Professional Documents

Culture Documents

Structural Analysis Using NX Nastran 9.0

Structural Analysis Using NX Nastran 9.0

Uploaded by

mattiaCopyright:

Available Formats

You might also like

- Finite Element Analysis for Design Engineers, Second EditionFrom EverandFinite Element Analysis for Design Engineers, Second EditionNo ratings yet

- Carcoseal / UNDocument2 pagesCarcoseal / UNmattiaNo ratings yet

- Hyundai Robotics CatalogueDocument2 pagesHyundai Robotics Cataloguejitender kumar0% (1)

- Department of Structural Engineering and Program of Computer Graphics, Cornell University, Ithaca, N Y 14853, U.S.ADocument14 pagesDepartment of Structural Engineering and Program of Computer Graphics, Cornell University, Ithaca, N Y 14853, U.S.AFrancesco MontagnoliNo ratings yet

- Tutorial #1:the Essential ANSYS.: ME309: Finite Element Analysis in Mechanical DesignDocument9 pagesTutorial #1:the Essential ANSYS.: ME309: Finite Element Analysis in Mechanical DesignTanu RdNo ratings yet

- Bilder in Bachelor ThesisDocument6 pagesBilder in Bachelor ThesisTye Rausch100% (2)

- Ansys Vs NX NastranDocument22 pagesAnsys Vs NX NastranErlantz72No ratings yet

- Mesh LabDocument8 pagesMesh LabnzagzoogNo ratings yet

- Ansys - MEMS Lab IntroductionDocument9 pagesAnsys - MEMS Lab IntroductionJag JagNo ratings yet

- Chapter 8 - Finite Element AnalysisDocument21 pagesChapter 8 - Finite Element AnalysisZaroui Benamor AliNo ratings yet

- Ansys Vs NX NastranDocument22 pagesAnsys Vs NX NastranAllen Jose George100% (2)

- Cad Lab Manual - MujDocument29 pagesCad Lab Manual - MujAabhaş AgrawałNo ratings yet

- Uni Wuppertal Bachelor Thesis FormatDocument7 pagesUni Wuppertal Bachelor Thesis Formatheatherreimerpeoria100% (2)

- Meen 19111063Document109 pagesMeen 19111063foruseopen29No ratings yet

- Bachelor Thesis Angewandte InformatikDocument7 pagesBachelor Thesis Angewandte InformatikAshley Carter67% (3)

- MD SimulationDocument12 pagesMD SimulationAnand aashishNo ratings yet

- 1.3 Definition of Cad/Cam/Cae: 1.3.1 Computer Aided Design - CADDocument10 pages1.3 Definition of Cad/Cam/Cae: 1.3.1 Computer Aided Design - CADSai ChNo ratings yet

- Ansys Lab Manual BvcoekDocument26 pagesAnsys Lab Manual Bvcoekavinash 879No ratings yet

- Fae10068 2Document7 pagesFae10068 2dgdgdNo ratings yet

- Comparison of Nonlinear Finite Element Modeling Tools For Structural ConcreteDocument58 pagesComparison of Nonlinear Finite Element Modeling Tools For Structural ConcreteafcisNo ratings yet

- Ansys ManualDocument108 pagesAnsys Manual016 ARUNACHALAM S R MNo ratings yet

- Bachelor Thesis Zu Wenig SeitenDocument7 pagesBachelor Thesis Zu Wenig Seitenafknyfene100% (2)

- ANSYS 6.1 TutorialDocument63 pagesANSYS 6.1 TutorialrakeshsakoteNo ratings yet

- Hfu Bachelor Thesis AnmeldungDocument7 pagesHfu Bachelor Thesis AnmeldungCheapestPaperWritingServiceCanada100% (2)

- CNN Model For Image Classification Using Resnet: Dr. Senbagavalli M & Swetha Shekarappa GDocument10 pagesCNN Model For Image Classification Using Resnet: Dr. Senbagavalli M & Swetha Shekarappa GTJPRC PublicationsNo ratings yet

- Lab Manual CAMADocument75 pagesLab Manual CAMASatish HSNo ratings yet

- Computer Aided Modeling & Analysis Lab Final BackupDocument48 pagesComputer Aided Modeling & Analysis Lab Final Backup4PS19ME015 Anushree N.RNo ratings yet

- Deep Neural Network DNNDocument5 pagesDeep Neural Network DNNjaffar bikatNo ratings yet

- A Deep Learning Convolutional Neural Network in Health Care EnvironmentDocument17 pagesA Deep Learning Convolutional Neural Network in Health Care EnvironmentVasiha Fathima RNo ratings yet

- MEA12 Finite Element Analysis Lab ManualDocument49 pagesMEA12 Finite Element Analysis Lab ManualYeshwanth SuryaNo ratings yet

- MDH - Se ThesisDocument5 pagesMDH - Se Thesisdnpqamfd100% (1)

- Ansys14 Classic TutorialDocument21 pagesAnsys14 Classic TutorialMAXNo ratings yet

- An Interactive Program For Doing Fry Strain Analysis On The Macintosh MicrocomputerDocument11 pagesAn Interactive Program For Doing Fry Strain Analysis On The Macintosh MicrocomputerMiningNo ratings yet

- Meen 19111101 (Umair Khalid)Document166 pagesMeen 19111101 (Umair Khalid)Haid AshfaqueNo ratings yet

- HDM Bachelor Thesis VorlageDocument5 pagesHDM Bachelor Thesis Vorlagesarahjimenezriverside100% (2)

- Bachelor Thesis Informatik ThemaDocument8 pagesBachelor Thesis Informatik Themafesegizipej2100% (1)

- CCA ExptDocument64 pagesCCA ExptAbhishek SharmaNo ratings yet

- TimeNET QEST2017Document5 pagesTimeNET QEST2017Mostafa J AlneamyNo ratings yet

- Cad/Cam Lab: Venkitaraj K PDocument60 pagesCad/Cam Lab: Venkitaraj K PJoe mNo ratings yet

- Mechanical Vibrations Modal Analysis Project With Arduinos: Computers in Education Journal December 2017Document8 pagesMechanical Vibrations Modal Analysis Project With Arduinos: Computers in Education Journal December 2017Crazy FireNo ratings yet

- Ansys History.Document8 pagesAnsys History.Eirick Wayne Zuñigga De-ItzelNo ratings yet

- NX5 Review: Jeffrey RoweDocument8 pagesNX5 Review: Jeffrey RoweOscar GuerraNo ratings yet

- Bachelor Thesis Informatik PDFDocument8 pagesBachelor Thesis Informatik PDFCynthia King100% (2)

