Professional Documents

Culture Documents

Steel Work Quality Assurance Plan

Steel Work Quality Assurance Plan

Uploaded by

Ramesh F SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Work Quality Assurance Plan

Steel Work Quality Assurance Plan

Uploaded by

Ramesh F SinghCopyright:

Available Formats

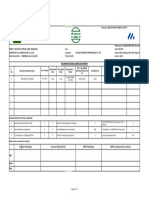

QUALITY ASSURANCE PLAN

Building Steel Structure Work

Name Of Customer : Hindalco

STANDARDS FOR

SR. NO. DESCRIPTION CHARACTERISTICS TYPE OF CHECK EXTENT OF CHECK INSPECTION BY FORMAT OF RECORDS REMARKS

ACCEPTANCE

Techbridge Hindalco

1 Raw material

1. Chemical 1. Mfgr TC

1. 100% 1. R 1. TC

properties Verification

IS2062 or

1.1 Steel plate 2. Mechanical 2. Mfgr TC

2. 100% Equivalent 2. R 2. TC

properties Verification

3. Dimensions 3. Measurement 3. 10% 3. I 3. Inspection report

1. Chemical 1. Mfgr TC

1.10% 1. R 1. TC

Anchor bolt properties Verification

IS2062 or

1.2 (Round Bar 2. Mechanical 2. Mfgr TC

2.10% Equivalent 2. R 2. TC

mechanism properties Verification

3. Dimensions 3. Measurement 3. 10% 3. I 3. Inspection report

Hot rolled 1. Chemical 1. Mfgr TC

1. 100% 1. R 1. TC

section properties Verification

IS2062 or

1.3 (Beam/ 2. Mechanical 2. Mfgr TC

2. 100% Equivalent 2. R 2. TC

channel/ properties Verification

angle/ bar/ 3. Dimensions 3. Measurement 3. 10% 3. I 3. Inspection report

1. Chemical 1. Mfgr TC

1. 100% 1. R 1. TC

properties Verification IS:1161 and IS:1239

Hollow section

1.4 2. Mechanical 2. Mfgr TC for Round pipes or

(Pipes/ etc) 2. 100% 2. R 2. TC

properties Verification Equivalent

3. Dimensions 3. Measurement 3. 10% 3. I 3. Inspection report

1. Chemical 1. Mfgr TC

1. 100% 1. R 1. TC

properties Verification ASTM A 792

1.5 Purlins 2. Mechanical 2. Mfgr TC Gr.50/80 for purlin

2. 100% 2. R 2. TC

properties Verification or Equivalent

3. Dimensions 3. Measurement 3. 10% 3. I 3. Inspection report

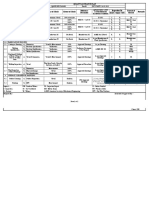

2 Bought Out Items

1. Chemical 1. Mfgr TC

High strength 1.100% 1. R 1. TC

properties Verification

bolts, nuts and

2. Mechanical 2. Mfgr TC ASTMA325 A563 &

2.1 washers for 2.100% 2. R 2. TC

properties Verification F436 or Equivalent

primary

connection 3. Dimensions 3. Measurement 3. 2% 3. I 3. Inspection report

Mild steel 1. Chemical 1. Mfgr TC

1.100% 1. R 1. TC

bolts , nuts properties Verification IS1367 Gr. A6 for

2.2 and washers 2. Mechanical 2. Mfgr TC bolts and nuts or

2.100% 2. R 2. TC

for secondary properties Verification Equivalent

connection 3. Dimensions 3. Measurement 3. 2% 3. I 3. Inspection report

1. Mfgr TC ASTM 3566 or As

1. Material 1.100% 1. R 1. TC

Fasteners Verification per drawing and

2.3

(Screw/ etc) 2. Dimensions 3. Measurement 3. 2% client specification 2. I 2. Inspection report

3 Fabrication Process

Fabrication of As per fabrication

3.1 1. Dimensions 1. Measurement 1. 10% 1. I 1. Inspection report

structure drawing

Final 1. Dimensions 1. Measurement 1. 10% As per structure 1. I 1. Inspection report

