Professional Documents

Culture Documents

Powertrac 4455 DX Tractor-T - 688-1194-2009

Powertrac 4455 DX Tractor-T - 688-1194-2009

Uploaded by

Suliman ZekriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Powertrac 4455 DX Tractor-T - 688-1194-2009

Powertrac 4455 DX Tractor-T - 688-1194-2009

Uploaded by

Suliman ZekriCopyright:

Available Formats

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 1

- Commercial (Initial)

Manufacturer : M/s. Escorts Limited,

Plot No. 2 & 3, Sector – 13

FARIDABAD – 121 007

HARYANA

Month: September Test Report No. T- 688/1194/2009 Year : 2009

GOVERNMENT OF INDIA

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE

TRACTOR NAGAR, BUDNI (MADHYA PRADESH) 466445, INDIA

E-mail: fmti-mp@nic.in

Web site: dacnet.nic.in/cfmtti

Telephone: 07564-234729 FAX: 07564-234743

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 2

- Commercial (Initial)

Type of Test : COMMERCIAL (INITIAL)

Test code/Procedure : IS: 5994-1998 (Reaffirmed in 2003)

IS: 9253-2001 and IS: 12207-2008

Period of Test : May, to August, 2009

Test Report No. : T- 688/1194/2009

Month/Year : September, 2009

i) The results reported in this report are observed values and no corrections have been

applied for atmospheric and site conditions.

ii) The data given in this report pertain to the particular machine submitted by the

applicant for test.

iii) The results presented in this report do not in any way attribute to the durability of the

machine.

iv) This report should not be reproduced in part or full without prior permission of the

Director, Central Farm Machinery Training and Testing Institute, Budni (M.P.).

SELECTED CONVERSIONS

S. No Units Conversion Factor

1 Force:

1 kgf 9.80665 N

2.20462 lbf

2 Power:

1 hp 1.01387 metric hp (Ps)

745.7 W

1 Ps 735.5 W

1 kW 1.35962 Ps

3 Pressure:

1 psi 6.895 kPa

2

1 kgf/cm 98.067 kPa = 735.56 mm of Hg

2

1 bar 100 kPa = 10 N/cm

1 mm of Hg 1.3332 m-bar

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 3

- Commercial (Initial)

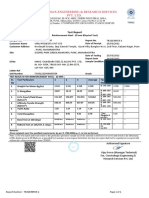

17. SUMMARY OF OBSERVATIONS, COMMENTS & RECOMMENDATIONS

17.1 Evaluative (mandatory) / Non-evaluation (Non-mandatory) parameters applicable for

qualifying Minimum Performance criteria as per Clause-4 (Table-1) of IS: 12207-2008 for

acceptance of the tractor for the purpose of subsidies/NABARD financing are

summarized as under:

S. No. Characteristic Category Requirements Values As Whether

(Evaluative / as per IS: 12207-2008 declared observed meets the

Non by the require-

Evaluative) applicant/ ments

Require- (Yes/No.)

ment

1 2 3 4 5 6 7

17.1.1 PTO Performance :

(a) - Max. power Evaluative Declared value to be

under 2 h test, achieved with a tolerance 31.6 32.5 Yes

(kW ) (Natural of: -5 / +10% for PTO

ambient power >35hp. –7.5/+10%

for PTO power 35 hp

condition)

(b) Power at rated Non 31.6 32.5

engine speed, Evaluative -do- Yes

(kW)

(c) Specific fuel Non

consumption Evaluative + 5% 265 265 Yes

corresponding to

maximum power,

(g/kWh)

(d) Maximum Non

equivalent Evaluative 8% 169.7 172.7 Yes

crankshaft

torque, (Nm)

(e) Back-up torque, Non 7 percent, min. -- 22.6 Yes

percent Evaluative

O

(f) Maximum operating temperature ( C)

1) Engine oil Non The declared value should

Evaluative not exceed the max. value 125 115 Yes

specified by the oil

company and the

observed value under

high ambient condition

should not exceed the

declaration.

2) Coolant Evaluative The declared value should

(water) not exceed the boiling 118 116 Yes

temperature of coolant

under the pressurized or

otherwise and the

observed value under

high ambient condition

should not exceed the

declaration.

