Professional Documents

Culture Documents

Stainless Steel Clamp Union Din 32676

Stainless Steel Clamp Union Din 32676

Uploaded by

Sándor PetrovicsCopyright:

Available Formats

You might also like

- Potassium TrihydrateDocument5 pagesPotassium TrihydrateTeresa Davis60% (15)

- Fire Safety NotesDocument13 pagesFire Safety Notesrescueone93% (14)

- Sample Vessel 3 96 Horizontal Vessel PreDocument24 pagesSample Vessel 3 96 Horizontal Vessel PresoloNo ratings yet

- Document 1Document13 pagesDocument 1Prince SharmaNo ratings yet

- C2quick PDFDocument34 pagesC2quick PDFJose Maria PedrazasNo ratings yet

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- DIN 11864-3/DIN 11853-3 Aseptic Clamp Unions For DIN 11866/11850 Table ADocument7 pagesDIN 11864-3/DIN 11853-3 Aseptic Clamp Unions For DIN 11866/11850 Table ADinh Nguyen DaoNo ratings yet

- FO-PC-001 Job Safety Analysis FormDocument92 pagesFO-PC-001 Job Safety Analysis FormRoshanie HoseinNo ratings yet

- LT Valves Knife Gate ValvesDocument2 pagesLT Valves Knife Gate Valvesdevang asherNo ratings yet

- Indian & International STDDocument8 pagesIndian & International STDMirza Sameer Ali BaigNo ratings yet

- WEP Standard For Reference OnlyDocument37 pagesWEP Standard For Reference OnlyKiran NikateNo ratings yet

- !indx PipDocument18 pages!indx PipCharles JacobNo ratings yet

- P 0200 152 LHS 01Document2 pagesP 0200 152 LHS 01Zaidi100% (1)

- Erection Proc of FRPDocument10 pagesErection Proc of FRPHalim IrhamiNo ratings yet

- Butterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentDocument9 pagesButterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentVinay SharmaNo ratings yet

- Flat End With A Full-Face Gasket For A Pair of OpeningsDocument3 pagesFlat End With A Full-Face Gasket For A Pair of OpeningsEng-CalculationsNo ratings yet

- AWWADocument10 pagesAWWARostarina AnggrainiNo ratings yet

- Is 14845-2000 (Air Relief Valves) PDFDocument18 pagesIs 14845-2000 (Air Relief Valves) PDFSarbendu PaulNo ratings yet

- 10.flange Bolts, STD TeesDocument7 pages10.flange Bolts, STD TeesNIRMAL SINGHNo ratings yet

- ISO 15348 2002 Metal Bellows Expansion Joints PDFDocument8 pagesISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezNo ratings yet

- Low-Pressure Hoselines SN 544: Double Nipple Welding NippleDocument2 pagesLow-Pressure Hoselines SN 544: Double Nipple Welding NippleNaveen Kumar Chauhan100% (1)

- Slurry Settling Velocity According JRIDocument8 pagesSlurry Settling Velocity According JRIChristopher LloydNo ratings yet

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- HB D KomplettDocument181 pagesHB D KomplettGabriel BourguignonNo ratings yet

- Indian Minerals Yearbook 2019: 58 EditionDocument33 pagesIndian Minerals Yearbook 2019: 58 EditionmodoyioNo ratings yet

- KTM - Eb11 Eb12 Eb21 Eb22Document12 pagesKTM - Eb11 Eb12 Eb21 Eb22psycloneses100% (1)

- Reactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralDocument1 pageReactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralAndrés SepúlvedaNo ratings yet

- DIN StandardDocument2 pagesDIN StandardViiee Chauhaan33% (3)

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Swagelok Needle ValvesDocument12 pagesSwagelok Needle Valvesnegg 348No ratings yet

- HDPE-MaterialData 78281Document2 pagesHDPE-MaterialData 78281tayyabmubarik2417No ratings yet

- Ghibson GB015Document2 pagesGhibson GB015Jessicalba LouNo ratings yet

- Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesDocument5 pagesContact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesJosé Luis Sierra100% (1)

- Brighton Spec ASME 80-10 2017 PDFDocument1 pageBrighton Spec ASME 80-10 2017 PDFSuhas JadhavNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Autodesk Feature CodesDocument14 pagesAutodesk Feature Codessplaw9484No ratings yet

- Bolt Length CalculationDocument1 pageBolt Length Calculationridho ziskaNo ratings yet

- Spe 170951 MSDocument13 pagesSpe 170951 MStyokNo ratings yet

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 pagesUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNo ratings yet

- Fig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsDocument1 pageFig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsRobertgomezNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Regulatory Guide 1.90Document23 pagesRegulatory Guide 1.90Luis Juan Trejo CruzNo ratings yet

- Technical Data Sheet: Behavior, Innovation, Responsibility, Learning, EnthusiasmDocument3 pagesTechnical Data Sheet: Behavior, Innovation, Responsibility, Learning, EnthusiasmHuber AlvaradoNo ratings yet

- Awwa C207 2018Document40 pagesAwwa C207 2018JacobUnda100% (1)

- Elastic Properties of PotatoDocument5 pagesElastic Properties of Potatopriya07rajNo ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- Sferova API6 Ball Valve CatalogueDocument27 pagesSferova API6 Ball Valve CatalogueWong JowoNo ratings yet

- 1.5 APS Powder Insert: Parts List PL 41001 EN 13Document18 pages1.5 APS Powder Insert: Parts List PL 41001 EN 13Alexandre VecaNo ratings yet

- Iso 15552 2004 en PDFDocument8 pagesIso 15552 2004 en PDFashokkumarNo ratings yet

- EN10255 Pipe SizeDocument3 pagesEN10255 Pipe SizeStefan CristescuNo ratings yet

- Senior Design Engineer For Static Equipment With 13 Years of ExperienceDocument7 pagesSenior Design Engineer For Static Equipment With 13 Years of ExperienceTushar MangratiNo ratings yet

- Data Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerDocument1 pageData Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerAnonymous 0OizFXUONo ratings yet

- Client: Contract: Job / Project TitleDocument5 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- 8-1280-13 Pipe Class HF-1Document4 pages8-1280-13 Pipe Class HF-1Jesus MendezNo ratings yet

- Psi Flange KitsDocument8 pagesPsi Flange Kitsdianudin safarudinNo ratings yet

- IMIOrton MV SeriesDocument4 pagesIMIOrton MV SeriesFelipe Gamboa GálvezNo ratings yet

- BP209 VIS - M Manual PDFDocument174 pagesBP209 VIS - M Manual PDFReena SharmaNo ratings yet

- Tri Clamp PDFDocument6 pagesTri Clamp PDFLeandro SantosNo ratings yet

- Heco Product Sheet 2207 Stainless Steel Plate Flanges DIN EN PN 10Document4 pagesHeco Product Sheet 2207 Stainless Steel Plate Flanges DIN EN PN 10hafiz ashidqiNo ratings yet

- Advantages of Axial Expansion Joints Application AreasDocument5 pagesAdvantages of Axial Expansion Joints Application AreasprabowopuguhNo ratings yet

