Professional Documents

Culture Documents

HIRA - Fixed Scaffold and Wall Breaking

HIRA - Fixed Scaffold and Wall Breaking

Uploaded by

Sujan AugustinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIRA - Fixed Scaffold and Wall Breaking

HIRA - Fixed Scaffold and Wall Breaking

Uploaded by

Sujan AugustinCopyright:

Available Formats

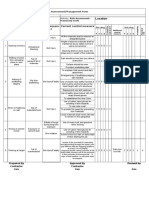

AL MUSAIRIE TRADING & CONTRACTING CO.

QATAR WLL

HAZARD IDENTIFICATION & RISK ASSESSMENT

Severity Factor: - (S) Probability Factor: - (P)

0 NO IMPACT UPON PERSONS, ENVIRONMENT OR PROPERTY

0 ZERO POSSIBILITY

< 1 EVERY 10,000 OPERATIONS 1 EVERY 10 YEARS OPERATING (Unlikely)

1 MINIMAL IMPACT FIRST AID, MINOR EQUIPMENT DAMAGE 1

(Remote)

(TRIVIAL)

< 1 EVERY 10,000 OPERATIONS 1 EVERY OPERATING YEARS

2 MODERATE IMPACT NON LOST TIME ACCIDENTS (LTA), DAMAGE REQUIRING 2

(Unlikely) (Possible but unlikely)

(MINOR) OUTSIDE HELP OR MINOR DELAY

< 10 EVERY 10,000 OPERATIONS 1 EVERY MONTH OPERATING (Likely to occur)

3

3 SERIOUS IMPACT LTA OR SERIOUS INJURIES POSSIBLE, DAMAGE / (Possible)

(LOSS TIME/ SUPSPENSION OF OPERATIONS

< 10 EVERY 100 OPERATIONS 1 EVERY WEEK OPERATING

MODERATE) 4

(Likely) (Hazard will Experienced)

4 MAJOR IMPACT LIFE THRETENING, MAJOR EQUIPMENT OR

(MAJOR) OPERATIONAL DAMAGE INCIDENT MOST LIKELY WILL HAPPEN 1 EVERY DAY OPERATING

5 (Certain)

5 CATASTROPHIC IMPACT LOSS OF PERSON (S), SEVERE STRUCTURAL OR

(FATAL) ENVIRONMENTAL DAMAGE

MTC-OHS-F-001 | REV 0 | 1st June, 2013 Page 1

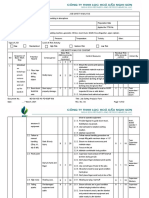

AL MUSAIRIE TRADING & CONTRACTING CO. QATAR WLL

HAZARD IDENTIFICATION & RISK ASSESSMENT

Client: Aspire Assessment Date: NOV 11, 2019

Project: Civil & Building Maintenance Project System/ Activity: Scaffolding –Removal of aluminum Rev. No.: 00

cladding and wall Breaking with the Use of Hilti Chipping

Drill Machine

Assessment Team: Bijukrishna P P Reviewed By: Sureshkumar

Task/Element Potential hazards/Consequences Population at Risk Rating Score Control Measures Revised Risk

Risk L S R L S R

Site Preparation Heavy Barriers – Improper Scaffolders, labors, 5 2 10 1. Choose lighter barriers (indoor barriers) 2 2 4

Manual Lifting supervisor, public 2. Isolate the area with barricade system

a. Muscle strain and caution signs

Unauthorized Entry 3. Educate workers about proper body

mechanics (bent knees, straight back

while lifting loads)

4. Coordinate with BMS about the time

when the task does not have an impact

on the public

Existing Services beneath Mason 4 5 20 1. Utilize Cable Avoidance Tool (CAT) to 1 5 5

the wall scan cables and pipes beneath the wall;

a. Property Damage should be done prior commencement of

b. Electrocution work

2. Check with MFMS & BMS Team the

layout/drawing for any buried services

Erection of Scaffold Damaged scaffold Scaffolders, labors, 5 4 20 1. Inspect scaffold materials before use 2 4 8

components (dented, supervisor, public 2. Remove dented or rusted materials from

rusted) service

a. Collapse of scaffold

b. Fatality

MTC-OHS-F-001 | REV 0 | 1st June, 2013 Page 2

AL MUSAIRIE TRADING & CONTRACTING CO. QATAR WLL

HAZARD IDENTIFICATION & RISK ASSESSMENT

Work at Height (Scaffolders) Scaffolders, labors, 5 4 20 1. Maintain the barricade system around 2 4 8

a. Fall of Worker supervisor, public the work area with caution signs

b. Fall of tools 2. Ensure the availability of Third Party

Certificates of Scaffolders

3. Provide tool lanyard for tools used

4. Wear FBH and required PPEs, i.e. hard

hat with chin strap

5. 100% tie off, higher than the D-ring

6. Toolbox talk on Work at Height

Poor Access during erection Scaffolders, labors 5 3 15 1. Clear obstructions; remove spectator 1 3 3

a. Slips, trips and falls seats temporarily

2. Remove unnecessary materials

a. Poor Illumination Scaffolders, labors, 4 4 16 1. Provide ample lighting in the area 2 4 8

supervisors 2. Wear clear glasses while working inside

Removal and Working at Height Scaffolders, sealant 4 4 16 1. Ensure toe boards are in place 2 2 4