1 2 3 4 5 6 7

(g) Engine oil Evaluative Not exceeding 1% of SFC

consumption, at max. power under High 2.67 0.77 Yes

ambient conditions

(g/kWh)

(h) Smoke level Evaluative Maximum light absorption

coefficient of 3.25 per 3.25 per 0.22 Yes

metre or equivalent metre

BOSCH No. 5.2 or 75

Hatridge value

(As per CMVR)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 4

- Commercial (Initial)

17.1.2 Drawbar performance :

(a) Max. drawbar pull Non Minimum 65% of static

with ballast Evaluative mass with ballast 15.97 20.66 Yes

corresponding to

15 percent wheel

slip, (kN)

(b) Max. drawbar pull Evaluative Minimum 65% of static

without ballast mass of tractor without 13.83 16.69 Yes

corresponding to ballast/ with standard

15 percent wheel ballast

slip, (kN)

(c) Maximum Evaluative Min. 80% of PTO Yes

drawbar power power as referred in 26.0 28.0

without ballast/ 17.1.1(a) of PTO

with standard performance

ballast, (kW).

(d) Max. transmission Non The declared value should Yes

oil temperature Evaluative not exceed the maximum 125 105

o value specified by oil

( C)

company

17.1.3 Power lift and hydraulic pump performance :

(a) Maximum lifting capacity throughout the range of lift, (kN):

1) At hitch Non [Tolerance of minus 13.72 16.26 Yes

points Evaluative 10%]

2) With the Evaluative The lift capacity should at

standard least be 18 kg/PTO hp.

frame and it should be 16

kg/engine hp where the 7.80 10.86 Yes

tractor is not provided with

a PTO shaft

(b) Maximum drop in Non

the height of the Evaluative [Tolerance of plus

point of 5 mm] 50 44 Yes

application of the

force after each 5

minutes interval

for a total duration

of 30 minute,

(mm)

17.1.4 Brake performance at 25 kmph:

(a) Maximum stopping distance at a force, equal to or less than 600 N on brake pedal with

ballast* (m):

1) Cold brake Evaluative 10 10 6.70 Yes

2) Hot brake Evaluative 10 10 7.30 Yes

(b) Maximum force Evaluative

exerted on the brake 600 600 300 Yes

pedal to achieve a

deceleration of 2.5 to

m/s2 (N) 345

*Ballast mass-as recommended for road work.

1 2 3 4 5 6 7

(c) Whether parking

brake is effective at a

force of 600 N at foot Evaluative Yes / No Yes Yes Yes

pedal(s) or 400 N at

hand lever

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 5

- Commercial (Initial)

17.1.5 Noise measurement :

(a) Maximum ambient

noise emitted by the Evaluative As per CMVR 88 85 Yes

tractor dB(A)

(b) Maximum noise at

operator’s ear level Evaluative As per CMVR 98 95 Yes

dB(A)

17.1.6 Amplitude of mechanical vibrations at :

1) Left foot rest 100 microns 100 90 Yes

(max)

Right food rest 100 230 No

Non

2) Seat (with driver Evaluative -do- 100 120 No

seated)

3) Steering wheel -do- 100 130 No

17.1.7 Haulage requirements :

(a) Gross mass of the trailers, (tones):

1) Two wheel Non -- 5.0 5.0 Yes

2) Four wheel Evaluative -- 6.0 6.0 Yes

(b) Distance travelled / litre of fuel consumption, (km/l):

1) Two wheel -- 5.0 to 6.5 6.30 to Yes

Non 6.54

2) Four wheel Evaluative -- 5.0 to 6.5 5.96 to Yes

6.01

(c) Fuel consumption (ml/km/tonne):

1) Two wheel -- 30 to 35 30.6 to Yes

Non 31.8

2) Four wheel Evaluative -- 30 to 35 27.7 to Yes

28.80

17.1.8 Wetland cultivation :

Sealing for the Evaluative The identified

following assemblies: assemblies should There should No ingress

1) Clutch -do- essentially meet the be no ingress of mud

requirement of IS: of water and/or and / or

assembly Yes

11082. No water mud water was

2) Brake housings -do- ingress in the observed

identified assembly

3) Front axle hubs -do- given in column-2.

If tractor does not

meet the

requirements of

wetland cultivation, it

may be

recommended for

dry land operation

only.

1 2 3 4 5 6 7

17.1.9 Safety features :

(a) Guards against Evaluative As per CMVR At present

no

moving and hot requirem-

Provided Yes

parts ents

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 6

- Commercial (Initial)

(b) Lighting Evaluative As per CMVR -- Provided Yes

arrangement

17.1.10 Labelling of tractors (Provision of labelling plate):

1) Make Evaluative -- Escorts Yes

Should conform to Limited

2) Model Evaluative the requirements -- Powertrac Yes

of CMVR along- 4455 DX

3) Year of Evaluative with declared -- 09-D-20 Yes

manufacture value

4) Engine number Evaluative of PTO HP -- E3096244 Yes

5) Chassis Evaluative -- B3087825 Yes

number

6) Declaration of Evaluative -- 31.62 Yes

PTO power,

(kW)