- Door Controller: Innovative and PowerfulDocument2 pagesDoor Controller: Innovative and PowerfulSándor PetrovicsNo ratings yet

- DS Starter Exp Kits 1627 EN LDocument2 pagesDS Starter Exp Kits 1627 EN LSándor PetrovicsNo ratings yet

- Biztonsági SzelepDocument2 pagesBiztonsági SzelepSándor PetrovicsNo ratings yet

- 7301 EngDocument4 pages7301 EngSándor PetrovicsNo ratings yet

- Prominent Equipment Catalogue PDFDocument684 pagesProminent Equipment Catalogue PDFSándor PetrovicsNo ratings yet

- First FerreroDocument1 pageFirst FerreroSándor PetrovicsNo ratings yet

- Time Table Chandigarh Campus-6Document2 pagesTime Table Chandigarh Campus-6upma gargNo ratings yet

- Take Home Pack Gr. 7 Natural Sciences T3Document21 pagesTake Home Pack Gr. 7 Natural Sciences T3debbiemotlatle22No ratings yet

- Trembesi SkriningDocument8 pagesTrembesi Skriningemadayanti65No ratings yet

- Assignment 1Document6 pagesAssignment 1Menna TantawiNo ratings yet

- Phase DiagramsDocument3 pagesPhase DiagramsSimon VladNo ratings yet

- Water Comfort: A Complete Range of Hot Water SolutionsDocument4 pagesWater Comfort: A Complete Range of Hot Water SolutionsRidwan PramudyaNo ratings yet

- A Method To Test The Detectability of GC PFPD ForDocument8 pagesA Method To Test The Detectability of GC PFPD ForMarian Si Teofana HasnaNo ratings yet

- Emflon PFR Sterilizing-Grade Filter Cartridge For Gas and VentDocument2 pagesEmflon PFR Sterilizing-Grade Filter Cartridge For Gas and VentTruong Anh TuanNo ratings yet

- Subject ChemistryDocument13 pagesSubject ChemistryWinki MansonNo ratings yet

- Acid-Base Equilibria: Insert Picture From First Page of ChapterDocument90 pagesAcid-Base Equilibria: Insert Picture From First Page of ChapterCacey Daiwey CalixtoNo ratings yet

- Noble Drug Delivery System Project Report For LrietDocument25 pagesNoble Drug Delivery System Project Report For LrietAshish NavalNo ratings yet

- Formula Sheet Thermodynamics Cengel PaDocument3 pagesFormula Sheet Thermodynamics Cengel PaonatbrossNo ratings yet

- Rutin NMR TableDocument4 pagesRutin NMR TableMema FathyNo ratings yet

- Deriving Schrödinger's Wave EquationDocument4 pagesDeriving Schrödinger's Wave EquationmfiarkeeaNo ratings yet

- GC1 Q2 Week-3Document11 pagesGC1 Q2 Week-3Nina Reca OmisolNo ratings yet

- Readme - Water Cooled Heat SinkDocument3 pagesReadme - Water Cooled Heat SinkVijay NarayanNo ratings yet

- Unit8. Wastewater EngineeringDocument87 pagesUnit8. Wastewater EngineeringGbenga Adewumi100% (1)

- Transient Heat Conduction (Chap# 4)Document55 pagesTransient Heat Conduction (Chap# 4)Saif UllahNo ratings yet

- Alfa Laval Manaul 26 C 100 PDFDocument131 pagesAlfa Laval Manaul 26 C 100 PDFMARCO VERAMENDINo ratings yet

- EXAMPLE SIZING OWS Calculation Per API 421 PDFDocument1 pageEXAMPLE SIZING OWS Calculation Per API 421 PDFKrisTian EdogawaNo ratings yet

- EC Lab ManualDocument70 pagesEC Lab ManualAbhishek NanavateNo ratings yet

- Dry Grinding of KaolinDocument16 pagesDry Grinding of Kaolinscata1117No ratings yet

- Aços Comp Aços Inox Torques (A1, A2, A4)Document3 pagesAços Comp Aços Inox Torques (A1, A2, A4)Paulo Henrique NascimentoNo ratings yet

- Msds Fineamin 06 Scav EnglDocument9 pagesMsds Fineamin 06 Scav EnglLuis PoncianoNo ratings yet

- Volatile Flavor Components of Strawberry PreservesDocument4 pagesVolatile Flavor Components of Strawberry Preserveszil197608No ratings yet

- Genius Physics ..Pradeep Kshetrapal ElectrostaticsDocument24 pagesGenius Physics ..Pradeep Kshetrapal ElectrostaticsFaaizNo ratings yet

- Experiment-439 S MEASUREMENT OF MAGNETIC PDFDocument11 pagesExperiment-439 S MEASUREMENT OF MAGNETIC PDFJhuma DeyNo ratings yet

- Flax FiberDocument33 pagesFlax FiberM Athar RiazNo ratings yet

Stainless Steel Clamp Union Din 32676

Stainless Steel Clamp Union Din 32676

Uploaded by

Sándor PetrovicsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless Steel Clamp Union Din 32676

Stainless Steel Clamp Union Din 32676

Uploaded by

Sándor PetrovicsCopyright:

Available Formats

CLAMP CONNECTION str.

str. H121

Z121

Clamp connection

DIN 32676 / ISO 1127 / ISO 2852 / ASME / BS 4825 ...

Ferrules / gaskets / heavy duty clamps / hose adaptors ...

armat@armat.cz ARMAT spol. s r. o.

http://www.armat.cz Řetová 82, 561 41 Czech Republic

Fax: +420 465 585 254 MADE OF STAINLESS ... Tel.: + 420 465 585 258 / 030 / 031

CLAMP CONNECTION page

str. H122

Z122

Specification:

Dimensions:

DIN 11850

ISO 1127

ISO 2852

BS 4825

ASME BPE

Marking:

dimension, material, heat number

Material:

standard: AISI 316L - DIN 1.4404

on request: DIN 1.4435 - DIN 1.4571 - 1.4301/7 etc.

Material of gaskets:

standard: EPDM

on demand: silicone - PTFE - VITON - Viton/PTFE and EPDM/PTFE (encapsulated) - Garlock/Gylon ...

Certificate (please write your requirements for certificates in inquiries or orderes):

EN 10204 3.1

EN 10204 3.1 AD-W2 (on demand)

FDA for gaskets (on demand USP Class IV)

Standard surface:

inside: Ra ≤ 0,8 µm

outside: Ra ≤ 1,6 µm

Possible variants of inner surface:

electro-chemical polished

Ra ≤ 0,6 µm

Ra ≤ 0,5 µm

Ra ≤ 0,4 µm

Ra ≤ 0,25 µm

Pressures according to standard DIN 32676 (max -10 / +140 °C):

connection 6,35 to 42,4 mm max. 25 bar

connection 48,3 to 76,2 mm max. 16 bar

connection 85,0 to 219,1 mm max. 10 bar

Characteristics:

High hygienic quality:

Perfectly smooth internal surfaces free from retention areas ensure continuous product flow, minimal pressure drop and

minimal danger of contamination.

