Professional Documents

Culture Documents

Week 3 Introduction To Flotation

Week 3 Introduction To Flotation

Uploaded by

abd ullahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Week 3 Introduction To Flotation

Week 3 Introduction To Flotation

Uploaded by

abd ullahCopyright:

Available Formats

2/28/2014

MinE 410 Mineral Processing II [3]

Dr. Ishaq Ahmad

• Froth flotation utilises the differences in physico –

Assistant Professor chemical surface properties of various minerals.

Dept. of Mining Engineering • Such differences in surface properties become

University of Engineering and Technology, appearent by the interaction of chemical reagents

with the mineral particles.

Peshawar

• To make the minerals selectively hydrophobic and

[Introduction to Flotation]

to separate it by the adherence of this specific

Spring Semester, 2014 particle to air bubble and then to rise to the

Week 3 surface in the form of froth

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

1 4

Ahmad Ahmad

Introduction • Direct Flotation : Valuable mineral is

• Patended in 1906 transferred to the froth, leaving the

• In earlier practice: gangue in the pulp.

– Tailings grade from various gravity plants were of • Reverse Flotation : Gangue is floated

higher grade than ore treated in many modern while leaving the valuable mineral in

flotation plants the pulp.

• Selective process to separate various ores

• Differential Flotation : In which more

– E.g Pb-Zn or Pb,Zn,Cu or Cu from its impurities

than one valuable is flotation one after

the other.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

2 5

Ahmad Ahmad

FLOTATION

Phases

• Flotation is the most important mineral processing

technique. 3 phases in froth flotation:

Flotation has permitted : 1. Solid phase (fine ore particles)

1. The mining of low grade deposits would have

2. Liquid phase (water)

2. The mining of complex ore bodies been regarded 3. Gaseous phase (air)

as uneconomic

3. Ores that require fine grinding to achieve

liberation

4. To treat greater tonnages.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

3 6

Ahmad Ahmad

MinE 410 Mineral Processing II Dr.Ishaq

Ahmad 1

2/28/2014

• Having reached the surface:

– the air bubbles, if make a stable froth then can

further support the particles

– Otherwise the bubbles burst and the particle fall

down in the pulp

– To form stable froth, numerous chemicals are

added called the flotation reagents

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

7 10

Ahmad Ahmad

Forces on Mineral Surface and

Contact Angle

Flotation

• The activity of a mineral surface in relation to

Principle:

flotation reagent in water depends on the forces

which operate on that surface.

• Contact anlge is the angle formed by a liquid at

• The particles which have been rendered: the three-phase boundary where the liquid, gas,

hydrophobic.(Water repellent : Aerophilic)

and solid meet.

• Hydrophilic (water wetted) particle which leaves in the

pulp.

• Most minerals are naturally hydrophilic.

To achieve a separation by flotation, the surfaces of one

mineral must be selectively rendered

MinE 410 Mineral Processing II Dr.Ishaq hydrophobic. 8 MinE 410 Mineral Processing II Dr.Ishaq

11

Ahmad Ahmad

γ are the surface

energies (surface

• The air/gas is provided which converts to tension) between the

bubbles solid air, solid water and

air water.

• These bubbles can only stick to the mineral θ is the contact angle

particles if they can displace water from the between the mineral

mineral surface, which can only happen if the surface and the bubble

mineral is to some extent water repellent or

Hydrophobic.

At equilibrium γ s / a = γ s / w + γ a / w ⋅ cos θ [1]

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

9 12

Ahmad Ahmad

MinE 410 Mineral Processing II Dr.Ishaq

Ahmad 2

2/28/2014

Work of Adhesion

PHYSICAL ASPECTS OF FLOTATION

• The force required to break the particle Wetting is the ability of a liquid to maintain contact with a solid surface.

bubble interface and is represented with W s/a It results from intermolecular interactions when the two are brought together.

The degree of wetting (wettability) is determined by a force balance between

• It separates the solid/air interface and ADHESIVE and COHESIVE forces.

produces separate air/water and solid/water COHESIVE FORCES within the liquid cause the drop to ball up and avoid contact

interfaces with the surface.

Cohesive forces are intermolecular forces (such as those from hydrogen bonding and Van der Waals

i.e. [2]

W = γ +γ −γ

s/a a/w s/ w s/a

forces).

