Professional Documents

Culture Documents

Boiler Coal Feeder

Boiler Coal Feeder

Uploaded by

Urej Bandiola0 ratings0% found this document useful (0 votes)

53 views11 pagesThe document describes an electronic weighing coal feeder (model EG2490) that is used to transport coal from a hopper into a boiler. Key details include:

- It has a maximum output of 110 tons per hour and uses a belt, drive system, and electronic control unit to precisely meter and feed coal into the boiler.

- Six of these coal feeders are installed on each boiler to provide continuous and evenly fed coal that can be regulated quickly based on boiler demands.

- It aims to accurately and reliably measure and control the coal feeding process within 1% precision and 15,000 hours of fault-free operation.

Original Description:

Original Title

336138938 Boiler Coal Feeder

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes an electronic weighing coal feeder (model EG2490) that is used to transport coal from a hopper into a boiler. Key details include:

- It has a maximum output of 110 tons per hour and uses a belt, drive system, and electronic control unit to precisely meter and feed coal into the boiler.

- Six of these coal feeders are installed on each boiler to provide continuous and evenly fed coal that can be regulated quickly based on boiler demands.

- It aims to accurately and reliably measure and control the coal feeding process within 1% precision and 15,000 hours of fault-free operation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

53 views11 pagesBoiler Coal Feeder

Boiler Coal Feeder

Uploaded by

Urej BandiolaThe document describes an electronic weighing coal feeder (model EG2490) that is used to transport coal from a hopper into a boiler. Key details include:

- It has a maximum output of 110 tons per hour and uses a belt, drive system, and electronic control unit to precisely meter and feed coal into the boiler.

- Six of these coal feeders are installed on each boiler to provide continuous and evenly fed coal that can be regulated quickly based on boiler demands.

- It aims to accurately and reliably measure and control the coal feeding process within 1% precision and 15,000 hours of fault-free operation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 11

Boiler Coal Feeder

2.0 Applicable Scope and Quoted Materials:

This chapter is applicable for EG 2490 weighing type coal feeder (produced by Shenyang Shi

DaoKe Electric Power Equipment Co., Ltd.) maintenance and overhaul and to offer references and

guides for the maintenance personnel.

Quoted materials: EG 2490 Weighing Type Coal Feeder Storage, Installation, Maintenance and

opration (Combined book) Shenyang Shi DaoKe Electric Power Equipment Co., Ltd

2.1 Equipment Brief Introduction and Parameter

2.1.1 Coal Feeder Brief Introduction

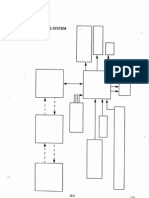

Six (6) electronic weighing type coal feeders produced by Shenyang Shi DaoKe Electric Power

Equipment Company limited are equipped for each boiler, which mainly consists of coal feeder body,

belt, drive device, cleaning transportation chain, drive and transmission device, coal feeder

electronic control device and Micro-processor control device. During work, raw coal drops from raw

coal hopper to transportation belt of coal feeder, which transports raw coal to inlet pipe of chute

under bringing of transmission device. Regulate tension degree of belt through tightening shaft and

regulate coal feeding amount through running speed of belt.

2.1.2 Parameter, Capacity

2.1.2.1 Equipment name: electronic weighing coal feeder

Type: electronic weighing type

Model: EG2490 type, output regulable range: 11~110t/h

Belt speed when maximum output: 0.26 m/s

Quantity: Six (6) coal feeders are equipped for each boiler, 12 sets installed for this project.

Coal feeder belt width: 840 mm

Feeding coal distance (coal feeder inlet & outlet centerline distance): 2500 mm (interim)

Nominal height with interface of raw coal bunker outlet: 20.5m (interim)

Nominal height with interface of coal mill inlet: 10.150m (interim)

Interface dimension of raw coal bunker outlet: 940×10 (interim)

Interface dimension of mill inlet: 720×10 (interim)

Chute inlet:

Length_1890_mm, Pipe diameter (outer diameter) 1000 ~ 629mm, wall thickness 10mm,

Material: Stainless steel

Chute inlet:

Length_4150_mm, Pipe diameter (outer diameter) 629mm, wall thickness 10mm, Material:

Stainless steel

Coal inlet flange inner diameter (inlet coal valve inner diameter):_929_mm, material: Q-235A

Coal outlet flange inner diameter (outlet coal valve inner diameter):_929_mm, material: Q-

235A

2.1.2.2 Interface dimension with mill: outer diameter 720 (final dimension of institute is

prevailed)mm, wall thickness _10_mm

2.1.2.3 Main drive motor

Type: Y3-4P

Power: 3kW

Power supply: 380V, three phases 50Hz

Full load start torque: 1132Nm

2.1.2.4 Motor of cleaning chain

Model: Y0.37-4P

Power: 0.37kW

Power supply: 380V, three phases 50Hz

2.1.2.5 Motor sealing air

Sealing air pressure (outlet differential pressure with mill): 500Pa

Sealing air amount: 10Nm3/min

2.1.2.6 Block excluding air:

Block excluding air pressure: >0.5MPa

Block excluding air amount: 0.2Nm3/min

2.1.2.7 Required minimum coal column height of sealing: 1.5 m

2.1.2.8 Coal gate valve purging air (if there is):

Purging air pressure: 0.5MPa

Purging air amount: 0.2Nm3/min

2.1.2.9 Fire fighting steam parameter:

Pressure: >0.4 MPa

Temperature: <250℃

Coal feeder body weight: 4000 kg

Inlet coal gate valve weight: 1000 kg

Outlet coal gate valve: 800 kg

Inlet chute and other accessories weight: 310 kg

Outlet chute and other accessories weight: 1400 kg

Coal feeder maximum weight when charged with coal: 8500 kg

2.1.2.10 Raw coal pile specific gravity: 0.9381 t/m3 (design coal) 0.8491 t/m3 (checked coal)

2.1.3 Basic performance

Life of coal feeder should be no less than 30 years.

Coal feeder can supply coal continuously and evenly, weighing is right and reliable, regulate

coal feeder output quickly and rightly according to boiler combustion control system to make actual

coal feeding amount match with boiler load. Coal feeder can start with full load.

Coal feeder measuring precision: ±0.25%。

Coal feeder control precision: ±1%。

Running with no fault: 15000h

Anti-explosion of coal feeder is designed as per 0.35Mpa.

Coal feeder has capacity measuring function, when electronic weighing system is in fault, it

can be converted to volume measuring type and send alarm signal.

During normal operation of coal feeder, noise at place 1m away from shell should not exceed

85dB (A).

2.1.4 Structure and System Configuration

Coal feeder shell, inlet & outlet flashboard valve, inlet & outlet chute and regulable connector

are pressure resistant design with pressure resistant degree of 0.35Mpa. Ensure sealing

performance fine and no powder leakage.

Sealing air is even and regulable, avoid upward return of hot air powder in mill effectively and

blowing coal on belt away.

Watch window is set in coal feeder shell and explosion-proof spot light are set in coal feeder

shell for watching operation condition inside shell. Compressed air nozzles are installed on watch

window for cleaning dust from inner surface, thus it is not necessary to open valve or stop coal

feeder.

2.1.5 Coal Transportation Machine

Main drive roller has function of anti-sliding and anti-deflection.

Driven roller has self-cleaning function.

Rubber belt tensioning device is set for coal feeder to keep constant tension of rubber belt and

ensure stable measuring precision. Tensioning device should be convenient for regulation.

Measures should be taken to avoid rubber belt deflection.

Coal feeders are equipped with functions of supervision and alarming of breaking coal,

blocking coal and insufficient coal.

Cleaning device is set at lower section of coal feeder.

Inlet and outlet chute of coal feeder should ensure no coal blocking and wall thickness should

be no less than 10mm, materials of all metal parts contacting with coal flow adopts stainless steel.

Inlet and outlet coal gate valves are able to open or close manually or automatically, its action

should be agile and reliable, valve position indication is set.

During coal block, coal feeder can turn in reversal to unload coal and necessary emergent coal

discharging device is also set.

Coal feeder is equipped with sealing air interface and fire fighting interface.

Valve convenient for maintenance id set for coal feeder, measuring transportation part can be

dismantled with special tools and can be drawn out wholly from shell for the convenience of

maintenance.

