Professional Documents

Culture Documents

PTA-JSA-013-Shot Blasting Operation

PTA-JSA-013-Shot Blasting Operation

Uploaded by

Saiyad RiyazaliCopyright:

Available Formats

You might also like

- Organic Chemistry Board Exam QuestionsDocument10 pagesOrganic Chemistry Board Exam QuestionsRiza Joie Versales100% (1)

- JSA For Garden Maint Tree Trim JobDocument1 pageJSA For Garden Maint Tree Trim JobMIAN MATEENNo ratings yet

- Vocabulary PowerDocument5 pagesVocabulary PowerstrawhatalexNo ratings yet

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- Subcontractor Production Report: Job SafetyDocument2 pagesSubcontractor Production Report: Job Safetyzubair nawazNo ratings yet

- Johnston (1999) Why We Feel. The Science of Human EmotionsDocument221 pagesJohnston (1999) Why We Feel. The Science of Human EmotionsNavi Setnom ArieugonNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- Job Cycle Check Plan 2019: Sr. No Work Order # Plant Asset Number Asset DescriptionDocument4 pagesJob Cycle Check Plan 2019: Sr. No Work Order # Plant Asset Number Asset DescriptionHamza NoumanNo ratings yet

- FR-HSE-65 Need Training AnalysisDocument1 pageFR-HSE-65 Need Training Analysishse grogolNo ratings yet

- JOB ANALISYS SAFETY All WorkDocument11 pagesJOB ANALISYS SAFETY All WorkMansur SaifudinNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- RF Tower ErectionDocument3 pagesRF Tower Erectionmohammed altmashNo ratings yet

- PTW Jha Air PipeDocument3 pagesPTW Jha Air PipePHH9834No ratings yet

- Hazards Identification Risk AssessmentRRRRDocument7 pagesHazards Identification Risk AssessmentRRRRArshad KhanNo ratings yet

- Overview of Assessment in Blasting Performance Analysis in Surface MinesDocument14 pagesOverview of Assessment in Blasting Performance Analysis in Surface MinesAnurag TripathyNo ratings yet

- RA0019 General Lifting Operation v1Document6 pagesRA0019 General Lifting Operation v1dsadasNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- Lifting Plan 50tonDocument9 pagesLifting Plan 50tonViejay BalachandarNo ratings yet

- 02 WMS - Loading Unloading of MaterialsDocument5 pages02 WMS - Loading Unloading of MaterialsHimanshu NiveriyaNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Confined Space Entry Plan FinalDocument7 pagesConfined Space Entry Plan FinalFaraz KhalidNo ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- HIRA - Pile CapDocument4 pagesHIRA - Pile CapMMRDACA07 SAFETYNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNo ratings yet

- Topography SurveyDocument2 pagesTopography SurveyAMIN100% (2)

- Solar Panel Installation - What You Need To Know To Work SafelyDocument4 pagesSolar Panel Installation - What You Need To Know To Work SafelyUlviyye Cavid-Umid ElesgerovaNo ratings yet

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- JSA Painting RM StoreDocument4 pagesJSA Painting RM StoreKhalid NaseemNo ratings yet

- IRQSDocument3 pagesIRQSBappaditya BhowmikNo ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- Jsa Energizing Final Tapping Back FeedingDocument7 pagesJsa Energizing Final Tapping Back FeedingekapadwiNo ratings yet

- Lifting Operation (JSA)Document4 pagesLifting Operation (JSA)abdullah ashrafNo ratings yet

- Safety Training Plan ExampleDocument2 pagesSafety Training Plan ExampleBilly Billy100% (1)

- HIRA - Material Handling and Piping WorkDocument16 pagesHIRA - Material Handling and Piping Worksrinu degalaNo ratings yet

- HIRAC B224 Najarul On 20.11Document33 pagesHIRAC B224 Najarul On 20.11Surendra JangidNo ratings yet

