Professional Documents

Culture Documents

01 - PVC Conduits Installation

01 - PVC Conduits Installation

Uploaded by

Raju ManojOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 - PVC Conduits Installation

01 - PVC Conduits Installation

Uploaded by

Raju ManojCopyright:

Available Formats

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 1 of 10

M/S KHALIFA JUMA AL NABOODA

M/S ART CONSULTANTS CONSULTING ARCHITECTS &

ENGINEERS

2B+G+M+P+R COMMERCIAL & RESIDENTAL BUILDING ON

PLOT : 214-0535, AL GARHOUD- DUBAI,UAE

METHOD STATEMENT

FOR

INSTALLATION ELECTRICAL PVC CONDUIT &

ACCESSORIES

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 2 of 10

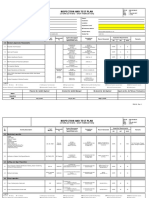

REVISION RECORD

This cover page is a record of all revisions of the document identified above by number and title.

All previous cover pages are hereby superseded and are to be destroyed.

Prepared By: Checked By: Approved

R Sub-Contractor Contractor By

e

Description and Page

v. Date

Prepa Numbers of Revisions

N

red

o. By : Approved Main QA/QC

P.M

MEP By: PM MANAGER

Engin

eer

00 18/12/2021 1st Issue 10 Pages

01

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 3 of 10

TABLE OF CONTENTS

1.0 PURPOSE PAGE – 4 of 9

2.0 SCOPE PAGE – 4 of 9

3.0 REFERENCES PAGE – 4 of 9

4.0 DEFINITIONS PAGE – 4 of 9

5.0 RESPONSIBILITIES PAGE – 5 of 9

6.0 MATERIALS PAGE – 6 of 9

7.0 EQUIPMENT PAGE – 6 of 9

8.0 PROCEDURE PAGE – 6 of 9

9.0 SAFETY PAGE – 9 of 9

10.0 ATTACHMENTS PAGE – 9 of 9

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 4 of 10

1.0 PURPOSE:

The purpose of this Method Statement is to define the procedure step by step to

implement the correct practices for Installation of PVC Conduits & Accessories

through the guidelines contained herein so as to ensure that the job execution

complies with the requirements.

2.0 SCOPE

This Method Statement refers to various work procedures which explains and covers

the installation of PVC Conduits & Accessories.

3.0 REFERENCES

3.1 Approved Shop Drawings.

3.2 Contract Specification

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 5 of 10

4.0 DEFINITIONS

CONSULTANT : M/S BH-NS ENGINEERING CONSULTANTS

CONTRACTOR : MODERN EXECUTIVE SYSYTEMS CONTRACTING

SUB CONTRACTOR: MODERN EXECUTIVE SYSYTEMS CONTRACTING-MEP

ITL : Independent Testing Laboratory

ITP : Inspection & Test Plan

HSE : Health, Safety & Environment

PPE : Personal Protective Equipment

PM : Project Manager

PE : Project Engineer

SD : Shop Drawing

5.0 RESPONSIBILITIES

5.1 Project Manager - shall be responsible for the overall project. The Project

Manager will be based on site and will be responsible for the

Management of the project, both on and off site, through delegation of

duties in accordance with the organization chart and for the effective

implementation of the Project Management System.

5.2 The MEP Coordinator: Responsible on behalf of main contractor to coordinate,

check and follow up all MEP related sub - contractors progress and installation

works in proper sequence of activities with main contractor to achieve targeted

completion.

5.3 Project Engineer is responsible for the execution of the activity in accordance

with the Project Specifications, Safety and Approved Method Statement.

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 6 of 10

5.4 The HSE officer will monitor and implement all HSE related issues. He shall

ensure that all necessary requirements regarding health, safety and environment

concerns are met and adhered to. The HSE officer shall ensure that all permits

and authorization are on hand prior to starting any site operation.

5.5 The site Engineer shall ensure that all works are carried out according to design

and approved shop drawings.

5.6 The Store keeper:

Shall be responsible for to ensure issuance of materials to the site with reference

to Material Inspection Request (MIR) and suitable manner of storing the material

as per manufacturer recommendation.

5.7 Foreman Responsibilities:

Shall be responsible for arranging the material by coordinating with the store

Keeper and follow the instructions of Site Engineer and carry out the installation

Process as per approved shop drawings and process by arranging his man power

accordingly.