Coal feeder weighing measuring device consists of weighing type transducer, weighing roller

and measuring roller. Weighing type transducer is anti-dust and anti-explosion type and can work

normally in abominable environment.

Coal feeder rubber belt is fire resistant, high intension, continuous type rubber belt, ring has no

tie-in and its permanent extension rate is less than 1%, wave baffle with skirt at two sides can

prevent coal powder from leaking out from belt.

Inside and outside cleaning devices are set for coal feeder to remove coal powder used on

rubber belt surface. Cleaning device scraper material should not damage rubber belt.

Scraper chain cleaning machine is set for coal feeder and installed on shell bedplate under

rubber belt for cleaning coal removed from rubber belt and coal dropped during running, all of which

makes shell bottom free from accumulated coal.

Air sealing of inlet and outlet motor-driven coal gate valve of coal feeder is fine and water

discharging interfaces are set. Materials of all metal parts contacting with coal flow adopts stainless

steel, structure design of coal gate valve meets the requirements of NFPA and can bear 0.35MPa

explosion pressure. Motor-driven coal gate valve has self-cleaning function, and could not be

blocked by coal particles after repeat operation; it can be closed or opened easily by manual. Inlet

coal gate valve inner diameter should not be less than 900mm and outlet coal gate valve inner

diameter should be no less than 600mm.

2.1.6 Motor

Drive device speed regulation control mode: frequency conversion speed regulation (transducer

inlet)

Motor voltage: 380V

Motor protection grade is: IP54。

Motor has proper position for connecting fixed earth lead.

Motor outlet box direction, position: from motor to coal feeder, outlet box is at left side.

Maximum noise at place 1.5m away from motor shell and 1.2m from operation platform should

not exceed 85dB(A).

Motor is with grade F insulation system, sealing or static winding of welding sealing.

Motor bearing structure is sealed, be able to isolate feculence and water and lubricant can not

enter into winding.

Bearing temperature measuring element adopts double supporter’s type and is reliably installed.

Down-lead and drive line of temperature detection element are separated and are led to junction

box separately.

2.1.7 Reducer transmission is stable and reliable and be with nine sealing and oil leakage.

2.1.8 Transducer AC Power Supply Parameter

Rated voltage 380V

Voltage normal variation range +10%~-10%

Bus line voltage when motor start automatically as a whole 60% Un

Bus line voltage when high voltage and low voltage start in series 55% Un

Rated frequency 50Hz

Frequency variation range +3%~-3%

short circuit current at 380V bus line side 50kA (effective value)

Neutral point Non-earth system

2.1.9 DC Power Supply: DC drives 220V, DC control 110V.

Transducer has the function of cutting off power for locking within limited time, that is, power

supply recovers after a long time of power cutting of bus line, and transducer will not start

immediately.

Current limit control, limit maximum current be within 1.0~1.1 rated value (including starting and

speed regulating), that is constant torque control.

Emergency button and current signal can satisfy remote transmission.

It is able to start automatically after instantaneous power cutting and continue state before

power cutting off to satisfy current requirement.

Protection functions of transducer, motor short circuit and overload are completed inside

transducer, the buyer supply power to transducer through air breaker.

No harmful effect should happen to equipments at state grid side, such as insulation damage,

protection control system error etc.

Harmonious wave produced by frequency conversion speed regulation system not only can

satisfy regulation of ‘GB/T 14549 Power energy quality common grid harmonious wave’, but also

‘GB/T13926 electromagnetic compatibility of industrial process measuring and control device’ and

related electromagnetism compatibility requirement of “GB/T14598.

9、GB/T14598.10、GB/T14598.13、GB/T14598.14”.

Equipment supplier supplies proper fittings to allow many transducers being connected in

parallel on the same bus line.

Transducer main technical parameter

Input rectifying bridge 12 impulse or higher

Inverter type Voltage source type

Inverter power element IGBT or IGCT

Auxiliary power supply 380V AC

Control mode PWM or DTC

Output voltage sine wave

Output frequency 0~50Hz

Cooling type air cooling or forceful air cooling

Isolation power supply part Fiber-optic Cable

Protection grade IP54

Transducer control system adopts digital microprocessor controller. There is operation interface

on transducer cabinet door, there are touching keyboard and LCD/LED display on operation

interface.

