Professional Documents

Culture Documents

Crib Walls - 1997 - : Section/Article Description

Crib Walls - 1997 - : Section/Article Description

Uploaded by

Marwan MokhadderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crib Walls - 1997 - : Section/Article Description

Crib Walls - 1997 - : Section/Article Description

Uploaded by

Marwan MokhadderCopyright:

Available Formats

8

Part 6

Crib Walls1

— 1997 —

TABLE OF CONTENTS

Section/Article Description Page

6.1 G eneral.................................................................. 8-6-2

6.1.1 Scope (1997).............................................................. 8-6-2

6.1.2 Definitions (1997) .................................................... ..... 8-6-2

6.2 D esign of C rib W alls ....................................................... 8-6-2

6.2.1 G eneral(1997)............................................................ 8-6-2 1

6.3 Specifications for R einforced C oncrete C rib W alls............................. 8-6-3

6.3.1 G eneral(1997)............................................................ 8-6-3

6.3.2 M anufacture (1997)........................................................ 8-6-4

6.3.3 Installation (1997)......................................................... 8-6-4

3

6.4 Specifications for M etal C rib W alls .......................................... 8-6-5

6.4.1 G eneral(1997)............................................................ 8-6-5

6.4.2 M anufacture (1997)........................................................ 8-6-5

6.4.3 Installation (1997)......................................................... 8-6-5

6.5 Specifications for T im ber C rib W alls......................................... 8-6-6

6.5.1 G eneral(1997)............................................................ 8-6-6

6.5.2 M aterials (1997)........................................................... 8-6-6

6.5.3 Installation (1997)......................................................... 8-6-6

LIST OF FIGURES

Figure Description Page

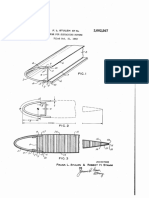

8-6-1 T ypicalSections through W alls ofT im ber Cribbing .................................. 8-6-7

8-6-2 W alls ofO pen-Face T im ber Cribbing .............................................. 8-6-7

8-6-3 W alls ofClosed-Face T im ber Cribbing ............................................. 8-6-8

1

R eferences,Vol.49,1948,p.244;Vol.50,1949,pp.290,757;Vol.62,1961,p.438,861;Vol.70,1969,p.223;Vol.71,1970,p.231;Vol.88,

1987,p 62.

© 2004, American Railway Engineering and Maintenance-of-Way Association 8-6-1

Concrete Structures and Foundations

SECTION 6.1 GENERAL

6.1.1 SCOPE (1997)

T hese specifications cover the design,m anufacture and installation ofcrib w alls as defined hereinafter.

6.1.2 DEFINITIONS (1997)

6.1.2.1 Crib Wall

a. A “Crib W all” is an earth-retaining structure,m ade up ofrigid m em bers that are fabricated in the shape

ofopen squares,open rectangles or other open shapes,or are assem bled in the shape ofsquare or

rectangular cells,or cells ofother shapes.T he cells are filled w ith granular m aterial.T he structure of

cells and granular infillallact together as a gravity structure,obtaining its safety and stability from the

proper proportioning ofits shape and w eight.

b. Crib w allm em bers can be ofconcrete,m etal,or tim ber.T hey can form cells w ith solid-surfaced w alls

(know n as “closed face” w alls) or w ith slotted openings (know n as “open face” w alls).T he m em bers

should interlock w ith each other,or otherw ise be connected in such a w ay as to resistthe pressures of the

granular filland the retained earth m aterial.Crib w alls can be a traditionalcribbing as described in

Article 6.1.2.2

,or ofother units that behave in accordance w ith this definition.

6.1.2.2 Cribbing

“Cribbing” defines a traditionalassem bly ofheaders and stretchers,used to form the m ost com m on kind ofcrib

w all.