- What Is Ansys 1Document7 pagesWhat Is Ansys 1Mohamed Bahaa HannoNo ratings yet

- Toward Creative 3D Modeling: An Architects' Sketches StudyDocument4 pagesToward Creative 3D Modeling: An Architects' Sketches StudyNina DmitrievaNo ratings yet

- Toward Creative 3D Modeling: An Architects' Sketches StudyDocument4 pagesToward Creative 3D Modeling: An Architects' Sketches StudyNina DmitrievaNo ratings yet

- I Jeter 039112021Document8 pagesI Jeter 039112021WARSE JournalsNo ratings yet

- EJ1064301Document8 pagesEJ1064301Enzo SantosNo ratings yet

- Structural AnalysisDocument21 pagesStructural Analysisom prakashNo ratings yet

- Assignment 2: Advanced Geographic Information Systems For Transport and Logistics (GIS-T 2, Group A)Document2 pagesAssignment 2: Advanced Geographic Information Systems For Transport and Logistics (GIS-T 2, Group A)Matze Jan FilipekNo ratings yet

- Ansys TutorialsDocument24 pagesAnsys TutorialsMahdiNo ratings yet

- Deep Learning with Python: A Comprehensive Guide to Deep Learning with PythonFrom EverandDeep Learning with Python: A Comprehensive Guide to Deep Learning with PythonNo ratings yet

- Artificial Neural Networks with TensorFlow 2: ANN Architecture Machine Learning ProjectsFrom EverandArtificial Neural Networks with TensorFlow 2: ANN Architecture Machine Learning ProjectsNo ratings yet

- Mesh Generation: Advances and Applications in Computer Vision Mesh GenerationFrom EverandMesh Generation: Advances and Applications in Computer Vision Mesh GenerationNo ratings yet

- Finite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaFrom EverandFinite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaNo ratings yet

- Convolutional Neural Networks with Swift for Tensorflow: Image Recognition and Dataset CategorizationFrom EverandConvolutional Neural Networks with Swift for Tensorflow: Image Recognition and Dataset CategorizationNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan International USADocument1 pageEurope Germany France Italy Belgium Sweden U.K. Canada India Japan International USAmattiaNo ratings yet

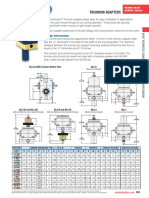

- Trunnion Adapters: Design InformationDocument1 pageTrunnion Adapters: Design InformationmattiaNo ratings yet

- Sym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedDocument6 pagesSym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedmattiaNo ratings yet

- CarcosealapDocument2 pagesCarcosealapmattiaNo ratings yet

- SealMaster InflatableDocument8 pagesSealMaster InflatablemattiaNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Aisi 316 L and Aluminium: Gas Springs Molle A GasDocument32 pagesAisi 316 L and Aluminium: Gas Springs Molle A GasmattiaNo ratings yet

- Thordon Rudder BrochureDocument8 pagesThordon Rudder BrochuremattiaNo ratings yet

- Aisi 316 L: Operating Valves - Evax SerieDocument59 pagesAisi 316 L: Operating Valves - Evax SeriemattiaNo ratings yet

- Proven Water Lubricated Propeller Shaft Bearing Solutions: V IronDocument8 pagesProven Water Lubricated Propeller Shaft Bearing Solutions: V IronmattiaNo ratings yet

- Ramnäs Quality Chains and AccessoriesDocument13 pagesRamnäs Quality Chains and AccessoriesmattiaNo ratings yet

- Process Pumps: Typical Fluids Pump UnitsDocument4 pagesProcess Pumps: Typical Fluids Pump UnitsmattiaNo ratings yet

- BallScrews and BallSplinesDocument160 pagesBallScrews and BallSplinesmattiaNo ratings yet

- Thomson Precision Linear Actuators Sep06Document8 pagesThomson Precision Linear Actuators Sep06mattiaNo ratings yet

- Carcoseal AP/WT/RR. The Lip Is Designed So ThatDocument2 pagesCarcoseal AP/WT/RR. The Lip Is Designed So ThatmattiaNo ratings yet

- Self Blocking Rail ClampsDocument17 pagesSelf Blocking Rail ClampsmattiaNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- CarcosealunsfDocument2 pagesCarcosealunsfmattiaNo ratings yet

- Materials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoreDocument14 pagesMaterials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoremattiaNo ratings yet

- Catene Rigide SerapidDocument19 pagesCatene Rigide SerapidmattiaNo ratings yet

- The Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012Document18 pagesThe Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012mattiaNo ratings yet

- Pluto Safety PLCDocument42 pagesPluto Safety PLCmattiaNo ratings yet

- Advanced Valuation Concepts and Methods - BLK - 1Document72 pagesAdvanced Valuation Concepts and Methods - BLK - 1Kim GeminoNo ratings yet

- HTW 1 - 3Document8 pagesHTW 1 - 3alonso_rNo ratings yet

- Gujarat Technological University: Power Electronics (24) Subject CodeDocument3 pagesGujarat Technological University: Power Electronics (24) Subject Codequdratullah ehsanNo ratings yet

- Pendulum SimulinkDocument10 pagesPendulum SimulinkSatyavir YadavNo ratings yet

- Fanuc CNC Guide 1Document4 pagesFanuc CNC Guide 1Stephano PortellaNo ratings yet

- On The Environmental Pollution Problem: A Review: Journal of Environmental Engineering and Landscape ManagementDocument7 pagesOn The Environmental Pollution Problem: A Review: Journal of Environmental Engineering and Landscape Managementmagizh tamizhiniNo ratings yet

- GSW Portfolio V02Document21 pagesGSW Portfolio V02أحمد فريد سعد عبد الفتاحNo ratings yet

- National Institute of Technology Durgapur: Name - Kundan Kumar ROLL NO.-18MA4108 Mtech-Third SemesterDocument34 pagesNational Institute of Technology Durgapur: Name - Kundan Kumar ROLL NO.-18MA4108 Mtech-Third SemesterDIPESHNo ratings yet

- Aspen Elearning: CatalogDocument122 pagesAspen Elearning: Catalogokky wddNo ratings yet

- The Meaning of Virtual Return Demonstrations To A Nursing Student of Capitol University: A Phenomenological InquiryDocument17 pagesThe Meaning of Virtual Return Demonstrations To A Nursing Student of Capitol University: A Phenomenological InquiryJeffrey TVNo ratings yet

- Cse Satrack ReportDocument19 pagesCse Satrack Reportkarthik naniNo ratings yet

- Synthesis of Aircraft Landing Gear Mechanism: P S, P. R RDocument5 pagesSynthesis of Aircraft Landing Gear Mechanism: P S, P. R Rshaotao guoNo ratings yet

