Professional Documents

Culture Documents

Technical Bulletin: FT1380-XL Fitting Locators

Technical Bulletin: FT1380-XL Fitting Locators

Uploaded by

Autieri AutieriCopyright:

Available Formats

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Continental TorquesDocument13 pagesContinental Torquesfredtanner100% (2)

- Ford Y-Block Engines: How to Rebuild & ModifyFrom EverandFord Y-Block Engines: How to Rebuild & ModifyRating: 4.5 out of 5 stars4.5/5 (3)

- Db2 DATA ADMINISTRATION LobDocument71 pagesDb2 DATA ADMINISTRATION LobAmlan Chowdhury100% (1)

- Vicarb Plate Heat ExchangersDocument17 pagesVicarb Plate Heat ExchangersFrederik BohyNo ratings yet

- Coin Sorter NewDocument14 pagesCoin Sorter Newvishnu100% (1)

- Clinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyDocument24 pagesClinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyErica AlabanNo ratings yet

- FT1390-2-9-500 Crimp MachineDocument8 pagesFT1390-2-9-500 Crimp MachineJulián Ricardo RodriguezNo ratings yet

- Serie FF PDFDocument3 pagesSerie FF PDFYanderier RiveraNo ratings yet

- Manual ConectoresDocument19 pagesManual ConectoresLuis EduardoNo ratings yet

- Installation Instructions For EWD13 and EWF13 Sprocket Box UpdateDocument14 pagesInstallation Instructions For EWD13 and EWF13 Sprocket Box UpdatePetrNo ratings yet

- DTANKDocument26 pagesDTANKVivekRaptorNo ratings yet

- Ford Installation InstructionDocument14 pagesFord Installation Instructiontxr qcNo ratings yet

- M O R S E 5 X 6 Jaw Crusher ManualDocument7 pagesM O R S E 5 X 6 Jaw Crusher ManualGilberto Garnica MurilloNo ratings yet

- Gared Sports Soccer Goal Football Fieldgoal Post Combo Installation InstructionsDocument10 pagesGared Sports Soccer Goal Football Fieldgoal Post Combo Installation InstructionsRobbins athleticsNo ratings yet

- WAI Transpo FordDocument16 pagesWAI Transpo FordELIAS CHAVESNo ratings yet

- 212 86 92 - RepairedDocument11 pages212 86 92 - Repairedsebastian cruzNo ratings yet

- 2NKX6 1Document24 pages2NKX6 1Ana Gabriela Gómez PeraltaNo ratings yet

- Dayton Integral and Fractional HP Motors: Motor Installation and Maintenance InformationDocument28 pagesDayton Integral and Fractional HP Motors: Motor Installation and Maintenance Informationjaime appletonNo ratings yet

- 4 TNV 84 TZDocument6 pages4 TNV 84 TZCarlos Rivera MontesNo ratings yet

- C18 Generator Set STM00001-UP (SEBP4100 - 43) Procedure For Installation of VR6 Voltage RegulatorDocument9 pagesC18 Generator Set STM00001-UP (SEBP4100 - 43) Procedure For Installation of VR6 Voltage RegulatorCEVegaONo ratings yet

- 4096 406Document5 pages4096 406Pranalanka WarunawansaNo ratings yet

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- FQ5-2011-028 FS-2575 FS-5075 Can Not Use The Handset FS-2575CDocument5 pagesFQ5-2011-028 FS-2575 FS-5075 Can Not Use The Handset FS-2575CAndrew NazarovNo ratings yet

- Parts and Installation Instructions Spring Trip Snow Plow Models TM 5.0, TM 6.0 and TM 6.5Document2 pagesParts and Installation Instructions Spring Trip Snow Plow Models TM 5.0, TM 6.0 and TM 6.5girtzengineeringNo ratings yet

- 120A2A Distribution PDFDocument49 pages120A2A Distribution PDFnachoNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- EG-00404 P-20 Cable RoutingDocument15 pagesEG-00404 P-20 Cable Routinggguadian21No ratings yet

- SL162B Helicoil PDFDocument2 pagesSL162B Helicoil PDFjeffrey_fay67% (3)

- AA00219 PC300-6 (Refuerzos PC300-6)Document11 pagesAA00219 PC300-6 (Refuerzos PC300-6)joaquin suarezNo ratings yet

