Professional Documents

Culture Documents

TMR Speedtronic™ Mark V LVDT Calibration Basics

TMR Speedtronic™ Mark V LVDT Calibration Basics

Uploaded by

TidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TMR Speedtronic™ Mark V LVDT Calibration Basics

TMR Speedtronic™ Mark V LVDT Calibration Basics

Uploaded by

TidCopyright:

Available Formats

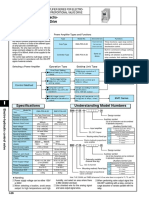

TMR SpeedTronic™ Mark V LVDT Calibration Basics

This document attempts to explain how the TMR SpeedTronic Mark V

calculates position feedback from LVDTs (this includes RVDTs, also) and

how this can cause the servo output currents to appear to be mismatched

and/or out of tolerance. This explanation also attempts to define when it is

necessary to adjust Null Bias current values, and when it is not.

This document is primarily directed at heavy-duty gas turbine applications,

though small- and medium steam turbines which employ only two LVDTs

per control valve, etc., do experience the same kind of problems.

(Steam turbine applications which use three LVDTs per device use a

unique method of downloading individual LVDT calibration information to

each control processor which does not result in the problems experienced

when one I/O Configuration is downloaded to all three control

processors—which is the case in the overwhelming majority of TMR Mark

V applications.)

But first, some basics of both LVDTs and three-coil electrohydraulic servo

valves are necessary. Then, a basic explanation of how feedback relates

to servo output current is given. Then a description of how the TMR

SpeedTronic Mark V converts LVDT feedback voltages into positions is

given. Finally, a description of when—and when it is not—necessary to

adjust servo valve Null Bias currents is given.

LVDT Basics

For most every heavy duty gas turbine application GE specifies to its

vendors that the voltage output of LVDTs is to be linear between

approximately 0.700 VAC RMS and 3.500 VAC RMS over the specified

range of travel of the LVDT. (The output voltage can be less than or

greater than the limits specified, but the voltage with respect to position

must be linear between the limits specified. The limits of 0.700 – 3.500

VAC RMS are almost always the standard for LVDTs; RVDTs sometimes

have higher or lower minimums, and usually have lower maximums, as

well.)

This is not to say that every device with an LVDT will have an output of

exactly 0.700 VAC RMS to 3.500 VAC RMS. Quite the contrary, most

devices will have an output of 0.700 VAC RMS at zero stroke, and

something less than 3.500 VAC RMS at maximum stroke (maximum

actuator travel)—but almost never more than 3.500 VAC RMS at

maximum actuator travel.

Further, GE specifies the range of travel of the actuators of devices to be

equipped with LVDTs should not exceed the linear range of travel of the

LVDT. In other words, when properly adjusted the output of an LVDT will

Practical Turbine Controls Page 1 of 7 Rev. 3

Mk V LVDT Feedback Calibration Basics

be between 0.700 VAC RMS and 3.500 VAC RMS over the range of travel

of the device actuator and that output will be proportional to stroke (linear)

over the range of travel of the device actuator. ‘Properly adjusted’ means

that the output of the LVDT is adjusted such that when the device is at it’s

fully closed mechanical stop the LVDT output voltage is approximately

0.700 VAC RMS, +/- 0.020 VAC RMS and does not usually exceed 3.500

VAC RMS at maximum actuator travel.

Servo Valve Basics

The three-coil electrohydraulic servo valves which GE uses to control the

position of hydraulic actuators have springs in them which, in the absence

of any electrical current being applied to the coils (all three coils) will

cause the device to move to shut off the flow of fuel or air or steam to the

turbine. This spring is called the fail-safe spring because it causes the

servo-valve to port the flow of high-pressure hydraulic oil to the actuator of

the device to move the device to a “safe” position in the event of a loss of

all electrical signals (“safe” meaning reducing the flow of air or fuel or

steam, etc., to the unit).