- TR - Aquaculture NC IIDocument64 pagesTR - Aquaculture NC IIherbert rebloraNo ratings yet

- A Simulation Approach To Manpower PlanningDocument9 pagesA Simulation Approach To Manpower PlanningenoNo ratings yet

- Ece Viii Embedded System Design (06ec82) NotesDocument270 pagesEce Viii Embedded System Design (06ec82) NotesBSRohitNo ratings yet

- Petsoc 01 06 03Document10 pagesPetsoc 01 06 03Francisco LaguardiaNo ratings yet

- BA Teknik Sipil - s12544-023-00590-5Document20 pagesBA Teknik Sipil - s12544-023-00590-5Ainayya AleenaNo ratings yet

- E:D Background Simulation GuideDocument7 pagesE:D Background Simulation GuidetomNo ratings yet

- Nasa TLX KuesionerDocument49 pagesNasa TLX KuesionerZikri Fathur RahmanNo ratings yet

- Istat CME TalkDocument22 pagesIstat CME TalkmuhammadNo ratings yet

- Concepts of Training and DevelopmentDocument24 pagesConcepts of Training and DevelopmentPrafful AgarwalNo ratings yet

- A Method To Design Vibratory Bowl FeederDocument5 pagesA Method To Design Vibratory Bowl Feederأحمد عاطف أبوغديرNo ratings yet

- AdtechDocument2 pagesAdtechJjp LopezNo ratings yet

- Matlab Books - TittlesDocument2 pagesMatlab Books - TittlesVenugopal KonapalaNo ratings yet

- Warship 10 BrochureDocument4 pagesWarship 10 Brochurehamid moaieriNo ratings yet

- M.E. EXAM Time TableDocument7 pagesM.E. EXAM Time Tablepa390786No ratings yet

- VDE-Vehicle Dynamics EngineDocument64 pagesVDE-Vehicle Dynamics EngineJordan HotCoffee Bennett67% (3)

- Maritime InstituteDocument10 pagesMaritime InstitutedweepNo ratings yet

Structural Analysis Using NX Nastran 9.0

Structural Analysis Using NX Nastran 9.0

Uploaded by

mattiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Analysis Using NX Nastran 9.0

Structural Analysis Using NX Nastran 9.0

Uploaded by

mattiaCopyright:

Available Formats

NASA KSC – Internship Final Report

Structural Analysis Using NX Nastran 9.0

Benjamin M. Rolewicz

Kennedy Space Center (KSC)

Major: Mechanical Engineering

Program: Structural or Fluids Analysis, Summer 2014

Date: 29/07/2014

NASA KSC Page 1 29/07/2014

NASA KSC – Internship Final Report

Structural Analysis Using NX Nastran 9.0

Benjamin M. Rolewicz1

Cornell University ‘15, Ithaca, NY, 14850

NX Nastran is a powerful Finite Element Analysis (FEA) software package used to solve

linear and non-linear models for structural and thermal systems. The software, which

consists of both a solver and user interface, breaks down analysis into four files, each of

which are important to the end results of the analysis. The software offers capabilities for a

variety of types of analysis, and also contains a respectable modeling program. Over the

course of ten weeks, I was trained to effectively implement NX Nastran into structural

analysis and refinement for parts of two missions at NASA’s Kennedy Space Center, the

Restore mission and the Orion mission.

I. Introduction

This written work reflects the work I performed during my internship at Kennedy Space Center during the

summer of 2014. My efforts began as being geared towards the goal of becoming effective and comfortable using

NX Nastran 9.0 for modeling and analysis in general. These efforts were fed by assistance from my mentor, Mr.

Syrus Jeanes of NE-M1, the individuals of M1 as a whole, and NX tutorials through Siemens Learning Advantage.

Initial learnings of mine were very basic, including starting the program, understanding the controls, and becoming

acquainted with the user interface. I moved on to learn about modeling a part or assembly, then learned about the

process of performing a successful and effective analysis, including the management of the four files involved in an

analysis procedure. As I progressed, I began to explore the capabilities of NX Nastran 9.0, such as thermal system

analysis, contact and glued surfaces, and result filtering with envelopes.

Upon achieving the goal of becoming effective in using the software, I performed structural analysis on parts for

two of NASA’s current missions. The first part, we (Syrus Jeanes and myself) termed the “Composite Flex Hose

Box”. It is a housing for a multi layered flex hose of a refueling subsystem led by Mr. Jeanes, approximately 36” by

24” by 1.5” and made of carbon fiber laminate. The second part was an aluminum mount for the Orion mission

subjected to an acceleration loading.

II. Learning How to Use NX Nastran

NX Nastran is a powerful tool for the engineer, to be used in parallel with first estimate hand calculations and

engineering reasoning. In most cases, all three are skills required to produce an accurate analysis. To improve my

skills using NX Nastran, I used a combination of experimentation, tutorials from Learning Advantage, and help from

the members of the M1 branch. The process began with the understanding of the user interface.

A. User Interface

Once a part or simulation is opened in NX, a variety of options and tools appear along the top and left edges of

the screen. Though memorizing these functions would be tedious to remember and difficult to understand, the best

way to master the tools of the user interface is to use as many of them as possible and as much as possible. However,

it can help the user to first understand what each toolbar contains, to make the learning experience smoother.

On the left edge of the screen is the resource bar. An important reason for the resource bar’s existence is the

organization of the current project. It contains tabs called “navigators” for each level of a project being worked on,

such as the part navigator, assembly navigator, and simulation navigator. Within a tab is a more detailed

organization of that level. For example, if the part was modeled in NX, the part navigator gives the user a

chronological list of geometry features, known as the model tree, created when building the part. Seeing this, the

user can understand how a change may impact other geometries in the part; all geometries created after the geometry

being altered are subject to error (However, proper modeling techniques should account for this). The simulation

navigator contains all conditions of the simulation, as well as all solutions and results (more details to come in

1

Summer 2014 Intern, NE-M1, KSC

NASA KSC Page 2 29/07/2014

NASA KSC – Internship Final Report

Section II.C.). Whichever level of a project

the user is working in, the navigator is

necessary for any progress to be made. The

resource bar contains other useful tabs as

well, most notably the roles tab and history

tab. The roles tab decides the degree of

complexity of tool icons seen by the user

throughout the screen. It is important to note

that are functions are still available for use, so

the role tab is only an attempt to make the

user’s most likely needed tools more readily

available. The history tab keeps track of all

files on which the user has performed work,

in chronological order, for the last 3 weeks

and beyond. Figure 1. User Interface at home of NX.

Along the very top edge of the screen is

the quick access toolbar. The quick access toolbar contains common file options such as save, undo, recently opened

parts, etc.

