Professional Documents

Culture Documents

Job Safety Analysis: Painting Activity

Job Safety Analysis: Painting Activity

Uploaded by

Saiyad RiyazaliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis: Painting Activity

Job Safety Analysis: Painting Activity

Uploaded by

Saiyad RiyazaliCopyright:

Available Formats

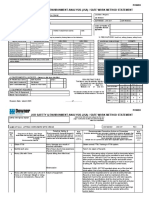

JOB SAFETY ANALYSIS

Composite Works at PTA Unit for Capacity Expansion of PX & PTA Project

PANIPAT REFINERY & PETROCHEMICAL COMPLEX

JOB SAFETY ANALYSIS

PART-A: JSA No.: PTA-JSA-014 Date: 31.10.2021 Page: 1 of 2

Unit: PX Area: PX 1&2 Location: IOCL Panipat – PTA PLANT - Cooling Water Pipeline Fabrication & Erection

Job Title: JSA done by:

Painting Activity SN. Name Designation Department

1. Rakesh Mahajan RCM L&T

2. Sandip Patil HSE – Manager L&T

Job to be Executed By

Department Contractor

.

JSA Reviewed By (HOD’s Name &

Name Designation

Designation)

HOD of Operation Department

HOD of Concerned Maintenance

Department

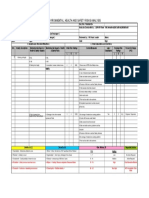

Sl. Activities Hazards Recommended Actions /Procedures Compliance Checked By

No. & Control Measures Status Name of Officer

(Complied/ Not

complied)

with Sign. date

& time

1. Painting Activity

Handling of paints. Spillage Use of Hand gloves

Use of Safety Goggle

Safe Handling

Mixing and spraying of Respiratory Use of mask, Safety goggle

paints and solvents. problem.

Skin irritation.

Fall of drum while Physical injury. Use of Hand gloves

handling Use of Mechanical Aid

Safe Handling

Wrong posture while Muscular skeleton Use of Mechanical Aid

handling disorder Safe Handling

Storage of paints. & Fire Maintain Good housekeeping

Empty Drums

Disposal of paint with proper

JOB SAFETY ANALYSIS

Composite Works at PTA Unit for Capacity Expansion of PX & PTA Project

Sl. Activities Hazards Recommended Actions /Procedures Compliance Checked By

No. & Control Measures Status Name of Officer

(Complied/ Not

complied)

with Sign. date

& time

guideline of client

Provision of Fire Extinguisher in

case of emergency

Disposal of used Fire Disposal of paint to authorized

soiled cotton waste.

agency

Disposal of paint to designated

location

Avoid land, water contamination

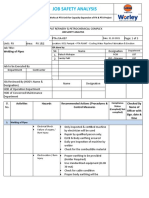

Job Safety Analysis Performed By

Name

Designation

Sign

Reviewed By HOD of Operation

HOD of Concerned Maintenance

Note:

1. To make JSA process effective, the defined job shall be broken down into sequential steps. Actions / activities for each steps

shall be logical & linked with previous & forward action steps. All possible hazards associated with each job step shall be

deliberated among team members and recorded carefully. JSA recommendations / control measures for each hazard / job step

should be validated by team members & recorded in the Part-A of JSA sheet. Use additional JSA sheets as per requirements.

1. Review of JSA shall be done by HOD of respective

Operation Department and HOD of Concerned Maintenance Department. After review, respective HOD to put his signature with

name & date.

2. The Job shall be carried out with safety precautions as per

JSA recommendations. HODs/ Fire & Safety & higher management personnel may also check compliance of JSA recommendations

while doing visit & checking of hot jobs during schedule visit to the unit / area.