17.1.11 Discard limit for:

(a) Cylinder bore Evaluative To be specified by 91.3 91.00 to Yes

diameter, (mm) the manufacturer- 91.03

(b) Clearance between Non 0.134 to Yes

piston & cylinder Evaluative 0.45 0.151

liner at skirt, (mm)

(c) Ring end gap (mm):

- Top comp. ring. -do- 2.0 0.30 Yes

nd

- 2 comp. ring. Evaluative -do- 2.0 1.0 to 1.05 Yes

- Oil ring. -do- 2.0 0.30 Yes

(d) Ring groove clearance (mm):

- Top comp. ring. -do- 0.20 0.126 to Yes

0.128

nd

- 2 comp. ring. -do- 0.20 0.074 to Yes

Evaluative

0.085

- Oil ring. -do- 0.15 0.042 to Yes

0.056

(e) Clearance of main bearings (mm):

- Diametrical 0.40 0.070 to Yes

Evaluative -do-

clearance 0.094

- Crankshaft end 0.67 0.25 Yes

Evaluative

float

(f) Clearance of big end bearings, (mm):

- Diametrical 0.40 0.056 to Yes

Evaluative -do-

0.078

- Axial Evaluative -do- 0.60 0.35 Yes

(g) Clearance between 0.40 0.11 to Yes

Non

king pin and bush, -do- 0.17

Evaluative

(mm)

(h) Clearance between -do- 0.40 0.11 to Yes

Non

center pin and bush, 0.20

Evaluative

(mm)

1 2 3 4 5 6 7

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 7

- Commercial (Initial)

17.1.12 CATEGORY OF BREAKDOWNS / DEFECTS :

Category Whether

S. No. Characteristic (Evaluative / Requirements As observed meets the

Non as per IS: 12207-2008 require-

Evaluative) ments

(Yes/No.)

1. Critical No critical breakdown None Yes

Evaluative

2. Major Not more than two and neither of None Yes

them should be repetitive in

Evaluative nature

3. Minor Not more than five and One (Mn8) Yes

frequency of each should not be

Evaluative more than two.

4. Total In no case, the total number One Yes

breakdowns of breakdowns should exceed

Evaluative

five, that is, (2 major + 3

minor) or 5 minor breakdowns

17.2 Optional requirements as per Clause-4 (Table-2) of IS:12207-2008:

S. No. Characteristic Requirements As observed Remarks

as per IS: 12207-2008

1 2 3 4 5

1. Air cleaner oil pull over, 0.25% (max.) 0.11 Yes

max. oil pull over (%)

2. Seating requirements Should meet the requirements of IS: Does not meet No

12343-1998 the

requirement

3. Fitment of ROPS With a provision for fitment of Not provided No

ROPS.

If ROPS fitted it should meet the Not provided --

requirement of IS: 11821-1992

4. Technical requirements Should meet the requirements of IS: Meets the Yes

for PTO shaft 4931 -1995 requirements

5. Dimensions of three Should meet the requirements of IS: Does not meet No

point linkage 4468 (Part-I)-1997 the

requirement

6. Specifications of linkage Should meet the requirements of IS: Meets the Yes

drawbar 12953-1990. requirements

Specifications of Should meet the requirements of Not provided --

swinging drawbar IS:12362 Part 3-1994.

7. Accessories Trailer hitch, front tow hook, linkage Provided Yes

drawbar may be provided.

17.3 Conformity with following IS:

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 8

- Commercial (Initial)

i) Guide lines for declaration of power and specific fuel : Conforms

consumption and labelling of agricultural tractors (First

revision) [IS10273: 1987 (Reaffirmed 2004)]

ii) Agricultural tractors - Rear mounted power take-off - : Conforms

Types 1, 2 and 3 (third revision) [IS:4931-1995

(Reaffirmed 2004)]

iii) Agricultural wheeled tractors - Rear mounted three-

point linkage: Part 1 Categories 1, 2, 3 & 4 (fourth : Does not conform

revision) [IS 4468 (Part-I):1997/ ISO 730-1:1994

(Reaffirmed 2007)]

iv) Drawbar for agricultural tractors – Link type [IS : Conforms

12953:1990 (Reaffirmed 2007)]

v) Agricultural tractors - Operator’s seat technical

requirement [IS 12343 –1998 (First revision) (Reaffirmed : Does not conform

2003)]

vi) Guide for safety & comport of operator of agricultural : Does not conform

tractors: Part 1 General requirements (first revision):

