Professional Documents

Culture Documents

Service - Manual: BW 211 D-4 / PD-4 BW 213 D-4 / PD-4 BW 214 D-4

Service - Manual: BW 211 D-4 / PD-4 BW 213 D-4 / PD-4 BW 214 D-4

Uploaded by

Khalid MajorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service - Manual: BW 211 D-4 / PD-4 BW 213 D-4 / PD-4 BW 214 D-4

Service - Manual: BW 211 D-4 / PD-4 BW 213 D-4 / PD-4 BW 214 D-4

Uploaded by

Khalid MajorCopyright:

Available Formats

Service - Manual

m

co

BW 211 D-4 / PD-4

BW 213 D-4 / PD-4

s.

BW 214 D-4

og

S/N 101 583 09 ....> S/N 101 583 10 ....>

S/N 101 583 08 ....> S/N 101 583 13 ....>

l

S/N 101 583 42 ....> S/N 101 584 15 ....>

ta

ca

ep

Single drum roller

Catalogue number.

008 911 49 06/2012

ep

ca

ta

log

s.

co

m

Table of Contents

General 9

1.1 Introduction 10

1.2 Safety regulations 11

1.3 General repair instructions 16

1.4 Tightening torques 28

Technical data 33

2.1 Technical data 34

Maintenance 43

3.1 General notes on maintenance 44

3.2 Fuels and lubricants 45

3.3 Table of fuels and lubricants 48

3.4 Running-in instructions 49

m

Caddy wiring diagrams 51

4.1 Understanding circuit diagrams

co 52

4.2 Circuit symbols in the circuit diagram 57

4.3 Identification of switch blocks in the Caddy wiring diagram 58

4.4 Designation of components in the wiring diagram 59

s.

4.5 Terminal designations in wiring diagram 60

E-Plan wiring diagrams 63

og

5.1 Understanding wiring diagrams 64

5.2 Circuit symbols in the circuit diagram 73

5.3 Identification of switch blocks in the wiring diagram 76

l

5.4 Designation of components in the wiring diagram 77

ta

5.5 Terminal designations in wiring diagram 78

Electrics 81

ca

6.1 Battery ground and analog ground 82

6.2 Current and voltage 82

ep

6.3 Pulse Width Modulation (PWM) 85

6.4 Resistance 87

6.5 Series / parallel connection 89

6.6 Ohm's law 91

6.7 Electrical energy 91

6.8 Formula diagram 92

6.9 Metrology 93

6.10 Diodes, relays, fuses 97

6.11 Telemecanique switch 100

6.12 Plug connectors 102

6.13 Magnetic coil plug 102

6.14 Deutsch plug, series DT and DTM 104

6.15 Plugs and terminals in spring clamping technology 109

6.16 Acceleration transducer 113

6.17 Proximity switches 114

6.18 Level sensor in diesel tank (R03) 116

6.19 Differential pressure switch for hydraulic oil filter, B21 117

6.20 Oil pressure switch, B06 118

6.21 Air filter vacuum switch, B03 119

008 911 49 BOMAG 3

Table of Contents

6.22 Sensor, water in fuel filter, B124 120

6.23 Charge control light (H08), operating hour meter (P00) 121

6.24 Float switch, coolant tank, B55 122

6.25 Coolant temperature switch, B30 123

6.26 Disassembling and assembling the coolant temperature switch 124

6.27 Boost fuel solenoid valve 125

6.28 Engine solenoid to shit down the engine, Y13 126

6.29 Electric throttle control 129

6.30 Fuel preheating, R79 130

6.31 Heating flange on engine, R19 131

6.32 Checking the heating flange control 133

6.33 Engine monitoring 135

6.34 Batteries 139

6.35 Battery service 143

m

6.36 Main battery fuse 144

6.37 Starting with jump wires 144

6.38 Generator

co 145

6.39 Replacing the voltage regulator 154

6.40 Electric starter 156

s.