Installation of Fall of tools, worker and workers, laborers 2. Tool lanyard for tools

Cladding Sheet materials 3. Guard rails should be complete

4. 100% tie off onto the scaffold or better

on a certified anchorage point

5. Transport the removed claddings with

the use of good-conditioned rope; edge

protection on the material should also be

considered

Breaking of Wall with Electrical Hazard (use of Masons, Labors, 4 4 16 1. Use battery-operated power tool, 2 4 8

the use of Chipping chipping drill) public wherever possible

Drill Machine (Hilti) a. Shock, burns, etc. 2. Ensure the equipment is double

insulated

3. Ensure the equipment has 3-pronged

plug (grounding system)

4. Use insulated hooks to hang the

extension cord onto the scaffold

5. Provide training on the safe use of power

tools

MTC-OHS-F-001 | REV 0 | 1st June, 2013 Page 3

AL MUSAIRIE TRADING & CONTRACTING CO. QATAR WLL

HAZARD IDENTIFICATION & RISK ASSESSMENT

Fire due to electrical Masons, labors, 4 4 16 1. No overloading of sockets 2 4 8

problem public 2. Outlets should only be 110V in power

a. Burns, property 3. Do not use multi-adapter to connect the

damage plug into the socket

4. Provide FFE

5. Ensure workers are trained to properly

use the FFE

Improper Access Mason, Labor 4 3 12 1. Provide training on work at height 2 3 6

Carrying tools & materials (three-point contact, etc.)

while climbing up 2. Provide fixed ladder on the mobile

a. Fall, injury, death scaffold

3. Provide holsters for tools

4. If no pulley is available, pass on to

another worker on top to safely transport

materials etc.

5. “NO” Shortcuts

Unstable ground, unstable Mason, Labors 5 4 20 1. Ensure the scaffold has been inspected by 1 4 4

scaffold the scaffold supervisor and scaffold

a. Fall, death inspector

2. Ensure the scaffold has been tagged

“safe”

3. Ensure all scaffold components are

complete with brace supports

4. Provide additional outrigger racks, if

needed

5. Ensure the scaffold is built with the right

base-height ratio (4:1)

Working at Height Mason, labor, 4 4 16 1. Maintain proper barricade system and 2 4 8

a. Fall of tools, worker supervisor, public caution signs

2. Ensure toe boards are in place

3. Tool lanyard for tools

4. Guard rails should be completed

MTC-OHS-F-001 | REV 0 | 1st June, 2013 Page 4

AL MUSAIRIE TRADING & CONTRACTING CO. QATAR WLL

HAZARD IDENTIFICATION & RISK ASSESSMENT

5. 100% tie off onto the scaffold or better

on a certified anchorage point

Vibration Masons, laborers 5 3 15 1. Ensure the tool has a spring-dampened 3 2 6

a. Hand-arm vibration handle to at least reduce the vibration

syndrome (AVR)

b. Carpal tunnel syndrome 2. Job Rotation

3. Frequent rest

4. Use Safety Gloves (preferably rubber

gloves)

5. Health Surveillance

Noise Masons, laborers 5 3 15 1. Wear earplugs/earmuffs 3 2 6

a. Tinnitus (ringing of the 2. Silencers, if possible

ear) 3. Other workers should keep distance from

b. Temporary deafness the area where chipping activity is

c. Permanent deafness ongoing

4. Job rotation

Presence of silica dust Masons, laborers, 5 4 20 1. Dampen the area with water 2 4 8

during breaking public 2. Ensure the area is well-ventilated

a. Irritation (acute) 3. Provide means for dust extraction in the

b. Respiratory diseases area

(lung cancer) 4. Wear dust mask

5. Dispose of chemical suit after use

Chipped off concrete (flying Laborers, masons, 5 3 15 1. Provide a net/polythene sheet to protect 2 3 6

debris) public other people from getting hit by flying

a. Concussions, debris

b. Cuts 2. Wear face shield, safety glasses

3. Wear hard hat

Dismantling, removal Transport of materials from Scaffolders, public 4 4 16 1. Use an inspected rope to safely transport 2 4 8