- Safety AlertDocument3 pagesSafety AlertAbdullah TwfeeqNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- CHRC SWMS Mobilisation and DeMobilisationDocument8 pagesCHRC SWMS Mobilisation and DeMobilisationStansilous Tatenda NyagomoNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Mohamad Afiq Hazwan (HIRARC 2021)Document3 pagesMohamad Afiq Hazwan (HIRARC 2021)afiq2697No ratings yet

- JHA For Excavation - JackhammerDocument4 pagesJHA For Excavation - JackhammerawadudalhassanNo ratings yet

- SHE Incident Investigation FormDocument3 pagesSHE Incident Investigation Formrozeena9824No ratings yet

- Training RecordDocument2 pagesTraining RecordppratheepriyaNo ratings yet

- Crawler Crane Assembling-De-assemblingDocument4 pagesCrawler Crane Assembling-De-assemblingum erNo ratings yet

- JHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10Document11 pagesJHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10M.k.BurhanNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobDocument3 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobYosua SitumorangNo ratings yet

- JHA Lifting-Moving Heavy ObjectsDocument5 pagesJHA Lifting-Moving Heavy ObjectsOgunwa EmmanuelNo ratings yet

- Hazard MappingDocument13 pagesHazard MappinggizewNo ratings yet

- JHA SampleDocument1 pageJHA SampleJoseph PerezNo ratings yet

- JSA of Materila Handling ApproviedDocument2 pagesJSA of Materila Handling Approviedsakthi venkatNo ratings yet

- Blasting: Assistants, Labourers & Security GuardsDocument4 pagesBlasting: Assistants, Labourers & Security GuardsSoundar PachiappanNo ratings yet

- Welding JSADocument2 pagesWelding JSAMD AbdullahNo ratings yet

- 15 JSA Intallation Support PipeDocument4 pages15 JSA Intallation Support PipeYosua SitumorangNo ratings yet

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- Risk Assessment: Job:Control Blasting For Wagon TipplerDocument1 pageRisk Assessment: Job:Control Blasting For Wagon Tipplerali rezaNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- PTA-JSA-006-Erection of PipesSpools at HeightsDocument3 pagesPTA-JSA-006-Erection of PipesSpools at HeightsSaiyad RiyazaliNo ratings yet

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- PTA-JSA-008 - Vessel & Pump ErectionDocument13 pagesPTA-JSA-008 - Vessel & Pump ErectionSaiyad RiyazaliNo ratings yet

- PTA-JSA-012-Diesel Generator Operation (For Electrical Supply)Document3 pagesPTA-JSA-012-Diesel Generator Operation (For Electrical Supply)Saiyad RiyazaliNo ratings yet

- Ccsm-Mie-Hse-Jha-003 3. Electrical Cable Tray & Conduit Installation Rev.0Document11 pagesCcsm-Mie-Hse-Jha-003 3. Electrical Cable Tray & Conduit Installation Rev.0Saiyad RiyazaliNo ratings yet

- PTA-JSA-007-Welding of PipesDocument3 pagesPTA-JSA-007-Welding of PipesSaiyad RiyazaliNo ratings yet

- Job Safety Analysis: Painting ActivityDocument2 pagesJob Safety Analysis: Painting ActivitySaiyad RiyazaliNo ratings yet

- PTA-JSA-009-Gas Cutting OperationDocument3 pagesPTA-JSA-009-Gas Cutting OperationSaiyad RiyazaliNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- PTA-JSA-006-Erection of PipesSpools at HeightsDocument3 pagesPTA-JSA-006-Erection of PipesSpools at HeightsSaiyad RiyazaliNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Lifting Plan General Risk Assessments AnDocument36 pagesLifting Plan General Risk Assessments AnSaiyad RiyazaliNo ratings yet

- PTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobDocument3 pagesPTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobSaiyad RiyazaliNo ratings yet

- (Instructor Version) : Packet Tracer - Ipv6 Dynamic Routing - EigrpDocument3 pages(Instructor Version) : Packet Tracer - Ipv6 Dynamic Routing - EigrpJangjung gmail.comNo ratings yet