6.41 Disassembling and assembling the starter 161

6.42 Overview of electric components 163

og

6.43 Operator's stand, old design 179

6.44 Operator's stand, new design 181

6.45 Cabin 182

l

ta

6.46 Fuses, old design 183

6.47 Fuses, new design 184

ca

6.48 Electronic control units 185

6.49 Checking the voltage supply for the control unit 188

6.50 Diagnostics concept 196

ep

Electronic modules 199

7.1 BEM, BOMAG Evib-meter 201

7.2 Electrics module A68 265

7.3 Electric module K04 273

7.4 Electric module A72, old design 277

7.5 Electric module A108 283

Speedometer Module 287

8.1 Speedometer module 288

582 502 15 dust protection / 582 502 16 gasket 291

9.1 Assembling the dust protection 292

Hydraulics 297

10.1 Hydraulic circuit 298

10.2 Connection overview 300

10.3 Travel pump 075 302

10.4 Vibration pump 42R 041 306

10.5 Axial piston swash plate principle / pump 309

10.6 Troubleshooting axial piston pumps 311

10.7 Travel motor 51 C/D 110 314

4 BOMAG 008 911 49

Table of Contents

10.8 Trouble shooting, variable displacement axial piston motor 316

10.9 Drum drive motor MSE 02 318

10.10 Vibration motor A10FM 45 321

10.11 Axial piston swash plate principle / motor 322

10.12 External gear pumps 324

10.13 Travel circuit 326

10.14 Stopping the machine, operating the parking brake 330

10.15 Towing in case of an engine failure 330

10.16 Adjust the parking brake 332

10.17 Vibration circuit 333

10.18 Steering circuit 338

10.19 Check the hydraulic oil level 344

10.20 Changing hydraulic oil and breather filter 344

10.21 Changing the hydraulic oil filter 345

m

10.22 Changing the bypass filter 346

Tests and adjustments 347

co

11.1 Special tools, tests and adjustments 348

11.2 Checking the rotation speeds 352

11.3 Checking / adjusting the neutral positions of the travel pump 354

s.

11.4 Pressure tests in the travel circuit 356

11.5 Checking / adjusting the vibrator shaft speeds 358

og

11.6 Pressure measurements in the vibration circuit 359

11.7 Check the leakage rate of the vibration motor 360

l

11.8 Pressure test in steering circuit 361

ta

Flushing and bleeding 363

12.1 Special tools for flushing 364

ca

12.2 Flushing - general 369

12.3 Flushing schematic travel circuit (distribution travel pump) 371

12.4 Flushing the travel circuit (travel pump distribution) 373

ep

12.5 Flushing schematic travel circuit (distribution axle motor) 379

12.6 Flushing the travel circuit (axle motor distribution) 384

12.7 Flushing schematic for vibration drive 389

12.8 Flushing the vibration circuit 390

12.9 Bleeding the travel circuit 394

12.10 Bleeding the vibration circuit 396

Engine 399

13.1 Diesel engine 400

13.2 Fuel filter and check valve 408

13.3 Check, clean the water separator 411

13.4 Change the fuel pre-filter cartridge 411

13.5 Change the fuel filter cartridge 413

13.6 Changing engine oil and oil filter cartridges 413

13.7 Removing and installing the thermostat 415

13.8 Checking the thermostat in disassembled state 416

13.9 Change the coolant 417

13.10 Checking the anti-freeze concentration 418

13.11 Checking / replacing the ribbed V-belt 419

13.12 Combustion air filter service 420

008 911 49 BOMAG 5

Buy now

Bomag BW211/213/214 D-4/PD-4 Single Drum Roller PDF Manual

With Instant Download

You might also like

- Kubota Excavator: Workshop ManualDocument442 pagesKubota Excavator: Workshop Manual江宗朋No ratings yet

- Training BW145 D3Document117 pagesTraining BW145 D3megane1772100% (1)

- Bomag BMP8500Service Manual Complete - WatermarkDocument300 pagesBomag BMP8500Service Manual Complete - WatermarkGiovanni Cacciamani100% (1)

- Sample Exam Questions Behavioral FinanceDocument2 pagesSample Exam Questions Behavioral FinanceDorian Jaumotte100% (1)

- Mitsubishi Electric Engine Fuel Pump Replacement Procedure (Hcea)Document16 pagesMitsubishi Electric Engine Fuel Pump Replacement Procedure (Hcea)Jorge Rojas100% (1)

- SM-VOLVO L120E WHEEL LOADER Service Repair ManualDocument14 pagesSM-VOLVO L120E WHEEL LOADER Service Repair ManualSameh Mohamed100% (1)

