Professional Documents

Culture Documents

Resistance To Wind Load (EN12207 Classes)

Resistance To Wind Load (EN12207 Classes)

Uploaded by

medin321Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resistance To Wind Load (EN12207 Classes)

Resistance To Wind Load (EN12207 Classes)

Uploaded by

medin321Copyright:

Available Formats

Windows and Doors

Air permeability, resistance to wind load, watertightness

Air permeability Classification EN 12207:1999-11

Test method EN 1026:2016-03 m /hm 2 der

3

overGall areatfläche

esam m 3 /hm joint length

der Fugenlänge

10 0

80

70

60 B G B -D 15

3 50

BG A

12 ,5

+∆p

40

[P a ] class 1 1

K lasse

10

30

27 6,75

20 5,0

class 2 2

K lasse

10 2,5

0 t [s ] 9 2 ,2

8 K lasse3 3

class 2,0

1 7

6

5

3 0,75

class

K lasse4 4

-∆ p 2 0,5

[P a ]

o p e n in g a n d c lo s in g

0,25

1

10 50 100 15 0 300 600

pressure

D ruck in P a

Resistance to wind load

Test method EN 12211:2016-03 Classification EN 12210:2016-03

73 s

p o s itiv e p r e s s u r e Table 1: Classification of relative frontal deflection

Class Relative frontale deflection

P3 A < l/150

3010 s 5 0 c y c le s B < l/200

P 1+ 1 0 % C < l/300

P1

73 s

Table 2: Classification of wind load

P2 73 s Class P1 P2

1)

P3

0 not tested

1 400 200 600

605 s 605 s 73 s 2 800 400 1200

3 1200 600 1800

AP AP

4 1600 800 2400

0 t [s ] 5 2000 1000 3000

2)

Exxxx xxxx

In c r e m e n ts o r 1)

This pressure having been repeated 50 times.

c o n tin u o u s r a te 2)

Specimen tested with wind loading above class5, classified Exxxx – where xxxx is

the actual test pressure P1 (e.g. 2350 etc.).

-P 2

73 s Table 3: Resistance to wind load − classification

Wind load Relative frontal deflection

-P 1 class A B C

P 1+ 1 0 % 73 s 1 A1 B1 C1

3010 s 2 A2 B2 C2

-P 3 3 A3 B3 C3

A P = a ir p e rm e a b ility te s t 4 A4 B4 C4

5 A5 B5 C5

n e g a tiv e p r e s s u r e Exxxx AExxxx BExxxx CExxxx

NOTE:

In the resistance to wind load classification the number refers to the wind load class,

see table 2 and the letter to the relative frontal deflection, see table 1.

Watertightness

Test method EN 1027:2016-03 Spraying methods EN 1027 Classification EN 12208

250+10

-0

Maße in mm

measurement in mm 250+10

-0 Classification DIN EN Test method DIN EN

12208:1999-11 1027:2016-03

2±0,2 l/minper nozzle

je Düse 2±0,2 l/min per nozzle

je Düse p in Pa

p [Pa] max. 150 max. 150 1A 1B 0

24°±2 84°±2 2A 2B 50

>3 s Pmax + 10% nozzle in

Düsenspitze Düsenspitze

3A 3B 100

between

muß zwischen muß zwischen

nozzle in

diesen Linien diesen Linien

these lines, between 4A 4B 150

Pmax liegen,

whole

liegen

these lines

600 der Prüfkörper

specimen

muß ganz

5A 5B 200

must

besprühtbe

6A 6B 250

spraying sprayed

werden

500 7A 7B 300

450 2500 2500

400 8A - 450

9A - 600

300 Exxxx - 600

200 1A to 9A = product fully exposed

150 1B to 7B = product partially shielded

äußerste Fugenebene 0 Pa 15 min

outer level of joints or

100 oder Ebene der

outer glazing surface after 15 min at 0 pressure and 5 min at

50 Verglasung

subsequent steps

0 t [min] method 1A

Methode 1A Methode 1B

method 1B

0 5 10 15 20 25 30 35 40 45 50 55

Stand: 10- 2016

ift Rosenheim | www.ift-rosenheim.de

Theodor-Gietl-Str. 7-9 | 83026 Rosenheim | Telefon: +49 8031 261-0 | Fax: +49 8031 261-290 | info@ift-rosenheim.de

You might also like

- Case Study FC Barcelona - More Than Just A ClubDocument24 pagesCase Study FC Barcelona - More Than Just A Clubpasap1233002No ratings yet

- 2010 Hawaii Install (Aranda)Document529 pages2010 Hawaii Install (Aranda)Jay GreenNo ratings yet

