Professional Documents

Culture Documents

Geometrical Tolerances

Geometrical Tolerances

Uploaded by

Jitendra BholeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geometrical Tolerances

Geometrical Tolerances

Uploaded by

Jitendra BholeCopyright:

Available Formats

Geometrical tolerance

Tolerances of size are not always sufficient to provide the required

control of form. For example, in Fig.a the shaft has the same diameter

measurement in all possible positions but is not circular; in Fig.b, the

component has the same thickness throughout but is not flat and in Fig.c,

the component is circular in all cross-sections but is not straight. The form

of these components can be controlled by means of geometrical tolerances.

Fig.a Fig.b Fig.c

Geometrical tolerance is defined as the maximum permissible overall

variation of form or position of a feature.

Geometrical tolerances are used,

(i) to specify the required accuracy in controlling the

(a)form of a feature, (b)to ensure correct functional

positioning of the feature,

(ii) to ensure the interchangeability of components, and

(iii) to facilitate the assembly of mating components.

Terms Used:

Datum:

It is a theoretically exact geometric reference (such as axes, planes,

straight lines, etc.) to which the tolerance features are related.

Datum Feature:

A datum feature is a feature of a part, such as an edge, surface, or a hole,

which forms the basis for a datum or is used to establish its location.

Datum Triangle:

The datums are indicated by a leader line, terminating in a filled or an open

triangle.

Datum Letter:

To identify a datum for reference purposes, a capital letter is enclosed in a

frame, connected to the Datum triangle.

Tolerance Frame:

Tolerance Frame is used to indicate the geometrical tolerance on the drawing. It is connected

to toleranced feature by a leader line. The first box in the frame specifies the symbol for

geometrical tolerance , next box specifies tolerance value and third box specifies datum

surface with reference to which the tolerance is to be maintained.

Modifier:

The modifier is used to specify the condition to which the tolerance is applied. There are

three modifiers-

Maximum Material Condition(MMC) and its symbol is

Least Material condition (LMC) and its symbol is

Regardless of feature size (RFS) is the default condition, it has no symbol.

Tolerance Zone:

It is an imaginary area or volume within which the controlled feature of

the manufactured component must be completely contained

Geometric Characteristic Symbols:

Representation of Geometrical Tolerance on Drawing:

Example:

1) Explain the meaning of symbol at X and Y.

Ans:

The toleranced surface at X is parallel to surface A within 0.030 mm.

The toleranced surface at Y is perpendicular to surface A within 0.030 mm.

2) State the meaning of symbol shown in the fig below:

Ans:

The radial run-out shall not be greater than 0.1 in any plane of measurement duing one

revolution about the datum axis A-B.

3) Draw the symbols for i) Flatness ii) Run-out.

i) ii)

Exercise:

1) Explain the meaning of symbol at Y.

2)Explain the meaning of symbol at X and Y.

3) Explain the meaning of geometrical characteristics shown in the fig.

4) Explain the meaning of symbols shown in the fig.

5) Explain the meaning of symbol at X.

6) Draw the symbols for i) Cylindricity ii) Concentricity.

PRODUCTION DRAWING

The orthographic views of the part will give the information about the shape and size of

the part. A production drawing, in addition to this, will give all the information which is

required to manufacture the part. A design engineer will give a production drawing to the

production engineer, which will give the following additional information-

a) Raw Material and its size.

b) Quantity to be produced.

c) Dimensional Tolerances.

d) Geometrical Tolerances.

e) Surface Roughness.

f) Heat Treatment.

g) Surface Treatment.

h) Special instructions about manufacturing.

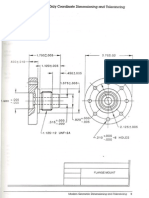

A production drawing of a flange is shown in the figure given below.

The meaning of various symbols shown on the drawing is explained below:-

Example:

Explain the meaning of various tolerances given in the production drawing of a

connector shown in the figure below.