SECTION 6.2 DESIGN OF CRIB WALLS

6.2.1 GENERAL (1997)

a. Crib w alls shallbe assum ed to act as a unit and shallbe designed toresist the overturning and sliding

forces specified in Part 5,R etaining W alls,A butm ents and Piers.

b. T he w allsection resisting overturning shallbe taken as a rectangle having a height equalto the total

height ofthe crib structure and a depth,norm alto the front surface,equalto the distance betw een the

front and rear outside faces ofthe crib structure.

c. T he unit w eight ofthe crib w allsection w ithin the above lim its,including the w eight ofthe crib

m em bers,m ay be assum ed to be equalto that ofthe com pacted filling m aterial.

d. In general,crib w alls shallhave a batter of2:12 on the face,except that low w alls,1.8 m eters (6 ft)high

and under,m ay be m ade w ith a plum b face. For w alls over 3.6 m eters (12 ft)high,supplem entalcrib

units m ay be added to provide stability in order to m eet design requirem ents.Crib w alls shallgenerally

not exceed 7.2 m eters (24 ft) in height. Higher lls shal

wa lreceive specialengineering considerations.

e. T he w allshallbe so located that no track tie w illbear directly on any crib m em ber.

© 2004, American Railway Engineering and Maintenance-of-Way Association

8-6-2 AREMA Manual for Railway Engineering

Crib Walls

f. Crib w allfoundations shallbe designed not to exceed safe soilpressures specified in Part 3,Spread

Footing Foundations,Section 3.4,Sizing ofFootings. The possibility ofa deep shear failure of the

em bankm ent shallbe considered sim ilar to the failure illustrated in Part 20,Flexible Sheet Pile

Bulkheads.

g. A llstructuralcrib units,including stretchers,headers,or other units,shallbe so designed that they w ill

resist the tensile,bending and shearing stresses im posed on them and shallprovide adequate bearing at

allcontact surfaces.For w alls ofcribbing,stretchers at the rear ofthe cells shallhave the sam e bearing

area as those at the front in the sam e courses.

h. T he headers and stretchers or other units shallbe so designed that w hen assem bled in a w all,they form

a cellular structure that w illbe flexible enough to w ithstand a reasonable am ount ofdifferential

settlem ent.T hese flexibility requirem ents w illgenerally depend on the use ofthe w alland on the

designer’s judgem ent.H ow ever,any crib w allcellw illbe expected to w ithstand a differentialdeflection

ofat least 0.015L w ithout dam age,w here L is the length ofthe cellas m easured along the face ofthe

w all.

i. T he verticalopenings w ithin the front face ofthe assem bly shallbe sm allenough to retain the fill

m aterial,placed as described in A rticle 6.3.3.3,A rticle 6.4.3.3,or A rticle 6.5.3.5.

j. Crib w alls shallbe designed in sections usually not to exceed 30 m eters (100 ft) in length.Ifthe soil

conditions vary considerably along this length,it m ay be necessary to build the ib w

crallin sections that

are shorter than 30 m eters (100 ft).

k. Provision shallbe m ade for drainage,ifnecessary,behind or w ithin cells by m eans ofFrench drains or

1

other approved m ethods,and potentialhydrostatic pressure shallbe taken into consideration in the w all

design.

3

SECTION 6.3 SPECIFICATIONS FOR REINFORCED CONCRETE CRIB WALLS

6.3.1 GENERAL (1997)

a. Crib w allunits defined as cribbing shallbe rectangular in cross section w ith allexposed edges beveled.

E ach cribbing unit shallbe reinforced w ith deform ed bars or w ith w elded w ire fabric,proportioned in

accordance w ith Part 2,R einforced Concrete D esign.H ow ever,the area ofreinforcem ent for each unit 4

shallbe not less than 0.9 percent ofits gross cross-sectionalarea.

b. M em bers shallbe provided w ith effective locking devices.T hey shallbe ofa type w hich w illperm it a

slight m ovem ent in the w allw ithout dam age to the crib units.

c. T he headers and stretchers shallbe so designed that w hen assem bled in a w allthey w illbear at tw o

points only,w ith bearing points for other kindsofunits subject to the engineer’s approval.T he

arrangem ent m ust form a cellular structure flexible enough to w ithstand a reasonable am ount of

settlem ent.

© 2004, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-6-3

Concrete Structures and Foundations

6.3.2 MANUFACTURE (1997)

6.3.2.1 General

T he m aterials,proportioning and w orkm anship shallconform to Part 1,M aterials,Tests and Construction

R equirem ents,w ith the follow ing m odifications:

a. A ggregates.T he m axim um size ofthe coarse aggregate shallnot be m ore than 25 m m (1 in).

b. Class ofConcrete.A ir-entrained concrete as specified in Part 1,M aterials,Tests and Construction

R equirem ents,shallbe used,having a m inim um com pressive strength of28 M pa (4,250 psi)at 28 days.

c. W orkability and Placem ent.T he concrete m ixture shallbe ofa w orkable consistency and placed to

prevent honeycom bing.Vibrating equipm ent shallbe used in the m anufacturing process.

d. C uring.Curing shallbe started as soon as possible after com pletion ofplacem ent ofthe concrete and

shallcom ply w ith the A rticles on curing in Part 1,M aterials,Tests and Construction R equirem ents.