- English File: 5 Quick TestDocument2 pagesEnglish File: 5 Quick TestDiệu HằngNo ratings yet

- Marmac 304 - Gen. ArrangementDocument1 pageMarmac 304 - Gen. ArrangementR. ADOLFO GARCIA RESENDIZNo ratings yet

- A Song For You TenorDocument2 pagesA Song For You TenorBoatman BillNo ratings yet

- Merry Go Round of Life: Violin 1Document2 pagesMerry Go Round of Life: Violin 1İnci SökmenNo ratings yet

- 640 0003 0011b05ed00Document1 page640 0003 0011b05ed00IlyasaNo ratings yet

- Alis Flow ChartDocument1 pageAlis Flow ChartMahesh KumarNo ratings yet

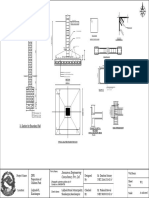

- X-Section For Boundary Wall: Janasewa Engineering Consultancy Pvt. LTDDocument1 pageX-Section For Boundary Wall: Janasewa Engineering Consultancy Pvt. LTDRooking Ewondo SfuutNo ratings yet

- Plan Cofraj ManasardaDocument1 pagePlan Cofraj ManasardaDani SerbanNo ratings yet

- 6153 ProblemDocument1 page6153 ProblemNy ChenqNo ratings yet

- ADV Major Site 030323 PDFDocument1 pageADV Major Site 030323 PDFmurtazaNo ratings yet

- Tub PVC Sap C-7.5 L 124m: Sub Sistema 02Document1 pageTub PVC Sap C-7.5 L 124m: Sub Sistema 02Lisde EspinozaNo ratings yet

- W SystemDocument1 pageW SystemSheila Mary CamuloNo ratings yet

- Water System 2Document1 pageWater System 2Sheila Mary CamuloNo ratings yet

- Gaucho (O Corta Jaca) Tango BrasileiroDocument2 pagesGaucho (O Corta Jaca) Tango BrasileirodjullyeghoticaNo ratings yet

- Wilian Condominio 03aDocument1 pageWilian Condominio 03ahinz_gauchoNo ratings yet

- Tito Nieves - Mas Que Tu AmigoDocument15 pagesTito Nieves - Mas Que Tu AmigoJulio César Gómez Torres0% (1)

- Warm-Up Area: Covered Court/Big TentDocument1 pageWarm-Up Area: Covered Court/Big TentKathleen A. PascualNo ratings yet

- TubaDocument1 pageTubaalexNo ratings yet

- Eb MQ" Eb MQ" Eb MQ"Document2 pagesEb MQ" Eb MQ" Eb MQ"Victor BMNo ratings yet

- I e AdelaDocument1 pageI e AdelastalinsanzNo ratings yet

- NID Site Analysis SHRUTI 1Document1 pageNID Site Analysis SHRUTI 1shruti agarwalNo ratings yet

- Assad Palace Pavilion 07062021 PDFDocument7 pagesAssad Palace Pavilion 07062021 PDFOmar AmirNo ratings yet

- Mubarakiya-Parking-OPT4B-31Oct2016 1-1500Document3 pagesMubarakiya-Parking-OPT4B-31Oct2016 1-1500Audie PinedaNo ratings yet

- Safety Notes: 1 L+ Q M Q 4 3 2 Q 5Document2 pagesSafety Notes: 1 L+ Q M Q 4 3 2 Q 5Quý Đình Mai MaiNo ratings yet

- Đế Vương 1Document4 pagesĐế Vương 1Duy Tính TrầnNo ratings yet

- E D C B' B A' A: Arie SubsolDocument1 pageE D C B' B A' A: Arie SubsolDeejay LpNo ratings yet

- Ci SS 01 04 017Document1 pageCi SS 01 04 017harihfclNo ratings yet

- RTN25 End Truck Top Joint SiDocument1 pageRTN25 End Truck Top Joint SiFrancisco San VicenteNo ratings yet

- PEQUITDocument1 pagePEQUITJohn paul LlauderNo ratings yet

- Midwood Floorplan EBrochureDocument44 pagesMidwood Floorplan EBrochureJEMAR MARIBONGNo ratings yet

- Site Development Plan: Construction LineDocument1 pageSite Development Plan: Construction LineMark Kristoffer HilarionNo ratings yet

- 13E9AA WentoinDocument1 page13E9AA WentoinscayNo ratings yet

- Light Cavalry: OvertureDocument3 pagesLight Cavalry: OvertureSpirous LibasNo ratings yet

- 23 - Star Wars 2 Láminas - Score - ScoreDocument3 pages23 - Star Wars 2 Láminas - Score - ScoremanuellguillenserNo ratings yet