There is start, stop transducer on cabinet door for regulating frequency.

Be with fault diagnose display.

1. 2.1.10 Instrumental Meters and Control

At least there are remote instructions inputs on cabinet of control box and drive box of coal

feeder:

Start coal feeder

Stop coal feeder

Control coal feeding amount (4-20mADC)

At least there are remote instruction outputs on cabinet of control box and drive box of coal

feeder:

Coal feeder run, stop state

Coal feeder current (4-20mADC)

Cleaner run, stop state

Belt conveyor motor fault

Cleaner motor fault

Instantaneous coal feeding amount

Accumulated feeding coal amount

Coal flow abnormal in chute at inlet side of coal feeder (coal block)

Coal flow abnormal in chute at outlet side of coal feeder (coal block)

Coal feeding rate error high

Belt lacks coal (coal feeding stopped)

Coal feeder is blocked by coal

Over-high temperature in coal feeder

Local or remote control

Sequence control fault

Cubage running signal

Belt conveyor normal running signal

Rubber belt reversal running signal

Coal feeder at least has following interlock protections:

Coal feeder stops automatically according to signal of ‘take two from three’ when

chute at outlet of coal feeder is seriously blocked

When belt conveyor motor is in fault, it cuts off power supply automatically

When cleaner motor is in fault, it cuts off power supply automatically

Inlet & outlet gate valve electric-control box of coal feeder at least have following functions:

Manual control of local electric control box

Open, close coal gate valve

Locally manual or remotely manual (automatic) transfer of control mode

Local electric control box display: coal gate valve full open, full close

Coal feeder electric control box at least has remote instruction input of opening, closing coal

gate valve:

Coal feeder electric control box at least has following instruction outputs:

Coal gate valve full open, full close

Coal gate valve suffocate to open, close (over torque)

On-off output supplied by seller is passive junction signal, its junction volume is no less than

220V AC 3A, 220V DC 1A.

2. 2.1.11 Performance Guarantee

1. Output regulation range: 11~110t/h

Coal feeder measuring precision: ±0.25%

2. Coal feeder control precision: ± 0.5%

3. Noise (1m away) ≤75dB(A)

4. Power consumption: 8kW

3. 2.1.12 Equipment Radius and Interface Regulations

On coal feeder, from coal bunker outlet flange connection to connection of chute in middle of

mill, including (but not limited):

Coal feeder proper (including motor, reducer, electronic weighing system)

1. Electric control box, drive box

2. Inlet, outlet coal gate valve (including electric-driven device and control box)

3. Inlet and outlet chute

4. Coal flow supervisor

5. Regulable connector

6. Counter flange and tightening fittings are offered to all flange interfaces

7. Maintenance chain

8. Reversal turning material unloading slot

9. Maintenance platform car

10. Spare parts

11. Special tools

4. 2.1.13 Equipment Component

Production

No. Name Specification Unit Qty Manufacturer Remark

area

Coal feeder proper (pressure

resistant sleeve, roller coal

flow molding device, roller,

sleeve, belt, anti-explosion

lighting device, cleaning

chain, coal smashing hole,

EG2490 set 6 Shenyang STOCK

tensioning device,

maintenance valve, watch

hole, sealing air interface,

manual valve coal sampling

device, all flange and bolts

tightening piece)

2 Coal feeder control cabinet 196NT MPC America STOCK Integer

(integrated with drive cabinet) import

Mainly contain following

set 6

parts:

piece 6

196 microprocessor controller

piece 6

Transducer

Production

No. Name Specification Unit Qty Manufacturer Remark

area

Display panel and keyboard piece 6

Power supply plate set 6

A1 card(input card) set 6

A2 card(Feedback card) set 12

A/D converter

Inlet coal gate valve

(including motor-driven

3 device, control box, raw coal 36-RR-VB set 6 Shenyang STOCK

bunker outlet flange and

tightening fittings)

Outlet coal gate valve

4 (including motor-driven 24-RR-VB-SP set 6 Shenyang STOCK

device, control box)