- Leakage Management TechnologiesDocument380 pagesLeakage Management TechnologiesWengineerNo ratings yet

- CSA Standard W178.2-01: Certification of Welding InspectorsDocument2 pagesCSA Standard W178.2-01: Certification of Welding InspectorsramalingamNo ratings yet

- Teaching For Reading MiDocument17 pagesTeaching For Reading MiRevi WijanarkoNo ratings yet

- A30 CismDocument14 pagesA30 CismRohan SharmaNo ratings yet

- Calculus III and IV - SodinDocument164 pagesCalculus III and IV - Sodintom-manor-1138No ratings yet

- Cabbash Vms BrochureDocument22 pagesCabbash Vms BrochureOghosa OsahenrhumwenNo ratings yet

- 72.61.00.045 26-MAR-2020 08-DEC-2021 Closed A319-100N, A320-200N, A321-200N, A321-200NX, A321-200NY 72-61 Iae LLC Pratt & Whitney TFU UpdateDocument9 pages72.61.00.045 26-MAR-2020 08-DEC-2021 Closed A319-100N, A320-200N, A321-200N, A321-200NX, A321-200NY 72-61 Iae LLC Pratt & Whitney TFU UpdatejivomirNo ratings yet

- Math in Focus 4A WorksheetDocument9 pagesMath in Focus 4A WorksheetBobbili PooliNo ratings yet

- 207 Money Saving FixesDocument149 pages207 Money Saving FixesCarmen Elena Nastasă100% (3)

- 3629 Structtimber1 PDFDocument33 pages3629 Structtimber1 PDFPrithwish2014No ratings yet

- BGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Document32 pagesBGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Nitesh MulukNo ratings yet

- METRIX AUTOCOMP - Company ProfileDocument2 pagesMETRIX AUTOCOMP - Company ProfileVaibhav AggarwalNo ratings yet

- SUVAT LoopDocument1 pageSUVAT LoopAhmed ZakiNo ratings yet

- COT1-3rd HirarkiyaDocument49 pagesCOT1-3rd HirarkiyaRommel LasugasNo ratings yet

- Psalm 127 - Overview"Document1 pagePsalm 127 - Overview"Malcolm CoxNo ratings yet

- University of Zimbabwe B.Sc. (Engineering) Honours - Level IIDocument6 pagesUniversity of Zimbabwe B.Sc. (Engineering) Honours - Level IIkundayi shavaNo ratings yet

- DichotomousKeyNYFish PDFDocument13 pagesDichotomousKeyNYFish PDFNermine AbedNo ratings yet

- IB Chemistry - SL Topic 7 Questions 1Document19 pagesIB Chemistry - SL Topic 7 Questions 1vaxor16689No ratings yet

- 7 - Simulations and PFDsDocument23 pages7 - Simulations and PFDsIslam SolimanNo ratings yet

- Aspirations of Peace and Nonviolence-Chandan-Sukumar-SenguptaDocument7 pagesAspirations of Peace and Nonviolence-Chandan-Sukumar-SenguptaSENGUPTA CHANDANNo ratings yet

- Page 5 of 48: Assignment On Garment Manufacturing - Quality Control PDFDocument50 pagesPage 5 of 48: Assignment On Garment Manufacturing - Quality Control PDFShivangi RajouriyaNo ratings yet

- Sprovieri (Final Assignment)Document9 pagesSprovieri (Final Assignment)Paulo Thiago SprovieriNo ratings yet

- 2july Grade 1 TestDocument12 pages2july Grade 1 TestEron Roi Centina-gacutanNo ratings yet

- Buying Guide Truck Scales EN v11 Low PDFDocument80 pagesBuying Guide Truck Scales EN v11 Low PDFBồ Công AnhNo ratings yet

- MLD 201aDocument13 pagesMLD 201aChaucer19No ratings yet

- Class XII Applied Mathematics 2023-24 (K R Mangalam School)Document7 pagesClass XII Applied Mathematics 2023-24 (K R Mangalam School)GouriJayanNo ratings yet