[IS 12239 (PT-1) 1996/ISO 4254-1:1989 (Reaffirmed

2007)]

vii) Tractors and machinery for agriculture and forestry – : Does not conform

Technical means for ensuring safety Part 2: Tractors

(first revision) (IS 12239 (PT-2) 1999) (Reaffirmed

2004)]

viii) Guide lines for location and operation of operator : Does not conform

controls on agricultural tractors and machinery (first

revision) IS: 8133-1983 (Reaffirmed 2004)]

ix) Tractors and machinery for agriculture and forestry, : Conforms

powered lawn and garden equipment - Symbols for

operator controls and other displays Part 2 Symbols for

agricultural tractors and machinery [IS:6283 (Part-1)

(Reaffirmed 2004) and IS: 6283 (Part-2)-1998

(Reaffirmed 2003)]

x) Agricultural Tractors and Machinery - Lighting device for : Conforms

travel on public roads (IS: 14683-1999) (Reaffirmed

2004)]

17.4 Salient Observations:

17.4.1 Laboratory tests:

17.4.1.1 PTO Performance:

i) The backup torque is 22.6 %.

ii) The specific fuel consumption corresponding to maximum power was recorded

as 265 g/kWh, against the declaration of 265 g/kWh.

iii) The high pressure injector pipe of second injector (Part No. D10166160) was

cracked and replaced with new one. This is a premature breakdown and

categorized as minor and calls for corrective necessary action at production

level.

17.4.1.2 Drawbar performance :

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 9

- Commercial (Initial)

The manufacturer has recommended the rear axle ballast mass as 334 kg only for

ballasted drawbar performance test. With this ballast mass, the rear axle mass of the

tractor was recorded as 1745 kg & the drawbar performance test of tractor was

limited to the rear axle weight of tractor as 1745 kg.

17.4.1.3 Mechanical Vibration:

The amplitude of mechanical vibration on various assemblies marked as (*) in

Chapter-9 of this test report is on higher side, especially at the foot rest, operator’s

seat & steering control wheel. This calls for dampening down of vibrations to improve

the operational comfort and service life of components.

17.4.1.4 Three point linkage:

i) Width of ball of lower hitch point and the lateral distance from the lower hitch

point to centre line of tractor does not meet the requirements of IS: 4468 (Part-

I)-1997. This should be looked into for necessary corrective action.

ii) Some of the parameters of three point linkage conform to Cat.I and some of

them conform to Cat.II. In view of the spirit of standardization necessary

improvement may be incorporated.

17.4.1.5 Linkage drawbar:

Some of the parameters of linkage drawbar conform to Cat.I and some of them

conform to Cat.II. In view of the spirit of standardization, necessary improvement may

be incorporated.

17.4.1.6 Operator’s Seat:

Longitudinal distance from SIP to the centre of steering control wheel does not meet

the requirement of IS:12343-1998. This should be looked into for necessary

corrective action.

17.4.2 Field performance test:

17.4.2.2 Wetland cultivation (Puddling operation):

No ingress of mud/or water was noticed during puddling operation of the tractor.

Hence, It meets the requirements of IS:11082-1984 (Technical requirements of

agricultural tractors for wetland operation). Thus the tractor was found suitable for

wetland operation (Puddling).

17.5 Recommendation with regard to safety on tractor:

The following requirements, inter-alia, may be considered for incorporation on the

tractor:

i) Provision of safety against accidental start of engine.

ii) Provision of spark arresting device in exhaust system.

iii) The fuel shut-off knob does not remain in “STOP” position.

iv) Transport lock in hydraulic system for hydraulic three point linkage.

v) The working clearance between the position control, draft control & external

circuit levers may be provided as per IS: 12239 (Part-2) – 1999.

17.6 Maintenance / Service Problems:

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 10

- Commercial (Initial)

No noticeable maintenance or service problem was observed during the test.

17.7 Adequacy of Literature supplied with machine:

The following literature was supplied with test sample for reference during the test.

a) Draft copy of operating manual of Powertrac-4455 Tractor

b) Draft copy of repair manual of Powertrac-4455 DX Tractor

c) Draft copy of spare parts catalogue of Powertrac-4455 DX Tractor

The supplied literature was not found adequate and following information should be

re-examined & included in the literature.

i) Information related to PTO & Drawbar performance of the tractor such as,

maximum PTO power, rated power, power at standard PTO speed, maximum

torque, backup torque, specific fuel consumption, maximum drawbar power &

pull etc should be included.

ii) Information regarding leballing of tractor as per IS:10273-1987 (Reaffirmed

2004)] should be included.

iii) Recommended maximum ballasting of tractor.

iv) Size of recommended implements, grade of lubricating oil for engine, front &

rear wheel track width adjustment & available PTO speeds should be re-

examined and corrected.

v) The lubricating oil change period for gearbox, differential, final drive & hydraulic

system has been specified as “First change after 150 hours of operation

subsequently after every 850 hours of operation”. Whereas, this has been not

incorporated in printed literature. It is therefore recommended that, suitable

chart for periodically maintenance & recommended fuel, lubricants & their

change frequencies should be prepared and included in the operator

manual.