6.0 MATERIAL

As per approved Material Submittal

7.0 EQUIPMENT

7.1 Portable Hand tools

7.2 Portable Drill Machine / Grinding Machine

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 7 of 10

7.3 Spirit Level

7.4 Level Threads

7.5 PVC Conduit bending and threading equipment

8.0 PROCEDURES

HANDLING AND STORAGE

On receipt of the PVC Conduit and accessories at site, necessary precautions shall

be taken for unloading, shifting & storage, as follows:-

8.1 All materials received at site shall be inspected (MVR shall be raised for

inspection) and ensured that the materials are as per approved material

submittal.

8.2 Material found not suitable for site use will be removed from site immediately.

8.3 All conduits and accessories delivered at site shall be carefully off-loaded

with adequate man power and equipment in such manner that no damage

shall be caused to conduits and accessories.

8.4 Materials shall be stored in a covered / dry space at all the time to avoid any

damage due to weather effect.

INSTALLATION: (All works shall be as per approved drawing & specification)

8.5 Ensure that the work area is ready and safe to start the installation of

Conduiting works.

8.6 Prior to start of installation, refer to the approved shop drawings to the area

of installation and ensure that required materials are available at site as per

approved material submittals.

8.7 Ensure the materials show no mark of damage or deformity of any kind

before issuing the material from site store.

All materials and accessories should also be free of dust or oil.

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 8 of 10

8.8 Ensure that the issued materials are of approved specifications/ submittals

and as per the requirement of the area shop drawings (i.e. Make, size, Model

/ Type etc.).

8.9 Engineers / Site Supervisors have to ensure for PVC Conduits installation block

work completed without plaster are completed for the area of installation and

released / cleared by civil contractor to proceed with conduit installations. Also

the work area should be clean and safe to take up activities.

8.10 Ensure the installation of Conduiting carried out in accordance with manufacturer's

installation recommendations, requirements applicable standards and in accordance

project specification.

8.11 Mark the location of the back box or pull box & place thermocol secured with

masking tape on location as per shop drawing. Fix height and level based on

surveyor mark point (reference point)

8.12 Install the PVC conduits utilizing the steel reinforcements as supports with

necessary binding wires.

8.13 The concealed conduiting in slab or any other concrete structure should be

securely fastened with binding wires to reinforcement rods or shuttering to

withstand concrete & screed pour with minimum intervels of 1 Meters.

8.14 The jointing of PVC conduits shall be done with suitable couplers and

solvent cement- The PVC conduits shall be bonded tightly to the back box /

pull box with suitable adapters. In case of G.I Conduits connected to trunking,

steel boxes, panels, switchgear or any item that having a tapped entry, the

connection shall be made by long threaded male brass bush with a coupling a

serrated spring washer after removing paint with a purpose made tool.

8.15 The jointing process of PVC conduit will be followed as below.

(a) Both the joining ends of conduits will be cleaned from inside as well as

from outside before putting solvent.

(b) A thin layer of solvent cement is applied to the inner surface of the coupler.

(a) Push fit the conduit to end fully into the coupler by slight twisting action &

remove the spilled or surplus solvent cement from around the joint.

Make sure the conduit has entered fully into the box spouts or

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 9 of 10

couplers.

(a) Make sure that the joint is tight enough and entry of water into the conduit

through joints is not possible_

(c) Approved connectors / adopters will be used for connections to back

boxes / pull boxes.

(d) Expansion couplers of approved type shall be provided wherever the

conduit passes through the expansion joints of the building.

8.16 All bends of PVC conduiting will be made by using correct size of bending

spring. Ensure the radius of any conduit bend shall not be less than four times

the outside diameter of the conduit to satisfy the easy cabling / wire pulling

requirements.

8.17 To facilitate easy cabling / wiring, sufficient pull box or junction boxes will be

provided in all conduiting. At least one pull box shall be provided on every two

90 deg bends with maximum distance of 6 Meters and 10 Meters for one 90

Deg.bends.

8.18 In longitudinal straight runs the pull boxes / junction boxes will be provided in

every 10 to 15 meters.

8.19 Close bunch of PVC conduits in slab shall be avoided to maximum possible

extent.

8.20 Sufficient gap shall be provided between conduits at crossing.

8.21 Ensure all open ends of the conduits are capped / plugged properly before

concrete pouring. Also ensure caps are provided for unused knock out holes

where blanks have been removed. Install a nylon fish cord (draw wire) in empty

conduits that are meant for future provision complete with cap and bushing at

each end.

8.22 In vertical wall, the conduits shall run vertically from the back box & Horizontal

runs shall be avoided on walls.

8.23 Ensure the recessed position of outlet box is accurate to allow for surface finish

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 10 of 10

thickness.

8.24 Conduits chased into wall should be recessed sufficiently to permit a minimum

thickness of 15mm for plaster cover. For conduits run embedded in concrete a

minimum 25mm cover will be provide.

