Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsTechnical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/paste

Technical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/paste

Uploaded by

Siddharth DasThis document outlines the technical specifications for three types of wear resistant coatings:

1) A metallic putty or paste that cures in under 8 hours, is heat resistant to 175°C, and has high adhesion and compressive strength.

2) A metallic paint that also cures quickly, is heat and chemically resistant, and has high adhesion and compressive strength.

3) An immersion grade paint suitable for submerged conditions that offers protection to 125°C and exceeds coverage and strength standards.

Bidders must meet the specifications and provide authorization and quality certificates from the manufacturer.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Q1 Descriptive Statistics PDFDocument6 pagesQ1 Descriptive Statistics PDFthis hihiNo ratings yet

- Single Arm Pantograph Model: WBL22.03: Description Maintenance and Operating ManualDocument71 pagesSingle Arm Pantograph Model: WBL22.03: Description Maintenance and Operating ManualKausik Das67% (3)

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Psychology Vs Christianity Bob JenningsDocument12 pagesPsychology Vs Christianity Bob JenningsRomarioNo ratings yet

- Strongcoat HB400Document53 pagesStrongcoat HB400irfan shafiqueNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- sikafloor_-262_asnDocument5 pagessikafloor_-262_asnferoz khanNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Durebild Ste Glass Flake pc239Document3 pagesDurebild Ste Glass Flake pc239livefreakNo ratings yet

- Belzona ProductsDocument174 pagesBelzona Productsrao abdul bariNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Belzona 1121 InstrustionsDocument2 pagesBelzona 1121 Instrustionssh4kesNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- PDS & MSDS PDFDocument37 pagesPDS & MSDS PDFsmartayaz1987No ratings yet

- TDS L2057216Document3 pagesTDS L2057216erolsarNo ratings yet

- DUPAC-0521®: DescriptionDocument6 pagesDUPAC-0521®: DescriptionPablo TorresNo ratings yet

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedNo ratings yet

- LOCTITE PC 7227 en - GLDocument4 pagesLOCTITE PC 7227 en - GLLuhur BudiNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- 7-1888 TDS Red High Temp Liquid Epoxy NOVALACDocument2 pages7-1888 TDS Red High Temp Liquid Epoxy NOVALACPedro Santo Orsini RevengaNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- TDS - 7-0008 - Internal Pipe Coating - EngDocument3 pagesTDS - 7-0008 - Internal Pipe Coating - Englong chanNo ratings yet

- 993 STRL Glazing Sealant-Product InfoDocument4 pages993 STRL Glazing Sealant-Product InfocurlyjockeyNo ratings yet

- Sikadur 31 CF SlowDocument4 pagesSikadur 31 CF SlowkhudhayerNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Sealtite Sealant Butyl Tape: DescriptionDocument2 pagesSealtite Sealant Butyl Tape: DescriptionSantoshNo ratings yet

- Epigen 0907: High Strength Epoxy AdhesiveDocument2 pagesEpigen 0907: High Strength Epoxy AdhesiveAfzal ImamNo ratings yet

- Adeco Graphite Grease: Technical Data SheetDocument1 pageAdeco Graphite Grease: Technical Data SheetVelibor KaranovicNo ratings yet

- Sikagard Wallcoat Id Pds enDocument4 pagesSikagard Wallcoat Id Pds enodang rizkiNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Ripstar 121: SpecificationDocument3 pagesRipstar 121: SpecificationAnkita Baban GavadeNo ratings yet

- V-Bond Ready Plaster TDSDocument4 pagesV-Bond Ready Plaster TDSBarlinNo ratings yet

- My T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsDocument2 pagesMy T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsShabarish KeshavNo ratings yet

- Lgep 2: SKF High Load, Extreme Pressure Bearing GreaseDocument2 pagesLgep 2: SKF High Load, Extreme Pressure Bearing GreaseStanislavNo ratings yet

- Sika Anchorfix - 1Document5 pagesSika Anchorfix - 1YASHICA VAITTIANATHANNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- TDS PRIMER 193V - EnglishDocument2 pagesTDS PRIMER 193V - Englishhoang BuiNo ratings yet

- Dokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry ConcreteDocument16 pagesDokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry Concretem_shahbaghiNo ratings yet

- Sika Anchorfix®-1: Product Data SheetDocument5 pagesSika Anchorfix®-1: Product Data SheetdherymuammarnazriNo ratings yet

- (Sika) Sikadur 41 CF RapidDocument6 pages(Sika) Sikadur 41 CF Rapid_at_to_No ratings yet

