.

Consumptio n : 1.5 VA max.

Power suppl y : 230 Vac. Others on r e-

quest.

Eliwell

via dell’Artigianato, 65

Zona Industriale

32010 Pieve d’Alpago (BL)

Italy

Telephone +39 (0)437 986111

Facsimile +39 (0)437 989066

3 EWLC 74 12/97 ing

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- CDT900 Series-Manual PDFDocument102 pagesCDT900 Series-Manual PDFJuan Cascante JiménezNo ratings yet

- Blood Pressure Levels For Boys by Age and Height PercentileDocument4 pagesBlood Pressure Levels For Boys by Age and Height PercentileNuzla EmiraNo ratings yet

- Ewpc972 Manual enDocument3 pagesEwpc972 Manual enMatjazNo ratings yet

- EWPC 974: Freezer ControlDocument3 pagesEWPC 974: Freezer ControlFlávio MatosNo ratings yet

- XW360K XW370K: Installing and Operating InstructionsDocument6 pagesXW360K XW370K: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- XR70C - XR70D - XR72C: Installing and Operating InstructionsDocument4 pagesXR70C - XR70D - XR72C: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- EWPC 901/A: Temperature Controller With Alarm OutputDocument5 pagesEWPC 901/A: Temperature Controller With Alarm OutputOswaldo Rengifo MuozNo ratings yet

- XR20C - XR20D: Installing and Operating InstructionsDocument4 pagesXR20C - XR20D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- XR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementDocument4 pagesXR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementJennifer Eszter SárközyNo ratings yet

- Dixell XR60CDocument4 pagesDixell XR60CCarlos0% (1)

- Controller For Temperature Control: - AK-CC 210Document24 pagesController For Temperature Control: - AK-CC 210Vasti Diaz AguilarNo ratings yet

- AK CC 250 User GuideDocument26 pagesAK CC 250 User GuideEisinhawer Medina SernaNo ratings yet

- Brukermanual AK CC210Document24 pagesBrukermanual AK CC210Øyvind SkulstadNo ratings yet

- XR60C - XR60D: Digital Controller With Defrost and Fans ManagementDocument4 pagesXR60C - XR60D: Digital Controller With Defrost and Fans ManagementHaiam BordaNo ratings yet

- True :dixell TS InstructionsDocument4 pagesTrue :dixell TS InstructionsFred Smif100% (1)

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- XR70C-D XR72C GB r1.0 18.11.2015Document4 pagesXR70C-D XR72C GB r1.0 18.11.2015Jennifer Eszter SárközyNo ratings yet

- Tecnologic TDR 26 Microprocessor-Based Digital Electronic Freezer ControllerDocument7 pagesTecnologic TDR 26 Microprocessor-Based Digital Electronic Freezer ControllerMaksims TarasovsNo ratings yet

- User Manual CAREL IR33 PlusDocument24 pagesUser Manual CAREL IR33 PlusffcancunmantenimientoNo ratings yet

- CH-DIN - P $fpENG031998Document12 pagesCH-DIN - P $fpENG031998Γεώργιος Παπαδόπουλος100% (1)

- Controller For Temperature Control: EKC 202D1Document24 pagesController For Temperature Control: EKC 202D1Jack AhmadNo ratings yet

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDocument4 pagesXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- A6V10056938Document10 pagesA6V10056938EdNo ratings yet

- Installing and Operating Instructions: DixelDocument4 pagesInstalling and Operating Instructions: Dixeldorin stoicuNo ratings yet

- XR30C - XR30D: Installing and Operating InstructionsDocument4 pagesXR30C - XR30D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Hướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXDocument4 pagesHướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXVĩnhNo ratings yet

- EWPC 901/AR: Temperature Controller With Alarm OutputDocument3 pagesEWPC 901/AR: Temperature Controller With Alarm OutputOswaldo Rengifo MuozNo ratings yet

- TroubleshootingDocument54 pagesTroubleshootingproyectoariesNo ratings yet

- dIXEL Installing and Operating Instructions Rel.2.0 - Cod. 1598002170, Manual XW60LDocument4 pagesdIXEL Installing and Operating Instructions Rel.2.0 - Cod. 1598002170, Manual XW60LAlexey IvanovNo ratings yet