8.25 After completion of conduit installation for any portion, the area will be cleaned

properly by removing all surplus material, construction debris or scrap material

etc., before leaving so that the area is in clean and tidy condition prior to

concrete pour.

8.26 After removal of concrete shuttering, all the conduits shall be checked for

blockage (wherever possible). Cleaned & plugged / covered.

9.0 SAFETY

9.1 Proper TOOL BOX talk will be given to the personnel involving in the laying of

conduits and PPE’s to be used.

9.2 Safety Equipment: Safety Shoes, Helmet, Gloves and Safety belt should be

available during this activity

9.3 During laying of conduits works the Safety Officer will ensure that all safety

precautions are taken as per Project Specification, Health & Safety Rules and

Regulations

10.0 ATTACHMENTS

Check List (CHK – P0057 –E-002, Rev.00) Page :1

Inspection Test Plan (ITP-P0057-E-002, Rev.00) Page :2

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

PROJECT: 2B+G+M+P+R COMMERCIAL & RESIDENTAL Agreement No.

BUILDING ON PLOT : 214-0535, AL GARHOUD-

DUBAI,UAE

Ref. No. J-261-ART-2021-

METHOD STATEMENT 08-EMT-TS-EL-001-00

Rev. No. 00

FOR INSTALLATION OF ELECTRICAL Date: 19-12-21

PVC CONDUIT & ACCESSORIES Page: 11 of 10

MAIN CONTRACTOR MEP CONTRACTOR

M/S AL SAHEL CONTRACTING Co., M/S EMT

L.L.C. ELECTROMECHANICAL

WORKS LLC.

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Method Statement For Concrete Slab CuttingDocument13 pagesMethod Statement For Concrete Slab CuttingACCURATE BUILDING DEMOLITION L.L.C.No ratings yet

- Mengo Senior School S1 - S5 Payment Reference GuideDocument5 pagesMengo Senior School S1 - S5 Payment Reference GuidePentNo ratings yet

- Method of Statement For Conduit InstallationDocument15 pagesMethod of Statement For Conduit InstallationMohd MuksinNo ratings yet

- Pros and Cons of Transnational or Multi-National Businesses (TNCS/MNCS) and The Integration of The Philippines To The Global Economy.Document1 pagePros and Cons of Transnational or Multi-National Businesses (TNCS/MNCS) and The Integration of The Philippines To The Global Economy.Cristel Jane Bautista100% (1)

- Method Statement For MV Power Cables & Accessories InstallationDocument9 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Approved Manufacturers of Steel ForgingsDocument53 pagesApproved Manufacturers of Steel Forgingsricardo_prado6342100% (2)

- 21 - Low Voltages Electl. Power Conductors and CablesDocument6 pages21 - Low Voltages Electl. Power Conductors and CablesWalid MarhabaNo ratings yet

- Method Statement - LightingDocument6 pagesMethod Statement - Lightingahmad.nazareeNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- CHECKLIST For Installation of Electrical UPVC DuctsDocument1 pageCHECKLIST For Installation of Electrical UPVC DuctskevinNo ratings yet

- QCS 2010 Section 28 Part 2Document38 pagesQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- Method Statement Elect Pipe UndergroundDocument67 pagesMethod Statement Elect Pipe Undergroundمقاول تكييف كهرباء وصحيNo ratings yet

- Method Statement For Cable TrenchDocument20 pagesMethod Statement For Cable Trenchjherzel90No ratings yet

- KMTC Advert For September 2021 and March 2022 IntakesDocument2 pagesKMTC Advert For September 2021 and March 2022 IntakesNjoroge MainaNo ratings yet

- Method Statement For Installation of Light Fittings Luminary's Exterior InteriorDocument7 pagesMethod Statement For Installation of Light Fittings Luminary's Exterior InteriorCSD shakthiNo ratings yet

- METHOD STATEMENT FOR Switch Box and Socket Fixing WorkDocument5 pagesMETHOD STATEMENT FOR Switch Box and Socket Fixing WorkNaveenNo ratings yet

- Method Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CDocument32 pagesMethod Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CAva GhaziNo ratings yet

- Method Statement For Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMethod Statement For Installation of Electric PVC Conduits and AccessoriessamsungloverNo ratings yet

- Erection of LV Switchgears (PCC, MCC, Aux PDB'S)Document6 pagesErection of LV Switchgears (PCC, MCC, Aux PDB'S)Sutanu BiswasNo ratings yet

- Method Statement LV MV CablesDocument14 pagesMethod Statement LV MV CablesehteshamNo ratings yet