Below the quick access toolbar is the ribbon bar. The ribbon bar holds the core of all actions the user will

perform. It is organized into tabs based on the type of action the user will perform, which include but are not limited

to: “Assemblies”, “Curve”, “Analysis”, “Surface”, “View”, “Render”, and “Application”. To give an idea of how

wide a range of activities are performed from within the ribbon bar, a user can design a part, change its appearance,

create an assembly, and start a simulation. The ribbon includes all details of each of the aforementioned activities. It

requires a book or set of tutorials to cover everything the user can do from the ribbon bar. This material is best

learned through using the software extensively.

Below the ribbon bar and above the graphics window is the top border bar. The top border bar’s most prevalent

reason for existence is convenience for the user. This bar contains selection filters, which can be very useful in the

case that the user wishes to select many of the same or similar type of geometry, or to select a group of related faces,

without having to select each one individually. The top border bar also has orientation and view options.

B. What Makes an Analysis

Finite Element Analysis is a method used by software such as Nastran to solve for conditions on complex

models. How this solving process is performed is a topic for another work, however, is can be summarized in the

following steps.

First, a model must exist. In the case of structural analysis, this is a part or assembly which, in the real world,

will be placed under certain conditions, i.e. loads and constraints, that may cause that part to fail in a way such that

its goal or the goal of a larger assembly will not be achieved. This is the problem at hand, for which an analysis can

help find a balance between risk and use of material and resources; in other words, an engineering solution is sought.

Next, the model is prepared for solving by

applying the situation and creating the mesh.

The situation includes all loads, constraints,

material properties of the part(s) or assembly,

and any other special conditions. A mesh is a

series of “nodes” that are spaced throughout

the model. The nodes are the points at which

the solver will solve. Each node is connected

to create a model that consists of a series of

“elements”, on which results will be

displayed. An element may display a specific

combination of the results associated with

each of its nodes. A mesh can contain

elements that are 0D (point), 1D (beam), 2D

(shell), or 3D (solid). A 3D mesh will contain

more nodes than a 2D mesh used to represent

a solid model, and thus, has more nodes to be

solved. An interesting skill aspect of the Figure 2. Example of a 3D tetrahedral mesh.

NASA KSC Page 3 29/07/2014

NASA KSC – Internship Final Report

mesh is the spacing of the nodes, in other words, the size of the elements. A “good” mesh is one that keeps elements

that are approximately in plane with the material they represent in the model; it keeps the mesh approximately

linear. Thus, it is logical that the mesh should be finer around curves and holes than flat faces. NX has a capability

known as mesh control, which allows the user to select a geometry feature and adjust the quality of the mesh within

that geometry. The user may select an edge, face, or body, and set the number of elements or size of the elements for

the selection.

Once the model is prepared, the solver can go to work. Within the software, a system of linear equations are

formulated and then solved. In the case of a stress analysis, FEA software uses complex stiffness matrices, which

cannot be solved by hand easily, to solve for the displacements of nodes within a model. These displacements are

then converted to stresses and strains using simple linear relations that are material-based. Results are written to a

file, which the user can view and use to make engineering judgments.

C. The Four Files

The four files that are important in an analysis are all important, and they are known, in order of creation, as the

master part, idealized part, fem file, and sim file. As the names may suggest, the master part and idealized part are

both .prt files, whereas the fem and sim are each their own unique file type. These descriptions are given in the case

of an analysis being done on a single part, rather than an assembly of multiple parts. However, the two processes are

very similar.

The master part is simply the modeled part that the user wishes to analyze. This file is no different than the file

that was saved after the part was modeled in NX, or imported from a separate CAD program, such as Pro/E, for

example. With just a master part file, there is no simulation in progress. However, the simulation is started from the

master part.

The idealized part is the only of the four files which is not necessary for a full analysis to occur. The idealized

part is nothing more than a copy of the master part to be altered and simplified for the running of the simulation.

Simplification is something that should be performed wherever possible, as it will decrease the overall run time of

the simulation, saving time without sacrificing significant accuracy in results. Some common examples of

simplification inside the idealized part include elimination of unimportant geometries such as small holes, and the

modeling of 3-dimensional objects as 2-dimensional surfaces (in FEA terms, modeling a solid as a shell) where

appropriate. The tool groups “geometry preparation” and “synchronous modeling” are very helpful for these tasks.

Geometry preparation is used for mesh preparation. For example, the user may want to model a thin solid as a 2D

surface, in which a tool known as a midsurface is often useful. A midsurface is, as the name suggests, a surface that

represents a solid through the middle of its thickness. The thickness is assigned to the midsurface’s properties.

Synchronous modeling is used to physically alter the part. From within the synchronous modeling tool, it is quite

easy to alter dimensions, adjust faces, and add or remove material. All of these actions may be performed for a given

idealized part. An example of a case in which the user may use an idealized part with many alterations using

synchronous modeling is an optimization attempt on a master part. The original part will be preserved as the

idealized part is altered and used for simulation. If a more preferred part is created, the user may start a new

simulation with the once idealized part as the new master part. A new idealized part will be created. This is just one

option if a user wishes to keep track of

iterations on a part being designed and

analyzed. The most important aspect of

the idealized part, and the reason for its

existence, is that when all files are

saved, the idealized part is just the part

that will undergo simulation, and the

original part (the master) will be

preserved.

The .fem file, commonly just called

the fem, contains all nodes and elements

(the mesh) for the geometry produced in

the idealized part (or master part, if no

idealized part is used). This includes all

0D, 1D, 2D, and 3D elements, as well as

all mesh controls. Fem is actually an

acronym for finite element management. Figure 3. The top four files, in order: .sim file, .fem file, idealized

The .sim file is where the simulation part, master part.

NASA KSC Page 4 29/07/2014

NASA KSC – Internship Final Report

is run, and where results are produced. Within the sim file are “containers” of the loads, constraints, and simulation

objects (such as contact surfaces) applied to the part being analyzed. Within the sim, there are one or many

solutions, each of which can contain their own combination constraints and objects from the containers. Within each

solution there may also be multiple subcases; each subcase contains its own combination of loads. Upon solving a

solution, a results file will be produced and saved for every subcase.

The four-file system is certainly a useful structure. For a single master part, there may be multiple idealized

parts, in the case that the user may want to understand the effects of simplifying a part on the simulation results. For

each idealized part, there may be multiple fem files, in the case that the user may like to study the effects of differing

meshes on simulation results. And finally, for each fem file, there may be multiple sim files, which can be beneficial

for reasons varying by user.

D. Some Specific Capabilities of the Program

There are a few functions of NX which I learned were particularly useful, or had to implement as part of a

specific analysis. Specifically, these functions are needed in the handling of interfaces.