It is therefore recommended that, these literatures may be revised and brought out

as per IS: 8132-1999 (Reaffirmed in Oct.2004) for the guidance of users and service

personnel in national as well as regional languages.

TESTING AUTHORITY:

J.J.R. NARWARE

SENIOR AGRICULTURAL ENGINEER

V.N. KALE

DIRECTOR

Test Report compiled by: Shri Sanjay Kumar, Senior Technical Assistant.

dongre/sae(N)/final report 2009/escort powertrac 4455 dx(ict)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 11

- Commercial (Initial)

18. APPLICANT’S COMMENTS

Para No. Our Reference Applicant’s comments

18.1 17.2 (2),(3) Your valuable comments and suggestions for

improvements are well taken. Under our policy of

continuous product improvement this aspect is

being looked into and will try to incorporate

changes wherever necessary.

18.2 17.1.12 (3) Matter is under study and the corrective action will

be taken based on analysis if required.

18.3 17.3 (iii), (v), Under our policy of continuous product

(vi),(vii) & (viii) improvement this aspect is further being looked

into and improved design will be incorporated in

product very soon.

18.4 17.4.1.2 The manufacturer has declared that “the rear axle

maximum load carrying capacity is already for

above the maximum permissible tyre loading

capacity in order to safeguard our design from

static and dynamic loading both in field

and on road condition” vide their letter

No.ERC/BUDNI/PT-4455 DX-09 dated 24.09.2009

18.5 17.1.6(1),(2),(3) & Suggestions well-taken & corrective action will be

17.4.1.3 initiated accordingly. However a study to reduce

vibration is in progress with IIT & other Institutes.

18.6 17.4.1.4, 17.4.1.5 & Suggestions well-taken & corrective action will be

17.4.1.6 initiated accordingly. However as most of the

Indian customers are using implements fitted with

pins of bigger diameter, we need to provide with

balls suiting the pins of category II diameter.

18.7 17.5 Under our policy of continuous product

improvement this aspect is being looked into and

will try to incorporate changes.

18.8 17.7 Suggestions well-taken. Proper manuals will be

provided to customers during regular production

after incorporating the suggestions provided by

you.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 12

- Commercial (Initial)

ANNEXURE- I

BRIEF SPECIFICATION OF IMPLEMENTS USED DURING FIELD TEST

S.

Item Mould Board Plough Rotavator

No.

1. Make Field king Maschio, Itali

2. Type Mounted Mounted

3. No. of bottoms/blades Three 42, in 8 flanges

4. Type of bottoms/blades General purpose Hatchet

5. Size of bottoms/blades, (mm) 385 245 x 75 x 6

6. Spacing of bottoms/flanges, (mm) 280 245

7. Lower hitch point span, (mm) 785 735

8. Mast height, (mm) 510 470 & 510

9. Overall dimensions, (mm):

- Length 1920 1020

- Width 1040 1985

- Height 1180 1045

10. Gross mass, (kg) 345 440

ANNEXURE- II

BRIEF SPECIFICATION OF FULL CAGE WHEEL

S. No. Items Specification

1. Type Full cage wheel

2. Dia, (mm) 1280

3. Width, (mm) 850

24, straight lugs made up of MS-angle

4. No. and types of lugs

section welded to angle iron frame.

5. Size of angle section, (mm) 50 x 50 x 6

6. Length of lugs, (mm) 425

7. Spacing of lugs, (mm) 160

8. Weight of each cage wheels (kg) 145

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

T- 688/1194/2009 ESCORTS, POWERTRAC 4455 DX TRACTOR 13

- Commercial (Initial)

ANNEXURE- III

TRACTOR RUN HOURS DURING TEST

A. LABORATORY AND TRACK TESTS: HOURS

1. Running-in --

2. PTO performance test 12.5

3. Power lift and hydraulic pump performance test 2.1

4. Drawbar performance test 15.1

5. Turning ability 0.3

6. Location of centre of gravity --

7. Operator’s field of vision 0.1

8. Brake test 1.0

9. Noise measurement 1.5

10. Air cleaner oil-pull over test 3.5

11. Mechanical vibration test 1.0

12. Theoretical speed test 0.8

B. FIELD TEST:

1. Mould board plough 10.3

2. Rotavation 10.5

3. Puddling (including five hours water proof test) 15.6

C. HAULAGE TEST: 8.8

D. Miscellaneous test and other run hours including idle 2.3

run, transportation, trials and preparation for test

TOTAL: 85.4

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Vta28 G5 PDFDocument4 pagesVta28 G5 PDFJULIO67% (3)