The servos which GE uses require negative current to cause the device to

increase the flow of fuel or air or steam to the turbine; positive servo

current decreases the flow of fuel or air or steam to the turbine. For this

reason, it is necessary to verify that the polarity of the servo current being

applied to each coil is correct before beginning any calibration procedure.

This document assumes that has been done and so the effects of

incorrect polarity will not affect the descriptions in this document.

To cause the servo valve to position the device at some mid-stroke,

‘steady-state’ position it is necessary to apply an electrical current to at

least one of the coils to overcome the spring tension and keep the device

at the mid-stroke position. This current is called the Null Bias current. The

servos which GE uses require a total of –0.8 mA, +/- 0.4 mA, in order to

overcome the fail-safe spring tension and keep the device at some mid-

stroke, ‘steady-state’ position.

Since there are three coils in the servo, the total can be divided by three to

determine the Null Bias current that each processor would supply under

ideal conditions to keep the device at some mid-stroke position. -0.8 mA

divided by three equals -0.267 mA per processor. Since the Mark V scales

0-10 mA as 0-100% for servo output current, this translates into

-2.67% servo current per processor under ideal conditions. (NOTE: The

I/O Configurator automatically converts the value entered into the Null

Bias Current field to a negative value when a ‘Save’ or a ‘Save and Exit’ is

performed, saving the value in IOCFG_Q.DAT as a negative value.

Therefore, it is NOT necessary—except under one circumstance, for the

Gas Transfer Valve of a DLN-I combustor-equipped gas turbine—to enter

a negative value of Null Bias current into the I/O Configurator.)

Practical Turbine Controls Page 2 of 7 Rev. 3

Mk V LVDT Feedback Calibration Basics

Note that the specified range of total Null Bias current required is -0.8 mA,

+/- 0.4 mA, meaning that the total can fall anywhere between -0.4 mA and

-1.2 mA. This means that the servo current output of any processor can

range between -0.133 mA and -0.400 mA and still fall within the

specification, or between -1.33 mA and -4.00 mA.

The fail-safe spring tension is adjusted by the servo valve manufacturer

and is not intended to be field-adjusted. In fact, most field attempts to

adjust servo valve fail-safe spring tension result in replacement of the

servo valve because it is just not possible to properly adjust the spring

tension without the use of calibrated pressure gauges and specified

hydraulic pressures, etc.

Further, most field attempts to adjust fail-safe spring tension are driven by

a desire to bring a single, or sometimes two, servo currents ‘into’

specification. Since there is only one spring, adjusting the spring tension

affects the servo current of all three coils. Resist the temptation to field

adjust a servo valve’s fail-safe spring—particularly on a new unit

installation or the installation of a new servo valve—and do so only if a

spare is readily available—again, since most field adjustment attempts

result in replacement of the servo anyway.

Mark V Regulators and Servo Output Currents

The regulators used in the SpeedTronic Mark V subtract the position

feedback from a position reference in what’s called a summing junction.

The difference is used to increase or decrease the amount of current

applied to the servo valve coils. Again, this is done in each of the three

control processors. If the feedback were equal to the reference, the

difference would be zero. If zero current were output to the servo valve,

the valve would not move to the required position because of the current

required to overcome the fail-safe spring. So, the value of current

specified as the Null Bias Current in the I/O Configurator is added to the

output of the regulator summing junction and that current is always

“added” to the output of the summing junction. In other words, the output

of the summing junction is biased by the addition of the Null Bias current.

Under ideal conditions—that is, when the calibrated position feedback for

all three processors is exactly identical—the total of the three servo

current outputs will be between -4.00% and -12.00%, and the individual

servo currents will be nearly equal. In fact, if the proper hydraulic pressure

is available and the correct regulator gain has been input to the I/O

Configurator and downloaded to the control processors, the individual

servo currents will be very close to -2.67%, if not nearly exactly -2.67%.