- T2700 Manual Rev 1Document79 pagesT2700 Manual Rev 1Daryl Barrios LamedaNo ratings yet

- EKC 315A Danfoss Rs8cS302Document16 pagesEKC 315A Danfoss Rs8cS302davebigelow42No ratings yet

- Technical Service Guide 1998 Adaptive DefrostDocument19 pagesTechnical Service Guide 1998 Adaptive DefrostoxmanamouNo ratings yet

- Capacity Controller EKC 331TDocument12 pagesCapacity Controller EKC 331Tabdur rafayNo ratings yet

- L-2281 DDC Control 20060512Document16 pagesL-2281 DDC Control 20060512Jesus OrtizNo ratings yet

- EKC 331T ManualDocument12 pagesEKC 331T ManualalphyjayemilianoNo ratings yet

- Tc940ri PlusDocument6 pagesTc940ri Plusluckyless94No ratings yet

- Danfoss EKC201CDocument16 pagesDanfoss EKC201CGabriel PiticasNo ratings yet

- Digicold Digicold Digicold Digicold: SeriesDocument4 pagesDigicold Digicold Digicold Digicold: SeriesdbricchiNo ratings yet

- York Split LargeDocument28 pagesYork Split LargedokundotNo ratings yet

- Heat Pump Defrost Control Book - 34-4101-07Document38 pagesHeat Pump Defrost Control Book - 34-4101-07skgadde100% (1)

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- Ch402 - 403 - OPDocument2 pagesCh402 - 403 - OPhp691550% (2)

- EKC 202ABC ManualDocument16 pagesEKC 202ABC ManualJose CencičNo ratings yet

- MBUS - IO3 User Guide: FeaturesDocument6 pagesMBUS - IO3 User Guide: FeaturesAnonymous eoV4CVyWNo ratings yet

- T2900 Manual Rev 5Document113 pagesT2900 Manual Rev 5brucelirockNo ratings yet

- UC8 Troubleshooting Guide v2 0715 2Document18 pagesUC8 Troubleshooting Guide v2 0715 2j.knightNo ratings yet

- XR10C - XR10D: Digital Controller With Cooling or Heating ActionDocument4 pagesXR10C - XR10D: Digital Controller With Cooling or Heating ActionJennifer Eszter SárközyNo ratings yet

- LX SeriesDocument56 pagesLX SeriesDanny AlejandroNo ratings yet

- Telepac Microcontroller Installation ServiceDocument28 pagesTelepac Microcontroller Installation ServiceAshfaque AhmedNo ratings yet

- 6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationDocument4 pages6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationJennifer Eszter SárközyNo ratings yet

- XR60CDocument4 pagesXR60CbrandboyvivekNo ratings yet

- Manual TC 900 RiDocument3 pagesManual TC 900 RiedgardoNo ratings yet

- XW60L VDocument4 pagesXW60L VGilles LE NOUVELNo ratings yet

- KLT11DS EN User-ManualDocument2 pagesKLT11DS EN User-ManualMario PitaNo ratings yet

- Ahu ManualDocument15 pagesAhu ManualAlan LaundrdayNo ratings yet

- 80 Series Thermostats Catalog en 1594386Document2 pages80 Series Thermostats Catalog en 1594386Tatiana DiazNo ratings yet

- Service Manual Daikin FTXN LDocument54 pagesService Manual Daikin FTXN LQasir MughalNo ratings yet

- FHP Upm IDocument10 pagesFHP Upm IAbdulSattarNo ratings yet

- XH360L VDocument5 pagesXH360L VJorge CantanteNo ratings yet

- Wallmat Supply Chain Analysis PDFDocument44 pagesWallmat Supply Chain Analysis PDFProsenjit RoyNo ratings yet

- CACR21 January 2015Document19 pagesCACR21 January 2015maikaNo ratings yet

- Q Bank Chem MCD Viii 2019Document19 pagesQ Bank Chem MCD Viii 2019hgbv tttbNo ratings yet