of materials above to ground level the materials from above to ground level

a. Head injury, other 2. Maintain barricade and caution signs

physical injuries around the dismantled scaffold

b. Death

MTC-OHS-F-001 | REV 0 | 1st June, 2013 Page 5

AL MUSAIRIE TRADING & CONTRACTING CO. QATAR WLL

HAZARD IDENTIFICATION & RISK ASSESSMENT

Loading and Incompetency of driver Driver, public, 5 4 20 1. Ensure driver is competent and not 2 4 8

unloading of scaffold (Impact) other workers intoxicated with alcohol and other drugs

materials a. Struck by 2. Ensure availability of 3rd party

b. Vehicle Collision certificates of operator and equipment

3. Observe speed limit

4. Provide banksman or flagman onsite

5. Check the condition of vehicle (with

reverse alarm system, horn, etc.)

6. Health surveillance of driver

MTC-OHS-F-001 | REV 0 | 1st June, 2013 Page 6

You might also like

- Risk Assessment For Demolition WorksDocument5 pagesRisk Assessment For Demolition Worksappu pocom3100% (4)

- Risk Assessment - Steel Erection WorksDocument11 pagesRisk Assessment - Steel Erection Worksmahmoud nadaNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- AHA - Working On Slope RoofDocument2 pagesAHA - Working On Slope RoofTopsun Energy100% (1)

- HIRA - Godrej GCR Project - PHE System-Water Supply WorkDocument11 pagesHIRA - Godrej GCR Project - PHE System-Water Supply WorkRajput AmitNo ratings yet

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- Al Door&WindowDocument1 pageAl Door&WindowChandruNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- Brick WorkDocument1 pageBrick WorkGyanendra Narayan NayakNo ratings yet

- CyclophosphamideDocument7 pagesCyclophosphamideFrances Ramos33% (3)

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 pagesRisk Assessment Sheet For Installation of Wooden Doorsrajat100% (1)

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal Pattanayak100% (2)

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- HIRA FOR SLICING DEMOLITION WORKS IN UG STATIONS - CMRL Rev 01Document21 pagesHIRA FOR SLICING DEMOLITION WORKS IN UG STATIONS - CMRL Rev 01mahesh naik100% (1)

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Back FillingDocument2 pagesBack FillingChandru0% (1)

- Hira Plastering Finishing WorkDocument2 pagesHira Plastering Finishing WorkDwitikrushna Rout0% (2)

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- RISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Document2 pagesRISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Raza Muhammad Soomro100% (2)

- Excavation, Trenching & Pot HolingDocument1 pageExcavation, Trenching & Pot HolingHafiz SabriNo ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- Hoist Erection Operation & Maintenance Work - R0 - 30.09.2017Document6 pagesHoist Erection Operation & Maintenance Work - R0 - 30.09.2017Nikhil Manjrekar100% (2)

- Risk Assement - (Paint Work)Document6 pagesRisk Assement - (Paint Work)Zohaib TahirNo ratings yet

- HIRA No. 08 Rev 04 - Lifting ActivityDocument7 pagesHIRA No. 08 Rev 04 - Lifting ActivityVenkadesh PeriathambiNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- JSA For Installation of Out Door UnitsDocument4 pagesJSA For Installation of Out Door UnitsMohammed MinhajNo ratings yet

- Welding and Gas CuttingDocument2 pagesWelding and Gas CuttingKrishna Patil100% (2)

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh50% (2)

- Risk Assessment - Installation of Exhaust FansDocument4 pagesRisk Assessment - Installation of Exhaust FansehteshamNo ratings yet

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- Use of Power ToolsDocument3 pagesUse of Power ToolsNisanth ThulasidasNo ratings yet

- Insignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicDocument6 pagesInsignificant (2) Minor (3) Moderate (4) Major (5) Catastrophicabhinav dj50% (2)

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRaju100% (1)

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- Shifting of Materials by Double HydraDocument1 pageShifting of Materials by Double HydraShahid RazaNo ratings yet

- Working at Height Op (Eration Scaffolding Work Risk AssessmentDocument22 pagesWorking at Height Op (Eration Scaffolding Work Risk AssessmentAhmed Farman Alqaysi100% (1)

- JSA For HILTIDocument3 pagesJSA For HILTIMohammed Minhaj100% (1)

- Risk Assessment For Anti Termite WorksDocument7 pagesRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Risk Assessment of Barricading WorkDocument3 pagesRisk Assessment of Barricading WorkGyanendra SrivastavaNo ratings yet