- New Samba Bass TromboneDocument3 pagesNew Samba Bass TromboneSergei SutulaNo ratings yet

- Lightning Strike Counter: Lightning Protection Equipment CatalogDocument1 pageLightning Strike Counter: Lightning Protection Equipment CatalogComsip400No ratings yet

- Lestere Beach PiccoloDocument1 pageLestere Beach PiccoloTom beauvoirNo ratings yet

- RCC-Stair DetailsDocument1 pageRCC-Stair Detailsa.farid1269No ratings yet

- Mas Que Tu Amigo Trumpet IDocument2 pagesMas Que Tu Amigo Trumpet IMarce CernaNo ratings yet

- Gypsy Dance No. 3Document2 pagesGypsy Dance No. 3António CorreiaNo ratings yet

- 09 SW Medley MODx - Violin IDocument2 pages09 SW Medley MODx - Violin IFrancesco CipulloNo ratings yet

- Plano de Planta de Redes ColectarasDocument1 pagePlano de Planta de Redes ColectarasDianaCanoSoveroNo ratings yet

- ML December 2023Document2 pagesML December 2023Jayesh KumarNo ratings yet

- PLANO LOTIZACION MODIFICADA MARZO 2022-Model PDFDocument1 pagePLANO LOTIZACION MODIFICADA MARZO 2022-Model PDFv&n proyectosNo ratings yet

- CM 1Document1 pageCM 1Solano ZanettiNo ratings yet

- Tenor SaxophoneDocument1 pageTenor Saxophonegleydsonraimundo539No ratings yet

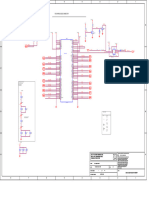

- Pci-Express Edge Connector: BI INDocument20 pagesPci-Express Edge Connector: BI INLeonel GalliNo ratings yet

- These Tears-Alto SaxophoneDocument2 pagesThese Tears-Alto SaxophoneRooney ChinNo ratings yet

- Tuba in BBDocument1 pageTuba in BBEdmar EmanoellNo ratings yet

- Warehouse Planting PlanDocument1 pageWarehouse Planting PlanVishal VatsNo ratings yet

- Handrail Blocking InstructionsDocument1 pageHandrail Blocking InstructionsAlejandro Bravo CastilloNo ratings yet

- Site Development Plan PDFDocument1 pageSite Development Plan PDFJohn Oliver GuiangNo ratings yet

- 97 76-89 03 2.8 MotronicDocument7 pages97 76-89 03 2.8 MotronicAlexis IbarraNo ratings yet

- Tempo Perdido - Trombone 3 PDFDocument2 pagesTempo Perdido - Trombone 3 PDFlanamusica-1No ratings yet

- Akamai Street: Kohanaiki RoadDocument3 pagesAkamai Street: Kohanaiki RoadJohn Carlo RoselloNo ratings yet

- Description Quantity Unit: General PlanDocument1 pageDescription Quantity Unit: General PlanVanessa Fortun EndozoNo ratings yet

- Lot PlanDocument1 pageLot PlanMark Kelly BalgosNo ratings yet

- Terrace Floor: A B C DDocument1 pageTerrace Floor: A B C DS KarthikeyanNo ratings yet

- ASOC. 07 DE JULIO - AMPLIACION IV ETAPA - FINAL - ORTOFOTO-ModelDocument1 pageASOC. 07 DE JULIO - AMPLIACION IV ETAPA - FINAL - ORTOFOTO-ModelBREHITER YAMIR ZARATE OLAYANo ratings yet

- Jardim Veneto 2 Sertaozinho MapaDocument1 pageJardim Veneto 2 Sertaozinho MapaTaís NogueiraNo ratings yet

- Glass Properties Pt.1Document1 pageGlass Properties Pt.1medin321No ratings yet

- Manufacturing Process of GlassDocument1 pageManufacturing Process of Glassmedin321No ratings yet

- Tempered GlassDocument1 pageTempered Glassmedin321No ratings yet

- Types of GlassDocument1 pageTypes of Glassmedin321No ratings yet

- Statics - Simply Supported Beam DiagramsDocument2 pagesStatics - Simply Supported Beam Diagramsmedin321No ratings yet

- Croatia - Basic InformationDocument2 pagesCroatia - Basic Informationmedin321No ratings yet

- AAMA TIR - Stainless Steel Screw CapacityDocument1 pageAAMA TIR - Stainless Steel Screw Capacitymedin321No ratings yet

- Structural Analysis of Continuous BeamDocument4 pagesStructural Analysis of Continuous Beammedin321No ratings yet