These attractive forces exist between molecules of the same substance.

From 1 and 2 It is the mutual tension ( energy of reaction ) between molecules of the same type .

Ws / a = γ a / w (1 − cos θ ) [3] Eg. Water .

Rain falls in droplets, rather than a fineMinE

mist, because water has strong cohesion which pulls its molecules

Eq. 3 is called the Young’s equation

MinE 410 Mineral Processing II Dr.Ishaq

Ahmad

13 tightly together, forming droplets.

410 Mineral Processing II Dr.Ishaq

Ahmad

16

• Now it can be observed that greater the contact PHYSICAL ASPECTS OF FLOTATION

angle, the greater is the work of adhesion and

more resistance the system is to disuptive forces. ADHESIVE FORCES are the mutual tension ( energy of reaction )

between two phases ( water and mineral).

If θ = 0 , cos θ = 1 They are the attractive forces between unlike molecules.

Ws/a = 0 When water is poured on clean glass, it tends to spread, forming a thin,

uniform film over the glasses surface.

The adhesive forces between water and glass are strong .

• No work is needed to break particle bubble They pull the water molecules out of their spherical formation

interface, because there is no particle bubble They hold them against the surface of the glass.

interface (surface is completely wetted by water) ADHESIVE forces between a liquid and solid cause a liquid drop

to spread across the surface.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

14 17

Ahmad Ahmad

PHYSICAL ASPECTS OF FLOTATION

If θ = 180 ° THE CONTACT ANGLE(θ)-

If the surface of one phase is plane ( as mineral surface M )

Surface is covered by air. Not valid in

practice

A

• The floatability of a mineral increases

θ W

with the contact angle. M

• Most minerals are NOT naturally

water repellent in their natural state

As the tendency of a drop to spread out over a flat, solid surface increases, the contact angle

and flotation reagents are added to decreases.

the pulp to make the surface of

Thus, the contact angle provides an inverse measure of wettability.

minerals hydrophobic A

i.e., as wettability increases, contact angle decreases. L

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

15 18

Ahmad θ Ahmad

θ

MinE 410 Mineral Processing II Dr.Ishaq

Ahmad 3

2/28/2014

PHYSICAL ASPECTS OF FLOTATION

MINERALISATION OF AIR BUBBLES.

Water particle on a flat surface, ESEM image

Froth flotation depends on attachment of mineral particles to air bubbles.

The bubble attachment is by

1. COLLISION BETWEEN PARTICLES AND BUBBLE IN THE PULP-

Lot of collisions takes place in a flotation cell in a second.

A definite proportion of theses collisions result in bubble - mineral attachment.

Maximum bubble attachment ( i.e, maximum separation of minerals from the

gangue ) is made possible by controlling the various physical and chemical Bubble radius R

parameters of flotation.

2. FORMATION OF GAS BUBBLES ON THE PARTICLE SURFACE FROM THE

R min

SOLUTION.

Ref. Y.C. Jung, B.J. Bhushan, Microsc. 229, 127 (2008) As the contact angle increases, the formation of gas bubble is easier.

Stage I - The pulp water is oversaturated- no bubbles formed- gas molecules I II III

move to areas where they can easily combine and break the binds in the water Time t

molecules.

Stage II - A large number of gas molecules accumulate in certain areas. They

unite forming bubble molecules.

Stage III - The gas molecules grow due to diffusion of dissolved gases.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

19 22

Ahmad Ahmad

PHYSICAL ASPECTS OF FLOTATION PHYSICAL ASPECTS OF FLOTATION

A contact angle less than 90° ( low contact angle ) - V MINERALISATION OF AIR BUBBLES.

wetting of the surface is very favorable,

L

the fluid will spread over a large area of the surface. COMBINED BUBBLE ATTACHMENT TO A MINERAL.

S

Hydrophilic

Contact angles greater than 90° (high contact angle)- The discussed two methods of bubble formation may be combined.

wetting of the surface is unfavorable,

the fluid will minimize contact with the surface and

1. A small bubble forms on a mineral particle-

form a compact liquid droplet.

It activates the mineral surface and

For water, a wettable surface may be termed hydrophilic and improves the attachment to other bubbles.

Hydrophobic

a non-wettable surface hydrophobic.

2. A larger bubble having enough lifting power to carry the

Superhydrophobic surfaces have contact angles greater than 150°, particle into the froth attaches to the first bubble.

showing almost no contact between the liquid drop and the surface.