- Strongcoat 400 - TDSDocument4 pagesStrongcoat 400 - TDSOsama Abu ShalthamNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Sikalastic8200 Product Data Sheet-EnDocument3 pagesSikalastic8200 Product Data Sheet-EnesselamiNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Winpower International Limited: ApplicationDocument2 pagesWinpower International Limited: ApplicationAHMED YOUSEFNo ratings yet

- Nitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsesDocument4 pagesNitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsestalatzahoorNo ratings yet

- EP 520 EPC 520 Rev. 3Document2 pagesEP 520 EPC 520 Rev. 3yoniNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- TD CAER21 Resin PDFDocument2 pagesTD CAER21 Resin PDFekaisthebestNo ratings yet

- HM500 Epoxy Anchor Adhesive Technical Data SheetDocument6 pagesHM500 Epoxy Anchor Adhesive Technical Data SheetA Bashir AsalaiNo ratings yet

- 7-1881 TDS Blue LP Liquid EpoxyDocument2 pages7-1881 TDS Blue LP Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- Ancamine 2739 TdsDocument8 pagesAncamine 2739 Tdsnc5r8fkp6zNo ratings yet

- RS-2000 BKM SpecDocument6 pagesRS-2000 BKM SpecHiền NguyễnNo ratings yet

- 745Document2 pages745idrees.theheroNo ratings yet

- COLORBOND® Steel For Insulated Panel (XIP) Datasheet May 2023Document4 pagesCOLORBOND® Steel For Insulated Panel (XIP) Datasheet May 2023Ramiro RivasNo ratings yet

- Surface Coating Quick Guide Glass Mould 0463hogDocument1 pageSurface Coating Quick Guide Glass Mould 0463hogSiddharth DasNo ratings yet

- Surface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogDocument16 pagesSurface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogSiddharth DasNo ratings yet

- Code of Conduct (English)Document25 pagesCode of Conduct (English)Siddharth DasNo ratings yet

- Eutec Tinweld 1Document1 pageEutec Tinweld 1Siddharth DasNo ratings yet

- Wall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Document4 pagesWall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Siddharth DasNo ratings yet

- Health Policy SiddharthDocument9 pagesHealth Policy SiddharthSiddharth DasNo ratings yet

- List of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalDocument3 pagesList of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalSiddharth DasNo ratings yet

- Application Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Document4 pagesApplication Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Siddharth DasNo ratings yet

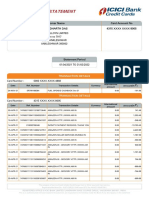

- Customer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Document8 pagesCustomer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Siddharth DasNo ratings yet

- Obstetrics & GynecologyDocument10 pagesObstetrics & GynecologyRaul DoctoNo ratings yet

- Fundamental Chemical LawsDocument19 pagesFundamental Chemical LawsMoh. AliNo ratings yet

- Tlm4all@NMMS 2019 Model Grand Test-1 (EM) by APMF, TenaliDocument12 pagesTlm4all@NMMS 2019 Model Grand Test-1 (EM) by APMF, TenaliThirupathaiah100% (2)

- Return and Refun PolicyDocument3 pagesReturn and Refun PolicyIhtisham Ul HaqNo ratings yet

- MS P2 CompilationDocument451 pagesMS P2 CompilationJe KirsteneNo ratings yet

- Majdanek, The Concetration Camp of LublinDocument72 pagesMajdanek, The Concetration Camp of Lublinheyyou100% (3)

- 52369.Đề ôn thi lớp 10Document5 pages52369.Đề ôn thi lớp 10Phương LinhNo ratings yet

- Intelect SWD100 Diathermy IFUDocument98 pagesIntelect SWD100 Diathermy IFUJose HernandezNo ratings yet

- Ha Vs NorthwesternDocument13 pagesHa Vs NorthwesternChad AlvarezNo ratings yet

- Results: Barkatullah University On-Line ResultsDocument3 pagesResults: Barkatullah University On-Line ResultsshazilNo ratings yet

- Addison DiseaseDocument23 pagesAddison DiseaseKompari EvansNo ratings yet

- Test 1 Paper 4: Listening: Part 1 (Questions 1-8)Document24 pagesTest 1 Paper 4: Listening: Part 1 (Questions 1-8)Trần Anh KiệtNo ratings yet

- 1 PBDocument10 pages1 PBRisna Amanda KirantiNo ratings yet

- AirbaseDocument48 pagesAirbaseimepsystems100% (1)