- Project:: Winbeam 3.30 - Registered To Axis/FffDocument4 pagesProject:: Winbeam 3.30 - Registered To Axis/Fffmedin321No ratings yet

- Conlift Ferrule Design Manual A5Document24 pagesConlift Ferrule Design Manual A5medin321No ratings yet

- Soal Mid Bahasa Inggris Wajib Kelas XDocument5 pagesSoal Mid Bahasa Inggris Wajib Kelas XNur Intan Surya SeptianaNo ratings yet

- Four Corners 2 - Unit 12Document13 pagesFour Corners 2 - Unit 12Amanda da SilvaNo ratings yet

- ESTIMAG - October 16, 2022Document60 pagesESTIMAG - October 16, 2022LeonardoNo ratings yet

- ELA 09 Multiple Choice 2012xxDocument39 pagesELA 09 Multiple Choice 2012xxjoanna.henryNo ratings yet

- Pe4 Team SportDocument7 pagesPe4 Team SportamorelyseNo ratings yet

- Safari - May 7, 2018 at 3:51 PMDocument1 pageSafari - May 7, 2018 at 3:51 PMDalen LennNo ratings yet

- Sage Steele LawsuitDocument16 pagesSage Steele LawsuitAnthony J. PerezNo ratings yet

- The Use of Global Positioning and Accelerometer SyDocument35 pagesThe Use of Global Positioning and Accelerometer SyTerem TebautaNo ratings yet

- Hope q3-4 Mod4 Moderatetovigorousphysicalactivitiesbadminton v2Document24 pagesHope q3-4 Mod4 Moderatetovigorousphysicalactivitiesbadminton v2Joannah Guevarra KatigbakNo ratings yet

- Vis Floor Hockey 5 Gameday UdlDocument6 pagesVis Floor Hockey 5 Gameday Udlapi-457181424No ratings yet

- Nota Kuliah 3Document28 pagesNota Kuliah 3syamimiNo ratings yet

- TV Channels 552828919578270Document189 pagesTV Channels 552828919578270joejurzkNo ratings yet

- Short Time?: Oral Exam Level 3 Practice The Following Questions. Don't Forget To Be Precise With Your PronunciationDocument3 pagesShort Time?: Oral Exam Level 3 Practice The Following Questions. Don't Forget To Be Precise With Your PronunciationAndrea SanchezNo ratings yet

- Arnis de Mano Is The Best Known and The Most Systematic Fighting Art in The Philippines. It Is The PerfectDocument2 pagesArnis de Mano Is The Best Known and The Most Systematic Fighting Art in The Philippines. It Is The PerfectAnna Tricia Envase AlpajoraNo ratings yet

- Kornev A - Practical Black Rep With Nf6, g6, d6 Vol 2 King S Indian PDFDocument382 pagesKornev A - Practical Black Rep With Nf6, g6, d6 Vol 2 King S Indian PDFYony Javier100% (4)

- Wing Chun - WikipediaDocument43 pagesWing Chun - WikipediaMāui TuheitiaNo ratings yet

- Thesis For Mixed Martial ArtsDocument4 pagesThesis For Mixed Martial Artsmitzilarrickakron100% (2)

- Summer 2 WorkDocument9 pagesSummer 2 WorknfrcvbztwtNo ratings yet

- 34 National Under-08 Open & Girls Chess Championships-2022: Organised byDocument10 pages34 National Under-08 Open & Girls Chess Championships-2022: Organised by9F ASMA MARYAMNo ratings yet

- PROJECTDocument3 pagesPROJECTJhorel Axel Ticlavilca VillazanteNo ratings yet

- Inter House Athletics 2024 ProgrammeDocument9 pagesInter House Athletics 2024 ProgrammeMichael UteteNo ratings yet

- ICSE Class 10 Physical EducationDocument15 pagesICSE Class 10 Physical Educationsukhmanivirk3No ratings yet

- Offensive Work Defense Team: Shooting Footwork & Positioning Offensive BreakdownsDocument2 pagesOffensive Work Defense Team: Shooting Footwork & Positioning Offensive BreakdownsCody NewmanNo ratings yet

- Liability Release PRINTDocument3 pagesLiability Release PRINTAndika PutraNo ratings yet

- Motor Trend - September 2017 PDFDocument118 pagesMotor Trend - September 2017 PDFhorseline2012 The same100% (2)

- 9-22-21 Valley Christian Academy Federal ComplaintDocument24 pages9-22-21 Valley Christian Academy Federal ComplaintDave Minsky100% (1)

- English 5 Q4 Module 4Document21 pagesEnglish 5 Q4 Module 4Rhea Villaceran100% (2)