Ans:

You might also like

- GD&T - Test Rev1Document6 pagesGD&T - Test Rev1Lucian Mudura25% (4)

- Gdtology GDTP Practice Exam 2009 Answers FDocument48 pagesGdtology GDTP Practice Exam 2009 Answers FSandeep Patnala100% (4)

- AutoCAD Civil 3D - Roads Design: 2From EverandAutoCAD Civil 3D - Roads Design: 2Rating: 3.5 out of 5 stars3.5/5 (2)

- GD&T PDFDocument49 pagesGD&T PDFnupurvinodNo ratings yet

- Material Q345BDocument2 pagesMaterial Q345Bzhonghao200933% (6)

- My First Book of Quantum Physics PDF Ebook by Kaid-Sala Ferrón SheddadDocument3 pagesMy First Book of Quantum Physics PDF Ebook by Kaid-Sala Ferrón SheddadAde Irman0% (4)

- Geometric Dimensioning and TolerancingDocument6 pagesGeometric Dimensioning and TolerancingPedro LeosNo ratings yet

- Form and PositionDocument54 pagesForm and PositionThangadurai Senthil Ram PrabhuNo ratings yet

- GD&T QuestionsDocument12 pagesGD&T Questionsநளின் கான்100% (1)

- Geometric TolerancesDocument6 pagesGeometric Tolerancesvaibhavgitevaibhav_9No ratings yet

- Data Analysis Lab: ME 288 Fall 2009 L6 BDocument16 pagesData Analysis Lab: ME 288 Fall 2009 L6 BJosephRomeraloNo ratings yet

- Geometric Dimensioning and TolerancingDocument4 pagesGeometric Dimensioning and TolerancingAshokNo ratings yet

- Common Geometric Symbols and TermsDocument25 pagesCommon Geometric Symbols and TermsManuel PelayoNo ratings yet

- GD T ExamplesDocument10 pagesGD T ExamplesJuan Posada GNo ratings yet

- Record Work Mechanical III SemDocument26 pagesRecord Work Mechanical III Semusiaf007No ratings yet

- GDT TutorialDocument76 pagesGDT TutorialSivananthaa MurtheeNo ratings yet

- GD&T TutorialDocument76 pagesGD&T TutorialAnish PaiNo ratings yet

- GDT TutorialDocument76 pagesGDT TutorialSrk ChowdaryNo ratings yet

- GD&TDocument76 pagesGD&TVictoria Indira Gandhi100% (18)

- Fits N TolernceDocument15 pagesFits N TolernceBitopan KaliyaNo ratings yet

- GD&T StdsDocument4 pagesGD&T StdsSri PupNo ratings yet

- GD&TDocument21 pagesGD&TJochelle Mae PecsonNo ratings yet

- Fundamentals 07.04.03Document22 pagesFundamentals 07.04.03maddy_scribdNo ratings yet

- GD & T PresentationDocument63 pagesGD & T PresentationPuneet Birla100% (2)

- Questionnaire On Geometric Dimensions and TolerancesDocument5 pagesQuestionnaire On Geometric Dimensions and TolerancesPOOJA KUMARINo ratings yet

- Tolerancias Pza FundicionDocument3 pagesTolerancias Pza FundicionGuero TeoNo ratings yet

- Chapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Document12 pagesChapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Jackie HwangNo ratings yet

- GD&T Day 1 Part 1Document22 pagesGD&T Day 1 Part 1harshkallani100% (2)

- Machine Drawing Notes - 1Document20 pagesMachine Drawing Notes - 1N Dhanunjaya Rao BorraNo ratings yet

- GD& T ReviewDocument92 pagesGD& T ReviewMoham'medAlthafAs'lamNo ratings yet

- Chapter 8 Detail Drawing: Understanding & CreatingDocument80 pagesChapter 8 Detail Drawing: Understanding & CreatingMohsin JavedNo ratings yet

- Print Reading and Welding SymbolsDocument30 pagesPrint Reading and Welding Symbolsmega accountNo ratings yet

- Glossary of CAD/Drafting Terms: Dimensioning Without Dimension Lines orDocument11 pagesGlossary of CAD/Drafting Terms: Dimensioning Without Dimension Lines orFrank Michael JaclaNo ratings yet