- Investigating Transformer FailuresDocument54 pagesInvestigating Transformer Failureslbk50100% (2)

- Power System Nagrath Kothari SolutionsDocument88 pagesPower System Nagrath Kothari SolutionsChandra Sekhar Chebiyyam81% (16)

- Uh Procedure Text XiDocument2 pagesUh Procedure Text XiMutia Chimoet100% (13)

- 30 Day SELTrackerDocument3 pages30 Day SELTrackerLiz Harrison PooleNo ratings yet

- Chap2 HRM581 Oct Feb 2023Document22 pagesChap2 HRM581 Oct Feb 2023liana bahaNo ratings yet

- Toronto Notes Nephrology 2015 34Document1 pageToronto Notes Nephrology 2015 34JUSASBNo ratings yet

- metabook_612Download ebook Return To Play After Lower Limb Muscle Injury In Football The Italian Consensus Conference Guidelines Bisciotti Gian Nicola Corsini Alessandro Volpi Piero 2 online pdf all chapter docx epubDocument55 pagesmetabook_612Download ebook Return To Play After Lower Limb Muscle Injury In Football The Italian Consensus Conference Guidelines Bisciotti Gian Nicola Corsini Alessandro Volpi Piero 2 online pdf all chapter docx epubannette.bodine942100% (6)

- Lab 5 Production of Ethyl ChlorideDocument19 pagesLab 5 Production of Ethyl ChloridelynNo ratings yet

- 14.3 and 14.4 WorksheetsDocument16 pages14.3 and 14.4 Worksheetssam playz08No ratings yet

- Leadingthewaytosafety Withvoicealarmand PublicaddressDocument24 pagesLeadingthewaytosafety Withvoicealarmand PublicaddressRonaldo RomeroNo ratings yet

- Ethnocultural InfluencesDocument17 pagesEthnocultural Influencesmuwaag musaNo ratings yet

- Leaflet Vandex Crystalline WaterproofingDocument12 pagesLeaflet Vandex Crystalline WaterproofingEngr. Mohammad Moinul HossainNo ratings yet

- Changing Environment of HRMDocument14 pagesChanging Environment of HRMSrishti GaurNo ratings yet

Technical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/paste

Technical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/paste

Uploaded by

Siddharth Das0 ratings0% found this document useful (0 votes)

9 views2 pagesThis document outlines the technical specifications for three types of wear resistant coatings:

1) A metallic putty or paste that cures in under 8 hours, is heat resistant to 175°C, and has high adhesion and compressive strength.

2) A metallic paint that also cures quickly, is heat and chemically resistant, and has high adhesion and compressive strength.

3) An immersion grade paint suitable for submerged conditions that offers protection to 125°C and exceeds coverage and strength standards.

Bidders must meet the specifications and provide authorization and quality certificates from the manufacturer.

Original Description:

Belzona Product

Original Title

Belzona Specifications

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the technical specifications for three types of wear resistant coatings:

1) A metallic putty or paste that cures in under 8 hours, is heat resistant to 175°C, and has high adhesion and compressive strength.

2) A metallic paint that also cures quickly, is heat and chemically resistant, and has high adhesion and compressive strength.

3) An immersion grade paint suitable for submerged conditions that offers protection to 125°C and exceeds coverage and strength standards.

Bidders must meet the specifications and provide authorization and quality certificates from the manufacturer.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views2 pagesTechnical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/paste

Technical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/paste

Uploaded by

Siddharth DasThis document outlines the technical specifications for three types of wear resistant coatings:

1) A metallic putty or paste that cures in under 8 hours, is heat resistant to 175°C, and has high adhesion and compressive strength.

2) A metallic paint that also cures quickly, is heat and chemically resistant, and has high adhesion and compressive strength.

3) An immersion grade paint suitable for submerged conditions that offers protection to 125°C and exceeds coverage and strength standards.