It is possible to model any practical kind of interface in NX. Some interfaces that can be seen in the mechanical

world that can be modeled in NX successfully are fixed points (perhaps a joint), edges (hinge), and faces, fixed

bodies that consist of different materials with different properties (either chemically bonded or assumed to be fixed

without disconnecting), bolted parts, and glued surfaces. In the case that the user has a single part that consists of

multiple unique materials, the functions “split body” and “divide face” can be very useful. Though still one part file,

and still capable of being a single body, these functions allow unique property sets to be applied to each section that

was split or divided. The split body function is made for use in solids, most simply by sketching the contour of the

split line and extruding through the body. The divide face function is useful in shell configurations, or in solids

which are being meshed as midsurfaces. Sometimes, when meshing a single part that has been split, the function

“stitch edge” is necessary to tell NX that the part is still a single part.

In the case that two parts or two sections of a single part interact with each other but are not fixed, simulation

objects are of good use. Two examples of simulation objects are contact surfaces and glued surfaces. Contact

surfaces are based upon friction; two surfaces are being pressed together, or perhaps they contact in small areas due

to deflections in parts. The solver requires iterations to produce results for this situation. Glued surfaces are used for

circumstances in which only a section two faces are fixed. To get this effect otherwise, the face would have to be

divided along the edge of the desired glue contact, and boundary conditions would need to be applied.

Bolted connections are another capability that is particularly useful, because they are found often in real

mechanical systems. NX allows the user to input the bolt material and profile from inside the .fem file, and also

allows a pre-load to be applied to the bolt due to the torque down of the bolt when tightening. The bolt connection is

a 1D element that extends from the center of a hole of one face/body to the center of a hole in another face/body.

The centers of these respective holes are marked by a node that is established with the creation of a “spider”, or a

web of elements extending from the edge of the hole and meeting in the center.

III. My Applications of NX Nastran

A. Restore Mission - Composite Flex Hose Box

My first true opportunity for application of NX Nastran to perform a structural analysis was a composite box

meant to house a flex hose as part of a refueling subsystem for NASA’s Restore mission. The Restore mission is a

satellite repair mission targeting satellites in the densely populated geostationary orbit. Syrus Jeanes is the leader of

this particular refueling subsystem, and he introduced me to the progression of the project. At the time, the hose box

was made of aluminum, with a composite box in the future plans. My role was to begin the process of designing this

composite box, by modeling the box based on initial specifications and performing a modal analysis. Without the

NX Nastran composite material software at hand, the material properties input were effective properties for an

isotropic material.

NASA KSC Page 5 29/07/2014

NASA KSC – Internship Final Report

The interior dimensions of the composite box are 36” by 24” by 1.5”. The box is constructed of two symmetrical

shell-like structures, bolted together along

an outer flange. The flange curves up into

the top face. The box is enclosed on three

of the four sides, with the fourth side

containing the exit port for the flex hose,

the motor which controls the hose’s in-

and-out motion, and a bolted-in bend

guard which the hose curves around. The

flange and curved edge leading to the top

face of each half is made of eight-ply

thick carbon fiber, while the top face of

each half has eighth-inch thick aluminum

honeycomb core between the eight layers,

making it a composite sandwich panel.

Each shell is intended to be fabricated in a

single layup, making each shell a single

body. The purpose of the honeycomb core Figure 4. Composite flex hose box shown with bolt halves and sketch

is to provide extra stiffness in the flat planes.

faces of the box, to help prevent

resonance by increasing the first natural frequency, or mode, of the box. In general, increasing the stiffness of an

object increases the value of its first mode, making it less possible that particular

mode will be reached. This is the purpose of a modal analysis: to solve the

vibrational model and determine the modes of a system. The user decides how

many modes the solver should determine.

An object should be modeled so that it can later be easily altered. NX has a

capability known as “expressions”, which are simply variables that are assigned

values and are referenced when assigning dimensions in the model. A good

practice is to create a plane for every major dimension in the model, and to

reference a plane for each portion of a sketch, rather than reference other

sketches. When a dimension needs to be changed later on, the plane for that

dimension can be moved (by simply changing the value of the expression to

which it is assigned) and all sketches in the model referencing that plane should

adjust accordingly.

The first simulation of the hose box was performed on only a single shell, or

one half of the entire box, in order to accomplish a working model and to gain

experience with a modal analysis. Being a single body comprised of two material

Figure 5. Midsurface of types, the body was split in the idealized part along the interface between the two

composite box (sketch shown material types so that different property sets could be applied. In the .fem file for

in blue outline). the simulation,

that edge was

stitched. The body was also split again on the top

face, two inches inside from the edge. This was

done to allow a smoother transition between the

fine mesh on the curved edge to the rougher mesh

on the top face, since the greatest stresses occurred

at that interface.

The modal analysis was solved multiple times

with differing edge constraints. The three cases of

edge constraints were a completely fixed edge (as

if the edges were bonded together), a 9-bolt

connection along three edges, and a 12-bolt

connection which constrained all four edges.

Intuition suggests that the four-side constraint

would offer the highest effective stiffness of the

Figure 6. Mesh of box with refinements.

box, with the fixed constraint coming next and the

NASA KSC Page 6 29/07/2014

NASA KSC – Internship Final Report

three-side bolt

constraint coming

third. The modal

analysis supported this

intuition, providing

magnitudes of first

modes that were

directly related to the

stiffness order.

Having some Figure 8. Spider mesh with

experience with the 1D bolt connection.

modal analysis, the

other shell of the hose box was added into the

model. The faces of the flanges were not fixed to

each other, but aligned to the same plane to be

connected by bolts in the future. The solver cannot

Figure 7. Box with contact surfaces and bolt pre-loads. perform a modal analysis simultaneously with

contact surfaces and bolt connections because of the

iterations required for contact surfaces. As a result, the strategy employed to complete the modal analysis is to first

perform a stress analysis using bolt connections and a surface contact, analyze the region around each bolt that

experiences significantly greater stresses than the outer area,

then create a glued contact that represents that stressed

region. Since glued surfaces do not require iterations, the

modal analysis can be performed in this setup. The same

body splitting and meshing procedures were followed for the

full box as the half box, up until the bolt connection. Spider

elements were created for each bolt hole on the shells, and

1D bolt connections were created. In addition to the full box

setup, the aluminum bend guard was modeled and

implemented into the system. The bend guard is constrained

by 5 bolts which extend through the full thickness of the box

from top to bottom surface. In addition to the new 1D bolt

connections, surface contacts were set up between the bend Figure 9. Aluminum Bend Guard.

guard and box on both the top and bottom faces of the box.

This analysis is currently still in progress, with the goal being the completion of a modal analysis and the

subsequent adjustment of the system to reach a first mode of at least 100 hertz.