Clean chain drive motor and

5 AE-100 set 6 Zhejiang JIE

reducer

Rubber drive motor and

6 set 6 Zhejiang JIE

reducer

Outlet coal block alarm

7 set 18 America STOCK

device

8 Belt breaking coal alarm set 6 America STOCK

Inlet, outlet chute pipe

9 Ae-100 set 6 Shenyang STOCK

ultrasonic coal flow inspector

Temperature alarm device Special

10 set 6 Wuxi instrumental

meter

11 Rotating measuring detector set 6 America STOCK

12 Maintenance chain set 6 Shenyang STOCK

Regulable connector (inlet,

13 set 6 Shenyang STOCK

outlet)

14 Inlet and outlet chute set 6 Shenyang STOCK

15 Electronic weighing system set 6 America STOCK

Mainly including following

parts

Weighing sensor piece

12

Weighing roller piece 6

Bearing piece 12

Production

No. Name Specification Unit Qty Manufacturer Remark

area

Sealing ring piece 24

Weighing lever

piece 12

subassemblies

piece

5. 2.1.14 Special Tools

No Specificatio Qt Productio

Name Unit Manufacturer Remark

. n y n area

Plane calibration 2 Special tool

piec

1 lever (measuring Shenyang STOCK for

e

feeler gauge) measuring

Detector (nominal piec 2

2 America STOCK

detector) e

Cable of detector piec 2

3 America STOCK

e

Glisten paper piec 16

4 America 3M

e

Nominal poise piec 2

5 Shenyang STOCK

e

Roller wheel piec Special tool

6 1 Shenyang STOCK

dismantling seat e for

maintenance

Roller lifting lever piec

7 1 Shenyang STOCK

e

Roller wheel

connection lever piec

8 2 Shenyang STOCK

(extension guide e

track)

Tool box piec

9 1 Shenyang STOCK

e

Reversal coal piec

10 1 Shenyang STOCK

discharging slot e

Maintenance piec

11 1 Shenyang STOCK

platform car e

6. 2.1.15 Imported Piece List

Specificatio Productio Manufacture Remar

No. Name Unit Qty

n n area r k

1 Electric weighing America STOCK Integer

system import

set 6

Mainly including

following parts:

piec 12

Specificatio Productio Manufacture Remar

No. Name Unit Qty

n n area r k

Weighing sensor e

Weighing roller piec

e 6

Bearing

piec 12

Sealing ring

e 24

Weighing lever

piec 12

subassemblies

e

set

outlet coal block

2 set 18 America STOCK

alarm device

Coal feeding control

system: 6

196 microprocessor set

controller

piec 6

Transducer (AB) e

6

Display panel and 196NT piec Integer

3 keyboard 6 America STOCK

MPC e import

Power supply plate 12

piec

A1 card (input card) e 6

A2 card (feedback set 6

card) set 12

A/D converter Set

Belt breaking coal

4 Set 6 America STOCK

alarm

Speed measuring

5 Set 6 America STOCK

device

6 Bearing Set 6 Sweden STOCK

Detector (nominal Piec

7 2 America STOCK

detector) e

7. 2.1.16 Spare Parts

2.1.16.1 Spare parts brought with machine

Production

No. Name Specification Unit Qty Manufacturer Remark

area

1 Air breaker set 1 France Schneider

2 Bearing set 1 Sweden STOCK

Scraper chain

3 Group 2 Shenyang STOCK

subassemblies

4 Sealing ring set 1 Shenyang STOCK

Middle relay Piece 2 France Schneider

AC contactor Piece 1 France Schneider

Hot relay Piece 1 France Schneider

Knob switch Piece 2 France Schneider

Transformer Piece 1 America STOCK

2.1.16.2 Recommended spare parts for three-year business operation

Specific Production

No. Name Unit Qty Manufacturer Remark

ation area

1 Weighing 2 (Respective

transducer Piece America STOCK one at left

and right)

2 Coal feeder belt 1

set Zhejiang JIE

motor transducer

3 Coal feeder belt 2 Xiangshan

Piece Zhejiang

rubber

4 Scraper chain 2

set Shenyang STOCK

subassemblies

5 Weighing roller Piece 2 Shenyang STOCK

6 Clean motor 1

reducer with set Germany FLENDER

scraper

7 Rotating speed 1

set America STOCK

measuring detector

8 196 1

microprocessor

piece America STOCK

controller

(CPU)