This is sometimes referred to as the "Lotus effect". 3. These two bubbles coalesce and a still larger bubble is formed.

4. It sticks to the particle.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

20 23

Ahmad Ahmad

PHYSICAL ASPECTS OF FLOTATION PHYSICAL ASPECTS OF FLOTATION

WSA = E AW ( 1 - Cos θ ),

For an aq. Solution with surface tension 70 dynes/ cm and θ = 60◦,

WSA = 70 ( 1 – Cos 60 )= 35 ergs/sqcm. FROTH PROPERTIES.

For θ = 90◦, Ω = 70 ergs/sqcm.

i.e, the work for adhesion ( adhesion is the measure of wettability) is

doubled. More work of adhesion needed to make surface wettable.

A contact angle less than

90° ( low contact angle ) –

1.Must retain the mineralised air bubbles.

As θ increases, WSA increases, wettability decreases. wetting of the surface is

very favorable,

2.The gangue materials must get detached in the froth.

Flotation process is made up of the fluid will spread over a

large area of the surface.

1. Artificially increasing the surface energy by introducing many fine

air bubbles in the system and Contact angles greater than 3.The froth should not be highly stable.

2. Causing the bubbles to adhere to each other and to suspend 90° (high contact angle)-

minerals whose contact angle is not ZERO. wetting of the surface is

unfavorable, The froth should breakdown easily on removal from the flotation cell.

OTHER THINGS BEING EQUAL, the fluid will minimize

AN INCREASE IN CONTACT ANGLE RESULTS IN contact with the surface

and

MORE RAPID FLOTATION.

form a compact liquid

droplet.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

21 24

Ahmad Ahmad

MinE 410 Mineral Processing II Dr.Ishaq

Ahmad 4

2/28/2014

PHYSICAL ASPECTS OF FLOTATION PHYSICAL ASPECTS OF FLOTATION

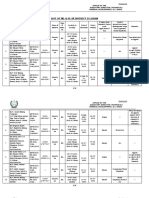

IN FROTH FLOTATION FACTORS AFFECTING FLOTATION.

1. The particles are made hydrophobic ( non wettable ) . 1. Size and shape of mineral particles –

2. They are brought in contact with gas bubbles . Optimum particle size depends on its surface property , specific gravity .

3. The bubbles attached to the particle surface.

2. Pulp Density-

4. The bubbles carry the particles to the surface. Flotation efficiency increases with pulp density.

5. If the bubbles and surfaces never come in contact, Usual pulp density – 15- 40% solids .

then no flotation can occur.

3. Pulp Temperature.

THREE IMPORTANT POINTS IN FROTH FLOTATION- Temperature influences the speed of reactions.

1. EFFECT OF PARTICLE SIZE. Rise in temperature improves flotation but reduces selectivity.

Particle/bubble collision is affected by the relative sizes of the particles.

4. Composition of process water.

If the bubbles are large relative to the particles, Ions present in the water affect the flotation process.

They may react with flotation reagents ( collectors, modifiers etc) .

the fluid flowing around the bubbles carries the particles

without coming in contact. 5. Reagent feed –reagent type, sequence of addition, time of contact between pulp and

reagent.

Best results if The sequence of addition- regulator to alter pH of medium, depressants to depress certain

THE BUBBLE DIAMETER IS COMPARABLE TO THE PARTICLE DIAMETER constituent, collector and frother.

IN ORDER TO ENSURE GOOD PARTICLE/BUBBLE CONTACT.

6. Particle agglomeration in the pulp.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

25 28

Ahmad Ahmad

PHYSICAL ASPECTS OF FLOTATION PHYSICAL ASPECTS OF FLOTATION

FACTORS AFFECTING FLOTATION.

2. COLLECTION IN THE FROTH LAYER 7. Slimes –

They are fine , sticky particles ( 3-10 micron size).

Once a particle and bubble have come in contact,

the bubble must be large enough for its buoyancy to lift the particle to the They

surface.

The particle and bubble must remain attached while they move up into the froth layer at the contaminate the froth,

top of the cell. increase the reagent consumption,

decrease the flotation speed.