You might also like

- Mineral Oil Safety Regulations 1997Document34 pagesMineral Oil Safety Regulations 1997Otoloko OgheneroNo ratings yet

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (4)

- F048-QC Earth Pit ChecklistDocument1 pageF048-QC Earth Pit ChecklistGopal Nagal - PadamsNo ratings yet

- Method Statement & Risk Assessment Hydrostatic Leak TestDocument7 pagesMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniNo ratings yet

- NAWPPL-BIMS-NPPL-000-HS-PRO-00015 - C01 - Trenching-Excavation Safety ProcedureDocument7 pagesNAWPPL-BIMS-NPPL-000-HS-PRO-00015 - C01 - Trenching-Excavation Safety ProcedureMoaatazz NouisriNo ratings yet

- JMS-STS-PIP - JMS Latest FormatDocument2 pagesJMS-STS-PIP - JMS Latest Formatmohd as shahiddin jafriNo ratings yet

- Method Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)Document4 pagesMethod Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)poovazhaganNo ratings yet

- Method Statement Fisher PlugDocument5 pagesMethod Statement Fisher PlugChezy629No ratings yet

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangNo ratings yet

- Radiography Work Permit (OGF-HSE-23)Document3 pagesRadiography Work Permit (OGF-HSE-23)Mock ProjectNo ratings yet

- OCP Confined Space ShahiDocument4 pagesOCP Confined Space ShahiVishal SrivastavaNo ratings yet

- JHA - Plumbing WorksDocument1 pageJHA - Plumbing WorksBilly Joe BreakfastNo ratings yet

- JHA Dryer Hot CommissioningDocument5 pagesJHA Dryer Hot CommissioningJowel MercadoNo ratings yet

- JSA For Confined Space 20 12 2019 - TS3Document5 pagesJSA For Confined Space 20 12 2019 - TS3narasimhamurthy414No ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- JSA - Installation, Operation and Maintenance of VSM 300 ShakerDocument5 pagesJSA - Installation, Operation and Maintenance of VSM 300 ShakerjinaNo ratings yet

- EGGS2 To GTS1 CoL Project - Night Work Waiver - Aug - UpdateDocument3 pagesEGGS2 To GTS1 CoL Project - Night Work Waiver - Aug - UpdateIkechukwu AkomaNo ratings yet

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisMuhammad TariqNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument5 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- Improvement Notice PDFDocument2 pagesImprovement Notice PDFFrancis BerryNo ratings yet

- JSA For Filter Cleaning by Steam and Water ManuallyDocument22 pagesJSA For Filter Cleaning by Steam and Water ManuallyThái Đạo Phạm LêNo ratings yet

- MS Working at HeightsDocument15 pagesMS Working at HeightsNauval FadliNo ratings yet

- Tool Box Talk Form: Date - Location - SupervisorDocument2 pagesTool Box Talk Form: Date - Location - SupervisorNeeraj SinghNo ratings yet

- Safety ObservationsDocument15 pagesSafety ObservationsPavle100% (1)

- JSA - Winstar Pipeline CrossingDocument6 pagesJSA - Winstar Pipeline CrossingRidha Bennasr100% (1)

- JSA G17 Lift Container With Crane PDFDocument4 pagesJSA G17 Lift Container With Crane PDFsetiawanaji407100% (1)

- JHA For To Carryout Activities During Unloading of Product From Ship Rev00Document4 pagesJHA For To Carryout Activities During Unloading of Product From Ship Rev00Sreekumar100% (1)

- Integrated Assurance - Checklist DetailsDocument438 pagesIntegrated Assurance - Checklist DetailsSyed AhmadNo ratings yet

- Earth Compactor Daily Check ListDocument2 pagesEarth Compactor Daily Check ListpjosesmNo ratings yet

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- 2009 Shutdown PlanDocument2 pages2009 Shutdown Planqwerty1234567894No ratings yet

- SHE Incident Investigation FormDocument3 pagesSHE Incident Investigation Formrozeena9824No ratings yet

- Erection Contractor's ScopeDocument4 pagesErection Contractor's ScopeasifaliabidNo ratings yet