Accurate coupling and alignment:

Perfect roundness at ends and all cross sections allows accurate coupling and alignment.

Ease of installation:

Strict dimensional tolerances ensure fast assembly and low installation costs.

Ease of maintenance:

Low maintenance with ease of access.

High corrosion resistance:

Solubilization of products ensures high corrosion resistance and long working life.

Non-toxicity of elastomers:

Broad range of non-toxic, non-absorbent agent-resistant elastomers.

armat@armat.cz ARMAT spol. s r. o.

http://www.armat.cz Řetová 82, 561 41 Czech Republic

Fax: +420 465 585 254 MADE OF STAINLESS ... Tel.: + 420 465 585 258 / 030 / 031

CLAMP CONNECTION - FERRULES str.

str. H123

Z123

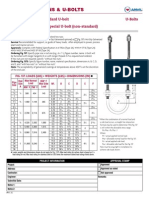

Cod. K14

Ferrule Clamp dle DIN 32676

ØA

S

ØE

Material: AISI 316L / DIN 1.4404 (other materials on demand)

Order example:

Clamp K14S - DIN 32676 - DN 10 (12 x 1,5) - diam. 34 - 316L - 1 piece

C

connection C C* C connection C C* C

DIN 32676 dimensions* ØE long middle short ISO 1127 dimensions* ØE long middle short

ØAxS K14WL K14W K14S ØAxS K14WL K14W K14S

DN 4 6,0 x 1,0 25,0 35,0 18,0 (28,0) 12,7 DN 8 13,5 x 1,6 (2,0) 25,0 35,0 18,0 (28,0) 12,7

DN 4 6,0 x 1,0 34,0 35,0 18,0 (28,0) 12,7 DN 8 13,5 x 1,6 (2,0) 34,0 35,0 18,0 (28,0) 12,7

DN 6 8,0 x 1,0 25,0 35,0 18,0 (28,0) 12,7 DN 8 13,5 x 1,6 (2,0) 50,5 35,0 18,0 (28,0) 12,7

DN 6 8,0 x 1,0 34,0 35,0 18,0 (28,0) 12,7 DN 10 17,2 x 1,6 (2,0) 25,0 35,0 18,0 (28,0) 12,7

DN 8 10,0 x 1,0 25,0 35,0 18,0 (28,0) 12,7 DN 10 17,2 x 1,6 (2,0) 34,0 35,0 18,0 (28,0) 12,7

DN 8 10,0 x 1,0 34,0 35,0 18,0 (28,0) 12,7 DN 10 17,2 x 1,6 (2,0) 50,5 35,0 18,0 (28,0) 12,7

DN 10 12,0 x 1 (1,5) 25,0 35,0 18,0 (28,0) 12,7 DN 15 21,3 x 1,6 (2,0) 34,0 35,0 18,0 (28,0) 12,7

DN 10 12,0 x 1 (1,5) 34,0 35,0 18,0 (28,0) 12,7 DN 15 21,3 x 1,6 (2,0) 50,5 35,0 18,0 (28,0) 12,7

DN 10 12,0 x 1 (1,5) 50,5 35,0 18,0 (28,0) 12,7 DN 20 26,9 x 1,6 (2,0) 50,5 39,0 21,5 (28,0) 12,7

DN 10 13,0 x 1,5 25,0 35,0 18,0 (28,0) 12,7 DN 25 33,7 x 2,0 50,5 39,0 21,5 (28,0) 12,7

DN 10 13,0 x 1,5 34,0 35,0 18,0 (28,0) 12,7 DN 32 42,4 x 2,0 50,5 39,0 21,5 (28,0) 12,7

DN 10 13,0 x 1,5 50,5 35,0 18,0 (28,0) 12,7 DN 32 42,4 x 2,0 64,0 39,0 21,5 (28,0) 12,7

DN 15 18,0 x 1,5 25,0 35,0 18,0 (28,0) 12,7 DN 40 48,3 x 2,0 64,0 41,0 21,5 (28,0) 12,7

DN 15 18,0 x 1,5 34,0 35,0 18,0 (28,0) 12,7 DN 50 60,3 x 2,0 77,5 43,0 28,0 12,7

DN 15 18,0 x 1,5 50,5 35,0 18,0 (28,0) 12,7 DN 65 76,1 x 2,0 91,0 49,0 28,0 15,8

DN 15 19,0 x 1,5 25,0 35,0 18,0 (28,0) 12,7 DN 80 88,9 x 2,3 106,0 49,0 28,0 15,8

DN 15 19,0 x 1,5 34,0 35,0 18,0 (28,0) 12,7 DN 100 114,3 x 2,3 130,0 49,0 28,0 15,8

DN 15 19,0 x 1,5 50,5 35,0 18,0 (28,0) 12,7 DN 125 139,7 x 2,6 155,0 - 28,0 -

DN 20 22,0 x 1,5 34,0 35,0 18,0 (28,0) 12,7 DN 150 168,3 x 2,6 183,0 - 28,0 -

DN 20 22,0 x 1,5 50,5 35,0 18,0 (28,0) 12,7 DN 200 219,1 x 2,6 233,5 - 28,0 -

DN 20 23,0 x 1,5 34,0 35,0 18,0 (28,0) 12,7

DN 20 23,0 x 1,5 50,5 35,0 18,0 (28,0) 12,7 connection C C* C

ASME

DN 25 28,0 x 1,5 50,5 39,0 21,5 (28,0) 12,7 dimensions* ØE long middle short

BPE

DN 25 29,0 x 1,5 50,5 39,0 21,5 (28,0) 12,7 ØAxS K14WL K14W K14S

DN 32 34,0 x 1,5 50,5 39,0 21,5 (28,0) 12,7 DN 1/4“ 6,35 x 0,89 25,0 35,0 21,5 12,7

DN 32 35,0 x 1,5 50,5 39,0 21,5 (28,0) 12,7 DN 3/8“ 9,53 x 0,89 25,0 35,0 21,5 12,7

DN 40 40,0 x 1,5 50,5 39,0 21,5 (28,0) 12,7 DN 1/2“ 12,7 x 1,65 25,0 35,0 21,5 12,7

DN 40 41,0 x 1,5 50,5 39,0 21,5 (28,0) 12,7 DN 3/4“ 19,05 x 1,65 25,0 35,0 21,5 12,7

DN 50 52,0 x 1,5 64,0 41,0 21,5 (28,0) 12,7 DN 1“ 25,4 x 1,65 50,5 39,0 21,5 12,7

DN 50 53,0 x 1,5 64,0 41,0 21,5 (28,0) 12,7 DN 1 1/2“ 38,1 x 1,65 50,5 39,0 21,5 12,7