The FROTH LAYER MUST PERSIST LONG ENOUGH TO EITHER

FLOW OVER THE DISCHARGE LIP OF THE CELL BY GRAVITY The negative impact of the slime can be reduced by

OR

1. Adding suitable reagents,

TO BE REMOVED BY MECHANICAL FROTH SCRAPERS. 2. Using dilute pulp,

3. Separating slime before flotation.

If the froth is unstable, the bubbles will break and drop the hydrophobic particles back into

the slurry prematurely.

But the froth should not be so stable as to become persistent foam, as a foam is difficult to

convey and pump through the plant.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

26 29

Ahmad Ahmad

PHYSICAL ASPECTS OF FLOTATION

3. THE SURFACE AREA OF THE BUBBLES IN THE FROTH .

Copper Flotation

LARGER THIS SURFACE AREA, MORE RAPID IS THE FLOTATION RATE OF PARTICLES.

But increased surface area also carries more water into the froth.

Video

Fine particles ( Gangue ) that are not attached to air bubbles will be unselectively

carried into the froth along with the water (entrainment).

MORE WATER IN THE FROTH RESULT S IN CONTAMINATION OF THE PRODUCT WITH GANGUE

MINERALS.

MinE 410 Mineral Processing II Dr.Ishaq MinE 410 Mineral Processing II Dr.Ishaq

27 30

Ahmad Ahmad

MinE 410 Mineral Processing II Dr.Ishaq

Ahmad 5

You might also like

- Comminution CourseDocument413 pagesComminution CourseNataniel Linares100% (1)

- Kami Export - Cameron Martin - The - Properties - of - Water - Worksheet - 1Document5 pagesKami Export - Cameron Martin - The - Properties - of - Water - Worksheet - 1Cameron MartinNo ratings yet

- Week 7 Flotation Circuits and MachinesDocument6 pagesWeek 7 Flotation Circuits and Machinesabd ullahNo ratings yet

- Mineral Processing - 2024Document46 pagesMineral Processing - 2024ziziphomkosana2003No ratings yet

- Particle Technology (PTY261S) : DR M AzizDocument46 pagesParticle Technology (PTY261S) : DR M AzizKyle AprilNo ratings yet

- Mineral ResourcesDocument3 pagesMineral ResourcesLeonie LanzadoNo ratings yet

- Beneficiation Process Control-1 (Mid Term)Document48 pagesBeneficiation Process Control-1 (Mid Term)Aklilu NegaNo ratings yet

- Ore MineralsDocument6 pagesOre MineralsSofia DomingoNo ratings yet

- Earth and Science Week 3Document20 pagesEarth and Science Week 3Precious Nichole FloridaNo ratings yet

- Metallurgy - Topic - 6Document49 pagesMetallurgy - Topic - 6mebaneNo ratings yet

- Q1 - Module 5 & 6Document36 pagesQ1 - Module 5 & 6Michelle Bernadette Co-GonzalesNo ratings yet

- Ore MineralsDocument4 pagesOre MineralsBeyhNo ratings yet

- During The Programme - Mining To RehabDocument5 pagesDuring The Programme - Mining To Rehabbridget.duncanNo ratings yet

- Mineral Processing (Extractive Metallurgy) For Non-Metallurgists Section 1 - IntroductionDocument25 pagesMineral Processing (Extractive Metallurgy) For Non-Metallurgists Section 1 - IntroductionmakimphoNo ratings yet

- Extraction of MetalsDocument31 pagesExtraction of MetalsTadiwa RylyNo ratings yet

- Mineral Processing in The Indian Nuclear Energy ProgrammeDocument8 pagesMineral Processing in The Indian Nuclear Energy ProgrammeArindam DasNo ratings yet

- Weathering of Rocks by LichenDocument61 pagesWeathering of Rocks by LichenanmolkhokharNo ratings yet

- Basics in Mineral Processing-Introduction1Document9 pagesBasics in Mineral Processing-Introduction1makedo33100% (1)

- (21910324 - High Temperature Materials and Processes) Current Practices in Tungsten Extraction and RecoveryDocument16 pages(21910324 - High Temperature Materials and Processes) Current Practices in Tungsten Extraction and RecoveryVăn Đại - BKHNNo ratings yet

- Handout MINERAL RESOURCESDocument3 pagesHandout MINERAL RESOURCESStephanie VicenteNo ratings yet

- Compilation Chapter 1 REDocument350 pagesCompilation Chapter 1 REMohd RafiqNo ratings yet