PTA-JSA-013-Shot Blasting Operation

PTA-JSA-013-Shot Blasting Operation

Uploaded by

Saiyad RiyazaliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTA-JSA-013-Shot Blasting Operation

PTA-JSA-013-Shot Blasting Operation

Uploaded by

Saiyad RiyazaliCopyright:

Available Formats

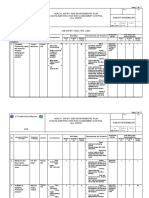

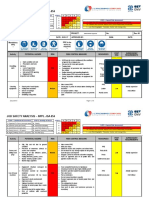

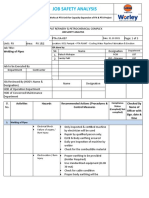

JOB SAFETY ANALYSIS

Composite Works at PTA Unit for Capacity Expansion of PX & PTA Project

PANIPAT REFINERY & PETROCHEMICAL COMPLEX

JOB SAFETY ANALYSIS

PART-A: JSA No.: PTA-JSA-013 Date: 31.10.2021 Page: 1 of 2

Unit: PX Area: PX 1&2 Location: IOCL Panipat – PTA PLANT - Cooling Water Pipeline Fabrication & Erection

Job Title: JSA done by:

Shot Blasting Operation SN. Name Designation Department

1. Rakesh Mahajan RCM L&T

2. Sandip Patil HSE – Manager L&T

Job to be Executed By

Department Contractor

.

JSA Reviewed By (HOD’s Name &

Name Designation

Designation)

HOD of Operation Department

HOD of Concerned Maintenance

Department

Sl. Activities Hazards Recommended Actions /Procedures & Compliance Checked By

No. Control Measures Status Name of

(Complied/ Not

complied)

Officer with

Sign. date &

time

1. Shot Blasting Operation

Shot Blasting Noise Use of Ear Plug/ Muff

Operation

Working at height Use of Scaffolding/ Platforms

Use of Safety Harness while work

Flying particles/ Use of shot blasting suit with supply

Dust airline with Deadman switch.

Hood & full body apron, Hand gloves

Busting of hose Use ISI marked hose & fittings

pipe Maintain hose test certificate.

Periodical checking of pipes visually

for any damage

Use whip lock for avoiding the pipe

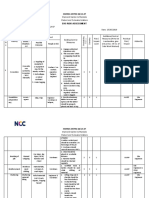

JOB SAFETY ANALYSIS

Composite Works at PTA Unit for Capacity Expansion of PX & PTA Project

Sl. Activities Hazards Recommended Actions /Procedures & Compliance Checked By

No. Control Measures Status Name of

(Complied/ Not

complied)

Officer with

Sign. date &

time

flyoff

Vibrations Use of hand gloves & intervals

breaks.

Preventive maintenance of equipment

Bursting of hopper Periodical Inspection by competent

person

Conditioning of Hopper

Compressor Regular preventive maintenance shall

failure, leakage carry out

Obtain third party inspection and

Form 1o

Check for any leakage

Job Safety Analysis Performed By

Name

Designation

Sign

Reviewed By HOD of Operation

HOD of Concerned Maintenance

Note:

1. To make JSA process effective, the defined job shall be broken down into sequential steps. Actions / activities for each steps

shall be logical & linked with previous & forward action steps. All possible hazards associated with each job step shall be

deliberated among team members and recorded carefully. JSA recommendations / control measures for each hazard / job step

should be validated by team members & recorded in the Part-A of JSA sheet. Use additional JSA sheets as per requirements.

1. Review of JSA shall be done by HOD of respective

Operation Department and HOD of Concerned Maintenance Department. After review, respective HOD to put his signature with

name & date.

2. The Job shall be carried out with safety precautions as per

JSA recommendations. HODs/ Fire & Safety & higher management personnel may also check compliance of JSA recommendations

while doing visit & checking of hot jobs during schedule visit to the unit / area.