3.2 inspection and fabrication

2. Part identification 1. Verification 2. 100% 1. I 1. Inspection report

(Before drawing

4 Welding

1. Procedure 1. Verification /

1. 100% 1. R 1.WPS

Specification review

Welding 2. Procedure 1. Verification /

4.1 2. 100% AWS D1.1.2015 2. R 2.PQR

procedure Qualification review

3. Welder 1. Verification /

3. 100% 3. R 3.WPQ

Qualification review

1. Visual Defects 1. Visual 1. 100% 1. I 1. Inspection report

Welding

4.2 2. Weld Size 2. Measurements 2. 10% AWS D1.1.2015 2. I 2. Inspection report

inspection

3. Surface Defect 3. DP test 3. 2% joint 3. I 3. Inspection report

5 Surface Cleaning and Painting

Surface 1.Surface

1. Visual 1. 10% 1. I 1. Inspection report

cleaning and Preparation As per client

5.1

painting 2. Measurement specification

2. Surface coating 2. 2% 2. I 2. Inspection report

process of DFT

6 Roll Forming

1. Dimensions 1. Measurement 1. 2% 1. I 1. Inspection report

As per drawing and

6.1 Purlin 2. Surface and

2. Visual 2. 2% client specification 2. I 2. Inspection report

Shape

LEGENDS

R Review ASTM American Society For Material and Testing

I Inspection MBMA Metal building manufacturers Association

AWS American Welding Society

IS Indian Standards

Prepared by Techbridge : Reviewed and Approved by Hindalco:

ISO 9001 Document No. DI/QA/ME01, IssueDate 23/11/19, Rev 0.0

You might also like

- AWS D1.2 AluminiumDocument2 pagesAWS D1.2 AluminiumAslamsherkhan Ibn Hussain Kandamangalam44% (9)

- CWB Study Guide - Welding SymbolsDocument36 pagesCWB Study Guide - Welding SymbolsPubcrawlNo ratings yet

- 5 Contractor Quality Control Plan For Steel StructureDocument3 pages5 Contractor Quality Control Plan For Steel Structurebehzad esNo ratings yet

- Procedure For Installation of Steel Stair StructureDocument6 pagesProcedure For Installation of Steel Stair StructureImamah AliNo ratings yet

- Quality Assurance Plan: An ISO 9001: 2015 CompanyDocument1 pageQuality Assurance Plan: An ISO 9001: 2015 CompanyMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Nde Request FormDocument1 pageNde Request Formfazeel mohammedNo ratings yet

- Form - Structural Concrete Pre-Pour Conference Agenda 1Document12 pagesForm - Structural Concrete Pre-Pour Conference Agenda 1masahinNo ratings yet

- Painting RecordDocument1 pagePainting RecordHimawan Setyarso100% (1)

- International Organization For Standardization (ISO) StandardsDocument3 pagesInternational Organization For Standardization (ISO) StandardsDileep100% (3)

- SMS Concast: Your Leading Lifecycle-Management Partner For Long-Product Continuous CastersDocument12 pagesSMS Concast: Your Leading Lifecycle-Management Partner For Long-Product Continuous CastersDanilo Hosken100% (1)

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Inspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationDocument3 pagesInspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationKhaled GamalNo ratings yet

- Field Inspection Plan (Brick and Masonry Walling)Document1 pageField Inspection Plan (Brick and Masonry Walling)christopher AdajoNo ratings yet

- Saes T 744 PDFDocument4 pagesSaes T 744 PDFabdullah sahibNo ratings yet

- Kinlong-2021Door Control Hardware Typical Product Catalogue (Thuy Luc)Document154 pagesKinlong-2021Door Control Hardware Typical Product Catalogue (Thuy Luc)vantanbkdnNo ratings yet

- QAP - Gate Valve - NPCILDocument6 pagesQAP - Gate Valve - NPCILkaustavNo ratings yet

- Alignment Inspection Report For Erection of Structural Steel (Gallery & Trestle)Document1 pageAlignment Inspection Report For Erection of Structural Steel (Gallery & Trestle)sivaNo ratings yet

- Structural (Building) Steel Installation ChecklistDocument1 pageStructural (Building) Steel Installation Checklistboz vanduyn100% (1)

- Dd0250 Material Receiving and Inspection ReportDocument1 pageDd0250 Material Receiving and Inspection ReportBelajar MONo ratings yet

- Dimensional Inspektion ReportDocument6 pagesDimensional Inspektion Reportdidi sudiNo ratings yet

- Electro-Motive Standard Welding Symbols AI01046Document9 pagesElectro-Motive Standard Welding Symbols AI01046eraman_meNo ratings yet