6.3.2.2 Defects

A llm em bers shallbe true to size,and free ofdepressions and ofspalled,patched or plastered surfaces or other

defects that m ay im pair strength or durability.

6.3.2.3 Handling

M em bers shallbe handled carefully.D ropping or severe jarring shallbe avoided.A ny cracked or otherw ise

defective m em bers w illbe rejected.

6.3.3 INSTALLATION (1997)

6.3.3.1 Preparing Base

a. T he foundation or bed for the crib w allshallbe firm and as uniform as possible,and shallbe approved by

the E ngineer before any m em bers are placed.Ifany m em bers are located directly above rock,a cushion

ofsand or gravelnot less than 200 m m (8 in) thick shallbe provided.

b. T he foundation shallbe sloped at a right angle to the batter on the face ofthe finished crib w all.

6.3.3.2 Placing

a. Stretchers or equivalent m em bers shallbe used to provide adequate support ofthe low est course,front

and back.

b. Crib m em bers shallbe carefully handled and installed in such a m anner as to avoid any dam age due to

shock or im pact.A ny m em ber w hich becom es cracked or otherw ise dam aged during erection shallbe

rem oved and replaced.

6.3.3.3 Filling

a. T he filling ofthe interior ofthe crib w allshallfollow closely the erection ofthe successive tiers ofunits,

and at no tim e shallthe w all be laid up higherthan 1 m eter (3 ft) above the backfilled portion.

© 2004, American Railway Engineering and Maintenance-of-Way Association

8-6-4 AREMA Manual for Railway Engineering

Crib Walls

b. A pproved fillm aterialshallbe pervious,free draining,preferably crushed stone,gravel,or other coarse

granular m aterial,w ellgraded from a m axim um size of100 m m (4 in)dow n,and shallbe placed

com pacted in the cells and for 600 m m (2 ft)im m ediately behind the cellin such a m anner as to provide

a m inim um ofvoids.A llorganic m atter shallbe excluded from the fillm aterials.T he fill and backfill

m aterialshallnot contain any elem ent detrim entalto concrete.

6.3.3.4 Drainage

See A rticle 6.2.1k,for any specialconditions.

SECTION 6.4 SPECIFICATIONS FOR METAL CRIB WALLS

6.4.1 GENERAL (1997)

a. T he sheets from w hich allm em bers are m anufactured shallbe m ade ofa base m etalm eeting the

requirem ents for chem icalcom position and zinc coating as specified by the E ngineer in conform ity w ith

Chapter 1,R oadw ay and B allast,Part 4,Culverts.

b. A lum inum m aterials m ay only be used w ith the engineer’s specific approval.

6.4.2 MANUFACTURE (1997) 1

a. A llm em bers shallbe prefabricated in the m anufacturer’s plant prior to shipm ent to the site.Ifspecified

by the E ngineer,the crib m em bers shallbe specially coated.

b. H eaders and stretchers and other m em bers shallinterlock or be joined together by m eans offlexible

bolted connections.B olts shallbe ofproper length,m ade ofsteel,and galvanized.

3

c. T he various m em bers shallbe constructed ofa base m etalofthe gage show n on the plans and not less

than 1.5 m m (16 ga) for w alls up to 10 feet in height and ofheavier gage for higher w alls.

d. T he m em bers shallbe so fabricated that units ofthe sam e nom inaldepth and length shallbe fully

interchangeable.A llm em bers shallbe straight andtrue before assem bly,and the galvanizing or other

coating shallnot be dam aged.A ny bent orotherw ise defective m em bers w illbe rejected.

4

6.4.3 INSTALLATION (1997)

6.4.3.1 Preparing Base

a. T he foundation or bed for the crib w allshallbe firm and as uniform as possible,and shallbe approved by

the E ngineer before any m em bers are placed.Ifany m em bers are located directly above rock,a cushion

ofsand or gravelnot less than 200 m m (8 in) thick shallbe provided.

b. T he foundation shallbe sloped at a right angle to the batter on the face ofthe finished crib w all.