JOB SAFETY ANALYSIS

Composite Works at PTA Unit for Capacity Expansion of PX & PTA Project

You might also like

- Organic Chemistry Board Exam QuestionsDocument10 pagesOrganic Chemistry Board Exam QuestionsRiza Joie Versales100% (1)

- JSA For Garden Maint Tree Trim JobDocument1 pageJSA For Garden Maint Tree Trim JobMIAN MATEENNo ratings yet

- Vocabulary PowerDocument5 pagesVocabulary PowerstrawhatalexNo ratings yet

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- Subcontractor Production Report: Job SafetyDocument2 pagesSubcontractor Production Report: Job Safetyzubair nawazNo ratings yet

- Johnston (1999) Why We Feel. The Science of Human EmotionsDocument221 pagesJohnston (1999) Why We Feel. The Science of Human EmotionsNavi Setnom ArieugonNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- Job Cycle Check Plan 2019: Sr. No Work Order # Plant Asset Number Asset DescriptionDocument4 pagesJob Cycle Check Plan 2019: Sr. No Work Order # Plant Asset Number Asset DescriptionHamza NoumanNo ratings yet

- FR-HSE-65 Need Training AnalysisDocument1 pageFR-HSE-65 Need Training Analysishse grogolNo ratings yet

- JOB ANALISYS SAFETY All WorkDocument11 pagesJOB ANALISYS SAFETY All WorkMansur SaifudinNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- RF Tower ErectionDocument3 pagesRF Tower Erectionmohammed altmashNo ratings yet

- PTW Jha Air PipeDocument3 pagesPTW Jha Air PipePHH9834No ratings yet

- Hazards Identification Risk AssessmentRRRRDocument7 pagesHazards Identification Risk AssessmentRRRRArshad KhanNo ratings yet

- Overview of Assessment in Blasting Performance Analysis in Surface MinesDocument14 pagesOverview of Assessment in Blasting Performance Analysis in Surface MinesAnurag TripathyNo ratings yet

- RA0019 General Lifting Operation v1Document6 pagesRA0019 General Lifting Operation v1dsadasNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- Lifting Plan 50tonDocument9 pagesLifting Plan 50tonViejay BalachandarNo ratings yet

- 02 WMS - Loading Unloading of MaterialsDocument5 pages02 WMS - Loading Unloading of MaterialsHimanshu NiveriyaNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Confined Space Entry Plan FinalDocument7 pagesConfined Space Entry Plan FinalFaraz KhalidNo ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- HIRA - Pile CapDocument4 pagesHIRA - Pile CapMMRDACA07 SAFETYNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNo ratings yet

- Topography SurveyDocument2 pagesTopography SurveyAMIN100% (2)

- Solar Panel Installation - What You Need To Know To Work SafelyDocument4 pagesSolar Panel Installation - What You Need To Know To Work SafelyUlviyye Cavid-Umid ElesgerovaNo ratings yet

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- JSA Painting RM StoreDocument4 pagesJSA Painting RM StoreKhalid NaseemNo ratings yet

- IRQSDocument3 pagesIRQSBappaditya BhowmikNo ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- Jsa Energizing Final Tapping Back FeedingDocument7 pagesJsa Energizing Final Tapping Back FeedingekapadwiNo ratings yet

- Lifting Operation (JSA)Document4 pagesLifting Operation (JSA)abdullah ashrafNo ratings yet

- Safety Training Plan ExampleDocument2 pagesSafety Training Plan ExampleBilly Billy100% (1)

- HIRA - Material Handling and Piping WorkDocument16 pagesHIRA - Material Handling and Piping Worksrinu degalaNo ratings yet

- HIRAC B224 Najarul On 20.11Document33 pagesHIRAC B224 Najarul On 20.11Surendra JangidNo ratings yet

