Professional Documents

Culture Documents

BS 1387: 1985/MS 863: 1983: Light, Medium and Heavy

BS 1387: 1985/MS 863: 1983: Light, Medium and Heavy

Uploaded by

HazimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS 1387: 1985/MS 863: 1983: Light, Medium and Heavy

BS 1387: 1985/MS 863: 1983: Light, Medium and Heavy

Uploaded by

HazimCopyright:

Available Formats

BS 1387 : 1985/MS 863 : 1983

LIGHT, MEDIUM AND HEAVY

Our Black and Galvanised pipes are produced to BS 1387 : 1985/MS 863 : 1983 / MANUFACTURER’S STANDARD on our precision electric-resistance-weld tube

mills, using prime quality steel.

(GENERAL INFORMATION ON BS 1387 : 1985/MS 863 : 1985 WELDED STEEL TUBE)

DESCRIPTIONS MIG-Maruichi BS 1387 : 1985 welded steel tube is produced in three thickness classes* - Light, Medium

and Heavy - and available in black finish or hot-dipped galvanised finish in 6 meter uniform mill lengths.

APPLICATIONS For ordinary conveyance of steam, gas, air, water, etc.

END FINISH AND PROTECTION Plain-end square-cut (PE) or threaded and fixed with coupling (T/C). PE tubes are chipped without any

protection on both ends. T/C tubes are supplied screwed with taper threads to BS 21 and fitted with one

parallel-threaded malleable iron socket, as required under this specification.

IDENTIFICATION MARKING Tubes are marked by colour bands about 50 mm wide, about 300 mm from each end, as follows :

Light Tubes - brown Medium Tubes - blue Heavy Tubes - red

PERTINENT EXCERPTS FROM BS 1387 : 1985/MS 863 : 1983 SPECIFICATION

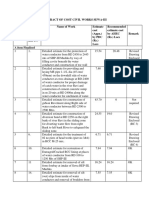

CHEMICAL COMPOSITION The chemical composition of the steel, by ladle analysis, shall comply with the table below :

C max. Mn max. P max. S max.

0.20% 1.20% 0.045% 0.045%

MECHANICAL PROPERTIES The mechanical properties at room temperature shall be as given in the table below :

Tensile strength (N/mm2) : 320 to 460

Elongation on gauge length Lo = 5.65 √So(%) : 20% min

Yield strength (N/mm2) : 195 min

TOLERANCES ON Outside Diameter : As shown in Tables on pages 10 and 11.

DIMENSIONS AND MASS Wall thickness : Light tubes - 8%

Medium and heavy tubes - 10%

Mass : The mean consignment mass for quantities of 150 m and over of one size shall not

deviate by more than ±4% from the mass of consignment calculated from the mass

9

given in Tables on pages 10 and 11 as appropriate. No single tube shall deviate by more

than +10%, -8% from the mass given in Tables on pages 10 and 11 as appropriate.

HOT-DIP ZINC COATING TEST (IF REQUIRED) After the four successive one-minute immersions in the copper-sulphate solution, the test sample shall not

show any adherent red deposit of metallic copper.

BEND TEST Black tubes up to and including DN 50 shall be bent cold without any sign of fracture or failure, through 180˚

round a former having a radius at the bottom of the groove equal to six times the outside diameter of the

tube as given in Tables on pages 10 and 11. Hot-dip zinc coated tubes shall be bent cold without cracking

of the steel, through 90˚ round a former having a radius at the bottom of the groove equal to eight times the

outside diameter of the tube.

FLATTENING TEST The flattening test applies to tubes greater than DN 50.

A ring not less than 40 mm in length taken from one end of each selected tube shall be flattened cold between

parallel flat platens without showing either crack or flaw until the distance between the platens, measured

under load, is not greater than 75% of the original outside diameter of the tube, and no cracks or flaws in metal

elsewhere than in the weld shall occur until the distance between the platens is less than 60% of original

diameter. The weld shall be placed at 90˚ to the direction of flattening.

LEAK TIGHTNESS TEST The test shall be either a hydraulic test at a pressure of 50 bar (50 X 105 N/M2), or alternatively, an eddy

current test.

BORE TEST FOR HOT-DIP COATED TUBES Hot-dip zinc coated tubes up to and including DN 25 shall have a rod 230 mm in length, of the appropriate

diameter specified below, passed through them and shall have a free bore.