2.2 Overhaul Sort, Cycle and Period

Sort Cycle Period

Major overhaul 3 years 60 days

Minor overhaul 1 year 15 days

You might also like

- Sac Training Guide 2019 Final PDFDocument49 pagesSac Training Guide 2019 Final PDFArmando Santos100% (1)

- Hayssen Training ElectricalDocument17 pagesHayssen Training ElectricalRoberto SanchezNo ratings yet

- Manual Book Coal FeederDocument22 pagesManual Book Coal Feedermuhlas fabregas100% (1)

- CS2024MANUALDocument41 pagesCS2024MANUALRiaz AhmedNo ratings yet

- SPJ150 English ManualDocument22 pagesSPJ150 English ManualtuchidanNo ratings yet

- Progressive Cavity Pump (PCP) : Mohamed ElbadriDocument46 pagesProgressive Cavity Pump (PCP) : Mohamed Elbadrimohanned salah100% (3)

- Primarchs DatasheetsDocument24 pagesPrimarchs DatasheetsJosiah Young1100% (5)

- Boiler Coal FeederDocument11 pagesBoiler Coal FeederIndra PratamaNo ratings yet

- Boiler Coal FeederDocument9 pagesBoiler Coal FeederGilang NurdiansyahNo ratings yet

- NCC Nangsing HaisiDocument10 pagesNCC Nangsing HaisiLam NgoNo ratings yet

- Steam Sterilizer Technical Parameters PDFDocument7 pagesSteam Sterilizer Technical Parameters PDFSivaNo ratings yet

- 6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDDocument58 pages6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDSANTOSH TIWARINo ratings yet

- Manual 35S EnglishDocument41 pagesManual 35S EnglishgugiNo ratings yet

- User'S Manual: MODEL: MMA160/200Document9 pagesUser'S Manual: MODEL: MMA160/200Vlaovic GoranNo ratings yet

- Grinding System and Circuit of VRM Process Data Plant DataDocument58 pagesGrinding System and Circuit of VRM Process Data Plant DataFasil Ayele60% (5)

- Sales M.35S EnglishDocument41 pagesSales M.35S EnglishgugiNo ratings yet

- Cut60 3PH380VDocument13 pagesCut60 3PH380VGame ChangerNo ratings yet

- Sales Manual 35SDocument47 pagesSales Manual 35SgugiNo ratings yet

- Thermovacuum Transformer Oil Treatment Machine From CTBUDocument6 pagesThermovacuum Transformer Oil Treatment Machine From CTBUilopera1971No ratings yet

- 48 Inch Pipe Bedning (Nigeria)Document9 pages48 Inch Pipe Bedning (Nigeria)Robin SuNo ratings yet

- Specification: Electronic Level TransmitterDocument11 pagesSpecification: Electronic Level TransmitterTushar BhingradiyaNo ratings yet

- P40PB (1004G) GensetDocument4 pagesP40PB (1004G) GensetBudi WaskitoNo ratings yet

- 18 Mas4000tecDocument12 pages18 Mas4000tecSimamora Samuel HansenNo ratings yet

- Klean Esp - Ecology Units SpecDocument3 pagesKlean Esp - Ecology Units SpecAdnan KhanNo ratings yet

- Ct312 Welder ManualDocument11 pagesCt312 Welder ManualMarino CANo ratings yet

- Specification of GHR 1520 - 3BDDocument3 pagesSpecification of GHR 1520 - 3BDDoãn VănNo ratings yet

- In Oerlikon CitolineDocument10 pagesIn Oerlikon CitolineJavid Ibrahim MohamedNo ratings yet

- Sales Manual 65SDocument41 pagesSales Manual 65SgugiNo ratings yet

- Manual 65S Eng.V6Document35 pagesManual 65S Eng.V6gugiNo ratings yet

- Cilindros e Servo CilindrosDocument16 pagesCilindros e Servo CilindrosluisbottonNo ratings yet

- Strip Cladding SolutionDocument12 pagesStrip Cladding SolutionKoshy JohnNo ratings yet

- SBM 1250 Double Twist Bunching LineDocument12 pagesSBM 1250 Double Twist Bunching LineEMRE KAAN USTANo ratings yet