- Safety AlertDocument3 pagesSafety AlertAbdullah TwfeeqNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- CHRC SWMS Mobilisation and DeMobilisationDocument8 pagesCHRC SWMS Mobilisation and DeMobilisationStansilous Tatenda NyagomoNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Mohamad Afiq Hazwan (HIRARC 2021)Document3 pagesMohamad Afiq Hazwan (HIRARC 2021)afiq2697No ratings yet

- JHA For Excavation - JackhammerDocument4 pagesJHA For Excavation - JackhammerawadudalhassanNo ratings yet

- SHE Incident Investigation FormDocument3 pagesSHE Incident Investigation Formrozeena9824No ratings yet

- Training RecordDocument2 pagesTraining RecordppratheepriyaNo ratings yet

- Crawler Crane Assembling-De-assemblingDocument4 pagesCrawler Crane Assembling-De-assemblingum erNo ratings yet

- JHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10Document11 pagesJHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10M.k.BurhanNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobDocument3 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobYosua SitumorangNo ratings yet

- JHA Lifting-Moving Heavy ObjectsDocument5 pagesJHA Lifting-Moving Heavy ObjectsOgunwa EmmanuelNo ratings yet

- Hazard MappingDocument13 pagesHazard MappinggizewNo ratings yet

- JHA SampleDocument1 pageJHA SampleJoseph PerezNo ratings yet

- JSA of Materila Handling ApproviedDocument2 pagesJSA of Materila Handling Approviedsakthi venkatNo ratings yet

- Blasting: Assistants, Labourers & Security GuardsDocument4 pagesBlasting: Assistants, Labourers & Security GuardsSoundar PachiappanNo ratings yet

- Welding JSADocument2 pagesWelding JSAMD AbdullahNo ratings yet

- 15 JSA Intallation Support PipeDocument4 pages15 JSA Intallation Support PipeYosua SitumorangNo ratings yet

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- Risk Assessment: Job:Control Blasting For Wagon TipplerDocument1 pageRisk Assessment: Job:Control Blasting For Wagon Tipplerali rezaNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- PTA-JSA-006-Erection of PipesSpools at HeightsDocument3 pagesPTA-JSA-006-Erection of PipesSpools at HeightsSaiyad RiyazaliNo ratings yet

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- PTA-JSA-008 - Vessel & Pump ErectionDocument13 pagesPTA-JSA-008 - Vessel & Pump ErectionSaiyad RiyazaliNo ratings yet

- PTA-JSA-012-Diesel Generator Operation (For Electrical Supply)Document3 pagesPTA-JSA-012-Diesel Generator Operation (For Electrical Supply)Saiyad RiyazaliNo ratings yet

- Ccsm-Mie-Hse-Jha-003 3. Electrical Cable Tray & Conduit Installation Rev.0Document11 pagesCcsm-Mie-Hse-Jha-003 3. Electrical Cable Tray & Conduit Installation Rev.0Saiyad RiyazaliNo ratings yet

- PTA-JSA-007-Welding of PipesDocument3 pagesPTA-JSA-007-Welding of PipesSaiyad RiyazaliNo ratings yet

- Job Safety Analysis: Painting ActivityDocument2 pagesJob Safety Analysis: Painting ActivitySaiyad RiyazaliNo ratings yet

- PTA-JSA-009-Gas Cutting OperationDocument3 pagesPTA-JSA-009-Gas Cutting OperationSaiyad RiyazaliNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- PTA-JSA-006-Erection of PipesSpools at HeightsDocument3 pagesPTA-JSA-006-Erection of PipesSpools at HeightsSaiyad RiyazaliNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Lifting Plan General Risk Assessments AnDocument36 pagesLifting Plan General Risk Assessments AnSaiyad RiyazaliNo ratings yet

- PTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobDocument3 pagesPTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobSaiyad RiyazaliNo ratings yet

- (Instructor Version) : Packet Tracer - Ipv6 Dynamic Routing - EigrpDocument3 pages(Instructor Version) : Packet Tracer - Ipv6 Dynamic Routing - EigrpJangjung gmail.comNo ratings yet