6.4.3.2 Placing

Crib m em bers shallbe carefully handled and installed in such a m anner as to avoid dam age.A ny m em ber

w hich becom es bent or otherw ise dam aged during erection shallbe rem oved and replaced.

© 2004, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-6-5

Concrete Structures and Foundations

6.4.3.3 Filling

a. T he filling ofthe interior ofthe crib w allshallfollow closely the erection ofthe successive tiers ofunits,

and at no tim e shallthe w all be laid up higherthan 1 m eter (3 ft) above the backfilled portion.

b. A pproved fillm aterialshallbe pervious,free draini ng,preferably crushed stone,gravel,or other coarse

granular m aterial,w ellgraded from a m axim um size of100 m m (4 in)dow n,and shallbe placed and

com pacted in the cells and for 600 m m (2 ft)im m ediately behind the cellin such a m anner as to provide

a m inim um ofvoids.A llorganic m atter shallbe excluded from the filling m aterials. T he filland backfill

m aterialshallnot contain any elem ent detrim entalto m etal.

6.4.3.4 Drainage

See A rticle 6.2.1k,for any drainage requirem ents.

SECTION 6.5 SPECIFICATIONS FOR TIMBER CRIB WALLS

6.5.1 GENERAL (1997)

T im ber crib w alls are m ade oftim ber cribbing,as defined in Article 6.1.2.2

and no other kinds oftim ber units

are considered or included herein.E ach crib unit shallbe rectangular in cross section.

6.5.2 MATERIALS (1997)

a. T im ber used for cribbing shallbe saw n,and new tim ber shallconform to the requirem ents ofChapter 7,

T im ber Structures,Part 1,M aterialSpecifications for Lum ber,Piles,G lued Lam inated T im ber and

Fasteners for the grade and species specified.T im ber shallbe treated in accordance w ith the

requirem ents ofChapter 30,T ies.

b. A llcutting and fram ing indicated on the plans shallbe com pleted before treatm ent.A llfram ing shallbe

done in a w orkm anlike m anner,true to line and angle.W hen any field fram ing,boring,and cutting of

treated m aterialis required,allsuch fram ing and cuts shallreceive a thorough coating ofapproved

preservative before assem bly.

6.5.3 INSTALLATION (1997)

6.5.3.1 Preparing Base

a. T he foundation or bed for the crib w allshallbe firm and as uniform as possible,and shallbe approved by

the E ngineer before any cribbing is placed.

b. T he foundation shallbe sloped at a right angle to the batter on the face ofthe finished crib w all.

6.5.3.2 Mud Sills

W hen m ud sills are used,they shallbeset at right angles to the face ofthe crib w alland bear firm ly and evenly

on the foundation m aterial(see Figure 8-6-1).M ud sills shallbe leveled to fit the base tier offace tim bers

resting directly on them .

© 2004, American Railway Engineering and Maintenance-of-Way Association

8-6-6 AREMA Manual for Railway Engineering

Crib Walls

6.5.3.3 Timbers

a. T he tim ber in the base tier and in alternate tiers above the base shallbe as long as practicable.

Preferably they shallhave a m inim um length of2.5 m eters (8 ft).Joints in each tier shallstagger w ith

joints in adjacent tiers.Crib w all faces shallbelaid closed or open as indicated on the plans.

b. Care shallbe exercised in the installation ofcrib w alls to produce a true and even face built to the line

and grade show n on the plans.A llface tim ber shallbe set horizontally (See Figure 8-6-2 and Figure 8-6-

3).

c. H eaders shallbe spaced not m ore than 2.5 m eters (8 ft) center to center in any horizontaltier if

staggered w ith the headers in tiers above and below.Ifheaders are not staggered,they shallbe spaced

not m ore than 1.8 m eters (6 ft)center to center.T he verticalspacing betw een headers in the sam e

verticalplane shallnot exceed 900 m m (3 ft).