- Taladro Magnetico Rotabest Mini 36-50 Manual OperacionDocument12 pagesTaladro Magnetico Rotabest Mini 36-50 Manual OperacionAtahualpa Bulganin Infante YañezNo ratings yet

- FRH FRG ManualDocument23 pagesFRH FRG ManualdlanorxNo ratings yet

- Installation Manual: Universal Top-of-Pole Mount UNI-TP/08LLDocument11 pagesInstallation Manual: Universal Top-of-Pole Mount UNI-TP/08LLlexdanteNo ratings yet

- FF Primary InstructionsDocument12 pagesFF Primary InstructionsKevin VillagranNo ratings yet

- Ontrac Cable Tray: Installation InstructionsDocument10 pagesOntrac Cable Tray: Installation Instructionsgeriko182No ratings yet

- Power Tools: Operating and Maintenance InstructionsDocument16 pagesPower Tools: Operating and Maintenance InstructionsBill WidmerNo ratings yet

- Inertia Dynamic TypeFL SpecsheetDocument3 pagesInertia Dynamic TypeFL SpecsheetElectromateNo ratings yet

- 180TCD Metric ManualDocument6 pages180TCD Metric ManualJose GonzalezNo ratings yet

- LG-6001 Lead Gage: Operation ManualDocument24 pagesLG-6001 Lead Gage: Operation ManualSukumarNo ratings yet

- 9901X0101 - 3 Operating InstructionsDocument7 pages9901X0101 - 3 Operating InstructionsElizabeth MejiaNo ratings yet

- Mitsubishi FV DrivelineDocument10 pagesMitsubishi FV Drivelinejs1290No ratings yet

- Pistons and Connecting Rods - AssembleDocument6 pagesPistons and Connecting Rods - AssemblealonsoNo ratings yet

- Interchangeable Spindle Users Guide 4C v0311 WebDocument21 pagesInterchangeable Spindle Users Guide 4C v0311 WebMynor SGNo ratings yet

- Rehs1037 04Document10 pagesRehs1037 04Pauk HseinNo ratings yet

- AA00220 PC400-6 (Refuerzos PC400-6)Document11 pagesAA00220 PC400-6 (Refuerzos PC400-6)joaquin suarezNo ratings yet

- 51550Document24 pages51550jombibiNo ratings yet

- Pennbarry Fumex IOM v6Document22 pagesPennbarry Fumex IOM v6RanielNo ratings yet

- Grease Fitting PDFDocument20 pagesGrease Fitting PDFleonardsiregarNo ratings yet

- 407ASB407ASB19119Document8 pages407ASB407ASB19119carolina.rossNo ratings yet

- Orifice PDFDocument11 pagesOrifice PDFb_wooNo ratings yet

- Alfra Rotabest Midi 5050 Operation ManualDocument13 pagesAlfra Rotabest Midi 5050 Operation Manualsudofim2006No ratings yet

- Rear Sway Bar Installation InstructionsDocument4 pagesRear Sway Bar Installation InstructionsRaduNo ratings yet

- Astro ContactDocument43 pagesAstro ContactEmiliano BoschettiNo ratings yet

- Sch80tech FL80 FL4PDocument18 pagesSch80tech FL80 FL4PDILSHAD AHEMADNo ratings yet

- HKS 2JZ CoilDocument19 pagesHKS 2JZ CoilernestoNo ratings yet

- 180TCD Brake ManualDocument5 pages180TCD Brake ManualJose GonzalezNo ratings yet

- Manual Pexto 137 Foot ShearDocument10 pagesManual Pexto 137 Foot Shearrubens072No ratings yet

- FG Wilson Service Bulletin: SB 0087 - PCADocument4 pagesFG Wilson Service Bulletin: SB 0087 - PCANacer Zehani100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 08-1090MF-1010 Full Catalog 02-2013Document416 pages08-1090MF-1010 Full Catalog 02-2013Autieri AutieriNo ratings yet

- En Stauff One B Stauff Test 2014Document48 pagesEn Stauff One B Stauff Test 2014Autieri AutieriNo ratings yet

- Sensor OCS-Software enDocument16 pagesSensor OCS-Software enAutieri AutieriNo ratings yet