- Leakage Management TechnologiesDocument380 pagesLeakage Management TechnologiesWengineerNo ratings yet

- CSA Standard W178.2-01: Certification of Welding InspectorsDocument2 pagesCSA Standard W178.2-01: Certification of Welding InspectorsramalingamNo ratings yet

- Teaching For Reading MiDocument17 pagesTeaching For Reading MiRevi WijanarkoNo ratings yet

- A30 CismDocument14 pagesA30 CismRohan SharmaNo ratings yet

- Calculus III and IV - SodinDocument164 pagesCalculus III and IV - Sodintom-manor-1138No ratings yet

- Cabbash Vms BrochureDocument22 pagesCabbash Vms BrochureOghosa OsahenrhumwenNo ratings yet

- 72.61.00.045 26-MAR-2020 08-DEC-2021 Closed A319-100N, A320-200N, A321-200N, A321-200NX, A321-200NY 72-61 Iae LLC Pratt & Whitney TFU UpdateDocument9 pages72.61.00.045 26-MAR-2020 08-DEC-2021 Closed A319-100N, A320-200N, A321-200N, A321-200NX, A321-200NY 72-61 Iae LLC Pratt & Whitney TFU UpdatejivomirNo ratings yet

- Math in Focus 4A WorksheetDocument9 pagesMath in Focus 4A WorksheetBobbili PooliNo ratings yet

- 207 Money Saving FixesDocument149 pages207 Money Saving FixesCarmen Elena Nastasă100% (3)

- 3629 Structtimber1 PDFDocument33 pages3629 Structtimber1 PDFPrithwish2014No ratings yet

- BGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Document32 pagesBGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Nitesh MulukNo ratings yet

- METRIX AUTOCOMP - Company ProfileDocument2 pagesMETRIX AUTOCOMP - Company ProfileVaibhav AggarwalNo ratings yet

- SUVAT LoopDocument1 pageSUVAT LoopAhmed ZakiNo ratings yet

- COT1-3rd HirarkiyaDocument49 pagesCOT1-3rd HirarkiyaRommel LasugasNo ratings yet

- Psalm 127 - Overview"Document1 pagePsalm 127 - Overview"Malcolm CoxNo ratings yet

- University of Zimbabwe B.Sc. (Engineering) Honours - Level IIDocument6 pagesUniversity of Zimbabwe B.Sc. (Engineering) Honours - Level IIkundayi shavaNo ratings yet

- DichotomousKeyNYFish PDFDocument13 pagesDichotomousKeyNYFish PDFNermine AbedNo ratings yet

- IB Chemistry - SL Topic 7 Questions 1Document19 pagesIB Chemistry - SL Topic 7 Questions 1vaxor16689No ratings yet

- 7 - Simulations and PFDsDocument23 pages7 - Simulations and PFDsIslam SolimanNo ratings yet

- Aspirations of Peace and Nonviolence-Chandan-Sukumar-SenguptaDocument7 pagesAspirations of Peace and Nonviolence-Chandan-Sukumar-SenguptaSENGUPTA CHANDANNo ratings yet

- Page 5 of 48: Assignment On Garment Manufacturing - Quality Control PDFDocument50 pagesPage 5 of 48: Assignment On Garment Manufacturing - Quality Control PDFShivangi RajouriyaNo ratings yet

- Sprovieri (Final Assignment)Document9 pagesSprovieri (Final Assignment)Paulo Thiago SprovieriNo ratings yet

- 2july Grade 1 TestDocument12 pages2july Grade 1 TestEron Roi Centina-gacutanNo ratings yet

- Buying Guide Truck Scales EN v11 Low PDFDocument80 pagesBuying Guide Truck Scales EN v11 Low PDFBồ Công AnhNo ratings yet

- MLD 201aDocument13 pagesMLD 201aChaucer19No ratings yet

- Class XII Applied Mathematics 2023-24 (K R Mangalam School)Document7 pagesClass XII Applied Mathematics 2023-24 (K R Mangalam School)GouriJayanNo ratings yet