- 914G Wheel Loader and Electrical System IT14G Intergrated ToolcarrierDocument2 pages914G Wheel Loader and Electrical System IT14G Intergrated ToolcarrierGilvan Junior100% (1)

- BW141 151 161 AC AD-4 Operation-MaintenanceDocument110 pagesBW141 151 161 AC AD-4 Operation-MaintenanceРуденко Роман100% (1)

- 18 T To 19 T Road Paver BF 691/BF 691 CDocument8 pages18 T To 19 T Road Paver BF 691/BF 691 CAliNo ratings yet

- 213D-4 Ra Eng 101583082400Document1,386 pages213D-4 Ra Eng 101583082400сергейNo ratings yet

- SM Bomag BW218 4dDocument1,446 pagesSM Bomag BW218 4dKevine Khaled100% (3)

- BW211D 4 Operation MaintenanceDocument102 pagesBW211D 4 Operation MaintenanceAlain Defoe100% (1)

- PC350-8 Troubleshooting of Hydraulic and Mechanical System (H-Mode) PDFDocument34 pagesPC350-8 Troubleshooting of Hydraulic and Mechanical System (H-Mode) PDFHai VanNo ratings yet

- Bomag BW213Document148 pagesBomag BW213edascribd80% (10)

- VOLVO ECR305C CatalogueDocument22 pagesVOLVO ECR305C CataloguePHÁT NGUYỄN THẾNo ratings yet

- Slipform Paver SP 150 / SP 250 / SP 500Document33 pagesSlipform Paver SP 150 / SP 250 / SP 500Edwin YucraNo ratings yet

- Cell Management (5G RAN2.1 - Draft A)Document35 pagesCell Management (5G RAN2.1 - Draft A)Mohammed Mokhtar100% (9)

- Bomag 211 - 213 - D4 - EN PDFDocument996 pagesBomag 211 - 213 - D4 - EN PDFJavier Castillo100% (2)

- Service Manual BF600CDocument782 pagesService Manual BF600Cshaheenikhtiyaralikhan100% (1)

- Bomag BW 161 AD-4, BW 202 AD-4 Tandem Rollers Service ManualDocument178 pagesBomag BW 161 AD-4, BW 202 AD-4 Tandem Rollers Service ManualAbdulmajid Abusitta100% (1)

- Tandem BW 141 BomagDocument4 pagesTandem BW 141 Bomagtemonggg0% (1)

- Standard Equipment Optional Equipment: Bucket Capacities 4.7 - 5.5 YdDocument4 pagesStandard Equipment Optional Equipment: Bucket Capacities 4.7 - 5.5 Ydtemonggg100% (2)

- Diagrama HD RM500Document16 pagesDiagrama HD RM500rafasel otubo guatiaNo ratings yet

- CatDocument7 pagesCathamda100% (1)

- Hitachi Zx330 3 Series Hydraulic ExcavatorDocument15 pagesHitachi Zx330 3 Series Hydraulic ExcavatorAgung Ardhana100% (1)

- D3G, D4G, D5G: Track-Type TractorsDocument20 pagesD3G, D4G, D5G: Track-Type TractorsDhee DoodzNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerAnsh MishraNo ratings yet

- Dynapac PaverDocument158 pagesDynapac PaverMamta Raybage100% (1)

- Bomag BW216D-4Document2 pagesBomag BW216D-4ibilge0% (1)

- Single DrumDocument12 pagesSingle DrumOmer AlansalNo ratings yet

- Bw 213 214 d3 Pd3 Ad3 Dh3 Pdh3 Англ.Document110 pagesBw 213 214 d3 Pd3 Ad3 Dh3 Pdh3 Англ.Danila1991No ratings yet

- Single Drum Soil Compactor: JCB 116DDocument2 pagesSingle Drum Soil Compactor: JCB 116DMuhammad ShofaNo ratings yet

- MX TRA 19003 E55W Control Valve KVSE72 en 09-09 RevBDocument37 pagesMX TRA 19003 E55W Control Valve KVSE72 en 09-09 RevBDani Setiawan100% (1)

- Dynapac Ca Rollers Workshop Manual Wheel Axle: Svedala Compaction and PavingDocument55 pagesDynapac Ca Rollers Workshop Manual Wheel Axle: Svedala Compaction and PavingMariê Ferreira Júnior100% (1)