- Terminais Reusáveis - PCT - 3234776Document68 pagesTerminais Reusáveis - PCT - 3234776Autieri AutieriNo ratings yet

- 100r4 - WinnerDocument2 pages100r4 - WinnerAutieri AutieriNo ratings yet

- EC600 X-FLEX Bend Radius 420 Bar Spiral Hydraulic HoseDocument2 pagesEC600 X-FLEX Bend Radius 420 Bar Spiral Hydraulic HoseAutieri AutieriNo ratings yet

- Couplings Oil and GasDocument4 pagesCouplings Oil and GasAutieri AutieriNo ratings yet

- 2.5 Inch 6-Spiral Hose: Eaton EC466-40Document8 pages2.5 Inch 6-Spiral Hose: Eaton EC466-40Autieri AutieriNo ratings yet

- TLSL 3428Document232 pagesTLSL 3428viniciusemanuelNo ratings yet

- Fluke Esa612 Specifications Spec Sheet Mt06Document8 pagesFluke Esa612 Specifications Spec Sheet Mt06ashishtrueNo ratings yet

- ISO 9001 2008 Awareness Training QuestionnaireDocument2 pagesISO 9001 2008 Awareness Training Questionnaireezal2100% (3)

- Apex MCQ Question1Document2 pagesApex MCQ Question1rajan251221No ratings yet

- Dynamic Programming Questions: 5. Longest Palindromic SubstringDocument38 pagesDynamic Programming Questions: 5. Longest Palindromic SubstringEren AvcıNo ratings yet

- MEGA Solution Footprint V5Document17 pagesMEGA Solution Footprint V5Wissam ShehabNo ratings yet

- GreyAtom Data Science Machine Learning CourseDocument21 pagesGreyAtom Data Science Machine Learning CoursevickychhedaNo ratings yet

- Oracle Erp Cloud Implementation Leading Practices WPDocument35 pagesOracle Erp Cloud Implementation Leading Practices WPMiguel Felicio100% (1)

- Section 9.6 Counting Principles: NameDocument2 pagesSection 9.6 Counting Principles: Namesarasmile2009No ratings yet

- 11-40 - SINUMERIK Edge - Concept - AppsDocument15 pages11-40 - SINUMERIK Edge - Concept - AppsAshish PatwardhanNo ratings yet

- Postdoctoral FellowDocument3 pagesPostdoctoral Fellowabidraza8No ratings yet

- Block ModelingDocument18 pagesBlock ModelingMphNo ratings yet

- Analytics - Practical FileDocument8 pagesAnalytics - Practical FileRockyNo ratings yet

- Destructive and Non-Destructive - QuizDocument15 pagesDestructive and Non-Destructive - QuizDiangelia ArtagameNo ratings yet

- PR2 Q2 Module 3Document9 pagesPR2 Q2 Module 3Ashes VillNo ratings yet

- AAU5612 Hardware Description (01) (PDF) - ENDocument21 pagesAAU5612 Hardware Description (01) (PDF) - ENvitor santosNo ratings yet

- Syllabus: Matrix Algebra DeterminantsDocument4 pagesSyllabus: Matrix Algebra DeterminantsshaannivasNo ratings yet

- Infernal Gpu SlidesDocument22 pagesInfernal Gpu SlidesRodrigoMansueliNunesNo ratings yet

- UART ArchitectureDocument23 pagesUART ArchitectureEdgar Mugabi Tusuubira100% (4)

- INT250Document2 pagesINT250Sambit Sagar PanigrahyNo ratings yet

- LO PresentationDocument3 pagesLO PresentationIsha KalyanNo ratings yet

- New Price List 2018-Q4: EG Price Availability Description Design Model NODocument16 pagesNew Price List 2018-Q4: EG Price Availability Description Design Model NOMohammed EL-bendaryNo ratings yet

- Creo Trendsetter Error, Command, NVS, ArchiveDocument4 pagesCreo Trendsetter Error, Command, NVS, ArchiveZevnik d.o.o.No ratings yet

- Bangladesh University Program: Day (Fall 2019 Class Schedule) SaturdayDocument7 pagesBangladesh University Program: Day (Fall 2019 Class Schedule) SaturdayMD Abu Ahammed BabuNo ratings yet