However, ideal conditions are not attainable in the TMR SpeedTronic

Mark V turbine control panel except: 1) immediately after an

AutoCalibrate has been performed, or, 2) if a special method is employed

Practical Turbine Controls Page 3 of 7 Rev. 3

Mk V LVDT Feedback Calibration Basics

to download individual 0%-stroke and 100%-stroke voltages to the three

control processors. (This special method is employed on most large

steam turbine applications where devices are equipped with three LVDTs.)

The I/O Configuration which is downloaded to all three control processors

includes the 0%-stroke and 100%-stroke voltages which the control

processors use to convert the LVDT feedback voltages into position

feedbacks. It also includes the Null Bias current value. Note, that all three

control processors get the same 0%-stroke and 100%-stroke voltage

values and the same Null Bias current value.

The TMR SpeedTronic Mark V panel typically has all LVDT feedback

voltage signals connected to a single I/O terminal board (usually the

TBQC card on <R> processors), and those voltages are “fanned out” to

three ribbon cables which are connected to individual cards (usually

TCQA cards) in <R>, <S>, and <T>. The analog-to-digital conversions

take place on the individual TCQA cards. Because of things like ribbon

cable lengths not being exactly equal, varying resistances of connectors

and printed-circuit card traces and other component tolerance values all

adding up, the voltages that the analog-to-digital converter on each

individual TCQA card reads can be—and, in fact, are—different.

(Resistors and capacitors and other electronic components are almost

never precision components—precision components are costly—and

always fall within a certain tolerance range: 5%, or 10%, or 1%. Cost and

the precision required by the application dictate the tolerance, or range, of

deviation from the desired value that can be acceptable when building

electronic equipment. This is true of all electronic equipment that employs

analog components. This is one of the reason many analog circuits

employ potentiometers, or “trimming pots”.)

If one manually reads the LVDT feedback voltages at the TBQC card

while performing a calibration of the LVDT feedback and then inputs these

values into the I/O Configurator for the 0%-stroke and 100%-stroke

voltages, then downloads these values to the three individual processors,

the slight mismatches in the actual voltages being read by the analog-to-

digital converters on the three TCQA cards are not accounted for and the

LVDT feedback for each control processor will be slightly different from the

other control processors—not usually different by a great amount, but

different enough to cause the servo output currents of the three control

processors to vary. This is because the slight differences will cause each

of the three control processors to determine the device to be at a slightly

different position, and therefore the output of the three summing junctions

will be slightly different—meaning the servo output currents of the three

control processors will be slightly different.

Similarly, if one uses AutoCalibrate to determine the 0%-stroke and 100%-

stroke voltages to put into the I/O Configurator, one has to take the

Practical Turbine Controls Page 4 of 7 Rev. 3

Mk V LVDT Feedback Calibration Basics

average of the three values since each control processor’s 0%-stroke and

100%-stroke voltage values are calculated and displayed and only one

value can be entered into the I/O Configurator and downloaded to all three

control processors. The act of averaging the values before entering them

in the I/O Configurator and downloading them to the three control

processors will cause each control processor to display a slightly different

feedback value from the other two processors—just as downloading the

voltage values read manually at the TBQC will cause.

The slight differences (usually just tenths of a percent) in themselves don’t

cause a problem—except that each control processor looks at the position

reference for the device (a single, voted value from sequencing) and then

compares the reference to the position feedback it believes the device to

be at and adjusts the servo output current accordingly to try to make the

feedback equal to the reference. With this happening in all three control

processors, the servo output currents of all three control processors can

be very different from each other.

For example, if <R> thought the IGVs were at 78.9 DGA, and <S> thought

they were at 78.6 DGA, and <T> thought they were at 79.1 DGA, and the

reference was 79.0 DGA, <R>’s servo output current would be

approximately -0.279 mA, or -2.79%, <S>’s servo output current might be

approximately -0.344 mA, or -3.44%, and <T>’s servo output current might

be approximately -0.121 mA, or -1.21%.

On first glance, this might appear to be a problem: the servo currents are

not approximately -0.267 mA, or -2.67%, and they appear to be

unbalanced. But, given the differences in position feedback seen by the

three processors it’s not a problem at all.