- Drawing Machine SpecificationDocument10 pagesDrawing Machine Specificationalopezalegria216No ratings yet

- High-Speed MIG Copper Coating Line (Single Wire)Document10 pagesHigh-Speed MIG Copper Coating Line (Single Wire)Nguyen Thanh TrungNo ratings yet

- Ta I-Series PDFDocument30 pagesTa I-Series PDFAwanNo ratings yet

- Medical Gas Pipeline SystemDocument16 pagesMedical Gas Pipeline Systemshivangiis0796511No ratings yet

- The Mid Way Report Is Expected To ExplainDocument15 pagesThe Mid Way Report Is Expected To ExplainDivanshu InsaNo ratings yet

- Diesel GensetDocument4 pagesDiesel GensetErwin GunawanNo ratings yet

- Turbine Flow Meter User Manual (003) Manual Del MedidorDocument22 pagesTurbine Flow Meter User Manual (003) Manual Del MedidorDAMASO MARTINEZ RODRIGUEZNo ratings yet

- 50DB Rig SpecificationDocument31 pages50DB Rig Specificationmartahan manurung100% (1)

- EP-SJ12025 Optical Cable Sheath Production LineDocument7 pagesEP-SJ12025 Optical Cable Sheath Production Linemehran khamsehzadehNo ratings yet

- GFM668-2 Automatic FFFdry Powder FfillerDocument17 pagesGFM668-2 Automatic FFFdry Powder Ffillermazen absiNo ratings yet

- Other - Products Slitting MachineDocument1 pageOther - Products Slitting MachineAhmad SalahNo ratings yet

- GW4-72.5/126/145D (W) Outdoor HV Disconnect Switch: Item Unit CJ6B Motor CS17 ManualDocument3 pagesGW4-72.5/126/145D (W) Outdoor HV Disconnect Switch: Item Unit CJ6B Motor CS17 ManualTerry HerreNo ratings yet

- Owner'S Manual: ModelDocument10 pagesOwner'S Manual: Modelramesh sahukhalNo ratings yet

- Fire Detection & Protection - ExcelDocument57 pagesFire Detection & Protection - ExcelMadhurima SenguptaNo ratings yet

- ZYD-Double Stages Transformer Oil Treatment NAKINDocument5 pagesZYD-Double Stages Transformer Oil Treatment NAKINKen HagemannNo ratings yet

- BY K.Prabhu 12BEEE1039Document30 pagesBY K.Prabhu 12BEEE1039raspberry piNo ratings yet

- Unilec ReportDocument18 pagesUnilec ReportKinginiKinginiNo ratings yet

- Rishu NewDocument37 pagesRishu NewAbhay AswalNo ratings yet

- Generator 1Document128 pagesGenerator 1Saravanan ElangovanNo ratings yet

- Manual OperationDocument14 pagesManual OperationJUAN DAVID DIAZ BUSTOSNo ratings yet

- English User Manuel of Mini Rotary OvensDocument40 pagesEnglish User Manuel of Mini Rotary Ovensiliad.zaryabNo ratings yet

- Technical Specifications For Centrifugal Pumps PDFDocument12 pagesTechnical Specifications For Centrifugal Pumps PDFVicky GautamNo ratings yet

- Report For 92MW Power Plant of UltratechDocument52 pagesReport For 92MW Power Plant of UltratechNirav Parmar100% (1)

- O SHZV Vacuum OLTC Leaflet-Oct.2009Document5 pagesO SHZV Vacuum OLTC Leaflet-Oct.2009Hung Cuong PhamNo ratings yet

- Spek Magnet Ctl-220 BcpspeDocument3 pagesSpek Magnet Ctl-220 BcpspeEkyharyans100% (1)

- Capital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityDocument8 pagesCapital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityLoan NguyênNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Defensive Driving SeminarDocument92 pagesDefensive Driving SeminarUrej BandiolaNo ratings yet

- Armies of Exigo CheatsDocument1 pageArmies of Exigo CheatsUrej BandiolaNo ratings yet

- Cheat Console and CodesDocument5 pagesCheat Console and CodesUrej BandiolaNo ratings yet