- Froth FlotationDocument5 pagesFroth FlotationJoyce MendozaNo ratings yet

- An Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDocument9 pagesAn Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDaniel Ernesto Nauduan FloresNo ratings yet

- Es - Unit 5Document38 pagesEs - Unit 5Joeddy Adrian LagahitNo ratings yet

- Processing of Ores of Titanium, Zirconium, Hafnium, Niobium, Tantalum, Molybdenum, Rhenium, and Tungsten: International Trends and The Indian SceneDocument32 pagesProcessing of Ores of Titanium, Zirconium, Hafnium, Niobium, Tantalum, Molybdenum, Rhenium, and Tungsten: International Trends and The Indian Scenemufti abdillahNo ratings yet

- Int. Journal of Refractory Metals and Hard Materials: M. Vosough, N. Shahtahmasebi, M. BehdaniDocument6 pagesInt. Journal of Refractory Metals and Hard Materials: M. Vosough, N. Shahtahmasebi, M. BehdanicatalinaNo ratings yet

- Volcanic DepositsDocument21 pagesVolcanic DepositsKabelo SerageNo ratings yet

- Presentation 2Document1 pagePresentation 2Theresa Rose AceroNo ratings yet

- Complete MetallurgyDocument53 pagesComplete Metallurgy9v67xgwzdpNo ratings yet

- GOC AllenDocument27 pagesGOC AllenAshish RanjanNo ratings yet

- Cor 5 - Week 8Document5 pagesCor 5 - Week 8Nazer M. LacaboNo ratings yet

- Ore MineralsDocument11 pagesOre MineralsMichelle Cariazo ManuelNo ratings yet

- Resource Geology The BasicsDocument5 pagesResource Geology The BasicsJhon Andro JarovillaNo ratings yet

- Pengmin LengkapDocument434 pagesPengmin Lengkaphilman fauziNo ratings yet

- Introduction HSE & BrecciaDocument28 pagesIntroduction HSE & Brecciatiara WataniaNo ratings yet

- Carmen Copper CorporationDocument9 pagesCarmen Copper CorporationMariel Mae A. MaculbeNo ratings yet

- The Revision Preparation Step of HydrometallurgcalDocument10 pagesThe Revision Preparation Step of HydrometallurgcalEbrianto Sattria MalikNo ratings yet

- Lecture 142507350622Document108 pagesLecture 142507350622SAYEENo ratings yet

- Reduce The Iron Content in Egyptian Feldspar Ore of Wadi Zirib For Industrial ApplicationsDocument10 pagesReduce The Iron Content in Egyptian Feldspar Ore of Wadi Zirib For Industrial ApplicationsSoloChicas VentasVallenarNo ratings yet

- Inhibition of The Pregrobbing Phenomenon in Gold OresDocument191 pagesInhibition of The Pregrobbing Phenomenon in Gold OresAnonymous FfIxH2o9No ratings yet

- True Flotation Versus Entrainment in Reverse FlotationDocument12 pagesTrue Flotation Versus Entrainment in Reverse FlotationAbrahan BVNo ratings yet

- 2-Endapan Mineral - Jenis Endapan MineralDocument17 pages2-Endapan Mineral - Jenis Endapan Mineralwahyu1507.0903No ratings yet

- Libro TraducidoDocument4 pagesLibro TraducidoKevin AguirreNo ratings yet

- 3.3.7 Initial Evaluation... Eview - 25 May 2009Document21 pages3.3.7 Initial Evaluation... Eview - 25 May 2009Slamet SetyowibowoNo ratings yet

- Febe1000a - Introduction To Materials - Rock-To-metal - Notes - Week 5 - 06042021Document48 pagesFebe1000a - Introduction To Materials - Rock-To-metal - Notes - Week 5 - 06042021uziNo ratings yet

- Unit 5 Minersl Resources of PakistamDocument24 pagesUnit 5 Minersl Resources of Pakistamm.furqanullahNo ratings yet

- Froth Flotation-Basic PrinciplesDocument11 pagesFroth Flotation-Basic PrinciplesJagdish vishnoiNo ratings yet

- Chap 01 Introduction To Minerals PDFDocument6 pagesChap 01 Introduction To Minerals PDFGianfranco FernandezNo ratings yet