If one performs an AutoCalibration of LVDT feedback and then

immediately uses the Manual feature of AutoCalibrate to position the

device to some mid-stroke position, one can see the three position

feedback values for the three control processors would be nearly identical

(within hundredths of a percent, usually)—and the three servo currents

would most likely be nearly identical, and usually very close to the desired

-2.67% value, +/- 1.33%.

This is because immediately after an AutoCalibrate (before an I/O Config.

download has been performed and the processors have been re-booted)

the 0%-stroke and 100%-stroke voltages in the TCQA RAM are the exact

values they need to be for that TCQA and processor to make it’s

calculation of position feedback from the LVDT voltages it reads nearly

identical to the other two TCQA cards and processors.

(The values in TCQA RAM are put there by AutoCalibrate after an

AutoCalibrate has been performed, and are written over by the values

from the I/O Config. download when the processor is re-booted.)

Practical Turbine Controls Page 5 of 7 Rev. 3

Mk V LVDT Feedback Calibration Basics

It should be clear that mismatches in servo currents can be attributed to

the mismatches in calculated position feedback done by the individual

control processors. This occurs when a single, or average, set of 0%-

stroke and 100%-stroke voltages are downloaded to the processors when,

in fact, each processor really sees slightly different voltages and needs

slightly different 0%-stroke and 100%-stroke voltages in order to calculate

position feedbacks identical to the other control processors.

Sometimes, one TCQA card will calculate a much higher or lower position

feedback than the other TCQA cards. This can cause concern, and could

even be cause for replacement of the TCQA card which has the abnormal

reading after all other possible reasons for the difference have been

investigated (such as poor ribbon cable connections; corrosion on the

ribbon cable connect pins; a chafed or worn ribbon cable with an exposed

conductor which might be in contact with a ground source, etc.).

When to Adjust the Null Bias Current

Now, the question which should be on the reader’s mind is: When is it

necessary to adjust servo Null Bias current values like the Control Spec

says should be done? The answer to that is: When the calibrated position

feedback differs from the reference by more than approximately 0.5%.

Assume that LVDT feedback has been recently calibrated, including the

downloading of the 0%-stroke and 100%-stroke voltages to the three

control processors and the re-booting of the processors. Then, when

verifying the accuracy of the calibration it is noted that the feedback differs

from the reference by more than 0.5%, it is acceptable to make small

changes in the Null Bias current value, download, and re-boot, and re-

check the accuracy of the positioning of the device.

For example, while checking the accuracy of LVDT feedback calibration

the device is commanded to go to the 80.0% stroke position. The device

moves to a position and stops moving, and the observed position

feedback is 79.2%, which is unacceptable. Assume another LVDT

feedback calibration is performed, and when the device is commanded to

go to the 80% stroke position, the feedback is 79.3%. Assume another

calibration is performed and the feedback is still 0.6% below commanded

position. Looking at the servo-currents, one can see that they are all fairly

well-balanced and within the specification. In this case, it would be

acceptable to increase the Null Bias current to, say, 3.00, download, re-

boot, and repeat the verification check. If the difference between the

actual position feedback and the commanded position was less than

0.5%, no further adjustment of the Null Bias current value is required.

However, assume that during the verification of the accuracy of LVDT

feedback calibration the total of the servo output currents is within the

desirable range of -4% -to -12% but the individual currents themselves are

not well balanced. Assume also that the actual position feedback for each

Practical Turbine Controls Page 6 of 7 Rev. 3

Mk V LVDT Feedback Calibration Basics

of the three processors is within 0.5% of the commanded position, as is

the “voted” value of position feedback for the device. In this case, it is not

required nor recommended to change the value of Null Bias current.

Remember when changing the value of Null Bias current in the I/O

Configurator, that single value gets downloaded to all three control

processors. If one is trying to get a single processor’s servo output current

‘into’ range, changing the Null Bias current will most likely make that

processor’s value only worse, and will affect the other two processors, as

well. If a single processor’s servo output current is well out of range, the

problem is most likely that processor’s calculated position feedback is also

out of range of the other two and that is a different problem which cannot

be solved by adjusting the Null Bias current.