Rod Diameter

Nominal size (DN) Diameter of rod (mm)

15 9.5

20 14.3

25 20.6

(*Special tubes sizes not stipulated in the BS specification may be made available upon request. Please feel free to enquire)

You might also like

- 2018 End of Term 1 Test Computer Studies Grade 8Document6 pages2018 End of Term 1 Test Computer Studies Grade 8Tahpehs Phiri76% (17)

- Warren Truss Bridge ReportDocument12 pagesWarren Truss Bridge ReportRaaj Chatterjee50% (2)

- StandardDocument3 pagesStandardAnonymous m4MF1gNo ratings yet

- Pipe DesignDocument6 pagesPipe DesignmaneeshmsanjagiriNo ratings yet

- Tube To Tube SheetDocument59 pagesTube To Tube Sheet0101100175% (12)

- ALS-R User's Manual: Amplified Spontaneous Emission Light SourceDocument16 pagesALS-R User's Manual: Amplified Spontaneous Emission Light SourceAnonymous 60esBJZIjNo ratings yet

- MasterPlay User GuideDocument29 pagesMasterPlay User GuideArul Patmose ParamanathanNo ratings yet

- Piping Components & Their Uses: PipeDocument3 pagesPiping Components & Their Uses: PipeParameswararao BillaNo ratings yet

- Aa10152 1518422251Document4 pagesAa10152 1518422251ARINDAM SETTNo ratings yet

- PED AssignmentProblems 2017 PDFDocument10 pagesPED AssignmentProblems 2017 PDFSwapnil GudmalwarNo ratings yet

- UntitledDocument3 pagesUntitledalexander quinterosNo ratings yet

- Pipe Specification A135Document1 pagePipe Specification A135Waseem Abbas AttariNo ratings yet

- Pipe Specification A135Document1 pagePipe Specification A135Rakesh PrabuNo ratings yet

- Astm A 53 BDocument4 pagesAstm A 53 BLauren BowenNo ratings yet

- Standard HFRW PDFDocument3 pagesStandard HFRW PDFGuidoColomboNo ratings yet

- Astm A557 A557mDocument3 pagesAstm A557 A557mارفع راسك فوق انت يمنيNo ratings yet

- Spiralco - Specifications - ASTM A-139Document4 pagesSpiralco - Specifications - ASTM A-139Özgür TuştaşNo ratings yet

- Super DuplexDocument6 pagesSuper DuplexMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Si. No DSR No. Description Unit Quantity Rate Amount Supply Installation & Commossioning of Fire Hydrant and Sprinkler System at ESIC Hospital PeenyaDocument3 pagesSi. No DSR No. Description Unit Quantity Rate Amount Supply Installation & Commossioning of Fire Hydrant and Sprinkler System at ESIC Hospital PeenyaSameena ShaikhNo ratings yet

- Tube FittingsDocument20 pagesTube FittingsMallesh KaruparthyNo ratings yet

- Astm A556 A556mDocument3 pagesAstm A556 A556macount checkNo ratings yet

- Pipeline DesignDocument42 pagesPipeline Designaydinjalali100% (4)

- Seamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Document8 pagesSeamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00refeiNo ratings yet

- ThyssenKrupp - XABO 500Document3 pagesThyssenKrupp - XABO 500Yesid Javier Martelo EllesNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Swagelok Tubing SpecificationsDocument8 pagesSwagelok Tubing SpecificationsAugustine Owo UkpongNo ratings yet

- AE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksDocument6 pagesAE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksQualityNo ratings yet

- Thermite WeldingDocument6 pagesThermite WeldingrachedNo ratings yet

- InstrumentationFittingsCat PDFDocument48 pagesInstrumentationFittingsCat PDFChowdhury FatemaNo ratings yet

- Thermowell General SpecsDocument3 pagesThermowell General SpecsEsakkirajaNo ratings yet

- Comparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Document17 pagesComparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Anonymous gr5Pr9AVNo ratings yet

- Eti Ohe 11 5 89Document12 pagesEti Ohe 11 5 89Abhishek PandeyNo ratings yet

- Çeşitli Standartlar Için Kaynaklar Arası Mesafeler (İngilizce)Document1 pageÇeşitli Standartlar Için Kaynaklar Arası Mesafeler (İngilizce)MustafaSaylavNo ratings yet