- Consulting Brochure enDocument12 pagesConsulting Brochure enbhargavNo ratings yet

- 3) RC Half & Full Wave Firing Circuit - RFCDocument8 pages3) RC Half & Full Wave Firing Circuit - RFCPradeep KumarNo ratings yet

- 8-5-19-Sequence Alignment in GpuDocument26 pages8-5-19-Sequence Alignment in GpuSiba PrasadNo ratings yet

- ESE (Book) PDFDocument486 pagesESE (Book) PDFVir DavinderNo ratings yet

Technical Bulletin: FT1380-XL Fitting Locators

Technical Bulletin: FT1380-XL Fitting Locators

Uploaded by

Autieri AutieriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Bulletin: FT1380-XL Fitting Locators

Technical Bulletin: FT1380-XL Fitting Locators

Uploaded by

Autieri AutieriCopyright:

Available Formats

Technical Bulletin

FT1380-XL Fitting Locators

For use with Eaton FT1380 “M” Series Die Cages

• Simplifies crimping of 4S series fittings

• Easy to install

• Perfectly positions the fitting within the crimp cage

every time

Consistent crimping of 4S series fittings is greatly

simplified when using Eaton fitting locators.

The locators are designed for easy installation and use on

the Eaton FT1380 “M” series die cages

noted below.

When using the locators, a crimp machine operator no

longer needs to “eyeball” the crimp location on the fitting.

The locators allow the operator to position the fittings for

consistent crimping and optimal performance of

assemblies.

The locator kits can be ordered as part number FT1380-XL.

Locator Kit includes—

• Locators (one each): 4S6P, 4S8P, 4S10P, 4S12P, 4S16P, 4S6, 4S12, 4S16

• Installation instructions

Locator Suffix Die Cage GH493/H430 EC415 FC500/H471 EC420 EC600

4S6P FT1380-200-M210 -6 -6

4S8P FT1381-200-M280 -8 -8

4S10P FT1381-200-M280 -10 -10

4S12P FT1380-200-M320 -12 -12 -12 -12 -12

4S16P FT1380-200-M420 -16 -16 -16 -16 -16

None Required FT1382-200-M465 -20 -20 -20

4S6 FT1380-275-M210 -6 -6

4S12 FT1380-275-M320 -12 -12 -12 -12 -12

4S16 FT1380-275-M420 -16 -16 -16 -16 -16

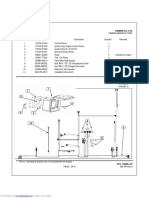

Selecting the Proper Locator and Die Cage

Combination

Using the chart on the front of this bulletin, match the proper

locator and die cage. When examining the dies, place the front of

the die cage down. The individual dies must be examined to

determine if the “standard” (example: 4S6) or “P” style (example:

4S6P) should be used, as shown in Figures 1 and 2.

Installation Instructions

1. Using a 5/32-inch allen wrench, remove the bottom bolt and

sleeve from the die cage.

2. Slide the locator over the 3/8-inch diameter sleeve, and re-install

as shown in figure 1.

Crimping Procedure Using the Locator

1. Establish the setting on the crimp machine.

2. Assemble the fitting onto the end of the hose, making certain

that the fitting has “bottomed-out” against the squarely cut hose.

3. Insert the fitting into the crimp cage, then locate the back edge of

the socket against the locator as shown in figure 2.

4. Complete the crimping cycle in the usual manner.

*Assembler to ensure the proper crimp diameter and correct crimp location to

the scribe line per Eaton’s specs for the hose and fitting combination.

Eaton © 2019 Eaton

Hydraulics Group USA All Rights Reserved

14615 Lone Oak Road Printed in USA

Eden Prairie, MN 55344 Document No.: E-HOAS-BB002-E

Tel: 952-937-9800 Fax: 952-294-7722 July 2019

www.Eaton.com/hydraulics

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Continental TorquesDocument13 pagesContinental Torquesfredtanner100% (2)

- Ford Y-Block Engines: How to Rebuild & ModifyFrom EverandFord Y-Block Engines: How to Rebuild & ModifyRating: 4.5 out of 5 stars4.5/5 (3)