- Gas TestingDocument1 pageGas TestingHow Chin Engineering Sdn BhdNo ratings yet

- Checklist ERDMP 100919Document3 pagesChecklist ERDMP 100919varunkumar415No ratings yet

- 07 - Tata Power Scaffold Safety ProcedureDocument24 pages07 - Tata Power Scaffold Safety Procedurehse bsj100% (1)

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- PTWC IssueDocument4 pagesPTWC IssueSajjad AfzalNo ratings yet

- New Jha Chemical Cleaning Phe Kakg-ADocument5 pagesNew Jha Chemical Cleaning Phe Kakg-Arizal azizan0% (1)

- 362-KMI-N2 Purging Into Station PipingDocument5 pages362-KMI-N2 Purging Into Station PipingNasrullah JanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Checklist For Equipment Inspection BikeDocument1 pageChecklist For Equipment Inspection BikeHung HoangNo ratings yet

- EHS VI 08 FaranaDocument2 pagesEHS VI 08 Faranashamshad ahamedNo ratings yet

- Confined Space Entry Plan FinalDocument7 pagesConfined Space Entry Plan FinalFaraz KhalidNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document2 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- Ansi Ppe StandardDocument1 pageAnsi Ppe StandardHerwandi Atmaja0% (1)

- Job Safety Analysis: Operating A Cordless DrillDocument3 pagesJob Safety Analysis: Operating A Cordless DrillAkmanezy Abdullah100% (1)

- Jsa 2Document5 pagesJsa 2Muddassir Baig MirzaNo ratings yet

- 10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetyDocument21 pages10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetySamerNo ratings yet

- Pre-Mobilisation Assurance Checklist BackupDocument7 pagesPre-Mobilisation Assurance Checklist BackupNazrin SHONo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Weekly Safety Management Walkthrough Report: Gas Compression Project DepartmentDocument12 pagesWeekly Safety Management Walkthrough Report: Gas Compression Project DepartmentSheri DiĺlNo ratings yet

- JSA Arc WeldingDocument2 pagesJSA Arc WeldinganeshseNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Ohs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordDocument1 pageOhs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordShafie ZubierNo ratings yet

- Safe Work Practice Dozer OperatorsDocument4 pagesSafe Work Practice Dozer OperatorsMuhammad Ashraf AhmadNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- PTA-JSA-013-Shot Blasting OperationDocument3 pagesPTA-JSA-013-Shot Blasting OperationSaiyad RiyazaliNo ratings yet

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- PTA-JSA-008 - Vessel & Pump ErectionDocument13 pagesPTA-JSA-008 - Vessel & Pump ErectionSaiyad RiyazaliNo ratings yet

- PTA-JSA-012-Diesel Generator Operation (For Electrical Supply)Document3 pagesPTA-JSA-012-Diesel Generator Operation (For Electrical Supply)Saiyad RiyazaliNo ratings yet

- Ccsm-Mie-Hse-Jha-003 3. Electrical Cable Tray & Conduit Installation Rev.0Document11 pagesCcsm-Mie-Hse-Jha-003 3. Electrical Cable Tray & Conduit Installation Rev.0Saiyad RiyazaliNo ratings yet

- PTA-JSA-007-Welding of PipesDocument3 pagesPTA-JSA-007-Welding of PipesSaiyad RiyazaliNo ratings yet

- PTA-JSA-013-Shot Blasting OperationDocument3 pagesPTA-JSA-013-Shot Blasting OperationSaiyad RiyazaliNo ratings yet

- PTA-JSA-009-Gas Cutting OperationDocument3 pagesPTA-JSA-009-Gas Cutting OperationSaiyad RiyazaliNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- PTA-JSA-006-Erection of PipesSpools at HeightsDocument3 pagesPTA-JSA-006-Erection of PipesSpools at HeightsSaiyad RiyazaliNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Lifting Plan General Risk Assessments AnDocument36 pagesLifting Plan General Risk Assessments AnSaiyad RiyazaliNo ratings yet

- PTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobDocument3 pagesPTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobSaiyad RiyazaliNo ratings yet

- PTW PresentationDocument13 pagesPTW Presentationkevin kishoreNo ratings yet

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Emergency Response Flow Chart: Job Saety AnalysisDocument5 pagesEmergency Response Flow Chart: Job Saety AnalysisjneNo ratings yet

- Job Safety Analysis Construction, EtcDocument3 pagesJob Safety Analysis Construction, EtcCamilo Salvadora MasbateNo ratings yet

- Hse Management SystemDocument163 pagesHse Management SystemYogesh HardasaniNo ratings yet

- Job Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRDocument5 pagesJob Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRAkash ShuklaNo ratings yet

- JSA - Replace Grinding Wheel From Bench GrinderDocument2 pagesJSA - Replace Grinding Wheel From Bench GrinderAshok Suresh100% (1)

- Job Safety Analysis Template - BatteryDocument3 pagesJob Safety Analysis Template - BatteryvenkateshbitraNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- 33 Allchapters PDFDocument88 pages33 Allchapters PDFSylvain DidyNo ratings yet

- Boiler Pressure Part Risk AssessmentDocument55 pagesBoiler Pressure Part Risk AssessmentSerkan YaşaNo ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- PROC-02 Training and Competency Procedure PDFDocument10 pagesPROC-02 Training and Competency Procedure PDFHaeqel FazarNo ratings yet

- 77 Chemical Mixing and Handling - JOB PROCEDUREDocument2 pages77 Chemical Mixing and Handling - JOB PROCEDUREShahrizatSmailKassim100% (1)

- JSA For Metering Panel Installation at SS 40 CO2 Recovery PlantDocument11 pagesJSA For Metering Panel Installation at SS 40 CO2 Recovery PlantHabib ur rahmanNo ratings yet

- JSA For Erection and Dismantling of ScaffoldingDocument4 pagesJSA For Erection and Dismantling of ScaffoldingAndoFritzzJrNo ratings yet

- Job Risk Assessment and Control GIS Recovery Boilerx1Document11 pagesJob Risk Assessment and Control GIS Recovery Boilerx1FerdyCodetzNo ratings yet

- Job Safety Analysis TemplateDocument1 pageJob Safety Analysis TemplateVikramNo ratings yet

- Cement Feeding From Bulker To Silo JSA HSE ProfessionalsDocument1 pageCement Feeding From Bulker To Silo JSA HSE Professionalsm.rehanhseNo ratings yet

- 8 Risk AssessmentDocument58 pages8 Risk AssessmentSuzaini SupingatNo ratings yet

- Evaporation Pond at SLBPDocument3 pagesEvaporation Pond at SLBPHaleemUrRashidBangashNo ratings yet

- 022 JSA Dry OvenDocument2 pages022 JSA Dry OvenBenjamin FabinNo ratings yet

- Field Level Risk AssessmentDocument31 pagesField Level Risk AssessmentAaquil RaziNo ratings yet

- SAFETY TAILGATE Job Safety Analysis (JSA) - Risk Control Online PDFDocument2 pagesSAFETY TAILGATE Job Safety Analysis (JSA) - Risk Control Online PDFS A L M A NNo ratings yet

- Electrical Safety Management Plan: (7 Revision)Document34 pagesElectrical Safety Management Plan: (7 Revision)Afandie Van WhyNo ratings yet

- HP Steam Drum-Hrsg IiDocument6 pagesHP Steam Drum-Hrsg IiDeepak SharmaNo ratings yet

- JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDocument2 pagesJSA - 008 - Hydraulic Rig and Mobile Crane MarchingAhmed AlderbiNo ratings yet

- Job Safety Analysis Work Sheet Steel FixingDocument17 pagesJob Safety Analysis Work Sheet Steel FixingHafiz M WaqasNo ratings yet