- Erth SayDocument9 pagesErth SayMichelle AlarcioNo ratings yet

- Extraction and Beneficiation of Ores and Minerals PDFDocument2 pagesExtraction and Beneficiation of Ores and Minerals PDFFredNo ratings yet

- Lecture 2 - The Mineralogy of Economic DepositsDocument38 pagesLecture 2 - The Mineralogy of Economic DepositsTimang JrNo ratings yet

- 1 Intro To Mineral ExplorationDocument17 pages1 Intro To Mineral ExplorationGabrielNo ratings yet

- Section 11 Hole Problems: Shale StabilityDocument36 pagesSection 11 Hole Problems: Shale StabilityAmine MimoNo ratings yet

- Leaching Procces 999666Document10 pagesLeaching Procces 999666Dr-Hani Elsayed Sharaf EldinNo ratings yet

- Department of Metallurgy and Material Engineering University of The PunjabDocument15 pagesDepartment of Metallurgy and Material Engineering University of The PunjabUsman PirzadaNo ratings yet

- Basic Concepts of Surface Mining PDFDocument56 pagesBasic Concepts of Surface Mining PDFHarikrishnaNo ratings yet

- PERFORMANCE TASK 2 ScienceDocument5 pagesPERFORMANCE TASK 2 ScienceCUIZON, GEORDETTE DIVINENo ratings yet

- Process of Extraction and Exploitation of Mineral Extraction of Copper From Copper SulfideDocument10 pagesProcess of Extraction and Exploitation of Mineral Extraction of Copper From Copper SulfidechoricuaNo ratings yet

- 02 Handout 1Document11 pages02 Handout 1fuenNo ratings yet

- Assalammu'Alaikum WR - WB: Preparation Step of MetallurgyDocument23 pagesAssalammu'Alaikum WR - WB: Preparation Step of MetallurgyEbrianto Sattria MalikNo ratings yet

- W-Sn Skarn Deposits: and Related Metamorphic Skarns and GranitoidsFrom EverandW-Sn Skarn Deposits: and Related Metamorphic Skarns and GranitoidsNo ratings yet

- Thermodynamics: Presentation By: BUSHRA NAWAZ Deptt:MiningDocument37 pagesThermodynamics: Presentation By: BUSHRA NAWAZ Deptt:Miningabd ullahNo ratings yet

- Presentation 1Document11 pagesPresentation 1abd ullahNo ratings yet

- GEOLOGICAL REPORT Rashid KamalDocument18 pagesGEOLOGICAL REPORT Rashid Kamalabd ullahNo ratings yet

- Classification of Dimension StonesDocument3 pagesClassification of Dimension Stonesabd ullahNo ratings yet

- How Does A Magnet Work?: Mine 410 Mineral Processing IiDocument12 pagesHow Does A Magnet Work?: Mine 410 Mineral Processing Iiabd ullahNo ratings yet

- List of ML & PL 2021Document17 pagesList of ML & PL 2021abd ullahNo ratings yet

- FYP ProposalDocument4 pagesFYP Proposalabd ullahNo ratings yet

- How Does A Magnet Work?: Mine 410 Mineral Processing IiDocument12 pagesHow Does A Magnet Work?: Mine 410 Mineral Processing Iiabd ullahNo ratings yet

- Week 7 Flotation Circuits and MachinesDocument6 pagesWeek 7 Flotation Circuits and Machinesabd ullahNo ratings yet

- China Gezhouba Group Explosive Co ., LTD Guidebook For BlastersDocument31 pagesChina Gezhouba Group Explosive Co ., LTD Guidebook For Blastersabd ullahNo ratings yet

- China Gezhouba Group Explosive Co ., LTD Guidebook For BlastersDocument23 pagesChina Gezhouba Group Explosive Co ., LTD Guidebook For Blastersabd ullahNo ratings yet

- 03-Blasting Operation ProcessDocument27 pages03-Blasting Operation Processabd ullahNo ratings yet

- 04-Blasting Safety RulesDocument15 pages04-Blasting Safety Rulesabd ullahNo ratings yet

- Conduct of Examination RulesDocument15 pagesConduct of Examination Rulesabd ullahNo ratings yet

- Khyber Pakhtunkhwa Coal Mines Rules, 2020: Chapter-I PreliminaryDocument48 pagesKhyber Pakhtunkhwa Coal Mines Rules, 2020: Chapter-I Preliminaryabd ullahNo ratings yet