- Concrete Pouring JSaDocument12 pagesConcrete Pouring JSaTheo Vidallon BautistaNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- Risk Assessment of Confined SpaceDocument29 pagesRisk Assessment of Confined Spaceطارق رضوانNo ratings yet

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- JSA For RCC, Foundation & Generator Installation (R-00)Document14 pagesJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanNo ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- HIRA - For Fixing Loose and Detached PipeDocument6 pagesHIRA - For Fixing Loose and Detached PipeSujan AugustinNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument9 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- MS For Scaffold and Cladding WorkDocument16 pagesMS For Scaffold and Cladding WorkSujan AugustinNo ratings yet

- MS For Fixing Loose and Detached PipeDocument5 pagesMS For Fixing Loose and Detached PipeSujan AugustinNo ratings yet

- HIRA - For Fixing Loose and Detached PipeDocument6 pagesHIRA - For Fixing Loose and Detached PipeSujan AugustinNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument9 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument3 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- Method Statement For Scaffolding Works and Installation of Acoustic PanelsDocument8 pagesMethod Statement For Scaffolding Works and Installation of Acoustic PanelsSujan AugustinNo ratings yet

- Emergency Evacuation PlanDocument4 pagesEmergency Evacuation PlanSujan AugustinNo ratings yet

- Pablocastillo PDFDocument44 pagesPablocastillo PDFPabloNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

- 400PNR CDocument3 pages400PNR CmdisicNo ratings yet

- Schiavi Enc Met Page015Document1 pageSchiavi Enc Met Page015Adel AdelNo ratings yet

- Tutorial-2 - Heterocycles Nomenclature-Part-IIDocument18 pagesTutorial-2 - Heterocycles Nomenclature-Part-IIamirNo ratings yet

- Lecture 7 - Synchronous Generators 7 PDFDocument28 pagesLecture 7 - Synchronous Generators 7 PDFDorwinNeroNo ratings yet

- SONTU Flat Panel Dectector CatalogDocument6 pagesSONTU Flat Panel Dectector CatalogWajahat SheikhNo ratings yet

- Textbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFDocument39 pagesTextbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFjanet.galloway812100% (8)

- Da0bl7mb6d0 Rev DDocument44 pagesDa0bl7mb6d0 Rev DFerreira da CunhaNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- Chapter8-Campuran Pada Tingkat Molekuler - Part 1Document58 pagesChapter8-Campuran Pada Tingkat Molekuler - Part 1Uswatun KhasanahNo ratings yet

- Plant Hormones PDFDocument5 pagesPlant Hormones PDFYASHNo ratings yet

- MATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Document17 pagesMATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Erika Mae TupagNo ratings yet

- Ag4q-212s KBDocument2 pagesAg4q-212s KBhtek.thunderainNo ratings yet

- Kore Network Device ConfigurationDocument61 pagesKore Network Device ConfigurationEllaziaNo ratings yet

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document16 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797warepneumomxkhf100% (17)

- Model 621 LR B Data SheetDocument1 pageModel 621 LR B Data SheetMohammed GallowNo ratings yet

- Understanding Your Electricity Bill in PakistanDocument13 pagesUnderstanding Your Electricity Bill in PakistanGhayas Ud-din DarNo ratings yet

- Exercise # 1: Statistics and ProbabilityDocument6 pagesExercise # 1: Statistics and ProbabilityAszyla ArzaNo ratings yet

- TPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™Document57 pagesTPS54160 1.5-A, 60-V, Step-Down DC/DC Converter With Eco-Mode™sbrhomeNo ratings yet

- LTE TDD - Network - Export - 2018 - 07 - 04Document3,760 pagesLTE TDD - Network - Export - 2018 - 07 - 04saadNo ratings yet

- Spider-81 Hardware Spec 7.7Document7 pagesSpider-81 Hardware Spec 7.7KonradNo ratings yet

- Louis I KahnDocument27 pagesLouis I KahnKiran BasuNo ratings yet

- 02 - D03 - Basic Funtion of SIPROTEC 5Document7 pages02 - D03 - Basic Funtion of SIPROTEC 5DianaNo ratings yet

- Credit Card Fraud Detection Using Improved Deep Learning ModelsDocument22 pagesCredit Card Fraud Detection Using Improved Deep Learning ModelsrauhNo ratings yet

- FlapDocument100 pagesFlapRicha Agrawal100% (2)

- Technical Specification: 1) Filter Feed Pump With Motor 1 NosDocument4 pagesTechnical Specification: 1) Filter Feed Pump With Motor 1 NosKamatchi NathanNo ratings yet

- Combustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningDocument17 pagesCombustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningNicole Mae AllosadaNo ratings yet