- JD 5075 E ConfDocument4 pagesJD 5075 E Confkvsj2001No ratings yet

- JD 5075 E (Conf.)Document4 pagesJD 5075 E (Conf.)Subhasis MishraNo ratings yet

- fr6672 QSK78-G7 PDFDocument4 pagesfr6672 QSK78-G7 PDFacere18100% (1)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- TM 5-3800-205-23P Model 613CS and Model 613CWDDocument630 pagesTM 5-3800-205-23P Model 613CS and Model 613CWDAdvocateNo ratings yet

- Agrolux 50E Tractor - T-676-1182-2009 PDFDocument10 pagesAgrolux 50E Tractor - T-676-1182-2009 PDFPreet SinghNo ratings yet

- Kubota B 2420 Tractor - T-674-1180-2009Document11 pagesKubota B 2420 Tractor - T-674-1180-2009Sooraj Kannan, P.V.No ratings yet

- Mahindra 605 Di PS Tractor-T-954-1472-2015Document12 pagesMahindra 605 Di PS Tractor-T-954-1472-2015Prashant PatilNo ratings yet

- Swaraj 855 Fe Xtra Tractor - T - 852-1362-2012Document12 pagesSwaraj 855 Fe Xtra Tractor - T - 852-1362-2012Surajit SarkarNo ratings yet

- Deutz Fahr Agrolux 55e Test ReportDocument12 pagesDeutz Fahr Agrolux 55e Test ReportMamta RaybageNo ratings yet

- MahindraDocument13 pagesMahindraCvsiva Krishna ReddyNo ratings yet

- Swaraj 735 Fe Tractor - T - 768-1276-2011Document13 pagesSwaraj 735 Fe Tractor - T - 768-1276-2011Amit Chopra Amit0% (1)

- Mahindra 475 DI Tractor BUDNI TEST REPORTDocument15 pagesMahindra 475 DI Tractor BUDNI TEST REPORTShyam Katare0% (1)

- Sonalika International Di-47 RX Heavy Duty Tractor-T - 957-1475-2015Document13 pagesSonalika International Di-47 RX Heavy Duty Tractor-T - 957-1475-2015kishor thakareNo ratings yet

- Ace Di 450 NG Tractor-T - 941-1459-2014Document13 pagesAce Di 450 NG Tractor-T - 941-1459-2014Dipen patraNo ratings yet

- Kubota MU 4501 Tractor - T-1034-1559-2016 PDFDocument13 pagesKubota MU 4501 Tractor - T-1034-1559-2016 PDFSathish EnjapellyNo ratings yet

- Gromax Trackstar 540Document44 pagesGromax Trackstar 540Fred WilfNo ratings yet

- CAPTAIN250DITEINCOMPLETEAug 2020Document15 pagesCAPTAIN250DITEINCOMPLETEAug 2020billal toufik BendjimaNo ratings yet

- VST Shakti MT 270 Viraat 4WDDocument12 pagesVST Shakti MT 270 Viraat 4WDhugo fernandezNo ratings yet

- Preet 955 Challenger First Batch FTR May 2020Document50 pagesPreet 955 Challenger First Batch FTR May 2020waris babaNo ratings yet

- O Kolkf D Ijh (K.K Fjiksvz Lak ( K Ekg: Tafe LTD., MF 7250 Di Power Drive Power Steering TractorDocument54 pagesO Kolkf D Ijh (K.K Fjiksvz Lak ( K Ekg: Tafe LTD., MF 7250 Di Power Drive Power Steering TractorGourav AgarwalNo ratings yet

- Mahindra Arjun 555 DIDocument9 pagesMahindra Arjun 555 DIPrashant Patil0% (1)

- Sonalika International 35Document49 pagesSonalika International 35Massey FergusonNo ratings yet

- Technical Service Bulletin: Service Action: Inspection For Noise From Engine Under Specific Conditions (Sa 141)Document5 pagesTechnical Service Bulletin: Service Action: Inspection For Noise From Engine Under Specific Conditions (Sa 141)Diego Fabian Vega AlpizarNo ratings yet

- Massey Ferguson 241 TractorDocument51 pagesMassey Ferguson 241 TractorMassey FergusonNo ratings yet