Figure 8-6-1. Typical Sections through Walls of Timber Cribbing 3

TIES STAGGERED TIES IN LINE

Figure 8-6-2. Walls of Open-Face Timber Cribbing

© 2004, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-6-7

Concrete Structures and Foundations

Figure 8-6-3. Walls of Closed-Face Timber Cribbing

6.5.3.4 Fastenings

a. E ach successive tier ofclosed-face cribbing shallbe drift bolted to the one upon w hich it rests by drift

bolts not less than 19 m m (3/4 in) in diam eter and ofsufficient length to extend through tw o tiers and

not less than 100 m m (4 in)into the third tier.D rift bolts shallbe staggered and not m ore than 2.5

m eters (8 ft)center to center in each tier.

b. A llend joints and splices shallbe lapped and drift bolted at the center;headers shallbe drift bolted to

face tim bers in like m anner (see Figure 8-6-3).

c. E ach tier ofopen-face cribbing shallbe drift bolted to the tiers beneath at each header using 19 m m (3/4

in)drift bolts at each intersection w here no splice occurs or at lap joints,and tw o 19 m m (3/4 in)inch

drift bolts at butt joints.D rift bolts shallbe long enough to extend through one tier and at least three-

quarters ofthe distance into the next tier.D rift bolts shallbe staggered from tier to tier (see Figure 8-6-

2).

d. In treated tim ber cribbing,the hardw are shallbe galvanized.

6.5.3.5 Filling

a. T he filling ofthe interior ofthe crib w allshallfollow closely the erection ofthe successive tiers ofunits,

and at no tim e shallthe w all be laid up higherthan 1 m eter (3 ft) above the backfilled portion.

b. A pproved fillm aterialofpervious,free draining,preferably crushed stone,gravelor other coarse

granular m aterial,w ellgraded from a m axim um size of100 m m (4 in)dow n,shallbe placed in the cells

in such a m anner as to provide a m inim um ofvoids.Larger stones m ay be included ifcarefully

em bedded.A llorganic m atter shallbe excluded from the filling m aterial.Clay or m aterialhaving a large

percentage ofclay shallnot be used as fill.

6.5.3.6 Drainage

See A rticle 6.2.1k,for drainage requirem ents.

© 2004, American Railway Engineering and Maintenance-of-Way Association

8-6-8 AREMA Manual for Railway Engineering

You might also like

- SBC Code 301Document350 pagesSBC Code 301Marwan Mokhadder100% (7)

- AGS-688 ManualDocument60 pagesAGS-688 Manualvatcslav0% (1)

- 1101.3-GraphicalSymbols For General EngineeringDocument84 pages1101.3-GraphicalSymbols For General EngineeringRayGaint100% (4)

- N4AIA04 ManualDocument11 pagesN4AIA04 Manualthành trung phạm100% (1)

- Drilled Shaft Foundations - 1997 - : Section/Article DescriptionDocument12 pagesDrilled Shaft Foundations - 1997 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Drilled Shaft Foundations - 1997 - : Section/Article DescriptionDocument12 pagesDrilled Shaft Foundations - 1997 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Almita Screw Pile Design Handbook 2008 PDFDocument59 pagesAlmita Screw Pile Design Handbook 2008 PDFMatthew Karabela100% (2)

- AISI Steel Plate Engineering Data-Volume 2-1992Document94 pagesAISI Steel Plate Engineering Data-Volume 2-1992jcarbajal2013No ratings yet

- Macalloy Bars For Use in Post Tensioning ApplicationDocument21 pagesMacalloy Bars For Use in Post Tensioning Applicationsanusi69No ratings yet

- Tata Steel Designers ManualDocument163 pagesTata Steel Designers ManualEnger AlingasaNo ratings yet

- Guide To Fixings For GRC CladdingDocument55 pagesGuide To Fixings For GRC CladdingThompson Lai100% (4)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 2 The Crystal Chemistry of ZeolitesDocument48 pages2 The Crystal Chemistry of ZeolitesJohn YuNo ratings yet

- Acdc1000 11124 & 11226Document34 pagesAcdc1000 11124 & 11226Jaime ArreolaNo ratings yet

- Advanced Trauma Life Support (Atls)Document44 pagesAdvanced Trauma Life Support (Atls)Danar Syahrial PradhiptaNo ratings yet

- HSNC Part 3 E-July13Document246 pagesHSNC Part 3 E-July13Neo ZaoNo ratings yet

- Flexible Sheet Pile Bulkheads - 1995 - : Section/Article DescriptionDocument18 pagesFlexible Sheet Pile Bulkheads - 1995 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Tem Porary Structures For C Onstruction: TableofcontentsDocument22 pagesTem Porary Structures For C Onstruction: TableofcontentsMarwan MokhadderNo ratings yet

- Steel Plate GirderDocument108 pagesSteel Plate GirderAngelina Winda0% (1)