DN 65 70,0 x 2,0 91,0 49,0 28,0 15,8 DN 2“ 50,8 x 1,65 64,0 41,0 21,5 12,7

DN 80 85,0 x 2,0 106,0 49,0 28,0 15,8 DN 2 1/2“ 63,5 x 1,65 77,5 43,0 28,0 15,8

DN 100 104,0 x 2,0 119,0 49,0 28,0 15,8 DN 3“ 76,2 x 1,65 91,0 49,0 28,0 15,8

DN 125 129,0 x 2,0 155,0 49,0 28,0 - DN 4“ 101,6 x 2,11 119,0 49,0 28,0 15,8

DN 150 154,0 x 2,0 183,0 49,0 28,0 - DN 6“ 152,4 x 2,77 167,0 - 28,0 -

DN 200 204,0 x 2,0 233,5 49,0 28,0 -

DN 250 254,0 x 2,0 268,0 49,0 28,0 - connection C C* C

DN 300 304,0 x 2,0 319,0 49,0 28,0 - ISO 2852 dimensions* ØE long middle short

ØAxS K14WL K14W K14S

connection C C* C DN 1“ 25,6 x 1,50 50,5 - 21,5 -

BS 4825 dimensions* ØE long middle short DN 1½“ 38,6 x 1,50 50,5 - 21,5 -

ØAxS K14WL K14W K14S DN 2“ 51,6 x 1,50 64,0 - 21,5 -

DN 1“ 25,65 x 1,725 50,5 - 21,5 - DN 2½“ 64,1 x 1,90 77,5 - 21,5 -

on request

on request

DN 1½“ 38,35 x 1,725 50,5 - 21,5 - DN 3“ 76,7 x 1,90 91,0 - 21,5 -

DN 2“ 51,05 x 1,725 64,0 - 21,5 - DN 3½“ 89,9 x 2,50 106,0 - 21,5 -

DN 2½“ 63,75 x 1,725 77,5 21,5 - DN 4“ 102,5 x 2,45 119,0 - 21,5 -

on request

on request

DN 3“ 76,45 x 1,725 91,0 21,5 - DN 4½“ 115,6 x 2,65 130,0 - 28,0 -

DN 4“ 101,85 x 2,125 119,0 - 21,5 - DN 5½“ 141,2 x 2,80 155,0 - 28,0 -

DN 4½“ 114,95 x 2,325 130,0 - 28,0 - DN 6⅝“ 170,0 x 3,45 183,0 - 28,0 -

DN 5½“ 140,55 x 2,425 155,0 - 28,0 - DN 8⅝“ 221,2 x 3,65 233,5 - 28,0 -

DN 6⅝“ 169,35 x 3,125 183,0 - 28,0 -

DN 8⅝“ 220,55 x 3,325 233,5 - 28,0 -

* () dimensions on request

armat@armat.cz ARMAT spol. s r. o.

http://www.armat.cz Řetová 82, 561 41 Czech Republic

Fax: +420 465 585 254 MADE OF STAINLESS ... Tel.: + 420 465 585 258 / 030 / 031

CLAMP CONNECTION str.

str. H124

Z124

Adaptor Hose adaptor Blind ferrule

CLAMP / thread with ferrule CLAMP CLAMP

AISI 304/L, AISI 316/L AISI 304/L, AISI 316/L AISI 316/L

K14B K14R K16

ØE

G

K

H

K

B B C

DN G B K DN H B K E C

15 1/2” 48 34 10 13 44 34 Ø 25,0 4,75

20 3/4” 53 50,5 15 19 (16)* 58 34 Ø 34,0 6,35

20 21,3 63 34

25 1” 53 50,5 Ø 50,5 6,35

25 26,9 73 50,5

32 1 1/4” 63 50,5 Ø 64,0 6,35

32 33,7 78 50,5

40 1 1/2” 63 64 Ø 77,5 6,35

40 42,4 (40)* 88 50,5

50 2” 66 77,5 Ø 91,0 7,0

50 52 93 64

65 2 1/2” 76 91 63 63,5 126 77,5

Ø 106,0 8,0

80 3” 86 106 65 76,1 126 91 Ø 119,0 8,0

100 4” 96 130 80 83 136 106 Ø 130,0 8,0

100 102 136 119 Ø 144,4 8,0

* option Ø 155,0 12,0

Ø 167,0 *

Ø 183,0 12,0

Ø 217,4 *

Ø 233,5 12,0

Ø 268,0 *

Ø 286,1 *

Ø 319,0 *

Ø 338,0 *

* on demand dimension

armat@armat.cz ARMAT spol. s r. o.

http://www.armat.cz Řetová 82, 561 41 Czech Republic

Fax: +420 465 585 254 MADE OF STAINLESS ... Tel.: + 420 465 585 258 / 030 / 031

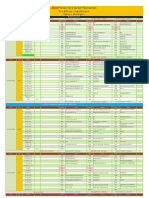

CLAMP CONNECTION - GASKETS str.

str. H125

Z125

Gasket Clamp

cod. K39 - lipped

cod. K40 - without lip

Materials: EPDM - silicone - NBR - Viton - PTFE (Teflon) - PTFE/VITON a EPDM/VITON (encapsulated)

Garlock/Gylon BIO-PRO (new)

Certificates: on request FDA, on demand USP Class VI

C

L

C

L

L

L

diam. of plate 25 mm without lip cod. K40 lipped cod. K39 encapsulated blind

connection connection connection

ASME

DIN 32676 dimensions C L dimensions C L ISO 1127 dimensions C L

BPE

øA x S øA x S øA x S

DN 4 6,0 x 1,0 ≥ 4,2 Ø 21,8 DN 1/4“ 6,35 x 0,89 ≥ 4,8 Ø 21,8 DN 8 13,5 x 1,6 ≥ 10,5 Ø 21,8

DN 4 6,0 x 1,0 ≥ 4,2 Ø 34,0 DN 3/8“ 9,53 x 0,89 ≥ 8,0 Ø 21,8 DN 8 13,5 x 1,6 ≥ 10,5 Ø 34,0

DN 6 8,0 x 1,0 ≥ 6,2 Ø 21,8 DN 1/2“ 12,7 x 1,65 ≥ 9,6 Ø 21,8 DN 8 13,5 x 1,6 ≥ 10,5 Ø 50,5

DN 6 8,0 x 1,0 ≥ 6,2 Ø 34,0 DN 3/4“ 19,05 x 1,65 ≥ 16,0 Ø 21,8 DN 10 17,2 x 1,6 ≥ 14,2 Ø 21,8

DN 8 10,0 x 1,0 ≥ 8,2 Ø 21,8 DN 1“ 25,4 x 1,65 ≥ 22,3 Ø 50,5 DN 10 17,2 x 1,6 ≥ 14,2 Ø 34,0

DN 8 10,0 x 1,0 ≥ 8,2 Ø 34,0 DN 1 1/2“ 38,1 x 1,65 ≥ 35,0 Ø 50,5 DN 10 17,2 x 1,6 ≥ 14,2 Ø 50,5

DN 10 12,0 x 1 (1,5) ≥ 10,2 (9,2) Ø 21,8 DN 2“ 50,8 x 1,65 ≥ 47,7 Ø 64,0 DN 15 21,3 x 1,6 ≥ 18,3 Ø 34,0