- REHS4987-02 Replacing Base Edge Assemblies in Large Wheel Loader BucketsDocument19 pagesREHS4987-02 Replacing Base Edge Assemblies in Large Wheel Loader BucketsCarlosNo ratings yet

- Railway Accounting: Indian Railway Accounts ServiceDocument5 pagesRailway Accounting: Indian Railway Accounts ServiceAbhijeet AsthanaNo ratings yet

- Ch123 Exam II Practice Exam Spring2011Document7 pagesCh123 Exam II Practice Exam Spring2011christopher92530% (1)

- Bicycle Repair ManualDocument162 pagesBicycle Repair Manualrazvancc89% (9)

- Biology Paper Ib: Maple Leaf International SchoolDocument22 pagesBiology Paper Ib: Maple Leaf International SchoolFcgfht ghkhkujk100% (1)

- F1.4 - Marine Sediment Treatment and ReuseDocument14 pagesF1.4 - Marine Sediment Treatment and ReuseKwan Chun SingNo ratings yet

- Indemnity Bond With SuretyDocument3 pagesIndemnity Bond With SuretyJnanaranjan PadhanNo ratings yet

- Proteomic Landscape Presents Cues For Vegetative To Reproductive Transition in MangoDocument7 pagesProteomic Landscape Presents Cues For Vegetative To Reproductive Transition in MangoShailendra RajanNo ratings yet

- Yoga 530Document90 pagesYoga 530Juan LatorreNo ratings yet

- Planned ParenthoodDocument2 pagesPlanned ParenthoodChylon BudagherNo ratings yet

- LA Myxoma Case PresentationDocument34 pagesLA Myxoma Case PresentationWiwik Puji LestariNo ratings yet

- Mos-Installation Stainless Steel Eye Bolt Filter TankDocument5 pagesMos-Installation Stainless Steel Eye Bolt Filter Tankhabibullah.centroironNo ratings yet

- Industrial HygineDocument33 pagesIndustrial HygineNiraj RanjanNo ratings yet

- The Cardiovascular System: The Heart: Part B: Prepared by Barbara Heard, Atlantic Cape Community CollegeDocument80 pagesThe Cardiovascular System: The Heart: Part B: Prepared by Barbara Heard, Atlantic Cape Community CollegeBrianna PinchinatNo ratings yet

- Experiment 13 Ultrafiltration UnitDocument13 pagesExperiment 13 Ultrafiltration UnitKishen NaniNo ratings yet

- Significant Risk RegisterDocument8 pagesSignificant Risk RegisterswestyNo ratings yet

- Modals of Obligation and Permission WorksheetDocument2 pagesModals of Obligation and Permission Worksheetyuleysi yuleysivelezmorogmail.comNo ratings yet

- Homeostasis Case StudyDocument3 pagesHomeostasis Case Studyapi-332887331No ratings yet

- Salvador Sanchez Complaint SignedDocument2 pagesSalvador Sanchez Complaint SignedStephen LoiaconiNo ratings yet

- Final Report of The Sandy Hook Advisory CommissionDocument277 pagesFinal Report of The Sandy Hook Advisory CommissionHartford Courant0% (1)

- A Review On The Enhancement of Figure of MeritDocument23 pagesA Review On The Enhancement of Figure of Meritsasa_22No ratings yet

- Employee Separation and Retention (Q3)Document2 pagesEmployee Separation and Retention (Q3)BSMA Third YearNo ratings yet

- Die Strongswan Open Source VPN LösungDocument45 pagesDie Strongswan Open Source VPN LösungFolha ChaNo ratings yet

- Styro FlexDocument7 pagesStyro Flexprabhat singhNo ratings yet

- Sonia Research ProposalDocument59 pagesSonia Research Proposalmullamuskaan95No ratings yet

- Hyva Oil Tank: Single Support Tank Double Support TankDocument4 pagesHyva Oil Tank: Single Support Tank Double Support TankPutera Bumi NusantaraNo ratings yet