- Draft Reinforcement Detailing Handbook Complete Version PR Incl FigsDocument272 pagesDraft Reinforcement Detailing Handbook Complete Version PR Incl Figsjiminy0750% (2)

- US6619645-Fixturing System For Holding and Aligning Engine BlocksDocument24 pagesUS6619645-Fixturing System For Holding and Aligning Engine BlocksMahnooshNo ratings yet

- Design of Sheet Pile WallsDocument76 pagesDesign of Sheet Pile WallsAli Öztürk100% (2)

- Anti Friction Bearings PDFDocument88 pagesAnti Friction Bearings PDFversine50% (2)

- Detail Design of Crane Runway Girders - bk105 PDFDocument6 pagesDetail Design of Crane Runway Girders - bk105 PDFTiago CastelaniNo ratings yet

- P 06Document23 pagesP 06Priyesh SaxenaNo ratings yet

- Fema 450 2 Commentary Part 2Document110 pagesFema 450 2 Commentary Part 2Tariq AbdulsalamNo ratings yet

- Elastomeros PDFDocument69 pagesElastomeros PDFBeatriz Bautista GutierrezNo ratings yet

- Design Sheet PileDocument75 pagesDesign Sheet Pileivan_indrawan_10111No ratings yet

- Recommendations For The Design of Segmental Bridges - 1996Document66 pagesRecommendations For The Design of Segmental Bridges - 1996Marwan MokhadderNo ratings yet

- Opr0RAZ7 TMPDocument4 pagesOpr0RAZ7 TMPSérgio BernardesNo ratings yet

- Caltran Prestressed Composite PDFDocument114 pagesCaltran Prestressed Composite PDFDinko NovakNo ratings yet

- Construction Standard: IPS-C-CE-200Document34 pagesConstruction Standard: IPS-C-CE-200lin xuNo ratings yet

- Propiedades Torsionales PDFDocument19 pagesPropiedades Torsionales PDFAnonymous fKv3jsANo ratings yet

- Design Procedure For Crane Runway Girders - bk105 PDFDocument7 pagesDesign Procedure For Crane Runway Girders - bk105 PDFFWICIPNo ratings yet

- Ufgs 07 61 15.00 20Document27 pagesUfgs 07 61 15.00 20sharethefilesNo ratings yet

- Bracing-Of-steel Beams in BridgesDocument91 pagesBracing-Of-steel Beams in Bridgespawkom pawkomNo ratings yet

- Section 2: ChassisDocument10 pagesSection 2: ChassisvinodpipeshdholpurNo ratings yet

- Latest Amendments in IRC Codes 2Document24 pagesLatest Amendments in IRC Codes 2Pravin GundeliNo ratings yet

- Application of Weldment Fatigue Methods To Conveyors Pulley DesignDocument6 pagesApplication of Weldment Fatigue Methods To Conveyors Pulley DesignIgor San Martín PeñalozaNo ratings yet

- tm5 822 13Document50 pagestm5 822 13Tin Aung KyiNo ratings yet

- United States Patent: Price (45) Date of Patent: Apr. 22, 2008Document11 pagesUnited States Patent: Price (45) Date of Patent: Apr. 22, 2008Aslam KhanNo ratings yet

- Bridge Manual: 23.1 2 23.2 Design Specifications and Data 3Document17 pagesBridge Manual: 23.1 2 23.2 Design Specifications and Data 3mud444No ratings yet

- Behavior and Design of Selected Elastomeric Bearing Pads: Leonard TulinDocument20 pagesBehavior and Design of Selected Elastomeric Bearing Pads: Leonard TulinpetricoqNo ratings yet

- Chapter 9 Bearings & Expansion Joints: WSDOT Bridge Design Manual M 23-50.06 Page 9-I July 2011Document34 pagesChapter 9 Bearings & Expansion Joints: WSDOT Bridge Design Manual M 23-50.06 Page 9-I July 2011Eddie Chan100% (1)

- Piping Tie-Rod Design Made SimpleDocument3 pagesPiping Tie-Rod Design Made SimpleSeungmin PaekNo ratings yet

- Poles (Concrete) Specification - NNSW PDFDocument35 pagesPoles (Concrete) Specification - NNSW PDFyahyaNo ratings yet

- Pages From 177344845 Aashto LRFD 4th 2007Document2 pagesPages From 177344845 Aashto LRFD 4th 2007vrajan1988No ratings yet