B. Orion Spacecraft – CTCS Mount

The other part on which I performed an analysis

was a bracket mount for the Cabin Temperature

Control Subassembly (CTCS) for the Orion

spacecraft. The task was presented to me by Mr. Jose

Mayi-Rivas. The CTCS, specified by the supplier,

must be kinematically mounted to reduce the force it

experiences. Each bracket attaches a strut to the

CTCS. The bracket was previously modeled, but had

to be analyzed and iterated upon to meet flight

hardware structural safety factors.

For the analysis, 48 specific load cases were

provided. These load cases reflect the worst-case Figure 10. CTCS Mount before (left) and after (right)

scenario loads, which occur during an on-pad abort. modifications.

With the bracket being bolted to the structural barrel,

the back face of the bracket lies flat against the surface of the barrel. Picturing the bracket as either being pushed

into or pulled away from the barrel (positive or negative z-component forces), the constraints must be setup

differently for each of these scenarios. In the push case, the back face of the bracket is constrained so as to resist

movement perpendicular to the face plane. In the pull case, however, this constraint does not exist. This constraint

NASA KSC Page 7 29/07/2014

NASA KSC – Internship Final Report

setup was recognized and created by Mr. Mayi-Rivas, though it was

important for me to understand before performing the iterations. In general,

constraints must be considered with an intuitive mind. Half of the load cases

(24) presented were pull loads; the other half were push loads. Since the

constraints were different for each half, there would be two solutions under

a single .sim file, each containing 24 load subcases.

Upon solving a solution, each subcase has its own set of results. Having

to view each set of results individually to decide where changes can be

made to the bracket can very tedious, and potentially flawed. Luckily, NX

provides a feature known as “envelopes”, which allows the user to pick out

important data from each subcase and combine it into a single results file.

For flight hardware, safety factors to be met are 1.5 for yield and 2 for

ultimate strength, whichever fails first. For this material, the ultimate failure

safety factor is first to fail, which worked out to requiring a maximum

principal stress equal to or less than 28.50 ksi. Thus, an envelope was

created for each solution, picking the maximum values of maximum

principal stress at each node of the mesh among the 24 subcases. From that

point, the results can be treated as if they are a single load case, rather than

24 subcases. This is a great example of how an envelope can both save time

and provide for a better analysis. A better analysis usually produces a better

part.

First iterations of the bracket violated the ultimate strength safety factor.

Failure tended to occur along a bend

on the back face of the bracket,

specifically for the push load

subcases. By slowly adjusting width

and thickness of this section of the

bracket using synchronous modeling,

safety factors were met, showing

maximum principal stresses of

Figure 11. Envelope creation roughly 26 ksi. Since design

window. specifications allow for 28.50 ksi,

some material could be subtracted

from the part. This is a situation in which a specific feature of the envelopes

function becomes useful. Envelopes allow the user to include subcase ID

numbers with the new results file. In other words, the user can look at the

nodes that fail to meet the safety factors given, and track the failure to the Figure 12. Bracket with maximum

subcase causing said failure. This can provide the analyst with important principal stress 28.50 ksi.

information about where material can be removed, by considering the load path through the part. Through this

procedure, the maximum principal stress was increased to exactly 28.50 ksi (Figure 2). It is not extremely common

to hit a safety factor exactly, but it is very important that the safety factor does not fail, even if slightly.

IV. Conclusion

NX Nastran is a very powerful tool with capabilities that enable the engineer to perform tasks more quickly and

effectively than any other method allows. With proper handling, many real-life scenarios can be simulated to

produce a variety of desired information, perhaps progressing projects forward very quickly to the prototype and test

stages. However, without proper usage, the software can produce inaccurate results that cannot be trusted. Thus, it is

crucial to understand the actions of the software and to investigate potential flaws in model setup. I believe I have

developed a solid grasp on the implementation of NX Nastran for structural analysis, though it is a constant learning

process for even the most skilled user.

Acknowledgments

I thank Mr. Syrus K. Jeanes and Mr. Jose J. Mayi-Rivas for their trust in me to complete the tasks at hand and

their guidance which followed. I also thank the NE-M1 branch as a whole for their support throughout the summer,

as I have learned something from every one of them.

NASA KSC Page 8 29/07/2014

NASA KSC – Internship Final Report

References

1

NX, Software Package, Ver. 9.0, Siemens PLM Software, Plano, TX, 14 October 2013.

2

“NX 9.0 Self-Paced Courses”, Siemens Learning Advantage, Siemens PLM Software, Plano, TX. [Referenced June-July

2014]. https://training.plm.automation.siemens.com/mytraining/home.cfm?cmd=&details=.

NASA KSC Page 9 29/07/2014

You might also like

- Finite Element Analysis for Design Engineers, Second EditionFrom EverandFinite Element Analysis for Design Engineers, Second EditionNo ratings yet

- Carcoseal / UNDocument2 pagesCarcoseal / UNmattiaNo ratings yet

- Hyundai Robotics CatalogueDocument2 pagesHyundai Robotics Cataloguejitender kumar0% (1)

- Department of Structural Engineering and Program of Computer Graphics, Cornell University, Ithaca, N Y 14853, U.S.ADocument14 pagesDepartment of Structural Engineering and Program of Computer Graphics, Cornell University, Ithaca, N Y 14853, U.S.AFrancesco MontagnoliNo ratings yet

- Tutorial #1:the Essential ANSYS.: ME309: Finite Element Analysis in Mechanical DesignDocument9 pagesTutorial #1:the Essential ANSYS.: ME309: Finite Element Analysis in Mechanical DesignTanu RdNo ratings yet

- Bilder in Bachelor ThesisDocument6 pagesBilder in Bachelor ThesisTye Rausch100% (2)

- Ansys Vs NX NastranDocument22 pagesAnsys Vs NX NastranErlantz72No ratings yet

- Mesh LabDocument8 pagesMesh LabnzagzoogNo ratings yet

- Ansys - MEMS Lab IntroductionDocument9 pagesAnsys - MEMS Lab IntroductionJag JagNo ratings yet

- Chapter 8 - Finite Element AnalysisDocument21 pagesChapter 8 - Finite Element AnalysisZaroui Benamor AliNo ratings yet

- Ansys Vs NX NastranDocument22 pagesAnsys Vs NX NastranAllen Jose George100% (2)

- Cad Lab Manual - MujDocument29 pagesCad Lab Manual - MujAabhaş AgrawałNo ratings yet

- Uni Wuppertal Bachelor Thesis FormatDocument7 pagesUni Wuppertal Bachelor Thesis Formatheatherreimerpeoria100% (2)