Bidders must meet the specifications and provide authorization and quality certificates from the manufacturer.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

TECHNICAL SPECIFICATIONS

1. Technical Specifications for Wear resistive metallic putty/paste

SN Description NEA Requirement To be Reference

filled by

bidder

1 Manufacturer

2 Product name

3 Mixed Form Paste/Putty

4 Mixing ratio by weight Any

5 Shelf Life (Base & Solidifier) @ 0 to ≥ 2 Years

30°C

6 Working Life (Mixture) at 25°C 15 to 60 minutes

7 Cure Time (No loading ) at 25°C ≤ 8 hours

Belzona 1311 or

8 Heat resistant under dry condition ≥ 175 °C

equivalent

9 Adhesion(Tensile Shear) to Stainless ≥ 2,600 psi

steel

10 Compressive strength (Maximum)(ASTM ≥ 9,800 psi

D695) at 20°C

11 Hardness (ASTM D790) ≥ 75 Shore D

12 Manufacturer’s authorization letter To be submitted

13 Quality ISO certificates of manufacturer To be submitted

2. Technical Specifications for wear resistive metallic paint

SN Description NEA Requirement To be filled Reference

by bidder

1 Manufacturer

2 Product name

3 Mixed Form Liquid

4 Mixing ratio by weight Any

5 Shelf Life (Base & Solidifier) @ ≥ 2 Years

0 to 30 °C

6 Working Life (Mixture) at 25 °C 25 to 60 minutes

7 Cure Time (No loading ) at 25 ≤ 16 Hrs

°C

8 Heat resistant under dry condition ≥ 175 °C

Belzona 1321

or equivalent

9 Adhesion(Tensile shear) to ≥ 2,800 psi

Stainless steel

10 Compressive strength (ASTM ≥ 10,000 psi

D695)

11 Hardness ≥ 75 Shore D

12 Coverage rate ≥ 1.2 m2/kg with film

thickness of 250 microns

13 Manufacturer’s authorization To be submitted

letter

14 Quality ISO certificates of To be submitted

manufacturer

3.Technical Specifications for Immersion Grade Paint

SN Description NEA Requirement To be filled Reference

by bidder

1 Manufacturer

2 Product name

3 Mixed Product Form Liquid

4 Mixing ratio by weight Any

5 Shelf Life (Base & Solidifier) @ 0 ≥ 2 Years

to 30 °C

6 Working Life of Mixture @25 °C 25 to 120 min

7 Cure Time at no loading @25 °C ≤ 16 Hrs

8 Heat resistant in dry condition ≥ 125 °C

Belzona 5811

9 Adhesion(Tensile shear) to ≥ 1,900 psi

or equivalent

Stainless steel

10 Compressive strength (ASTM ≥ 6,700 psi

D695)

11 Hardness ≥ 75 Shore D

12 Coverage rate ≥ 2.5 m2/l with film

thickness of 250 microns

13 Manufacturer’s authorization letter To be submitted

14 Quality ISO certificates of To be submitted

manufacturer

You might also like

- Q1 Descriptive Statistics PDFDocument6 pagesQ1 Descriptive Statistics PDFthis hihiNo ratings yet

- Single Arm Pantograph Model: WBL22.03: Description Maintenance and Operating ManualDocument71 pagesSingle Arm Pantograph Model: WBL22.03: Description Maintenance and Operating ManualKausik Das67% (3)

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Psychology Vs Christianity Bob JenningsDocument12 pagesPsychology Vs Christianity Bob JenningsRomarioNo ratings yet

- Strongcoat HB400Document53 pagesStrongcoat HB400irfan shafiqueNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- sikafloor_-262_asnDocument5 pagessikafloor_-262_asnferoz khanNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Durebild Ste Glass Flake pc239Document3 pagesDurebild Ste Glass Flake pc239livefreakNo ratings yet

- Belzona ProductsDocument174 pagesBelzona Productsrao abdul bariNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Belzona 1121 InstrustionsDocument2 pagesBelzona 1121 Instrustionssh4kesNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- PDS & MSDS PDFDocument37 pagesPDS & MSDS PDFsmartayaz1987No ratings yet

- TDS L2057216Document3 pagesTDS L2057216erolsarNo ratings yet

- DUPAC-0521®: DescriptionDocument6 pagesDUPAC-0521®: DescriptionPablo TorresNo ratings yet

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedNo ratings yet

- LOCTITE PC 7227 en - GLDocument4 pagesLOCTITE PC 7227 en - GLLuhur BudiNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- 7-1888 TDS Red High Temp Liquid Epoxy NOVALACDocument2 pages7-1888 TDS Red High Temp Liquid Epoxy NOVALACPedro Santo Orsini RevengaNo ratings yet

- Ceramic Repair Putty: Technical Data SheetDocument2 pagesCeramic Repair Putty: Technical Data SheetNiku SamarthNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- TDS - 7-0008 - Internal Pipe Coating - EngDocument3 pagesTDS - 7-0008 - Internal Pipe Coating - Englong chanNo ratings yet

- 993 STRL Glazing Sealant-Product InfoDocument4 pages993 STRL Glazing Sealant-Product InfocurlyjockeyNo ratings yet