- Design of FoundationDocument26 pagesDesign of Foundationmessinho70% (1)

- Concrete Structures and Foundations: ForewordDocument8 pagesConcrete Structures and Foundations: ForewordMarwan MokhadderNo ratings yet

- Pile Foundations - 1994 - : 8www - NBMDocument20 pagesPile Foundations - 1994 - : 8www - NBMMarwan MokhadderNo ratings yet

- Gusset Plate Connections For Seismic DesignDocument15 pagesGusset Plate Connections For Seismic DesignIndah Permata YeniNo ratings yet

- Us4173933 PDFDocument10 pagesUs4173933 PDFRizki Fajar NovantoNo ratings yet

- 7 1 A11y PDFDocument69 pages7 1 A11y PDFMahri SyNo ratings yet

- Section 6 - Prestressed Concrete: 6.1 - DESIGNDocument11 pagesSection 6 - Prestressed Concrete: 6.1 - DESIGNAnonymous mcHqIfbnV1No ratings yet

- Channel Lining and Pier Scour Design ManualDocument53 pagesChannel Lining and Pier Scour Design ManualAdeRatihIspandiariNo ratings yet

- CFD Parchute ClustersDocument32 pagesCFD Parchute Clustersaaron prakashNo ratings yet

- Is 3063-Spring WashersDocument11 pagesIs 3063-Spring Washerspbp2956No ratings yet

- 132 s2.0 Sa031232s638f2312200f4031b3 MDocument23 pages132 s2.0 Sa031232s638f2312200f4031b3 MUnknown WKNo ratings yet

- Supports Fabrication and Installation Practices: MSS SP 89 2003Document24 pagesSupports Fabrication and Installation Practices: MSS SP 89 2003FathyNo ratings yet

- Patente Aspa Parsons Como Las Que Tengo de 1953 Us3002567Document4 pagesPatente Aspa Parsons Como Las Que Tengo de 1953 Us3002567Mariela TisseraNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Geotechnical Subsurface Investigation - 1992 - : Section/Article DescriptionDocument10 pagesGeotechnical Subsurface Investigation - 1992 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Recommendations For The Design of Segmental Bridges - 1996Document66 pagesRecommendations For The Design of Segmental Bridges - 1996Marwan MokhadderNo ratings yet

- Bibliography - 2001 - : C Hapter 8, C Oncrete Structures and FoundationsDocument6 pagesBibliography - 2001 - : C Hapter 8, C Oncrete Structures and FoundationsMarwan MokhadderNo ratings yet

- Inspection of Concrete and Masonry Structures - 1997 - : Section/Article DescriptionDocument26 pagesInspection of Concrete and Masonry Structures - 1997 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Flexible Sheet Pile Bulkheads - 1995 - : Section/Article DescriptionDocument18 pagesFlexible Sheet Pile Bulkheads - 1995 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Concrete Slab Track - 1999 - : Section/Article DescriptionDocument26 pagesConcrete Slab Track - 1999 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Tem Porary Structures For C Onstruction: TableofcontentsDocument22 pagesTem Porary Structures For C Onstruction: TableofcontentsMarwan MokhadderNo ratings yet

- Pile Foundations - 1994 - : 8www - NBMDocument20 pagesPile Foundations - 1994 - : 8www - NBMMarwan MokhadderNo ratings yet

- Slurry Wall Construction - 2002 - : Section/Article DescriptionDocument14 pagesSlurry Wall Construction - 2002 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Materials, Tests and Construction Requirements - 2004 - : Section/Article DescriptionDocument72 pagesMaterials, Tests and Construction Requirements - 2004 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Concrete Structures and Foundations: ForewordDocument8 pagesConcrete Structures and Foundations: ForewordMarwan MokhadderNo ratings yet

- Reinforced Concrete Design - 2002 - : Section/Article DescriptionDocument70 pagesReinforced Concrete Design - 2002 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- NFPA 130-2003 p21-39 613Document19 pagesNFPA 130-2003 p21-39 613Marwan MokhadderNo ratings yet

- Revues FibDocument1 pageRevues FibMarwan MokhadderNo ratings yet

- NFPA 130-2003 p56-70 615Document15 pagesNFPA 130-2003 p56-70 615Marwan MokhadderNo ratings yet

- NFPA 130-2003 p40-55 614Document16 pagesNFPA 130-2003 p40-55 614Marwan MokhadderNo ratings yet