- The Three-Point HitchDocument6 pagesThe Three-Point HitchlucasNo ratings yet

- Section 3 Structural Drawing For Detailing Table 3Document9 pagesSection 3 Structural Drawing For Detailing Table 3swatiNo ratings yet

- Section I. Print Reading: 3-1. GENERALDocument34 pagesSection I. Print Reading: 3-1. GENERALSikandar HayatNo ratings yet

- Welding PDFDocument34 pagesWelding PDFSikandar HayatNo ratings yet

- Design of Machine Elements ProjectDocument43 pagesDesign of Machine Elements ProjectGirish ChandankarNo ratings yet

- Worksheet No. 5 Engineering DrawingsDocument2 pagesWorksheet No. 5 Engineering DrawingsNeal John VillarmenteNo ratings yet

- Latest Report 2Document13 pagesLatest Report 2Piyush BariNo ratings yet

- Examples On How To Interpret GD&T: Form, Orientation, Location and Run-Out TolerancesDocument28 pagesExamples On How To Interpret GD&T: Form, Orientation, Location and Run-Out TolerancesSUDHIR SINGH PATYALNo ratings yet

- Section I. Print Reading: 3-1. GENERALDocument32 pagesSection I. Print Reading: 3-1. GENERALarnolhariNo ratings yet

- Welding SymbolsDocument37 pagesWelding SymbolsmehmetsalliNo ratings yet

- Geometrical Dimensioning and TolerenceDocument61 pagesGeometrical Dimensioning and TolerenceAd Man GeTigNo ratings yet

- GD&TDocument14 pagesGD&TsrajubasavaNo ratings yet

- Dimensioning ME DrawingsDocument50 pagesDimensioning ME DrawingsLuis NunesNo ratings yet

- Flat Ness: Our Comprehensive List of GD&T SymbolsDocument29 pagesFlat Ness: Our Comprehensive List of GD&T SymbolsMidhilesh RavikindiNo ratings yet

- GD&T - Toronto Mechanical Design, Part and Assembly Drawings, Toronto CAD DrawingsDocument12 pagesGD&T - Toronto Mechanical Design, Part and Assembly Drawings, Toronto CAD DrawingsPuneet Bahri100% (1)

- Geometric ToleranceDocument9 pagesGeometric ToleranceJohn RobinNo ratings yet

- GT&DDocument17 pagesGT&DMicha VardyNo ratings yet

- Geometric Dimensioning and Tolerancing: Navigation Search Citations Reliable and Independent SourcesDocument8 pagesGeometric Dimensioning and Tolerancing: Navigation Search Citations Reliable and Independent SourcesDeepak LogesonNo ratings yet

- Common Terms and Definitions: Basic DimensionDocument9 pagesCommon Terms and Definitions: Basic Dimensionswap dNo ratings yet

- Engineering Drawings - GD&TDocument45 pagesEngineering Drawings - GD&TMichael Wood100% (1)

- Joining Welders Since 1995Document38 pagesJoining Welders Since 1995Sanjay Kumar SinghNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- International Standard: Norme InternationaleDocument11 pagesInternational Standard: Norme InternationalezoombadosNo ratings yet

- Original PDF Differential Equations With Boundary Value Problems 9tdownload Original PDF Differential Equations With Boundary Value Problems 9th PDFDocument41 pagesOriginal PDF Differential Equations With Boundary Value Problems 9tdownload Original PDF Differential Equations With Boundary Value Problems 9th PDFcynthia.stewart295100% (40)

- Prediction and Analysis of Gear Rattle: Development TransmissionsDocument5 pagesPrediction and Analysis of Gear Rattle: Development TransmissionssmsnvhNo ratings yet

- Chapter 8 Review and Test SolutionsDocument15 pagesChapter 8 Review and Test SolutionsIrfanKhanNo ratings yet

- Math 46 Sample MidtermDocument2 pagesMath 46 Sample MidtermMt RushNo ratings yet