- HKKJR LJDKJ D'F"K, Oka Fdlku Dy K.K Ea Ky D'F"K) LGDKFJRK, Oa Fdlku Dy K.K Fohkkx) E'Khuhdj.K, Oa Izks - KSFXDH IzhkkxDocument31 pagesHKKJR LJDKJ D'F"K, Oka Fdlku Dy K.K Ea Ky D'F"K) LGDKFJRK, Oa Fdlku Dy K.K Fohkkx) E'Khuhdj.K, Oa Izks - KSFXDH IzhkkxFred WilfNo ratings yet

- Constrologix Engineering & Research Services Pvt. LTD.: Test ReportDocument1 pageConstrologix Engineering & Research Services Pvt. LTD.: Test ReportPRASAD THOMBARENo ratings yet

- Mahindra 415 Di XP PlusDocument12 pagesMahindra 415 Di XP Plushugo fernandezNo ratings yet

- BHM60 Testwriteup BarhDocument5 pagesBHM60 Testwriteup BarhMohammad AtaullahNo ratings yet

- O Kolkf D Ijh (K.K Fjiksvz Lak ( K Ekg: Mahindra, Arjun 605 Di I TractorDocument12 pagesO Kolkf D Ijh (K.K Fjiksvz Lak ( K Ekg: Mahindra, Arjun 605 Di I Tractornagorao bachewarNo ratings yet

- Eicher 280 - Ict ReportDocument47 pagesEicher 280 - Ict Reportfarlight7028No ratings yet

- VST Shakti MT 270 Viraat Plus 4WDocument49 pagesVST Shakti MT 270 Viraat Plus 4Wbharath100% (1)

- FTR TEST REPORT OF MAHINDRA 605 DI I Aug 2020Document57 pagesFTR TEST REPORT OF MAHINDRA 605 DI I Aug 2020Mekh MitraNo ratings yet

- Data Sheet S12R PtaDocument13 pagesData Sheet S12R PtagondrayNo ratings yet

- G Ijh (K.K Fjiksvz RD Os/K GS: John Deere 5045D V2 TractorDocument7 pagesG Ijh (K.K Fjiksvz RD Os/K GS: John Deere 5045D V2 Tractormanne praveenNo ratings yet

- FR 6019700Document4 pagesFR 6019700halexNo ratings yet

- Data Sheet 4B-G2Document4 pagesData Sheet 4B-G2acere18No ratings yet

- Air Resources Board: New Off-RoadDocument2 pagesAir Resources Board: New Off-RoadDavid J SandersNo ratings yet

- Engine Performance Data at 1500 RPM: Chongqing Cummins Engine Company LTDDocument4 pagesEngine Performance Data at 1500 RPM: Chongqing Cummins Engine Company LTDMaryolisNo ratings yet

- 12 AirHeaterLeakage PDFDocument36 pages12 AirHeaterLeakage PDFIfani DwiRamadhanNo ratings yet

- X Series x13 g2 20jul09Document4 pagesX Series x13 g2 20jul09Laiq ZamanNo ratings yet

- Bid Document Bid DetailsDocument5 pagesBid Document Bid Detailskrishniel industriesNo ratings yet

- Engine DataSheetDocument4 pagesEngine DataSheetLinda ApriyantiNo ratings yet

- GeM Bidding 3802360Document5 pagesGeM Bidding 3802360MIHIR RANJANNo ratings yet

- Technical Specification - MGS-BC - 1500B - 2Document11 pagesTechnical Specification - MGS-BC - 1500B - 2DodongNo ratings yet

- KTA19-G8 Advantage Data Sheet: Emergency Standby Ratings For Application in Corporate Generator Sets OnlyDocument4 pagesKTA19-G8 Advantage Data Sheet: Emergency Standby Ratings For Application in Corporate Generator Sets OnlyDuc Thao VuNo ratings yet

- 872-Kirloskar Mega T-15 Batch TestDocument7 pages872-Kirloskar Mega T-15 Batch TestSelvakumarNo ratings yet

- 4bt g3Document4 pages4bt g3acere18No ratings yet

- Gromax Trakstar 545Document14 pagesGromax Trakstar 545Fred Wilf0% (1)

- Kubota MU 5501 Test ReportDocument50 pagesKubota MU 5501 Test ReportMamta RaybageNo ratings yet

- New Aps Commercial Test ReportDocument17 pagesNew Aps Commercial Test Reportprashanth mvNo ratings yet

- 25 kVA - 125 kVA Gas Generators & Gensets - Mahindra Powerol PDFDocument2 pages25 kVA - 125 kVA Gas Generators & Gensets - Mahindra Powerol PDFRajesh SamoraNo ratings yet

- Sabp G 006Document8 pagesSabp G 006Li PengNo ratings yet

- 6090HFC95 325HP 2200RPMDocument4 pages6090HFC95 325HP 2200RPMMarcelo FloresNo ratings yet