- As 3894.9-2003 Site Testing of Protective Coatings Determination of AdhesionDocument2 pagesAs 3894.9-2003 Site Testing of Protective Coatings Determination of AdhesionSAI Global - APAC67% (3)

- Bromobutyl Spec (BLAIR)Document1 pageBromobutyl Spec (BLAIR)proloy12No ratings yet

- Comprehending Pull-Off Adhesion TestingDocument5 pagesComprehending Pull-Off Adhesion Testingzavisa2No ratings yet

- Titanium Nitride Based Coatings On Implantable Medical Devices PDFDocument21 pagesTitanium Nitride Based Coatings On Implantable Medical Devices PDFDavid ToroNo ratings yet

- NPL MGPG No 26 - TackDocument26 pagesNPL MGPG No 26 - TackCentzon TotochtinNo ratings yet

- Concepts of Surface TensionDocument31 pagesConcepts of Surface TensionMartin AdriazolaNo ratings yet

- Plasmatreat ImagebrochureDocument28 pagesPlasmatreat ImagebrochurechibigarNo ratings yet

- Kruss Tn306 enDocument8 pagesKruss Tn306 enPlínio FurtatNo ratings yet

- 1.3.proteins, Platelets, and Blood Coagulation at Biomaterial, Xu (2014)Document54 pages1.3.proteins, Platelets, and Blood Coagulation at Biomaterial, Xu (2014)LUCERONo ratings yet

- Biology Notes: Chemical Principles: Properties of WaterDocument5 pagesBiology Notes: Chemical Principles: Properties of WaterMuhammad AkramNo ratings yet

- Dolly Preparation For Pull Out TestDocument6 pagesDolly Preparation For Pull Out TestLaughlikesiao HeheNo ratings yet

- Patent LeatherDocument10 pagesPatent LeathervinothjohnnashNo ratings yet

- Properties of WaterDocument23 pagesProperties of WaterJohnnardBelenNo ratings yet

- Technology Update No. 3: SSPC: The Society For Protective CoatingsDocument12 pagesTechnology Update No. 3: SSPC: The Society For Protective CoatingsachusanachuNo ratings yet

- Surface Tension and CapillarityDocument9 pagesSurface Tension and CapillarityBala Krishnan PNo ratings yet

- Kenaf FibreDocument10 pagesKenaf FibreIfkar AzmiNo ratings yet

- 3M Converter Markets GuideDocument104 pages3M Converter Markets GuideDaren NeradNo ratings yet

- Free Mastic G 316Document5 pagesFree Mastic G 316Kelly RobertsNo ratings yet

- Engine Bearing MaterialsDocument4 pagesEngine Bearing Materialspugazh MarinerNo ratings yet

- 288d6065-e116-45c1-8114-54e3ea6ee4f3Document13 pages288d6065-e116-45c1-8114-54e3ea6ee4f3Mostafa Hussein AbdouNo ratings yet

- NovamidID1030CF10 - Print Guideline Novamid ID 1030-CF10Document5 pagesNovamidID1030CF10 - Print Guideline Novamid ID 1030-CF10Vô ThườngNo ratings yet

- Hodam Barbara L1965Document164 pagesHodam Barbara L1965Rhison AsiaNo ratings yet

- Fibre Epoxy Composites at Low Temperature HartwigDocument9 pagesFibre Epoxy Composites at Low Temperature HartwigodormicchiNo ratings yet

- Hulin Li, Zhongwei Yin, Dan Jiang, Liyong Jin, Yuqing Cui: SciencedirectDocument11 pagesHulin Li, Zhongwei Yin, Dan Jiang, Liyong Jin, Yuqing Cui: SciencedirectAnnamalai PalaniappanNo ratings yet

- MSc. Thesis - P.D.cheyyarNageswaranDocument65 pagesMSc. Thesis - P.D.cheyyarNageswaranAbrahamIerNo ratings yet

- 5034 92Document5 pages5034 92Sulaiman Mohsin AbdulAzizNo ratings yet

- Aos Article 0260Document10 pagesAos Article 0260Bagis Emre GulNo ratings yet

- Henniker Plasma Surface Testing OverviewDocument7 pagesHenniker Plasma Surface Testing OverviewLenti TiborNo ratings yet