- Db2 DATA ADMINISTRATION LobDocument71 pagesDb2 DATA ADMINISTRATION LobAmlan Chowdhury100% (1)

- Vicarb Plate Heat ExchangersDocument17 pagesVicarb Plate Heat ExchangersFrederik BohyNo ratings yet

- Coin Sorter NewDocument14 pagesCoin Sorter Newvishnu100% (1)

- Clinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyDocument24 pagesClinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyErica AlabanNo ratings yet

- FT1390-2-9-500 Crimp MachineDocument8 pagesFT1390-2-9-500 Crimp MachineJulián Ricardo RodriguezNo ratings yet

- Serie FF PDFDocument3 pagesSerie FF PDFYanderier RiveraNo ratings yet

- Manual ConectoresDocument19 pagesManual ConectoresLuis EduardoNo ratings yet

- Installation Instructions For EWD13 and EWF13 Sprocket Box UpdateDocument14 pagesInstallation Instructions For EWD13 and EWF13 Sprocket Box UpdatePetrNo ratings yet

- DTANKDocument26 pagesDTANKVivekRaptorNo ratings yet

- Ford Installation InstructionDocument14 pagesFord Installation Instructiontxr qcNo ratings yet

- M O R S E 5 X 6 Jaw Crusher ManualDocument7 pagesM O R S E 5 X 6 Jaw Crusher ManualGilberto Garnica MurilloNo ratings yet

- Gared Sports Soccer Goal Football Fieldgoal Post Combo Installation InstructionsDocument10 pagesGared Sports Soccer Goal Football Fieldgoal Post Combo Installation InstructionsRobbins athleticsNo ratings yet

- WAI Transpo FordDocument16 pagesWAI Transpo FordELIAS CHAVESNo ratings yet

- 212 86 92 - RepairedDocument11 pages212 86 92 - Repairedsebastian cruzNo ratings yet

- 2NKX6 1Document24 pages2NKX6 1Ana Gabriela Gómez PeraltaNo ratings yet

- Dayton Integral and Fractional HP Motors: Motor Installation and Maintenance InformationDocument28 pagesDayton Integral and Fractional HP Motors: Motor Installation and Maintenance Informationjaime appletonNo ratings yet

- 4 TNV 84 TZDocument6 pages4 TNV 84 TZCarlos Rivera MontesNo ratings yet

- C18 Generator Set STM00001-UP (SEBP4100 - 43) Procedure For Installation of VR6 Voltage RegulatorDocument9 pagesC18 Generator Set STM00001-UP (SEBP4100 - 43) Procedure For Installation of VR6 Voltage RegulatorCEVegaONo ratings yet

- 4096 406Document5 pages4096 406Pranalanka WarunawansaNo ratings yet

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- FQ5-2011-028 FS-2575 FS-5075 Can Not Use The Handset FS-2575CDocument5 pagesFQ5-2011-028 FS-2575 FS-5075 Can Not Use The Handset FS-2575CAndrew NazarovNo ratings yet

- Parts and Installation Instructions Spring Trip Snow Plow Models TM 5.0, TM 6.0 and TM 6.5Document2 pagesParts and Installation Instructions Spring Trip Snow Plow Models TM 5.0, TM 6.0 and TM 6.5girtzengineeringNo ratings yet

- 120A2A Distribution PDFDocument49 pages120A2A Distribution PDFnachoNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- EG-00404 P-20 Cable RoutingDocument15 pagesEG-00404 P-20 Cable Routinggguadian21No ratings yet

- SL162B Helicoil PDFDocument2 pagesSL162B Helicoil PDFjeffrey_fay67% (3)

- AA00219 PC300-6 (Refuerzos PC300-6)Document11 pagesAA00219 PC300-6 (Refuerzos PC300-6)joaquin suarezNo ratings yet

- Taladro Magnetico Rotabest Mini 36-50 Manual OperacionDocument12 pagesTaladro Magnetico Rotabest Mini 36-50 Manual OperacionAtahualpa Bulganin Infante YañezNo ratings yet

- FRH FRG ManualDocument23 pagesFRH FRG ManualdlanorxNo ratings yet

- Installation Manual: Universal Top-of-Pole Mount UNI-TP/08LLDocument11 pagesInstallation Manual: Universal Top-of-Pole Mount UNI-TP/08LLlexdanteNo ratings yet