- Meen 19111063Document109 pagesMeen 19111063foruseopen29No ratings yet

- Bachelor Thesis Angewandte InformatikDocument7 pagesBachelor Thesis Angewandte InformatikAshley Carter67% (3)

- MD SimulationDocument12 pagesMD SimulationAnand aashishNo ratings yet

- 1.3 Definition of Cad/Cam/Cae: 1.3.1 Computer Aided Design - CADDocument10 pages1.3 Definition of Cad/Cam/Cae: 1.3.1 Computer Aided Design - CADSai ChNo ratings yet

- Ansys Lab Manual BvcoekDocument26 pagesAnsys Lab Manual Bvcoekavinash 879No ratings yet

- Fae10068 2Document7 pagesFae10068 2dgdgdNo ratings yet

- Comparison of Nonlinear Finite Element Modeling Tools For Structural ConcreteDocument58 pagesComparison of Nonlinear Finite Element Modeling Tools For Structural ConcreteafcisNo ratings yet

- Ansys ManualDocument108 pagesAnsys Manual016 ARUNACHALAM S R MNo ratings yet

- Bachelor Thesis Zu Wenig SeitenDocument7 pagesBachelor Thesis Zu Wenig Seitenafknyfene100% (2)

- ANSYS 6.1 TutorialDocument63 pagesANSYS 6.1 TutorialrakeshsakoteNo ratings yet

- Hfu Bachelor Thesis AnmeldungDocument7 pagesHfu Bachelor Thesis AnmeldungCheapestPaperWritingServiceCanada100% (2)

- CNN Model For Image Classification Using Resnet: Dr. Senbagavalli M & Swetha Shekarappa GDocument10 pagesCNN Model For Image Classification Using Resnet: Dr. Senbagavalli M & Swetha Shekarappa GTJPRC PublicationsNo ratings yet

- Lab Manual CAMADocument75 pagesLab Manual CAMASatish HSNo ratings yet

- Computer Aided Modeling & Analysis Lab Final BackupDocument48 pagesComputer Aided Modeling & Analysis Lab Final Backup4PS19ME015 Anushree N.RNo ratings yet

- Deep Neural Network DNNDocument5 pagesDeep Neural Network DNNjaffar bikatNo ratings yet

- A Deep Learning Convolutional Neural Network in Health Care EnvironmentDocument17 pagesA Deep Learning Convolutional Neural Network in Health Care EnvironmentVasiha Fathima RNo ratings yet

- MEA12 Finite Element Analysis Lab ManualDocument49 pagesMEA12 Finite Element Analysis Lab ManualYeshwanth SuryaNo ratings yet

- MDH - Se ThesisDocument5 pagesMDH - Se Thesisdnpqamfd100% (1)

- Ansys14 Classic TutorialDocument21 pagesAnsys14 Classic TutorialMAXNo ratings yet

- An Interactive Program For Doing Fry Strain Analysis On The Macintosh MicrocomputerDocument11 pagesAn Interactive Program For Doing Fry Strain Analysis On The Macintosh MicrocomputerMiningNo ratings yet

- Meen 19111101 (Umair Khalid)Document166 pagesMeen 19111101 (Umair Khalid)Haid AshfaqueNo ratings yet

- HDM Bachelor Thesis VorlageDocument5 pagesHDM Bachelor Thesis Vorlagesarahjimenezriverside100% (2)

- Bachelor Thesis Informatik ThemaDocument8 pagesBachelor Thesis Informatik Themafesegizipej2100% (1)

- CCA ExptDocument64 pagesCCA ExptAbhishek SharmaNo ratings yet

- TimeNET QEST2017Document5 pagesTimeNET QEST2017Mostafa J AlneamyNo ratings yet

- Cad/Cam Lab: Venkitaraj K PDocument60 pagesCad/Cam Lab: Venkitaraj K PJoe mNo ratings yet

- Mechanical Vibrations Modal Analysis Project With Arduinos: Computers in Education Journal December 2017Document8 pagesMechanical Vibrations Modal Analysis Project With Arduinos: Computers in Education Journal December 2017Crazy FireNo ratings yet

- Ansys History.Document8 pagesAnsys History.Eirick Wayne Zuñigga De-ItzelNo ratings yet

- NX5 Review: Jeffrey RoweDocument8 pagesNX5 Review: Jeffrey RoweOscar GuerraNo ratings yet

- Bachelor Thesis Informatik PDFDocument8 pagesBachelor Thesis Informatik PDFCynthia King100% (2)

- What Is Ansys 1Document7 pagesWhat Is Ansys 1Mohamed Bahaa HannoNo ratings yet

- Toward Creative 3D Modeling: An Architects' Sketches StudyDocument4 pagesToward Creative 3D Modeling: An Architects' Sketches StudyNina DmitrievaNo ratings yet

- Toward Creative 3D Modeling: An Architects' Sketches StudyDocument4 pagesToward Creative 3D Modeling: An Architects' Sketches StudyNina DmitrievaNo ratings yet

- I Jeter 039112021Document8 pagesI Jeter 039112021WARSE JournalsNo ratings yet

- EJ1064301Document8 pagesEJ1064301Enzo SantosNo ratings yet

- Structural AnalysisDocument21 pagesStructural Analysisom prakashNo ratings yet

- Assignment 2: Advanced Geographic Information Systems For Transport and Logistics (GIS-T 2, Group A)Document2 pagesAssignment 2: Advanced Geographic Information Systems For Transport and Logistics (GIS-T 2, Group A)Matze Jan FilipekNo ratings yet

- Ansys TutorialsDocument24 pagesAnsys TutorialsMahdiNo ratings yet

- Deep Learning with Python: A Comprehensive Guide to Deep Learning with PythonFrom EverandDeep Learning with Python: A Comprehensive Guide to Deep Learning with PythonNo ratings yet

- Artificial Neural Networks with TensorFlow 2: ANN Architecture Machine Learning ProjectsFrom EverandArtificial Neural Networks with TensorFlow 2: ANN Architecture Machine Learning ProjectsNo ratings yet

- Mesh Generation: Advances and Applications in Computer Vision Mesh GenerationFrom EverandMesh Generation: Advances and Applications in Computer Vision Mesh GenerationNo ratings yet

- Finite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaFrom EverandFinite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaNo ratings yet

- Convolutional Neural Networks with Swift for Tensorflow: Image Recognition and Dataset CategorizationFrom EverandConvolutional Neural Networks with Swift for Tensorflow: Image Recognition and Dataset CategorizationNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan International USADocument1 pageEurope Germany France Italy Belgium Sweden U.K. Canada India Japan International USAmattiaNo ratings yet

- Trunnion Adapters: Design InformationDocument1 pageTrunnion Adapters: Design InformationmattiaNo ratings yet