DN 10 12,0 x 1 (1,5) ≥ 10,2 (9,2) Ø 34,0 DN 2 1/2“ 63,5 x 1,65 ≥ 60,4 Ø 77,5 DN 15 21,3 x 1,6 ≥ 18,3 Ø 50,5

DN 10 12,0 x 1 (1,5) ≥ 10,2 (9,2) Ø 50,5 DN 3“ 76,2 x 1,65 ≥ 73,1 Ø 91,0 DN 20 26,9 x 1,6 ≥ 23,9 Ø 50,5

DN 10 13,0 x 1,5 ≥ 10,2 Ø 21,8 DN 4“ 101,6 x 2,11 ≥ 97,6 Ø 119,0 DN 25 33,7 x 2,0 ≥ 29,9 Ø 50,5

DN 10 13,0 x 1,5 ≥ 10,2 Ø 34,0 DN 6“ 152,4 x 2,77 ≥ 147,1 Ø 167,0 DN 32 42,4 x 2,0 ≥ 38,6 Ø 50,5

DN 10 13,0 x 1,5 ≥ 10,2 Ø 50,5 connection DN 32 42,4 x 2,0 ≥ 38,6 Ø 64,0

DN 15 18,0 x 1,5 ≥ 15,2 Ø 21,8 DN 40 48,3 x 2,0 ≥ 44,5 Ø 64,0

BS 4825 dimensions C L

DN 15 18,0 x 1,5 ≥ 15,2 Ø 34,0 DN 50 60,3 x 2,0 ≥ 56,5 Ø 77,5

DN 15 18,0 x 1,5 ≥ 15,2 Ø 50,5 øA x S DN 65 76,1 x 2,0 ≥ 72,3 Ø 91,0

DN 15 19,0 x 1,5 ≥ 16,2 Ø 21,8 DN 1“ 25,65 x 1,725 22,4 Ø 50,5 DN 80 88,9 x 2,3 ≥ 84,5 Ø 106,0

DN 15 19,0 x 1,5 ≥ 16,2 Ø 34,0 DN 1½“ 38,35 x 1,725 35,1 Ø 50,5 DN 100 114,3 x 2,3 ≥ 109,9 Ø 130,0

DN 15 19,0 x 1,5 ≥ 16,2 Ø 50,5 DN 2“ 51,05 x 1,725 47,8 Ø 64,0 DN 125 139,7 x 2,6 ≥ 134,7 Ø 155,0

DN 20 22,0 x 1,5 ≥ 19,2 Ø 34,0 DN 2½“ 63,75 x 1,725 60,5 Ø 77,5 DN 150 168,3 x 2,6 ≥ 163,3 Ø 183,0

DN 20 22,0 x 1,5 ≥ 19,2 Ø 50,5 DN 3“ 76,45 x 1,725 73,2 Ø 91,0 DN 200 219,1 x 2,6 ≥ 214,1 Ø 233,5

DN 20 23,0 x 1,5 ≥ 20,2 Ø 34,0 DN 4“ 101,85 x 2,125 97,8 Ø 119,0

DN 4½“ 114,95 x 2,325 110,5 Ø 130,0 connection

DN 20 23,0 x 1,5 ≥ 20,2 Ø 50,5

DN 5½“ 140,55 x 2,425 135,9 Ø 155,0 ISO 2852 dimensions C L

DN 25 28,0 x 1,5 ≥ 25,2 Ø 50,5

DN 6⅝“ 169,35 x 3,125 163,3 Ø 183,0 øA x S

DN 25 29,0 x 1,5 ≥ 26,2 Ø 50,5

DN 8⅝“ 220,55 x 3,325 214,1 Ø 233,5 DN 1“ 25,6 x 1,50 22,8 Ø 50,5

DN 32 34,0 x 1,5 ≥ 31,2 Ø 50,5

DN 1½“ 38,6 x 1,50 35,8 Ø 50,5

DN 32 35,0 x 1,5 ≥ 32,2 Ø 50,5

DN 2“ 51,6 x 1,50 48,8 Ø 64,0

DN 40 40,0 x 1,5 ≥ 37,2 Ø 50,5

DN 2½“ 64,1 x 1,90 60,5 Ø 77,5

DN 40 41,0 x 1,5 ≥ 38,2 Ø 50,5

DN 3“ 76,7 x 1,90 73,1 Ø 91,0

DN 50 52,0 x 1,5 ≥ 49,2 Ø 64,0

DN 3½“ 89,9 x 2,50 85,1 Ø 106,0

DN 50 53,0 x 1,5 ≥ 50,2 Ø 64,0

DN 4“ 102,5 x 2,45 97,8 Ø 119,0

DN 65 70,0 x 2,0 ≥ 66,2 Ø 91,0

DN 4½“ 115,6 x 2,65 110,5 Ø 130,0

DN 80 85,0 x 2,0 ≥ 81,2 Ø 106,0

DN 5½“ 141,2 x 2,80 135,9 Ø 155,0

DN 100 104,0 x 2,0 ≥ 100,2 Ø 119,0

DN 6⅝“ 170,0 x 3,45 163,3 Ø 183,0

DN 125 129,0 x 2,0 ≥ 125,2 Ø 155,0

DN 8⅝“ 221,2 x 3,65 214,1 Ø 233,5

DN 150 154,0 x 2,0 ≥150,2 Ø 183,0

DN 200 204,0 x 2,0 ≥ 200,2 Ø 233,5

DN 250 254,0 x 2,0 ≥ 250,2 Ø 268,0

DN 300 304,0 x 2,0 ≥ 300,2 Ø 319,0

Characteristics EPDM silicone PTFE Viton Garlock/Gylon

code “E“ “S“ “T“ “V“ “G“

temperature -30 °C to + 140 °C -50 °C to + 200 °C -40 °C to + 150 °C -15 °C to + 220 °C -210 °C to + 260 °C

diluted acids A/B C A C pressure: 55 bar

basis A/B C A X compress.: 22-45%

vegetable and animal fats and oils B/C B A A excelent chemical

mechanical characteristics under traction B C B B resistent

resistance to abrasive wear B/C C/X A B

permanent (plastic) deformation A (100 0C) A/B (175 0C) - A (175 0C)

colour black red / white white green

A ... excellent B ... good C ... average X ... poor

armat@armat.cz ARMAT spol. s r. o.

http://www.armat.cz Řetová 82, 561 41 Czech Republic

Fax: +420 465 585 254 MADE OF STAINLESS ... Tel.: + 420 465 585 258 / 030 / 031

CLAMP CONNECTION - HEAVY DUTY CLAMP str.

str. H126

Z126

Cod. K12 Cod. K12SH

Heavy duty Clamp Objímka CLAMP dvoudílná

Materiál: AISI 304 Materiál: AISI 304

DN DN max.

Ø Ø

press.