- FF Primary InstructionsDocument12 pagesFF Primary InstructionsKevin VillagranNo ratings yet

- Ontrac Cable Tray: Installation InstructionsDocument10 pagesOntrac Cable Tray: Installation Instructionsgeriko182No ratings yet

- Power Tools: Operating and Maintenance InstructionsDocument16 pagesPower Tools: Operating and Maintenance InstructionsBill WidmerNo ratings yet

- Inertia Dynamic TypeFL SpecsheetDocument3 pagesInertia Dynamic TypeFL SpecsheetElectromateNo ratings yet

- 180TCD Metric ManualDocument6 pages180TCD Metric ManualJose GonzalezNo ratings yet

- LG-6001 Lead Gage: Operation ManualDocument24 pagesLG-6001 Lead Gage: Operation ManualSukumarNo ratings yet

- 9901X0101 - 3 Operating InstructionsDocument7 pages9901X0101 - 3 Operating InstructionsElizabeth MejiaNo ratings yet

- Mitsubishi FV DrivelineDocument10 pagesMitsubishi FV Drivelinejs1290No ratings yet

- Pistons and Connecting Rods - AssembleDocument6 pagesPistons and Connecting Rods - AssemblealonsoNo ratings yet

- Interchangeable Spindle Users Guide 4C v0311 WebDocument21 pagesInterchangeable Spindle Users Guide 4C v0311 WebMynor SGNo ratings yet

- Rehs1037 04Document10 pagesRehs1037 04Pauk HseinNo ratings yet

- AA00220 PC400-6 (Refuerzos PC400-6)Document11 pagesAA00220 PC400-6 (Refuerzos PC400-6)joaquin suarezNo ratings yet

- 51550Document24 pages51550jombibiNo ratings yet

- Pennbarry Fumex IOM v6Document22 pagesPennbarry Fumex IOM v6RanielNo ratings yet

- Grease Fitting PDFDocument20 pagesGrease Fitting PDFleonardsiregarNo ratings yet

- 407ASB407ASB19119Document8 pages407ASB407ASB19119carolina.rossNo ratings yet

- Orifice PDFDocument11 pagesOrifice PDFb_wooNo ratings yet

- Alfra Rotabest Midi 5050 Operation ManualDocument13 pagesAlfra Rotabest Midi 5050 Operation Manualsudofim2006No ratings yet

- Rear Sway Bar Installation InstructionsDocument4 pagesRear Sway Bar Installation InstructionsRaduNo ratings yet

- Astro ContactDocument43 pagesAstro ContactEmiliano BoschettiNo ratings yet

- Sch80tech FL80 FL4PDocument18 pagesSch80tech FL80 FL4PDILSHAD AHEMADNo ratings yet

- HKS 2JZ CoilDocument19 pagesHKS 2JZ CoilernestoNo ratings yet

- 180TCD Brake ManualDocument5 pages180TCD Brake ManualJose GonzalezNo ratings yet

- Manual Pexto 137 Foot ShearDocument10 pagesManual Pexto 137 Foot Shearrubens072No ratings yet

- FG Wilson Service Bulletin: SB 0087 - PCADocument4 pagesFG Wilson Service Bulletin: SB 0087 - PCANacer Zehani100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 08-1090MF-1010 Full Catalog 02-2013Document416 pages08-1090MF-1010 Full Catalog 02-2013Autieri AutieriNo ratings yet

- En Stauff One B Stauff Test 2014Document48 pagesEn Stauff One B Stauff Test 2014Autieri AutieriNo ratings yet

- Sensor OCS-Software enDocument16 pagesSensor OCS-Software enAutieri AutieriNo ratings yet

- Terminais Reusáveis - PCT - 3234776Document68 pagesTerminais Reusáveis - PCT - 3234776Autieri AutieriNo ratings yet

- 100r4 - WinnerDocument2 pages100r4 - WinnerAutieri AutieriNo ratings yet

- EC600 X-FLEX Bend Radius 420 Bar Spiral Hydraulic HoseDocument2 pagesEC600 X-FLEX Bend Radius 420 Bar Spiral Hydraulic HoseAutieri AutieriNo ratings yet