Practical Turbine Controls Page 7 of 7 Rev. 3

Mk V LVDT Feedback Calibration Basics

You might also like

- Software Dev Technical Challenge - Task OneDocument6 pagesSoftware Dev Technical Challenge - Task OneJaveria Zia0% (1)

- Alarms 7fa Process GF - SignalDocument43 pagesAlarms 7fa Process GF - SignalTid100% (1)

- Measuring Mosfet Curve Tracer PDFDocument11 pagesMeasuring Mosfet Curve Tracer PDFEugene Chew100% (2)

- Project On Ac Voltage Controller Using TriacDocument33 pagesProject On Ac Voltage Controller Using Triackatul830486% (7)

- Understanding Voltage Regulators - Smart Grid Solutions - SiemensDocument5 pagesUnderstanding Voltage Regulators - Smart Grid Solutions - SiemenstusarNo ratings yet

- Amit - Optimizing Oracle Essbase Formulas & Calc ScriptsDocument100 pagesAmit - Optimizing Oracle Essbase Formulas & Calc ScriptsAraz AbbaszadehNo ratings yet

- Null BiasDocument33 pagesNull BiasGoh Seng TakNo ratings yet

- Avr Newage mx321 PDFDocument4 pagesAvr Newage mx321 PDFLiya MahagamaNo ratings yet

- GCV SRV Calib..Document36 pagesGCV SRV Calib..bhavansaravanabeNo ratings yet

- Moog ValveDocument76 pagesMoog Valveramkrishna100% (1)

- Servo Valve Null Bias CurrentDocument41 pagesServo Valve Null Bias CurrentRam MeenaNo ratings yet

- Overload and Short Circuit Relay: Eocr-3Dis-AuDocument2 pagesOverload and Short Circuit Relay: Eocr-3Dis-AuAngelo Michael ClementeNo ratings yet

- Null Bias ControlDocument44 pagesNull Bias ControlAbderrahmane Ayoun100% (1)

- MX 321Document4 pagesMX 321derickteo5971100% (1)

- Avr MX321Document3 pagesAvr MX321Ahmad ArpaniNo ratings yet

- Chapter - 08 Switchboard and VSDDocument44 pagesChapter - 08 Switchboard and VSDdewidar1234100% (2)

- Technical Feedback On EHCDocument8 pagesTechnical Feedback On EHCvesridhar100% (1)

- Selsin Motori I Pokazivanje PravcaDocument6 pagesSelsin Motori I Pokazivanje PravcaSlobodan KojicNo ratings yet

- Catalogo Tecnico InglesDocument52 pagesCatalogo Tecnico InglesIngenieria Soporte Técnico SolconNo ratings yet

- Lab Procedures: (EE-455) Electrical Power System ProtectionDocument17 pagesLab Procedures: (EE-455) Electrical Power System Protectionax33m144No ratings yet

- 05 - Electro - Hydraulic ControllerDocument7 pages05 - Electro - Hydraulic Controllerwildhoney1979No ratings yet

- 220v DC Motor Speed Control Using Ic RegulatorDocument14 pages220v DC Motor Speed Control Using Ic RegulatorZagorchillo0% (1)

- H1000e I Ema-Emc PDFDocument4 pagesH1000e I Ema-Emc PDFNguyen Van ChungNo ratings yet

- MX321 ManualDocument4 pagesMX321 ManualFernando MendozaNo ratings yet

- EN em 160Document2 pagesEN em 160Merk ErikNo ratings yet

- SS440 InstructionsDocument4 pagesSS440 Instructionsgurunathan14No ratings yet

- 25 Kva - Three Phase Under Slung Inverter FOR Roof Mounted Ac Package UnitDocument29 pages25 Kva - Three Phase Under Slung Inverter FOR Roof Mounted Ac Package UnitAbhaya Kumar NayakNo ratings yet