- 6CTA8.3-G2 DatasheetDocument4 pages6CTA8.3-G2 DatasheetVictor Ortega SamNo ratings yet

- Engine Performance Data at 1500 RPMDocument6 pagesEngine Performance Data at 1500 RPMaltogarNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Vaccum TankDocument58 pagesVaccum TankSaber ArfaouiNo ratings yet

- ROPS ThesisDocument6 pagesROPS ThesisashokkdesignNo ratings yet

- 850TM 880TM 810TM: Marshall MultispreadDocument23 pages850TM 880TM 810TM: Marshall Multispreadal110No ratings yet

- DAF Superstructures BodyBuilders - GuideDocument34 pagesDAF Superstructures BodyBuilders - GuideЮлия Дам100% (1)

- USAREUR PAM 30-60-1 Identification Guide Part Two Weapons and Equipment East European Communist Armies Volume II Soviet Trucks and Trailers (15 Feb 1974)Document266 pagesUSAREUR PAM 30-60-1 Identification Guide Part Two Weapons and Equipment East European Communist Armies Volume II Soviet Trucks and Trailers (15 Feb 1974)Paul D Carrier100% (2)

- Definitions Basic Tillage GoalsDocument16 pagesDefinitions Basic Tillage GoalsFelizardo GuiananNo ratings yet

- Replacement Parts ListDocument39 pagesReplacement Parts ListLuis Orlando Paez CubillosNo ratings yet

- AP 800d FolletoDocument12 pagesAP 800d FolletoeddyfredyNo ratings yet

- Agricultural-Statistics of Pakistan 2017-18 For WebDocument404 pagesAgricultural-Statistics of Pakistan 2017-18 For WebPASSCO HEAD OFFICENo ratings yet

- Mazone: Instruction Manual and Seed Rate Setting Chart For Seed DrillDocument132 pagesMazone: Instruction Manual and Seed Rate Setting Chart For Seed DrillMariusz MurawskiNo ratings yet

- Module-6-Agri - Crop-Production-Grade-10 For Student PDFDocument29 pagesModule-6-Agri - Crop-Production-Grade-10 For Student PDFRey Ian Tariga100% (1)

- Unigreen LASER-FUTURA - EXPO Series AT STD - TOP - AT BASE 44447Document40 pagesUnigreen LASER-FUTURA - EXPO Series AT STD - TOP - AT BASE 44447Gc KeyNo ratings yet

- SPV MCQ LMPDocument66 pagesSPV MCQ LMPNimesh HalaiNo ratings yet

- Applied Sciences: Fficiency of Agricultural Tractors ForDocument19 pagesApplied Sciences: Fficiency of Agricultural Tractors For29 - 023 - Abid HasanNo ratings yet

- Crankshaft Main BearingDocument4 pagesCrankshaft Main BearingSteven Y.MNo ratings yet

- KINZE 2000 - Do - 2004 - GodaDocument224 pagesKINZE 2000 - Do - 2004 - Godascynya77No ratings yet

- Manual Z562Document49 pagesManual Z562Tomas AurilaNo ratings yet

- Axion Profi PDF DataDocument73 pagesAxion Profi PDF DataAnonymous OFfJVrQY6No ratings yet

- Craftsman Tractor ManualDocument72 pagesCraftsman Tractor Manualbjhoxie106100% (1)

- Steals Deals Southeastern Edition 5-9-24Document12 pagesSteals Deals Southeastern Edition 5-9-24Felicia HolmesNo ratings yet

- Renault Trucks K Evolution Brochure - GmeDocument15 pagesRenault Trucks K Evolution Brochure - GmeHanna obeidNo ratings yet

- BLN 9885BDocument32 pagesBLN 9885Bseaqu3stNo ratings yet

- QuestionnaireDocument4 pagesQuestionnaireMa. Edcille MaataNo ratings yet

- Pithampur Company List: Designation Cmpany Name Contact No. Contact PersonDocument16 pagesPithampur Company List: Designation Cmpany Name Contact No. Contact PersonMuskan ThakurNo ratings yet

- Project On VST TillersDocument7 pagesProject On VST TillersrajeshthumsiNo ratings yet

- Westwood T1600 Éclaté PiècesDocument69 pagesWestwood T1600 Éclaté PiècesBenoît MARTINNo ratings yet

- Agrale 4233 Tractor Technical SpecificationsDocument2 pagesAgrale 4233 Tractor Technical Specificationsradostin radanovNo ratings yet

- ScaniaDocument28 pagesScaniaMurali Sambandan100% (1)

- March 31, 2015 Central Wisconsin ShopperDocument24 pagesMarch 31, 2015 Central Wisconsin ShoppercwmediaNo ratings yet