- Sym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedDocument6 pagesSym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedmattiaNo ratings yet

- CarcosealapDocument2 pagesCarcosealapmattiaNo ratings yet

- SealMaster InflatableDocument8 pagesSealMaster InflatablemattiaNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Aisi 316 L and Aluminium: Gas Springs Molle A GasDocument32 pagesAisi 316 L and Aluminium: Gas Springs Molle A GasmattiaNo ratings yet

- Thordon Rudder BrochureDocument8 pagesThordon Rudder BrochuremattiaNo ratings yet

- Aisi 316 L: Operating Valves - Evax SerieDocument59 pagesAisi 316 L: Operating Valves - Evax SeriemattiaNo ratings yet

- Proven Water Lubricated Propeller Shaft Bearing Solutions: V IronDocument8 pagesProven Water Lubricated Propeller Shaft Bearing Solutions: V IronmattiaNo ratings yet

- Ramnäs Quality Chains and AccessoriesDocument13 pagesRamnäs Quality Chains and AccessoriesmattiaNo ratings yet

- Process Pumps: Typical Fluids Pump UnitsDocument4 pagesProcess Pumps: Typical Fluids Pump UnitsmattiaNo ratings yet

- BallScrews and BallSplinesDocument160 pagesBallScrews and BallSplinesmattiaNo ratings yet

- Thomson Precision Linear Actuators Sep06Document8 pagesThomson Precision Linear Actuators Sep06mattiaNo ratings yet

- Carcoseal AP/WT/RR. The Lip Is Designed So ThatDocument2 pagesCarcoseal AP/WT/RR. The Lip Is Designed So ThatmattiaNo ratings yet

- Self Blocking Rail ClampsDocument17 pagesSelf Blocking Rail ClampsmattiaNo ratings yet

- Carcoseal AP / WT. The Lip Is Designed So That TheDocument2 pagesCarcoseal AP / WT. The Lip Is Designed So That ThemattiaNo ratings yet

- CarcosealunsfDocument2 pagesCarcosealunsfmattiaNo ratings yet

- Materials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoreDocument14 pagesMaterials: Bending and Buckling of Circular Sandwich Plates With A Hardened CoremattiaNo ratings yet

- Catene Rigide SerapidDocument19 pagesCatene Rigide SerapidmattiaNo ratings yet

- The Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012Document18 pagesThe Iraqi Journal For Mechanical and Material Engineering, Vol.12, No.2, 2012mattiaNo ratings yet

- Pluto Safety PLCDocument42 pagesPluto Safety PLCmattiaNo ratings yet

- Advanced Valuation Concepts and Methods - BLK - 1Document72 pagesAdvanced Valuation Concepts and Methods - BLK - 1Kim GeminoNo ratings yet

- HTW 1 - 3Document8 pagesHTW 1 - 3alonso_rNo ratings yet

- Gujarat Technological University: Power Electronics (24) Subject CodeDocument3 pagesGujarat Technological University: Power Electronics (24) Subject Codequdratullah ehsanNo ratings yet

- Pendulum SimulinkDocument10 pagesPendulum SimulinkSatyavir YadavNo ratings yet

- Fanuc CNC Guide 1Document4 pagesFanuc CNC Guide 1Stephano PortellaNo ratings yet

- On The Environmental Pollution Problem: A Review: Journal of Environmental Engineering and Landscape ManagementDocument7 pagesOn The Environmental Pollution Problem: A Review: Journal of Environmental Engineering and Landscape Managementmagizh tamizhiniNo ratings yet

- GSW Portfolio V02Document21 pagesGSW Portfolio V02أحمد فريد سعد عبد الفتاحNo ratings yet

- National Institute of Technology Durgapur: Name - Kundan Kumar ROLL NO.-18MA4108 Mtech-Third SemesterDocument34 pagesNational Institute of Technology Durgapur: Name - Kundan Kumar ROLL NO.-18MA4108 Mtech-Third SemesterDIPESHNo ratings yet

- Aspen Elearning: CatalogDocument122 pagesAspen Elearning: Catalogokky wddNo ratings yet

- The Meaning of Virtual Return Demonstrations To A Nursing Student of Capitol University: A Phenomenological InquiryDocument17 pagesThe Meaning of Virtual Return Demonstrations To A Nursing Student of Capitol University: A Phenomenological InquiryJeffrey TVNo ratings yet

- Cse Satrack ReportDocument19 pagesCse Satrack Reportkarthik naniNo ratings yet

- Synthesis of Aircraft Landing Gear Mechanism: P S, P. R RDocument5 pagesSynthesis of Aircraft Landing Gear Mechanism: P S, P. R Rshaotao guoNo ratings yet

- TR - Aquaculture NC IIDocument64 pagesTR - Aquaculture NC IIherbert rebloraNo ratings yet

- A Simulation Approach To Manpower PlanningDocument9 pagesA Simulation Approach To Manpower PlanningenoNo ratings yet

- Ece Viii Embedded System Design (06ec82) NotesDocument270 pagesEce Viii Embedded System Design (06ec82) NotesBSRohitNo ratings yet

- Petsoc 01 06 03Document10 pagesPetsoc 01 06 03Francisco LaguardiaNo ratings yet

- BA Teknik Sipil - s12544-023-00590-5Document20 pagesBA Teknik Sipil - s12544-023-00590-5Ainayya AleenaNo ratings yet

- E:D Background Simulation GuideDocument7 pagesE:D Background Simulation GuidetomNo ratings yet

- Nasa TLX KuesionerDocument49 pagesNasa TLX KuesionerZikri Fathur RahmanNo ratings yet

- Istat CME TalkDocument22 pagesIstat CME TalkmuhammadNo ratings yet

- Concepts of Training and DevelopmentDocument24 pagesConcepts of Training and DevelopmentPrafful AgarwalNo ratings yet

- A Method To Design Vibratory Bowl FeederDocument5 pagesA Method To Design Vibratory Bowl Feederأحمد عاطف أبوغديرNo ratings yet

- AdtechDocument2 pagesAdtechJjp LopezNo ratings yet

- Matlab Books - TittlesDocument2 pagesMatlab Books - TittlesVenugopal KonapalaNo ratings yet

- Warship 10 BrochureDocument4 pagesWarship 10 Brochurehamid moaieriNo ratings yet

- M.E. EXAM Time TableDocument7 pagesM.E. EXAM Time Tablepa390786No ratings yet

- VDE-Vehicle Dynamics EngineDocument64 pagesVDE-Vehicle Dynamics EngineJordan HotCoffee Bennett67% (3)

- Maritime InstituteDocument10 pagesMaritime InstitutedweepNo ratings yet