- Data Sheet SS316L Seamless Tube Fluidline CustomerDocument2 pagesData Sheet SS316L Seamless Tube Fluidline Customerinstrument.engineer.123No ratings yet

- 06c PDFDocument29 pages06c PDFProcess EngineerNo ratings yet

- Instrument TubingDocument11 pagesInstrument Tubingbab_ooNo ratings yet

- SubmittalSheetRevised A53Standard PDFDocument1 pageSubmittalSheetRevised A53Standard PDFnacho_rNo ratings yet

- Jeppesen Fluid Lines and FittingsDocument53 pagesJeppesen Fluid Lines and FittingsMarlou DyNo ratings yet

- Dimensionare Bare CupruDocument5 pagesDimensionare Bare CupruAnne KelleyNo ratings yet

- Barras de CobreDocument5 pagesBarras de Cobrenicolasgimenez1984No ratings yet

- Welded Precision Steel Tubes Technical Information RoundDocument1 pageWelded Precision Steel Tubes Technical Information RoundsalimmalmaliNo ratings yet

- Butting Seamless or WeldedDocument4 pagesButting Seamless or Weldedkhanz88_rulz1039No ratings yet

- API NotesDocument4 pagesAPI NotesMohammad RizwanNo ratings yet

- TRITORC для сервиса теплообменников и бойлеров - ENDocument84 pagesTRITORC для сервиса теплообменников и бойлеров - ENjason forsythNo ratings yet

- S355MLDocument2 pagesS355MLMohammed ShamilNo ratings yet

- Unit2B SSDocument8 pagesUnit2B SSRahul YadavNo ratings yet

- 32 - Seamless EO Steel Tubes Material E235N (St. 37.4)Document6 pages32 - Seamless EO Steel Tubes Material E235N (St. 37.4)samohaomer001No ratings yet

- A106 Pipe SpecificationsDocument3 pagesA106 Pipe Specificationspundir_vineet100% (1)

- Technical Manual: Couple With ConfidenceDocument16 pagesTechnical Manual: Couple With Confidencescribd99190No ratings yet

- Specification For Acmv PipingDocument5 pagesSpecification For Acmv PipingcashloverNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- Matrl CS P355NL1 PDFDocument2 pagesMatrl CS P355NL1 PDFbramantiya100% (1)

- T000003407 - FileName1 - 6079A-B-590-006 Vol-2Document32 pagesT000003407 - FileName1 - 6079A-B-590-006 Vol-2kanchanabalajiNo ratings yet

- Padrões de Resposta Padrões de Resposta: Questão 1 (Valor: 10,0 Pontos)Document22 pagesPadrões de Resposta Padrões de Resposta: Questão 1 (Valor: 10,0 Pontos)carlofilippinNo ratings yet

- Stress Analysis Methods For Underground Pipe Lines Part 1 - Basic CalculationsDocument5 pagesStress Analysis Methods For Underground Pipe Lines Part 1 - Basic Calculationskumaran__k100% (4)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Backbeat Go 2 Charging Case Ug enDocument16 pagesBackbeat Go 2 Charging Case Ug enHazimNo ratings yet

- Axial and Pressure Thrust Stiffness of Metal Bellows For Vibration IsolatorsDocument5 pagesAxial and Pressure Thrust Stiffness of Metal Bellows For Vibration IsolatorsHazimNo ratings yet

- Stress Analysis of GRP - GRE - FRP Piping System Using Caesar II - What Is PipingDocument23 pagesStress Analysis of GRP - GRE - FRP Piping System Using Caesar II - What Is PipingHazimNo ratings yet

- Field and Range of Inspection Regulations, Standards, Specifications and Inspection ProceduresDocument5 pagesField and Range of Inspection Regulations, Standards, Specifications and Inspection ProceduresHazimNo ratings yet

- Woodenstavepipeb 00 RedwrichDocument76 pagesWoodenstavepipeb 00 RedwrichHazimNo ratings yet

- Uniqlo Polo Collar Stripe Made in China Condition 9/10 Tage L Manual Panjang 29" Manual Pit To Pit 21"Document1 pageUniqlo Polo Collar Stripe Made in China Condition 9/10 Tage L Manual Panjang 29" Manual Pit To Pit 21"HazimNo ratings yet