- Coal CalculationDocument11 pagesCoal CalculationUrej BandiolaNo ratings yet

- Cheat Console and CodesDocument5 pagesCheat Console and CodesUrej BandiolaNo ratings yet

- What Is Hydrocephalus?Document8 pagesWhat Is Hydrocephalus?Urej BandiolaNo ratings yet

- Fizika RadiologijaDocument9 pagesFizika RadiologijaBorislav TapavičkiNo ratings yet

- 3.3 PfmeaDocument5 pages3.3 PfmeaEaswaranNo ratings yet

- Teaching Maths PDFDocument171 pagesTeaching Maths PDFAnkit Emmenual RamNo ratings yet

- Low Voltage Current and Voltage Transformers PDFDocument260 pagesLow Voltage Current and Voltage Transformers PDFGustavo GamezNo ratings yet

- Remanufactured Genuine Parts CatalogueDocument22 pagesRemanufactured Genuine Parts CatalogueHenrique CorreiaNo ratings yet

- Bishop 1997Document25 pagesBishop 1997Celina AgostinhoNo ratings yet

- SOAL MID TERM ENGLISH 13 Tyad 1Document6 pagesSOAL MID TERM ENGLISH 13 Tyad 1ani julitaNo ratings yet

- LSS Benefits of Kaizen To Business Excellence Evidence From A Case Study 2169 0316 1000251 (3197)Document15 pagesLSS Benefits of Kaizen To Business Excellence Evidence From A Case Study 2169 0316 1000251 (3197)Dasa ShelkNo ratings yet

- How To Extend A BrandDocument7 pagesHow To Extend A BrandDhruv AggarwalNo ratings yet

- 1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangDocument6 pages1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangJaja JamaludinNo ratings yet

- Chapter 24 Practice QuestionsDocument7 pagesChapter 24 Practice QuestionsArlene F. Montalbo100% (1)

- 30 Top HTML Interview Questions and AnswersDocument15 pages30 Top HTML Interview Questions and AnswersAurobindaNo ratings yet

- 中论Document112 pages中论张晓亮No ratings yet

- CMIME Question Bank PDFDocument26 pagesCMIME Question Bank PDFnikNo ratings yet

- Bahir Dar University College of Medicine and Health SciencesDocument21 pagesBahir Dar University College of Medicine and Health SciencesMegbaruNo ratings yet

- Six C's of Effective MessagesDocument40 pagesSix C's of Effective MessagessheilaNo ratings yet

- CH 12Document31 pagesCH 12asin12336No ratings yet

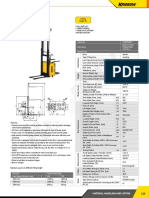

- Electric Stacker: Article No. KW0500894 Description Electric Stacker (Triplex Mast) 1.5T x3 M SpecificationDocument1 pageElectric Stacker: Article No. KW0500894 Description Electric Stacker (Triplex Mast) 1.5T x3 M SpecificationAsty RikyNo ratings yet

- IGST CH Status As On 01.01.2018Document443 pagesIGST CH Status As On 01.01.2018SK Business groupNo ratings yet

- Turbine Gas G.T.G. 1Document17 pagesTurbine Gas G.T.G. 1wilsonNo ratings yet

- GPRS Evolution PH 2Document43 pagesGPRS Evolution PH 2Nur AfiyatNo ratings yet

- Social Work - BSWDocument3 pagesSocial Work - BSWUniversity of LouisvilleNo ratings yet

- Peek - POLYETHER ETHER KETONEDocument58 pagesPeek - POLYETHER ETHER KETONEBryan Jesher Dela Cruz100% (1)

- Week 17 2nd Bondy SchoolDocument4 pagesWeek 17 2nd Bondy SchoolOswaldo Coronel UlloaNo ratings yet

- Oracle Business Intelligence Answers: Presentation ServicesDocument6 pagesOracle Business Intelligence Answers: Presentation Servicesvenkatesh.gollaNo ratings yet

- 02TP PrelimExam MITDocument2 pages02TP PrelimExam MITSnapShop by AJNo ratings yet

- Adverb Worksheet For Class 4 With AnswersDocument10 pagesAdverb Worksheet For Class 4 With Answersrodolfo penaredondoNo ratings yet