DIN ISO ASME diameter A kg DIN ISO ASME diam. A kg

at

32676 1127 BPE of plate 32676 1127 BPE of plate 150°C

8-10 ¼“-¾“ 25,0 28,0 0,15 150 150 6⅝“ 183,0 187,0 10 1,69

10-15-20 34,0 37,0 0,17 8“ 217,4 220,0 10 2,19

25-32-40 15-32 1“-1½“ 50,5 53,0 0,22 200 200 8⅝“ 233,5 238,0 10 2,34

50 40 2“ 64,0 67,0 0,30 250 10“ 268,0 272,0 5 2,78

50 2½“ 77,5 80,0 0,35 250 10“s.5 286,1 289,5 4 2,97

65 65 3“ 91,0 94,0 0,40 300 12“ 319,0 322,0 2 3,37

80 80 3½“ 106,0 109,0 0,44 300 12“s.5 338,0 340,0 2 3,69

100 4“ 119,0 122,0 0,50

100 130,0 133,0 0,58

5“ 144,4 147,0 0,77

125 125 155,0 158,0 1,30

6“ 167,0 170,0 1,40

150 150 183,0 187,0 1,54

200 200 233,5 238,0 2,02

Cod. K12SSH Cod. K13

Heavy duty Clamp Heavy duty Clamp 3-part

C

Material: AISI 304 Material: AISI 304 A

for higher pressures

B

DN max.

Ø Ø

press.

DIN ISO ASME diam. A kg DN diam. of A B C kg

at

32676 1127 BPE of plate plate

150°C

8-10 ¼“-¾“ 25,0 28,0 80 0,16 25 50,5 53,4 45,0 53,0 0,270

10-15-20 34,0 37,0 80 0,22 38 50,5 53,4 45,0 53,0 0,270

25-32-40 15-32 1“-1½“ 50,5 52,0 80 0,66 51 64,0 67,0 51,5 53,0 0,330

50 40 2“ 64,0 65,5 55 0,82 63 77,5 80,4 58,2 53,0 0,395

50 2½“ 77,5 79,0 50 0,94 76 91,0 94,0 65,0 53,0 0,425

65 65 3“ 91,0 92,5 45 1,02 101 119,0 122,0 81,0 53,0 0,540

80 80 3½“ 106,0 109,0 40 1,07

100 4“ 119,0 122,0 40 1,27

100 130,0 133,0 40 1,33

6“ 167,0 168,0 30 1,93

150 150 183,0 187,0 25 2,11

200 200 233,5 238,0 20 2,52

armat@armat.cz ARMAT spol. s r. o.

http://www.armat.cz Řetová 82, 561 41 Czech Republic

Fax: +420 465 585 254 MADE OF STAINLESS ... Tel.: + 420 465 585 258 / 030 / 031

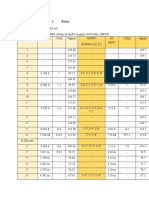

AMT Connect

AMT Connect

material: DIN 1.4404 (na přání DIN 1.4435)

Ø A max. Ø A max.

E <= 77,5 E > 77,5

T H T

H

ID ID

E E

OD OD

DIN A

DN

E ID OD

max

H Ordering code T Ordering code T Ordering code T Ordering code T

DN 10 34,0 10,0 70,0 23,5 T-3 NAD-010-012-1.4404 12 NAD-010-025-1.4404 25 NAD-010-038-1.4404 38 NAD-010-051-1.4404 51

DN 15 34,0 16,0 70,0 23,5 T-3 NAD-015-012-1.4404 12 NAD-015-025-1.4404 25 NAD-015-038-1.4404 38 NAD-015-051-1.4404 51

DN 20 34,0 20,0 70,0 23,5 T-3 NAD-020-012-1.4404 12 NAD-020-025-1.4404 25 NAD-020-038-1.4404 38 NAD-020-051-1.4404 51

DN 25 50,5 26,0 85,0 43,8 T-3 NAD-025-012-1.4404 12 NAD-025-025-1.4404 25 NAD-025-038-1.4404 38 NAD-025-051-1.4404 51

DN 32 50,5 32,0 85,0 43,8 T-3 NAD-032-012-1.4404 12 NAD-032-025-1.4404 25 NAD-032-038-1.4404 38 NAD-032-051-1.4404 51

DN 40 50,5 38,0 85,0 43,8 T-3 NAD-040-012-1.4404 12 NAD-040-025-1.4404 25 NAD-040-038-1.4404 38 NAD-040-051-1.4404 51

DN 50 64,0 50,0 100,0 55,0 T-3 NAD-050-015-1.4404 15 NAD-050-025-1.4404 25 NAD-050-038-1.4404 38 NAD-050-051-1.4404 51

DN 65 91,0 66,0 131,0 78,0 T-3 NAD-065-015-1.4404 15 NAD-065-025-1.4404 25 NAD-065-038-1.4404 38 NAD-065-051-1.4404 51

DN 80 106,0 81,0 146,0 93,0 T-3 NAD-080-015-1.4404 15 NAD-080-025-1.4404 25 NAD-080-038-1.4404 38 NAD-080-051-1.4404 51

DN 100 119,0 100,0 170,0 105,0 T-3 NAD-100-015-1.4404 15 NAD-100-025-1.4404 25 NAD-100-038-1.4404 38 NAD-100-051-1.4404 51

ISO A

E ID OD H Ordering code T Ordering code T Ordering code T Ordering code T

DN max

DN 8 25,0 10,2 55,0 20,0 T-3 NAI-008-012-1.4404 12 NAI-008-025-1.4404 25 NAI-008-038-1.4404 38 NAI-008-051-1.4404 51

DN 10 34,0 14,0 70,0 23,5 T-3 NAI-010-012-1.4404 12 NAI-010-025-1.4404 25 NAI-010-038-1.4404 38 NAI-010-051-1.4404 51

DN 15 34,0 18,1 70,0 23,5 T-3 NAI-015-012-1.4404 12 NAI-015-025-1.4404 25 NAI-015-038-1.4404 38 NAI-015-051-1.4404 51

DN 20 50,5 23,7 85,0 43,8 T-3 NAI-020-012-1.4404 12 NAI-020-025-1.4404 25 NAI-020-038-1.4404 38 NAI-020-051-1.4404 51

DN 25 50,5 29,7 85,0 43,8 T-3 NAI-025-012-1.4404 12 NAI-025-025-1.4404 25 NAI-025-038-1.4404 38 NAI-025-051-1.4404 51

DN 32 64,0 38,4 100,0 55,0 T-3 NAI-032-015-1.4404 15 NAI-032-025-1.4404 25 NAI-032-038-1.4404 38 NAI-032-051-1.4404 51

DN 40 64,0 44,3 100,0 55,0 T-3 NAI-040-015-1.4404 15 NAI-040-025-1.4404 25 NAI-040-038-1.4404 38 NAI-040-051-1.4404 51

DN 50 77,5 56,3 112,0 65,5 T-3 NAI-050-015-1.4404 15 NAI-050-025-1.4404 25 NAI-050-038-1.4404 38 NAI-050-051-1.4404 51

DN 65 91,0 71,5 131,0 78,0 T-3 NAI-065-015-1.4404 15 NAI-065-025-1.4404 25 NAI-065-038-1.4404 38 NAI-065-051-1.4404 51

DN 80 106,0 84,3 146,0 93,0 T-3 NAI-080-015-1.4404 15 NAI-080-025-1.4404 25 NAI-080-038-1.4404 38 NAI-080-051-1.4404 51

DN 100 130,0 109,7 170,0 117,0 T-3 NAI-100-015-1.4404 15 NAI-100-025-1.4404 25 NAI-100-038-1.4404 38 NAI-100-051-1.4404 51