- Ms For Indoor Ligthing InstallationDocument6 pagesMs For Indoor Ligthing InstallationJoe_AverageNo ratings yet

- Android Based Electrical Appliance ControlDocument5 pagesAndroid Based Electrical Appliance Controlharrysingh100% (1)

- KP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSDocument22 pagesKP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSUtku Can KılıçNo ratings yet

- Cable Ladder Method of Statement.Document4 pagesCable Ladder Method of Statement.Ahmad DagamsehNo ratings yet

- Earthing Method StatementDocument5 pagesEarthing Method StatementMuhammad Saqib AsifNo ratings yet

- Method Statement IPBsDocument7 pagesMethod Statement IPBskamil100% (1)

- Method Statement For Electrical ServicesDocument6 pagesMethod Statement For Electrical ServicesUmaira ZainalNo ratings yet

- MOS For Electrical UG Ducts (PVC Pipes) InstallationDocument3 pagesMOS For Electrical UG Ducts (PVC Pipes) Installationmagdi badran100% (2)

- Electrical Junction Box ITPDocument1 pageElectrical Junction Box ITPkamilNo ratings yet

- UPVC Drainage Pipes & Fittings - ACDocument101 pagesUPVC Drainage Pipes & Fittings - ACsushant_moreyNo ratings yet

- Itp FBSB Moc Fibreoptic 005 FinalDocument6 pagesItp FBSB Moc Fibreoptic 005 FinalVictor BiacoloNo ratings yet

- 2.MS For Clearing & GrubbingDocument3 pages2.MS For Clearing & Grubbingcharith senavirathnaNo ratings yet

- Table of Contents: Method Statement FOR Lightning Protection System InstallationDocument10 pagesTable of Contents: Method Statement FOR Lightning Protection System Installationw fathyNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- Project Internal Audit Procedure: SheetalkumarDocument4 pagesProject Internal Audit Procedure: SheetalkumarTwin BullsNo ratings yet

- Internal Approval of Method StatementsDocument12 pagesInternal Approval of Method Statementsmidhun muraliNo ratings yet

- Method Statement For GIDocument9 pagesMethod Statement For GIAleen Gamal Al-DinjiNo ratings yet

- Method StatementDocument6 pagesMethod Statementanon_208207357No ratings yet

- Method Statement Lamps, Switches and Socket Outlets InstallationDocument2 pagesMethod Statement Lamps, Switches and Socket Outlets InstallationVõ Khắc GhiNo ratings yet

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- Wiring Device Second Fix Installation &wiring Termination Rev01Document7 pagesWiring Device Second Fix Installation &wiring Termination Rev01Mohammed Mujeeb Ali FathaanNo ratings yet

- BEW - Method Statement For Electrical Conduiting in Concealed WallDocument9 pagesBEW - Method Statement For Electrical Conduiting in Concealed WallArun UdayabhanuNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Method Statement - Excavation, Bracing & Backfilling WorksDocument10 pagesMethod Statement - Excavation, Bracing & Backfilling WorksKamal Deo ShahNo ratings yet

- Metherd Statement For Wiring & Cable-R0Document11 pagesMetherd Statement For Wiring & Cable-R0Ahmad Saqqa100% (1)

- M1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - ADocument48 pagesM1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - AAnandu AshokanNo ratings yet

- Termostato AKM 446 PDFDocument4 pagesTermostato AKM 446 PDFPaulo RebeloNo ratings yet

- MST For EARTHING SYSTEMDocument13 pagesMST For EARTHING SYSTEMمقاول تكييف كهرباء وصحيNo ratings yet

- Transformer 1 MosDocument5 pagesTransformer 1 MosMohamedAhmedFawzyNo ratings yet

- ITP-Line Hardware - Sample Test PDFDocument3 pagesITP-Line Hardware - Sample Test PDFPrabhakar Sv100% (1)

- HG Power Transmission Sdn. BHD.: Method StatementDocument6 pagesHG Power Transmission Sdn. BHD.: Method StatementNabil MazelanNo ratings yet

- MET HangersDocument5 pagesMET Hangersjay mamucayNo ratings yet

- FEWA LV Joints & TerminationsDocument13 pagesFEWA LV Joints & TerminationsMuhammad RazaNo ratings yet

- Inspection & Test Check ListDocument1 pageInspection & Test Check ListPRAKTISINo ratings yet

- Method of Statement-13.8KVDocument57 pagesMethod of Statement-13.8KVzaheerNo ratings yet

- Electrical & Wiring METHOD STATEMENTDocument4 pagesElectrical & Wiring METHOD STATEMENTAfiq JamalNo ratings yet