- Komatsu Wa500-6 Wheel LoadersDocument16 pagesKomatsu Wa500-6 Wheel LoadersAbd Alkarem SalamhNo ratings yet

- Compaction EquipmentDocument63 pagesCompaction EquipmentSamuel Espartero50% (2)

- Engine & Attaching Parts (Engine Mounts) - MT55Document4 pagesEngine & Attaching Parts (Engine Mounts) - MT55Iliyan VasilevNo ratings yet

- Operating Instructions Maintenance Instructions: Catalogue NumberDocument89 pagesOperating Instructions Maintenance Instructions: Catalogue NumberThein Htoon lwin100% (1)

- Bomag Heavy Articulated Tandem Vibratory Rollers BW 161 & BW 190 (UK WebsiteDocument2 pagesBomag Heavy Articulated Tandem Vibratory Rollers BW 161 & BW 190 (UK WebsitesandycastleNo ratings yet

- Specalog CS533EDocument16 pagesSpecalog CS533Earfa ujianto100% (1)

- Electric BW202AD 4Document59 pagesElectric BW202AD 4LENIN100% (3)

- Fuel System C27Document7 pagesFuel System C27insano008No ratings yet

- 14HDocument2 pages14HWiliam Vega Farias100% (2)

- JS205LC NXTDocument15 pagesJS205LC NXTbakrimohNo ratings yet

- Dynapac Compactor ManualDocument33 pagesDynapac Compactor Manualmliugong100% (2)

- Bomag BW211D-40 BW211PD-40 Single Drum RollerDocument2 pagesBomag BW211D-40 BW211PD-40 Single Drum RollerEndra0% (1)

- Furukawa Breakers F-SeriesDocument3 pagesFurukawa Breakers F-SeriesmaarwaanNo ratings yet

- Sk200-8-Kobelco Paint ColorDocument4 pagesSk200-8-Kobelco Paint Colorfebru100% (1)

- Sakai SV521 - Spec 2019Document4 pagesSakai SV521 - Spec 2019Maz Ariez EkaNo ratings yet

- Bomag Bw211 D-40 Training ManualDocument1,364 pagesBomag Bw211 D-40 Training ManualmoamenNo ratings yet

- Volvo G940 Hydraulic Diagram - PDF Versión 1Document4 pagesVolvo G940 Hydraulic Diagram - PDF Versión 1José Lopez100% (2)

- Entire Group Ref. Note Part No. Part Name 137-0266-PRODUCT Valve Gp-Pilot CartridgeDocument2 pagesEntire Group Ref. Note Part No. Part Name 137-0266-PRODUCT Valve Gp-Pilot CartridgeLenin Gullapalli100% (1)

- Caterpillar 350 Hydraulic ExcavatorDocument4 pagesCaterpillar 350 Hydraulic ExcavatorAgus Budiluhur100% (1)

- Pc200-8 Valve ClearanceDocument3 pagesPc200-8 Valve ClearanceAl FurkhanNo ratings yet

- Furukawa Hydraulic Breakers FXJ Series PDFDocument2 pagesFurukawa Hydraulic Breakers FXJ Series PDFAndrew50% (2)

- Instructions For Repair: BW 180 ADDocument326 pagesInstructions For Repair: BW 180 ADEnzo Derrien100% (1)

- Caterpillar Excabadora 246d Diagrama HydraDocument11 pagesCaterpillar Excabadora 246d Diagrama Hydrahitler morales gavidia100% (1)

- Machine Identification 535-125 HiViz, 535-140 HiViz, 540-140, 540-170 (Engine JCB Tier 4i (DH SH SL) )Document12 pagesMachine Identification 535-125 HiViz, 535-140 HiViz, 540-140, 540-170 (Engine JCB Tier 4i (DH SH SL) )ניקולאי איןNo ratings yet

- 140H Transmission RepairDocument2 pages140H Transmission RepairHussein Sayed100% (2)

- Wa270 8Document16 pagesWa270 8jesus manuel arze carrascoNo ratings yet

- Tana Gseries Ho C110304enDocument65 pagesTana Gseries Ho C110304enNguyen Ngoc100% (1)

- Mic 770 V2 - DS (072523) 20230801132011Document3 pagesMic 770 V2 - DS (072523) 20230801132011Srijumpeno PenoNo ratings yet