ASME A

E ID OD H Objednací kód T Objednací kód T Objednací kód T Objednací kód T

DN max

DN 12 25,0 9,4 55 20,0 T-3 NAS-012-012-1.4404 12 NAS-012-025-1.4404 25 NAS-012-038-1.4404 38 NAS-012-051-1.4404 51

DN 19 25,0 15,7 55 20,0 T-3 NAS-019-012-1.4404 12 NAS-019-025-1.4404 25 NAS-019-038-1.4404 38 NAS-019-051-1.4404 51

DN 25 50,5 22,1 85 43,8 T-3 NAS-025-012-1.4404 12 NAS-025-025-1.4404 25 NAS-025-038-1.4404 38 NAS-025-051-1.4404 51

DN 38 50,5 34,8 85 43,8 T-3 NAS-038-012-1.4404 12 NAS-038-025-1.4404 25 NAS-038-038-1.4404 38 NAS-038-051-1.4404 51

DN 51 64 47,5 100 55,0 T-3 NAS-051-015-1.4404 15 NAS-051-025-1.4404 25 NAS-051-038-1.4404 38 NAS-051-051-1.4404 51

DN 63 77,5 60,2 112 65,5 T-3 NAS-063-015-1.4404 15 NAS-063-025-1.4404 25 NAS-063-038-1.4404 38 NAS-063-051-1.4404 51

DN 76 91,0 72,9 131 78,0 T-3 NAS-076-015-1.4404 15 NAS-076-025-1.4404 25 NAS-076-038-1.4404 38 NAS-076-051-1.4404 51

DN 101 119,0 97,4 170 105,0 T-3 NAS-101-015-1.4404 15 NAS-101-025-1.4404 25 NAS-101-038-1.4404 38 NAS-101-051-1.4404 51

armat@armat.cz ARMAT spol. s r. o.

http://www.armat.cz Řetová 82, 561 41 Czech Republic

Fax: +420 465 585 254 MADE OF STAINLESS ... Tel.: + 420 465 585 258 / 030 / 031

You might also like

- Potassium TrihydrateDocument5 pagesPotassium TrihydrateTeresa Davis60% (15)

- Fire Safety NotesDocument13 pagesFire Safety Notesrescueone93% (14)

- Sample Vessel 3 96 Horizontal Vessel PreDocument24 pagesSample Vessel 3 96 Horizontal Vessel PresoloNo ratings yet

- Document 1Document13 pagesDocument 1Prince SharmaNo ratings yet

- C2quick PDFDocument34 pagesC2quick PDFJose Maria PedrazasNo ratings yet

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- DIN 11864-3/DIN 11853-3 Aseptic Clamp Unions For DIN 11866/11850 Table ADocument7 pagesDIN 11864-3/DIN 11853-3 Aseptic Clamp Unions For DIN 11866/11850 Table ADinh Nguyen DaoNo ratings yet

- FO-PC-001 Job Safety Analysis FormDocument92 pagesFO-PC-001 Job Safety Analysis FormRoshanie HoseinNo ratings yet

- LT Valves Knife Gate ValvesDocument2 pagesLT Valves Knife Gate Valvesdevang asherNo ratings yet

- Indian & International STDDocument8 pagesIndian & International STDMirza Sameer Ali BaigNo ratings yet

- WEP Standard For Reference OnlyDocument37 pagesWEP Standard For Reference OnlyKiran NikateNo ratings yet

- !indx PipDocument18 pages!indx PipCharles JacobNo ratings yet

- P 0200 152 LHS 01Document2 pagesP 0200 152 LHS 01Zaidi100% (1)

- Erection Proc of FRPDocument10 pagesErection Proc of FRPHalim IrhamiNo ratings yet

- Butterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentDocument9 pagesButterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentVinay SharmaNo ratings yet

- Flat End With A Full-Face Gasket For A Pair of OpeningsDocument3 pagesFlat End With A Full-Face Gasket For A Pair of OpeningsEng-CalculationsNo ratings yet

- AWWADocument10 pagesAWWARostarina AnggrainiNo ratings yet

- Is 14845-2000 (Air Relief Valves) PDFDocument18 pagesIs 14845-2000 (Air Relief Valves) PDFSarbendu PaulNo ratings yet

- 10.flange Bolts, STD TeesDocument7 pages10.flange Bolts, STD TeesNIRMAL SINGHNo ratings yet

- ISO 15348 2002 Metal Bellows Expansion Joints PDFDocument8 pagesISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezNo ratings yet

- Low-Pressure Hoselines SN 544: Double Nipple Welding NippleDocument2 pagesLow-Pressure Hoselines SN 544: Double Nipple Welding NippleNaveen Kumar Chauhan100% (1)

- Slurry Settling Velocity According JRIDocument8 pagesSlurry Settling Velocity According JRIChristopher LloydNo ratings yet

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- HB D KomplettDocument181 pagesHB D KomplettGabriel BourguignonNo ratings yet

- Indian Minerals Yearbook 2019: 58 EditionDocument33 pagesIndian Minerals Yearbook 2019: 58 EditionmodoyioNo ratings yet

- KTM - Eb11 Eb12 Eb21 Eb22Document12 pagesKTM - Eb11 Eb12 Eb21 Eb22psycloneses100% (1)

- Reactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralDocument1 pageReactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralAndrés SepúlvedaNo ratings yet

- DIN StandardDocument2 pagesDIN StandardViiee Chauhaan33% (3)

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Swagelok Needle ValvesDocument12 pagesSwagelok Needle Valvesnegg 348No ratings yet

- HDPE-MaterialData 78281Document2 pagesHDPE-MaterialData 78281tayyabmubarik2417No ratings yet

- Ghibson GB015Document2 pagesGhibson GB015Jessicalba LouNo ratings yet

- Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesDocument5 pagesContact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesJosé Luis Sierra100% (1)

- Brighton Spec ASME 80-10 2017 PDFDocument1 pageBrighton Spec ASME 80-10 2017 PDFSuhas JadhavNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Autodesk Feature CodesDocument14 pagesAutodesk Feature Codessplaw9484No ratings yet

- Bolt Length CalculationDocument1 pageBolt Length Calculationridho ziskaNo ratings yet

- Spe 170951 MSDocument13 pagesSpe 170951 MStyokNo ratings yet

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 pagesUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNo ratings yet

- Fig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsDocument1 pageFig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsRobertgomezNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Regulatory Guide 1.90Document23 pagesRegulatory Guide 1.90Luis Juan Trejo CruzNo ratings yet

- Technical Data Sheet: Behavior, Innovation, Responsibility, Learning, EnthusiasmDocument3 pagesTechnical Data Sheet: Behavior, Innovation, Responsibility, Learning, EnthusiasmHuber AlvaradoNo ratings yet