- 01CEEETCDIIAGT202122Document151 pages01CEEETCDIIAGT202122arindam sarkarNo ratings yet

- Ms Plu 002 SoftDocument38 pagesMs Plu 002 SoftShakila NishaniNo ratings yet

- Ford CX 430 Welding Fixtures For Welded S.A Stabi Bracket & Abs Bracket Assy 100+S/1Document11 pagesFord CX 430 Welding Fixtures For Welded S.A Stabi Bracket & Abs Bracket Assy 100+S/1Bernardo IglesiasNo ratings yet

- NS Grout - Sec by Al FanarDocument3 pagesNS Grout - Sec by Al FanarAngelo Carlo MalabananNo ratings yet

- Bakery Strategy Overview: Richard LanDocument25 pagesBakery Strategy Overview: Richard LanLuis Jun NaguioNo ratings yet

- Chapter 1Document8 pagesChapter 1cadevidajimboy1026No ratings yet

- Baumgartner Organizational Culture and Leadership PDFDocument13 pagesBaumgartner Organizational Culture and Leadership PDFVEGA AGNITYA EKA PANGESTINo ratings yet

- Letter of IntentDocument3 pagesLetter of IntentMARY ANN LIWANAGNo ratings yet

- Construction Site Safety Program REV-03Document97 pagesConstruction Site Safety Program REV-0301095902062ahmedNo ratings yet

- Choosing The Right ESOP PlanDocument10 pagesChoosing The Right ESOP PlanSriram VeeramaniNo ratings yet

- Accenture InnovationDocument8 pagesAccenture InnovationMOHIT KUMARNo ratings yet

- Ecofin BG PDFDocument12 pagesEcofin BG PDFBarathy KolappanNo ratings yet

- Management Australia 7th Edition Stagg Test Bank Full Chapter PDFDocument54 pagesManagement Australia 7th Edition Stagg Test Bank Full Chapter PDFberthaluyenkaq9w100% (13)

- Building A Strengths-Based Organization: by Tony RutiglianoDocument16 pagesBuilding A Strengths-Based Organization: by Tony Rutiglianovenu4u498No ratings yet

- Mobile Money Services Development: Policy Research Working Paper 6786Document23 pagesMobile Money Services Development: Policy Research Working Paper 6786NapsterNo ratings yet

- H9Jlfv2H: M-Pesa StatementDocument1 pageH9Jlfv2H: M-Pesa StatementTHE EMPIRE LIONS ROBOTICS INVESTMENTS LTDNo ratings yet

- AB 36 Racial Diversity and Its Asymmetry Within and Across Hierarchical Levels The Effects On Financial PerformanceDocument26 pagesAB 36 Racial Diversity and Its Asymmetry Within and Across Hierarchical Levels The Effects On Financial PerformanceMuhammad hamzaNo ratings yet

- 46595-261231-302061 A Welding TechnologyDocument2 pages46595-261231-302061 A Welding TechnologyVijay Kumar DodaiNo ratings yet

- ENTREP-Wk 8 PDFDocument4 pagesENTREP-Wk 8 PDFandrea jane hinaNo ratings yet

- Inspector Stamp ControlDocument4 pagesInspector Stamp ControlGeorgeNo ratings yet

- A Roadmap To Accounting For Non Controlling Interests 2020Document200 pagesA Roadmap To Accounting For Non Controlling Interests 2020pravinreddyNo ratings yet

- Republic Act 9418 Without IRRDocument12 pagesRepublic Act 9418 Without IRRyear87phNo ratings yet

- TLE7 Q3M4 Coalculatingcostof-ProductionDocument11 pagesTLE7 Q3M4 Coalculatingcostof-ProductionMarie FontanillaNo ratings yet

- Summer Intership Project Report OnDocument83 pagesSummer Intership Project Report Onastha shuklaNo ratings yet

- Part 1 Section A: Note That The New Markband Doesn't Include Example in Any of The Level DescriptorsDocument10 pagesPart 1 Section A: Note That The New Markband Doesn't Include Example in Any of The Level DescriptorsahaanNo ratings yet

- Time To MarketDocument4 pagesTime To MarketMy SelfNo ratings yet

- CadburyDocument61 pagesCadburysuryakantshrotriya100% (1)

- CSR Activities 10: Month Wise ScheduleDocument14 pagesCSR Activities 10: Month Wise ScheduleakanshatyagiNo ratings yet

- GeM Bidding 3465201Document5 pagesGeM Bidding 3465201Apna time aayegaNo ratings yet

- Dossier 4Document4 pagesDossier 4Nicolas DESHAYESNo ratings yet

- CG Question 567Document1 pageCG Question 567Maryam MalikNo ratings yet