- Schematic 1Document14 pagesSchematic 1yeremia kristianNo ratings yet

- As480 Avr Newage StamfordDocument6 pagesAs480 Avr Newage Stamfordabuzer1981No ratings yet

- VVC ControlDocument14 pagesVVC ControlRyte EchanoNo ratings yet

- AVR AS440 Data SheetDocument4 pagesAVR AS440 Data SheetMazhar Hussain100% (2)

- Sx440, STAMFORD ManualDocument4 pagesSx440, STAMFORD ManualSarawut PipeNo ratings yet

- AVR Operation For Three Transformers - MZECDocument18 pagesAVR Operation For Three Transformers - MZECFeroz HakkimNo ratings yet

- TD - As480 Avr - 04.08 - 02 - GBDocument6 pagesTD - As480 Avr - 04.08 - 02 - GBmo7amedengNo ratings yet

- Characterstics of Static Relay UndervoltageovervoltageDocument7 pagesCharacterstics of Static Relay Undervoltageovervoltagesaimanobhiram100% (2)

- Static Voltage Regulator SynopsisDocument4 pagesStatic Voltage Regulator SynopsisShravan JadhavNo ratings yet

- EHTC Functional DescriptionDocument8 pagesEHTC Functional Descriptionveer_s100% (2)

- 100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDocument7 pages100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDaniel SanchezNo ratings yet

- PrinciplesDocument5 pagesPrinciplesSachin RohillaNo ratings yet

- Atm 72Document8 pagesAtm 72muhammad arifNo ratings yet

- Measurements: CDG 11 CDG 16Document4 pagesMeasurements: CDG 11 CDG 16girish1950% (2)

- UC3879Document9 pagesUC3879Christina Tio TrisnasariNo ratings yet

- Servo Stabilizer ControllerDocument39 pagesServo Stabilizer Controllershalu29No ratings yet

- A3930 1 Datasheet PDFDocument21 pagesA3930 1 Datasheet PDFKaan GünayNo ratings yet

- Technical Feedback EhtcDocument9 pagesTechnical Feedback EhtcPrashant Kumar ChoudharyNo ratings yet

- SVPWM VTRDocument14 pagesSVPWM VTRAtiqMarwatNo ratings yet

- Regulator - ESTAmat MH Mounting Instructions MV1151 (Sept 2000)Document11 pagesRegulator - ESTAmat MH Mounting Instructions MV1151 (Sept 2000)Ieremeiov Vladimir100% (1)

- Scalar Control of Ac DrivesDocument38 pagesScalar Control of Ac Drivessureshy-ee213No ratings yet

- 2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsDocument2 pages2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsmachevallieNo ratings yet

- Designing With HV Microcontrollers: Author: Keith Curtis Microchip Technology IncDocument8 pagesDesigning With HV Microcontrollers: Author: Keith Curtis Microchip Technology Inctare890No ratings yet

- Sx460 Automatic Voltage Regulator (Avr)Document4 pagesSx460 Automatic Voltage Regulator (Avr)rajan_2002eee100% (1)

- CTER Polarity TestDocument30 pagesCTER Polarity TestforeverjaiNo ratings yet

- Electronic Slot Car Controller Mysteries Revealed - JayGee RacingDocument13 pagesElectronic Slot Car Controller Mysteries Revealed - JayGee RacingBeen DeeNo ratings yet

- Inching 1Document6 pagesInching 1Sridhar MakkapatiNo ratings yet

- CMC P 530 Rms ManualDocument17 pagesCMC P 530 Rms ManualVicente GarciaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- GT and Auxiliaries Connection DiagramDocument70 pagesGT and Auxiliaries Connection DiagramTidNo ratings yet

- Monitoring Software: Markvie Maintenance Class Energy Learning Center, Salem VaDocument22 pagesMonitoring Software: Markvie Maintenance Class Energy Learning Center, Salem VaTidNo ratings yet