- Volkmann CTwisterDocument20 pagesVolkmann CTwisterimma coverNo ratings yet

- DPP - 01 - ElectrostaticsDocument4 pagesDPP - 01 - ElectrostaticsPubg prakhar PrakharNo ratings yet

- Testing of Stator Windings For Thermal Aging PDFDocument102 pagesTesting of Stator Windings For Thermal Aging PDFHuong TranNo ratings yet

- Basic Welding EngineeringDocument60 pagesBasic Welding EngineeringYuwantoniAlNo ratings yet

- Analysis of Uplift Bearing Capacity of Pile Based On ABAQUSDocument5 pagesAnalysis of Uplift Bearing Capacity of Pile Based On ABAQUSramtin hajirezaeiNo ratings yet

- Physics Notes Fbise FSC 2 CHAPTER - 18 THE ATOMIC SPECTRADocument5 pagesPhysics Notes Fbise FSC 2 CHAPTER - 18 THE ATOMIC SPECTRAflyfalconNo ratings yet

- Thermal Analysis ReportDocument17 pagesThermal Analysis ReportGaurav GayakeNo ratings yet

- Donald A. Neumann - Kinesiology of The Musculoskeletal System 3rd Edition (2018, ELSEVIER) - Libgen - Li-P Íginas-6Document42 pagesDonald A. Neumann - Kinesiology of The Musculoskeletal System 3rd Edition (2018, ELSEVIER) - Libgen - Li-P Íginas-6ritaalmeida98No ratings yet

- Impact of FireDocument61 pagesImpact of FireDaniel MilosevskiNo ratings yet

- BCC - 1,2 H SPLN 41-4Document1 pageBCC - 1,2 H SPLN 41-4TPNo ratings yet

- Ultrasensitive Fluorescence Detection of Peroxymonosulfate Based On A Sulfate Radical-Mediated Aromatic Hydroxylation - SuppDocument15 pagesUltrasensitive Fluorescence Detection of Peroxymonosulfate Based On A Sulfate Radical-Mediated Aromatic Hydroxylation - SuppSantosh Srinivas NNo ratings yet

- Technical Datasheet - Solumer 871 - EngDocument1 pageTechnical Datasheet - Solumer 871 - EngCristhian Villegas OrtizNo ratings yet

- XMFR Impedance FactorsDocument13 pagesXMFR Impedance Factorssalemg82No ratings yet

- Evaluation of Gas in Place, Drainage EfficienyDocument76 pagesEvaluation of Gas in Place, Drainage EfficienytahaNo ratings yet

- SQB (Rotational Dynamics) - With SolutionDocument52 pagesSQB (Rotational Dynamics) - With SolutionAkshat GuptaNo ratings yet

- Iso 2954 2012 en PDFDocument8 pagesIso 2954 2012 en PDFJulio Castillo100% (1)

- Conductors and Electric Field in Static EquilibriumDocument1 pageConductors and Electric Field in Static Equilibriumfrance villNo ratings yet

- 2002 - Math - EnglishDocument10 pages2002 - Math - EnglishThree Bilan Rezkyta SimatupangNo ratings yet

- IITs Branchwise Cut Off Marks and RanksDocument64 pagesIITs Branchwise Cut Off Marks and RanksPrithviraj GhoshNo ratings yet

- EDC-DTS-MV017 - Longitudinally Waterproof 22 KV Cable (Cooper Screen) and Connecting AccessoriesDocument42 pagesEDC-DTS-MV017 - Longitudinally Waterproof 22 KV Cable (Cooper Screen) and Connecting AccessoriesJoe bilouteNo ratings yet

- S1-6-Transformer Explosion and Fire Prevention System - T P Govindan-ConsultantDocument6 pagesS1-6-Transformer Explosion and Fire Prevention System - T P Govindan-ConsultantMallikarjunNo ratings yet

- PHY301 Handouts 1 45Document191 pagesPHY301 Handouts 1 45zaheerNo ratings yet

- MCQ in Strength of Materials Part 1 ECE Board ExamDocument11 pagesMCQ in Strength of Materials Part 1 ECE Board Examlance galorportNo ratings yet