- Fib Bull28 NMGDocument81 pagesFib Bull28 NMGMarwan MokhadderNo ratings yet

- 1004Document7 pages1004Marwan MokhadderNo ratings yet

- Fib Symposium in Tel Aviv:: 2013 Engineering A Concrete FutureDocument7 pagesFib Symposium in Tel Aviv:: 2013 Engineering A Concrete FutureMarwan MokhadderNo ratings yet

- Fib Symposium in Tel Aviv:: 2013 Engineering A Concrete FutureDocument7 pagesFib Symposium in Tel Aviv:: 2013 Engineering A Concrete FutureMarwan MokhadderNo ratings yet

- Zeal IngredientsDocument4 pagesZeal IngredientsRob HarnageNo ratings yet

- Using Geophysics To Characterize The Subsurface: The PrinciplesDocument152 pagesUsing Geophysics To Characterize The Subsurface: The PrinciplesMasahiro Galang SusantoNo ratings yet

- 4th Quarter ExamDocument2 pages4th Quarter ExamMa. Cynthia San JuanNo ratings yet

- Analysis of Diaphragm WallDocument6 pagesAnalysis of Diaphragm WallSanthosh BabuNo ratings yet

- Quanta G31a Dag31amb6d0 Y61x-6l Rev 1aDocument49 pagesQuanta G31a Dag31amb6d0 Y61x-6l Rev 1aKrystian PalaciosNo ratings yet

- Factsheet - REPowerEU PDFDocument2 pagesFactsheet - REPowerEU PDFconor farrellNo ratings yet

- Calibracion Motor Aceleracion 320CDocument12 pagesCalibracion Motor Aceleracion 320CJoan CardonaNo ratings yet

- Photoelastic Coatings PDFDocument2 pagesPhotoelastic Coatings PDFAnia Jeune AviatriceNo ratings yet

- PanasonicDocument26 pagesPanasonicmecatronic22No ratings yet

- Kala-2000 LedDocument2 pagesKala-2000 LedJohnNo ratings yet

- Preparing For EnemaDocument11 pagesPreparing For Enemapassion26100% (1)

- Notes On Hegel's Shorter LogicDocument13 pagesNotes On Hegel's Shorter LogicShaun PoustNo ratings yet

- Comparative Study Based On Thermal Efficiency of Solar Air HeatersDocument6 pagesComparative Study Based On Thermal Efficiency of Solar Air Heatershicham El FeroualiNo ratings yet

- ZX450 ZX650Document109 pagesZX450 ZX650mohanNo ratings yet

- Package FaultsDocument6 pagesPackage FaultsArunraj Arumugam100% (1)

- Mercedes Actros Head FAHES - Vehicle Inspection Result 25-02-24Document1 pageMercedes Actros Head FAHES - Vehicle Inspection Result 25-02-24Sreeja LinNo ratings yet

- Federal Register / Vol. 88, No. 81 / Thursday, April 27, 2023 / Proposed RulesDocument236 pagesFederal Register / Vol. 88, No. 81 / Thursday, April 27, 2023 / Proposed RulesSimon AlvarezNo ratings yet

- DD Soft Copy and Hard Copy Recieved Details Journal Review Process 21 April 2014 8 PM1Document34 pagesDD Soft Copy and Hard Copy Recieved Details Journal Review Process 21 April 2014 8 PM1Puneet AjalNo ratings yet

- Beating The Bonk QuestionsDocument1 pageBeating The Bonk Questionst3xxaNo ratings yet

- SAS 19 - Capangpangan, Trisha Mariz M.Document2 pagesSAS 19 - Capangpangan, Trisha Mariz M.Bernadeth Barrientos ZamoraNo ratings yet

- Iq TestDocument18 pagesIq TestAmrita BawaNo ratings yet

- The Yoga Sutras of PatanjaliDocument23 pagesThe Yoga Sutras of Patanjaliapi-3736105No ratings yet

- Soal Sem Genap Kls 9Document7 pagesSoal Sem Genap Kls 9RioNo ratings yet

- Best Control For FliesDocument30 pagesBest Control For FliesDavidNo ratings yet

- Elements of Weather Climate Quarter 4 Week 3 Day 1-Day 41Document89 pagesElements of Weather Climate Quarter 4 Week 3 Day 1-Day 41BENJ AMINNo ratings yet