- Critical To Quality (CTQ) Points Mode 5 Steady State EliminationDocument6 pagesCritical To Quality (CTQ) Points Mode 5 Steady State EliminationTidNo ratings yet

- Bio Amp Owner's GuideDocument50 pagesBio Amp Owner's GuideAmador Garcia IIINo ratings yet

- BB 6630 AlarmsDocument24 pagesBB 6630 Alarmsivan hary4No ratings yet

- UntitledDocument47 pagesUntitledavi privacyNo ratings yet

- (MAN-025!1!0) Trigno SDK User GuideDocument21 pages(MAN-025!1!0) Trigno SDK User GuideAndrea SpencerNo ratings yet

- TB15 Re EngineeringDocument15 pagesTB15 Re EngineeringnotmebugNo ratings yet

- Concept PaperDocument7 pagesConcept PaperChloe Krystel FaundoNo ratings yet

- DS MicroDocument2 pagesDS MicroAman RajNo ratings yet

- New Final MicroDocument13 pagesNew Final Microq.maitum.518224No ratings yet

- NI PXI-4071 Calibration ProcedureDocument150 pagesNI PXI-4071 Calibration Procedurecisco211No ratings yet

- TelitDocument6 pagesTelitPiyush BaradNo ratings yet

- Rslinx Classic Setup: Reporting From Rslinx Classic Defining A Dde/Opc TopicDocument2 pagesRslinx Classic Setup: Reporting From Rslinx Classic Defining A Dde/Opc TopicBhamidipati PremNo ratings yet

- Solving DC Analysis and Plotting Load Line With Q PointDocument29 pagesSolving DC Analysis and Plotting Load Line With Q PointMOHD REZA FADHLAN B DAUD100% (3)

- 2.1 Timing Paths (STA) Basic (Part 1)Document14 pages2.1 Timing Paths (STA) Basic (Part 1)Sudheer GangisettyNo ratings yet

- Apt AreDocument112 pagesApt ArebgadikotaNo ratings yet

- PCBDesign Studio TutorialDocument30 pagesPCBDesign Studio Tutorialthanh cong TruongNo ratings yet

- 2008, Mac OS X, Unix and Linux My Digital LifeDocument10 pages2008, Mac OS X, Unix and Linux My Digital LifeArto MoroNo ratings yet

- Tutorial 2Document3 pagesTutorial 2Dung NguyễnNo ratings yet

- M. Tarik Soysal: EducationDocument1 pageM. Tarik Soysal: EducationtariksoysalNo ratings yet

- CSGE 101 Programming Using Python 32345104Document7 pagesCSGE 101 Programming Using Python 32345104Aditya VashisthNo ratings yet

- 8086 Software ProgramsDocument29 pages8086 Software ProgramsBrijesh Balaram0% (1)

- Statistical Process Control Module: Mes Built On IgnitionDocument2 pagesStatistical Process Control Module: Mes Built On IgnitionHéctor TostadoNo ratings yet

- Direct Memory Access: Direct Memory Access (DMA) Is A Process in Which An External Device TakesDocument21 pagesDirect Memory Access: Direct Memory Access (DMA) Is A Process in Which An External Device TakesLeonardo Cavero FarfánNo ratings yet

- Syllabus For ADCA & PGDCADocument8 pagesSyllabus For ADCA & PGDCAPratyush AryaNo ratings yet

- V&V - TestingDocument43 pagesV&V - Testingmahamd saiedNo ratings yet

- Kazimierczuk1993 Voltage-Mode-Controlled PWM Buck20DC-DCDocument8 pagesKazimierczuk1993 Voltage-Mode-Controlled PWM Buck20DC-DCHamidNo ratings yet

- FanglingNCCuttingMachineControlSystem F7000 v2 0oycDocument137 pagesFanglingNCCuttingMachineControlSystem F7000 v2 0oycDejan MilanovicNo ratings yet

- Adv 7623Document16 pagesAdv 7623ajoaomvNo ratings yet

- EE213 Topic00 IntroDocument84 pagesEE213 Topic00 Introapplebao1022No ratings yet