- Hydraulic Pallet ClampDocument40 pagesHydraulic Pallet ClampYuri KarpovNo ratings yet

- TISS Empanelment FormDocument42 pagesTISS Empanelment FormRavindraNo ratings yet

- Jurist-Diction: Perbedaan Cyber Attack, Cybercrime, Dan Cyber WarfareDocument16 pagesJurist-Diction: Perbedaan Cyber Attack, Cybercrime, Dan Cyber Warfareteguh imam perdanaNo ratings yet

- OPCRF Ppt-HenryDocument23 pagesOPCRF Ppt-HenryRodel Agcaoili100% (1)

- The Future of ManageBac PDFDocument49 pagesThe Future of ManageBac PDFManageBacNo ratings yet

- ZKAccess3.5 Security System User Manual V3.0 PDFDocument97 pagesZKAccess3.5 Security System User Manual V3.0 PDFJean Marie Vianney Uwizeye100% (2)

- Nestle Sales: Product Groups Quantity (MT) Amount (' in Million) Quantity (MT) Amount (' in Million)Document4 pagesNestle Sales: Product Groups Quantity (MT) Amount (' in Million) Quantity (MT) Amount (' in Million)neha mundraNo ratings yet

- Usb Wifi UputstvoDocument11 pagesUsb Wifi UputstvoKOMPO TRANSNo ratings yet

- CHSD230 Math 1 Honors Module 4H SEDocument82 pagesCHSD230 Math 1 Honors Module 4H SEAngela LynnNo ratings yet

- Angrenaje Conice 2 PDFDocument19 pagesAngrenaje Conice 2 PDFpaula09No ratings yet

- The Principles of Scientific Management (PDFDrive)Document152 pagesThe Principles of Scientific Management (PDFDrive)Renato Sukno RojasNo ratings yet

- Industrial Filters PDFDocument14 pagesIndustrial Filters PDFSameera LakmalNo ratings yet

- Pedersen - Gem and Ornamental Materials of Organic OriginDocument283 pagesPedersen - Gem and Ornamental Materials of Organic OriginLeila MazzonNo ratings yet

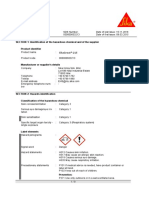

- Sika Grout 215Document9 pagesSika Grout 215Sri EkoNo ratings yet

- 단어시험 (Day 1~3)Document15 pages단어시험 (Day 1~3)qkrwldnjs0314No ratings yet

- Management Principles Developed by Henri FayolDocument1 pageManagement Principles Developed by Henri FayolMuthyala AkhilNo ratings yet

- HRM20016 Essay AssignmentDocument5 pagesHRM20016 Essay AssignmentLin QiNo ratings yet

- III 1 Electrification 1 28Document30 pagesIII 1 Electrification 1 28Kevin LampaanNo ratings yet

- GB Pant NewDocument18 pagesGB Pant NewEnergy EmissionNo ratings yet

- Rigid Pavement DesignDocument81 pagesRigid Pavement DesignKaustubh Kulkarni100% (1)

- Language and Linguistics Solved MCQs (Set-1)Document6 pagesLanguage and Linguistics Solved MCQs (Set-1)Rai Zia Ur RahmanNo ratings yet

- Dummy Block Lubrication Best PracticesDocument6 pagesDummy Block Lubrication Best PracticesLeonel Velasquez100% (1)

- The Stakeholder Analysis For SEA of Chinese Foreign Direct Investment The Case of One Belt One Road Initiative in PakistanDocument15 pagesThe Stakeholder Analysis For SEA of Chinese Foreign Direct Investment The Case of One Belt One Road Initiative in PakistanlalisangNo ratings yet

- Unit I IntroductionDocument138 pagesUnit I IntroductionSteffiNo ratings yet

- Rangkaian Doa RasulullahDocument22 pagesRangkaian Doa RasulullahPETUA PESONA UTTANUANo ratings yet

- Civil EngineeringDocument77 pagesCivil EngineeringRajput Ayush ThakurNo ratings yet

- Daily Irradiance Data: PVGIS-5 Geo-Temporal Irradiation DatabaseDocument1 pageDaily Irradiance Data: PVGIS-5 Geo-Temporal Irradiation DatabaseJasmina F.No ratings yet