- Couplings Oil and GasDocument4 pagesCouplings Oil and GasAutieri AutieriNo ratings yet

- 2.5 Inch 6-Spiral Hose: Eaton EC466-40Document8 pages2.5 Inch 6-Spiral Hose: Eaton EC466-40Autieri AutieriNo ratings yet

- TLSL 3428Document232 pagesTLSL 3428viniciusemanuelNo ratings yet

- Fluke Esa612 Specifications Spec Sheet Mt06Document8 pagesFluke Esa612 Specifications Spec Sheet Mt06ashishtrueNo ratings yet

- ISO 9001 2008 Awareness Training QuestionnaireDocument2 pagesISO 9001 2008 Awareness Training Questionnaireezal2100% (3)

- Apex MCQ Question1Document2 pagesApex MCQ Question1rajan251221No ratings yet

- Dynamic Programming Questions: 5. Longest Palindromic SubstringDocument38 pagesDynamic Programming Questions: 5. Longest Palindromic SubstringEren AvcıNo ratings yet

- MEGA Solution Footprint V5Document17 pagesMEGA Solution Footprint V5Wissam ShehabNo ratings yet

- GreyAtom Data Science Machine Learning CourseDocument21 pagesGreyAtom Data Science Machine Learning CoursevickychhedaNo ratings yet

- Oracle Erp Cloud Implementation Leading Practices WPDocument35 pagesOracle Erp Cloud Implementation Leading Practices WPMiguel Felicio100% (1)

- Section 9.6 Counting Principles: NameDocument2 pagesSection 9.6 Counting Principles: Namesarasmile2009No ratings yet

- 11-40 - SINUMERIK Edge - Concept - AppsDocument15 pages11-40 - SINUMERIK Edge - Concept - AppsAshish PatwardhanNo ratings yet

- Postdoctoral FellowDocument3 pagesPostdoctoral Fellowabidraza8No ratings yet

- Block ModelingDocument18 pagesBlock ModelingMphNo ratings yet

- Analytics - Practical FileDocument8 pagesAnalytics - Practical FileRockyNo ratings yet

- Destructive and Non-Destructive - QuizDocument15 pagesDestructive and Non-Destructive - QuizDiangelia ArtagameNo ratings yet

- PR2 Q2 Module 3Document9 pagesPR2 Q2 Module 3Ashes VillNo ratings yet

- AAU5612 Hardware Description (01) (PDF) - ENDocument21 pagesAAU5612 Hardware Description (01) (PDF) - ENvitor santosNo ratings yet

- Syllabus: Matrix Algebra DeterminantsDocument4 pagesSyllabus: Matrix Algebra DeterminantsshaannivasNo ratings yet

- Infernal Gpu SlidesDocument22 pagesInfernal Gpu SlidesRodrigoMansueliNunesNo ratings yet

- UART ArchitectureDocument23 pagesUART ArchitectureEdgar Mugabi Tusuubira100% (4)

- INT250Document2 pagesINT250Sambit Sagar PanigrahyNo ratings yet

- LO PresentationDocument3 pagesLO PresentationIsha KalyanNo ratings yet

- New Price List 2018-Q4: EG Price Availability Description Design Model NODocument16 pagesNew Price List 2018-Q4: EG Price Availability Description Design Model NOMohammed EL-bendaryNo ratings yet

- Creo Trendsetter Error, Command, NVS, ArchiveDocument4 pagesCreo Trendsetter Error, Command, NVS, ArchiveZevnik d.o.o.No ratings yet

- Bangladesh University Program: Day (Fall 2019 Class Schedule) SaturdayDocument7 pagesBangladesh University Program: Day (Fall 2019 Class Schedule) SaturdayMD Abu Ahammed BabuNo ratings yet

- Consulting Brochure enDocument12 pagesConsulting Brochure enbhargavNo ratings yet

- 3) RC Half & Full Wave Firing Circuit - RFCDocument8 pages3) RC Half & Full Wave Firing Circuit - RFCPradeep KumarNo ratings yet

- 8-5-19-Sequence Alignment in GpuDocument26 pages8-5-19-Sequence Alignment in GpuSiba PrasadNo ratings yet

- ESE (Book) PDFDocument486 pagesESE (Book) PDFVir DavinderNo ratings yet