- Owner'S Manual: Air CoolerDocument7 pagesOwner'S Manual: Air CoolerHazimNo ratings yet

- Suzuki Tuning GuideDocument7 pagesSuzuki Tuning GuideHazimNo ratings yet

- Lexicology: - Structure of The LexiconDocument16 pagesLexicology: - Structure of The LexiconAdina MirunaNo ratings yet

- MQP Keys Mbf106Document18 pagesMQP Keys Mbf106Rajeev DayalNo ratings yet

- Value of G at Different Locations On EarthDocument4 pagesValue of G at Different Locations On EarthDannyRaoNo ratings yet

- Stock April 2020Document5 pagesStock April 2020roby aldiNo ratings yet

- Module in ED 101-Child and Adolescent Learners and Learning PrinciplesDocument54 pagesModule in ED 101-Child and Adolescent Learners and Learning PrinciplesCassy Casey100% (3)

- What Is A Clone?Document6 pagesWhat Is A Clone?Mohamed Tayeb SELTNo ratings yet

- Four Japanese Brainstorming Techniques A-Small-LabDocument7 pagesFour Japanese Brainstorming Techniques A-Small-LabChris BerthelsenNo ratings yet

- Prof Ed 104 SG 5Document27 pagesProf Ed 104 SG 5smileydaintyNo ratings yet

- SuperstitionsDocument5 pagesSuperstitionssina badz100% (1)

- Abstract of Cost Civil Works SewaDocument3 pagesAbstract of Cost Civil Works SewaPrabhat MicNo ratings yet

- Collins - 2005 - The Concept of Stored Plastic Work or Frozen Elastic Energy in Soil MechanicsDocument10 pagesCollins - 2005 - The Concept of Stored Plastic Work or Frozen Elastic Energy in Soil MechanicsHUGINo ratings yet

- Assignment 2 - EconometricsDocument7 pagesAssignment 2 - EconometricsFatlinda Kuqi SulejmaniNo ratings yet

- Delta Ia-Plc DVP-PLC PM en 20140804Document749 pagesDelta Ia-Plc DVP-PLC PM en 20140804Ali PadaryamNo ratings yet

- June 2022 (R) MSDocument23 pagesJune 2022 (R) MSNajmul AktherNo ratings yet

- Piping General Arrangement Cooling Tower Water System AreaDocument1 pagePiping General Arrangement Cooling Tower Water System AreaajmainNo ratings yet

- FGD Vs CompetitorCustomer - Final - LF14000NN & P559000Document9 pagesFGD Vs CompetitorCustomer - Final - LF14000NN & P559000munhNo ratings yet

- Sizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONDocument31 pagesSizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONHai PhanNo ratings yet

- Naskah DramaDocument14 pagesNaskah Dramaalfia hafizahNo ratings yet

- Lines On A Chart Joining Places of Equal Grivation Are Named IsogrivsDocument5 pagesLines On A Chart Joining Places of Equal Grivation Are Named IsogrivsFirdaus92No ratings yet

- Chapter 2 Empiricism and PositivismDocument15 pagesChapter 2 Empiricism and PositivismJames RayNo ratings yet

- 2 Logic Design For 4-Bit ComparatorDocument6 pages2 Logic Design For 4-Bit Comparatoramta1No ratings yet

- Contaminated Land Management and Control Guidelines No. 2: Assessing and Reporting Contaminated SitesDocument48 pagesContaminated Land Management and Control Guidelines No. 2: Assessing and Reporting Contaminated SitesGloria YongNo ratings yet

- Ch. 3 NumericalsDocument29 pagesCh. 3 NumericalsMriduNo ratings yet

- Colgate Annual Report 2020 21Document164 pagesColgate Annual Report 2020 21Sanjay RainaNo ratings yet

- Armor X 3C XHHW-2 Power 3GND 600V 2017 - CCDocument2 pagesArmor X 3C XHHW-2 Power 3GND 600V 2017 - CCpglv0210No ratings yet

- Performace Task No. 1 PrelimDocument2 pagesPerformace Task No. 1 PrelimAlyanna MagkalasNo ratings yet