- Sikadur 31 CF SlowDocument4 pagesSikadur 31 CF SlowkhudhayerNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Sealtite Sealant Butyl Tape: DescriptionDocument2 pagesSealtite Sealant Butyl Tape: DescriptionSantoshNo ratings yet

- Epigen 0907: High Strength Epoxy AdhesiveDocument2 pagesEpigen 0907: High Strength Epoxy AdhesiveAfzal ImamNo ratings yet

- Adeco Graphite Grease: Technical Data SheetDocument1 pageAdeco Graphite Grease: Technical Data SheetVelibor KaranovicNo ratings yet

- Sikagard Wallcoat Id Pds enDocument4 pagesSikagard Wallcoat Id Pds enodang rizkiNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Ripstar 121: SpecificationDocument3 pagesRipstar 121: SpecificationAnkita Baban GavadeNo ratings yet

- V-Bond Ready Plaster TDSDocument4 pagesV-Bond Ready Plaster TDSBarlinNo ratings yet

- My T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsDocument2 pagesMy T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsShabarish KeshavNo ratings yet

- Lgep 2: SKF High Load, Extreme Pressure Bearing GreaseDocument2 pagesLgep 2: SKF High Load, Extreme Pressure Bearing GreaseStanislavNo ratings yet

- Sika Anchorfix - 1Document5 pagesSika Anchorfix - 1YASHICA VAITTIANATHANNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- TDS PRIMER 193V - EnglishDocument2 pagesTDS PRIMER 193V - Englishhoang BuiNo ratings yet

- Dokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry ConcreteDocument16 pagesDokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry Concretem_shahbaghiNo ratings yet

- Sika Anchorfix®-1: Product Data SheetDocument5 pagesSika Anchorfix®-1: Product Data SheetdherymuammarnazriNo ratings yet

- (Sika) Sikadur 41 CF RapidDocument6 pages(Sika) Sikadur 41 CF Rapid_at_to_No ratings yet

- Strongcoat 400 - TDSDocument4 pagesStrongcoat 400 - TDSOsama Abu ShalthamNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Sikalastic8200 Product Data Sheet-EnDocument3 pagesSikalastic8200 Product Data Sheet-EnesselamiNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Winpower International Limited: ApplicationDocument2 pagesWinpower International Limited: ApplicationAHMED YOUSEFNo ratings yet

- Nitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsesDocument4 pagesNitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsestalatzahoorNo ratings yet

- EP 520 EPC 520 Rev. 3Document2 pagesEP 520 EPC 520 Rev. 3yoniNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- TD CAER21 Resin PDFDocument2 pagesTD CAER21 Resin PDFekaisthebestNo ratings yet

- HM500 Epoxy Anchor Adhesive Technical Data SheetDocument6 pagesHM500 Epoxy Anchor Adhesive Technical Data SheetA Bashir AsalaiNo ratings yet

- 7-1881 TDS Blue LP Liquid EpoxyDocument2 pages7-1881 TDS Blue LP Liquid EpoxyPedro Santo Orsini RevengaNo ratings yet

- Ancamine 2739 TdsDocument8 pagesAncamine 2739 Tdsnc5r8fkp6zNo ratings yet

- RS-2000 BKM SpecDocument6 pagesRS-2000 BKM SpecHiền NguyễnNo ratings yet

- 745Document2 pages745idrees.theheroNo ratings yet

- COLORBOND® Steel For Insulated Panel (XIP) Datasheet May 2023Document4 pagesCOLORBOND® Steel For Insulated Panel (XIP) Datasheet May 2023Ramiro RivasNo ratings yet

- Surface Coating Quick Guide Glass Mould 0463hogDocument1 pageSurface Coating Quick Guide Glass Mould 0463hogSiddharth DasNo ratings yet

- Surface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogDocument16 pagesSurface Coating Thermal Surfacing Glass Mould Industry Solutions 1949hogSiddharth DasNo ratings yet

- Code of Conduct (English)Document25 pagesCode of Conduct (English)Siddharth DasNo ratings yet

- Eutec Tinweld 1Document1 pageEutec Tinweld 1Siddharth DasNo ratings yet

- Wall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Document4 pagesWall Colmonoy - Colmonoy 6 6PTA 6L TDS - July2021Siddharth DasNo ratings yet

- Health Policy SiddharthDocument9 pagesHealth Policy SiddharthSiddharth DasNo ratings yet