- Awwa C207 2018Document40 pagesAwwa C207 2018JacobUnda100% (1)

- Elastic Properties of PotatoDocument5 pagesElastic Properties of Potatopriya07rajNo ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- Sferova API6 Ball Valve CatalogueDocument27 pagesSferova API6 Ball Valve CatalogueWong JowoNo ratings yet

- 1.5 APS Powder Insert: Parts List PL 41001 EN 13Document18 pages1.5 APS Powder Insert: Parts List PL 41001 EN 13Alexandre VecaNo ratings yet

- Iso 15552 2004 en PDFDocument8 pagesIso 15552 2004 en PDFashokkumarNo ratings yet

- EN10255 Pipe SizeDocument3 pagesEN10255 Pipe SizeStefan CristescuNo ratings yet

- Senior Design Engineer For Static Equipment With 13 Years of ExperienceDocument7 pagesSenior Design Engineer For Static Equipment With 13 Years of ExperienceTushar MangratiNo ratings yet

- Data Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerDocument1 pageData Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerAnonymous 0OizFXUONo ratings yet

- Client: Contract: Job / Project TitleDocument5 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- 8-1280-13 Pipe Class HF-1Document4 pages8-1280-13 Pipe Class HF-1Jesus MendezNo ratings yet

- Psi Flange KitsDocument8 pagesPsi Flange Kitsdianudin safarudinNo ratings yet

- IMIOrton MV SeriesDocument4 pagesIMIOrton MV SeriesFelipe Gamboa GálvezNo ratings yet

- BP209 VIS - M Manual PDFDocument174 pagesBP209 VIS - M Manual PDFReena SharmaNo ratings yet

- Tri Clamp PDFDocument6 pagesTri Clamp PDFLeandro SantosNo ratings yet

- Heco Product Sheet 2207 Stainless Steel Plate Flanges DIN EN PN 10Document4 pagesHeco Product Sheet 2207 Stainless Steel Plate Flanges DIN EN PN 10hafiz ashidqiNo ratings yet

- Advantages of Axial Expansion Joints Application AreasDocument5 pagesAdvantages of Axial Expansion Joints Application AreasprabowopuguhNo ratings yet

- Door Controller: Innovative and PowerfulDocument2 pagesDoor Controller: Innovative and PowerfulSándor PetrovicsNo ratings yet

- DS Starter Exp Kits 1627 EN LDocument2 pagesDS Starter Exp Kits 1627 EN LSándor PetrovicsNo ratings yet

- Biztonsági SzelepDocument2 pagesBiztonsági SzelepSándor PetrovicsNo ratings yet

- 7301 EngDocument4 pages7301 EngSándor PetrovicsNo ratings yet

- Prominent Equipment Catalogue PDFDocument684 pagesProminent Equipment Catalogue PDFSándor PetrovicsNo ratings yet

- First FerreroDocument1 pageFirst FerreroSándor PetrovicsNo ratings yet

- Time Table Chandigarh Campus-6Document2 pagesTime Table Chandigarh Campus-6upma gargNo ratings yet

- Take Home Pack Gr. 7 Natural Sciences T3Document21 pagesTake Home Pack Gr. 7 Natural Sciences T3debbiemotlatle22No ratings yet

- Trembesi SkriningDocument8 pagesTrembesi Skriningemadayanti65No ratings yet

- Assignment 1Document6 pagesAssignment 1Menna TantawiNo ratings yet

- Phase DiagramsDocument3 pagesPhase DiagramsSimon VladNo ratings yet

- Water Comfort: A Complete Range of Hot Water SolutionsDocument4 pagesWater Comfort: A Complete Range of Hot Water SolutionsRidwan PramudyaNo ratings yet

- A Method To Test The Detectability of GC PFPD ForDocument8 pagesA Method To Test The Detectability of GC PFPD ForMarian Si Teofana HasnaNo ratings yet

- Emflon PFR Sterilizing-Grade Filter Cartridge For Gas and VentDocument2 pagesEmflon PFR Sterilizing-Grade Filter Cartridge For Gas and VentTruong Anh TuanNo ratings yet

- Subject ChemistryDocument13 pagesSubject ChemistryWinki MansonNo ratings yet

- Acid-Base Equilibria: Insert Picture From First Page of ChapterDocument90 pagesAcid-Base Equilibria: Insert Picture From First Page of ChapterCacey Daiwey CalixtoNo ratings yet

- Noble Drug Delivery System Project Report For LrietDocument25 pagesNoble Drug Delivery System Project Report For LrietAshish NavalNo ratings yet

- Formula Sheet Thermodynamics Cengel PaDocument3 pagesFormula Sheet Thermodynamics Cengel PaonatbrossNo ratings yet

- Rutin NMR TableDocument4 pagesRutin NMR TableMema FathyNo ratings yet

- Deriving Schrödinger's Wave EquationDocument4 pagesDeriving Schrödinger's Wave EquationmfiarkeeaNo ratings yet

- GC1 Q2 Week-3Document11 pagesGC1 Q2 Week-3Nina Reca OmisolNo ratings yet

- Readme - Water Cooled Heat SinkDocument3 pagesReadme - Water Cooled Heat SinkVijay NarayanNo ratings yet

- Unit8. Wastewater EngineeringDocument87 pagesUnit8. Wastewater EngineeringGbenga Adewumi100% (1)

- Transient Heat Conduction (Chap# 4)Document55 pagesTransient Heat Conduction (Chap# 4)Saif UllahNo ratings yet

- Alfa Laval Manaul 26 C 100 PDFDocument131 pagesAlfa Laval Manaul 26 C 100 PDFMARCO VERAMENDINo ratings yet

- EXAMPLE SIZING OWS Calculation Per API 421 PDFDocument1 pageEXAMPLE SIZING OWS Calculation Per API 421 PDFKrisTian EdogawaNo ratings yet

- EC Lab ManualDocument70 pagesEC Lab ManualAbhishek NanavateNo ratings yet

- Dry Grinding of KaolinDocument16 pagesDry Grinding of Kaolinscata1117No ratings yet

- Aços Comp Aços Inox Torques (A1, A2, A4)Document3 pagesAços Comp Aços Inox Torques (A1, A2, A4)Paulo Henrique NascimentoNo ratings yet

- Msds Fineamin 06 Scav EnglDocument9 pagesMsds Fineamin 06 Scav EnglLuis PoncianoNo ratings yet

- Volatile Flavor Components of Strawberry PreservesDocument4 pagesVolatile Flavor Components of Strawberry Preserveszil197608No ratings yet

- Genius Physics ..Pradeep Kshetrapal ElectrostaticsDocument24 pagesGenius Physics ..Pradeep Kshetrapal ElectrostaticsFaaizNo ratings yet

- Experiment-439 S MEASUREMENT OF MAGNETIC PDFDocument11 pagesExperiment-439 S MEASUREMENT OF MAGNETIC PDFJhuma DeyNo ratings yet

- Flax FiberDocument33 pagesFlax FiberM Athar RiazNo ratings yet