- List of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalDocument3 pagesList of Participating Airport Lounges :: S.No. City Lounge Name Airport TerminalSiddharth DasNo ratings yet

- Application Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Document4 pagesApplication Form For Re-Kyc Updation Through Video Kyc (V-Kyc) (For Resident Individual Savings Account & Individual Current Account)Siddharth DasNo ratings yet

- Customer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Document8 pagesCustomer Name Card Account No MR Siddharth Das 4315 XXXX XXXX 8005Siddharth DasNo ratings yet

- Obstetrics & GynecologyDocument10 pagesObstetrics & GynecologyRaul DoctoNo ratings yet

- Fundamental Chemical LawsDocument19 pagesFundamental Chemical LawsMoh. AliNo ratings yet

- Tlm4all@NMMS 2019 Model Grand Test-1 (EM) by APMF, TenaliDocument12 pagesTlm4all@NMMS 2019 Model Grand Test-1 (EM) by APMF, TenaliThirupathaiah100% (2)

- Return and Refun PolicyDocument3 pagesReturn and Refun PolicyIhtisham Ul HaqNo ratings yet

- MS P2 CompilationDocument451 pagesMS P2 CompilationJe KirsteneNo ratings yet

- Majdanek, The Concetration Camp of LublinDocument72 pagesMajdanek, The Concetration Camp of Lublinheyyou100% (3)

- 52369.Đề ôn thi lớp 10Document5 pages52369.Đề ôn thi lớp 10Phương LinhNo ratings yet

- Intelect SWD100 Diathermy IFUDocument98 pagesIntelect SWD100 Diathermy IFUJose HernandezNo ratings yet

- Ha Vs NorthwesternDocument13 pagesHa Vs NorthwesternChad AlvarezNo ratings yet

- Results: Barkatullah University On-Line ResultsDocument3 pagesResults: Barkatullah University On-Line ResultsshazilNo ratings yet

- Addison DiseaseDocument23 pagesAddison DiseaseKompari EvansNo ratings yet

- Test 1 Paper 4: Listening: Part 1 (Questions 1-8)Document24 pagesTest 1 Paper 4: Listening: Part 1 (Questions 1-8)Trần Anh KiệtNo ratings yet

- 1 PBDocument10 pages1 PBRisna Amanda KirantiNo ratings yet

- AirbaseDocument48 pagesAirbaseimepsystems100% (1)

- Investigating Transformer FailuresDocument54 pagesInvestigating Transformer Failureslbk50100% (2)

- Power System Nagrath Kothari SolutionsDocument88 pagesPower System Nagrath Kothari SolutionsChandra Sekhar Chebiyyam81% (16)

- Uh Procedure Text XiDocument2 pagesUh Procedure Text XiMutia Chimoet100% (13)

- 30 Day SELTrackerDocument3 pages30 Day SELTrackerLiz Harrison PooleNo ratings yet

- Chap2 HRM581 Oct Feb 2023Document22 pagesChap2 HRM581 Oct Feb 2023liana bahaNo ratings yet

- Toronto Notes Nephrology 2015 34Document1 pageToronto Notes Nephrology 2015 34JUSASBNo ratings yet

- metabook_612Download ebook Return To Play After Lower Limb Muscle Injury In Football The Italian Consensus Conference Guidelines Bisciotti Gian Nicola Corsini Alessandro Volpi Piero 2 online pdf all chapter docx epubDocument55 pagesmetabook_612Download ebook Return To Play After Lower Limb Muscle Injury In Football The Italian Consensus Conference Guidelines Bisciotti Gian Nicola Corsini Alessandro Volpi Piero 2 online pdf all chapter docx epubannette.bodine942100% (6)

- Lab 5 Production of Ethyl ChlorideDocument19 pagesLab 5 Production of Ethyl ChloridelynNo ratings yet

- 14.3 and 14.4 WorksheetsDocument16 pages14.3 and 14.4 Worksheetssam playz08No ratings yet

- Leadingthewaytosafety Withvoicealarmand PublicaddressDocument24 pagesLeadingthewaytosafety Withvoicealarmand PublicaddressRonaldo RomeroNo ratings yet

- Ethnocultural InfluencesDocument17 pagesEthnocultural Influencesmuwaag musaNo ratings yet

- Leaflet Vandex Crystalline WaterproofingDocument12 pagesLeaflet Vandex Crystalline WaterproofingEngr. Mohammad Moinul HossainNo ratings yet

- Changing Environment of HRMDocument14 pagesChanging Environment of HRMSrishti GaurNo ratings yet