- ADG 25 - Value Engineering GuidelinesDocument74 pagesADG 25 - Value Engineering GuidelinesRahul DivakaranNo ratings yet

- Final Inspection ProcedureDocument1 pageFinal Inspection ProcedurePamela ColemanNo ratings yet

- Quality Assurance (QA) StructureDocument10 pagesQuality Assurance (QA) Structureyuwantoni100% (1)

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- Procedure Qualification RecordsDocument2 pagesProcedure Qualification RecordsRM ENTERPRISESNo ratings yet

- HK CS2 - 2012Document50 pagesHK CS2 - 2012bobbyccwNo ratings yet

- Fabrication and Erection MSDocument6 pagesFabrication and Erection MSShrikant BudholiaNo ratings yet

- Nspection Eport: EneralDocument3 pagesNspection Eport: Eneralberbin josNo ratings yet

- Quality ControlDocument51 pagesQuality ControlOprisor CostinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- QC 64247-1 Contact Plate Inspection ReportDocument2 pagesQC 64247-1 Contact Plate Inspection ReportSenthil KumarNo ratings yet

- ThyssenDocument0 pagesThyssenAbbas RizviNo ratings yet

- KON 8.2 QA PRO 0024 C1 Certification ProcedureDocument8 pagesKON 8.2 QA PRO 0024 C1 Certification ProcedureAlizamin SalmanovNo ratings yet

- Silo-1 Fit-Up Inspection ReportDocument3 pagesSilo-1 Fit-Up Inspection ReportsivaNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Ncpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Document11 pagesNcpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)mohammed shaffi abdul rahman0% (1)

- SOP For Laser CuttingDocument2 pagesSOP For Laser CuttingSaravana kumar NagarajanNo ratings yet

- Template Quality Assurance Inspection and Test PlanDocument2 pagesTemplate Quality Assurance Inspection and Test PlanSiva Naga Prasad TadipartiNo ratings yet

- Vendor Qualification Check ListDocument2 pagesVendor Qualification Check ListAndi YanuarNo ratings yet

- Inspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoDocument1 pageInspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoDelta akathehusky100% (1)

- Understanding About Inspection and Test PlanDocument2 pagesUnderstanding About Inspection and Test PlanPageduesca RouelNo ratings yet

- NCR Tracking Log AAILDocument5 pagesNCR Tracking Log AAILssenthil04No ratings yet

- Pre-Grouting ChecklistDocument1 pagePre-Grouting ChecklistChukwuma OgbonnaNo ratings yet

- B 928 - 04 - QjkyoaDocument10 pagesB 928 - 04 - Qjkyoamercab15No ratings yet

- HMC Spec 001 - Welding and Fabrication of Structural SteelDocument29 pagesHMC Spec 001 - Welding and Fabrication of Structural SteelJohnnyNo ratings yet

- Tea Staining - 2 PDFDocument4 pagesTea Staining - 2 PDFharishNo ratings yet

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- PBI-WI 005 Dimensional Control Procedure Rev.0Document5 pagesPBI-WI 005 Dimensional Control Procedure Rev.0Tadaya KasaharaNo ratings yet

- Anchor Bolt Inspection ReportDocument2 pagesAnchor Bolt Inspection Reportansarisaeed100% (1)

- Job Description NDTDocument4 pagesJob Description NDTNDTInstructorNo ratings yet

- RTC-161-MIR-A-ID-174 - R0 - B Off Site Material Inspection Request For Free Standing Bathtub 21095T-0 (Option 2) From KHALID CORPORATIONDocument7 pagesRTC-161-MIR-A-ID-174 - R0 - B Off Site Material Inspection Request For Free Standing Bathtub 21095T-0 (Option 2) From KHALID CORPORATIONeslam100% (2)

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- 01-Checklist For Excavation To BackfillingDocument2 pages01-Checklist For Excavation To Backfillingmd_rehan_2No ratings yet

- 07-Schedule A - Inspection & Test Plan ITPDocument2 pages07-Schedule A - Inspection & Test Plan ITPamir100% (1)

- Seeion No. Session Title Date From To Chair Paper No. Presetation ID Paper Title SpeakerDocument4 pagesSeeion No. Session Title Date From To Chair Paper No. Presetation ID Paper Title SpeakerSERRA DANIŞ100% (1)

- Inspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksDocument3 pagesInspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksjitendraNo ratings yet

- WEP For Steel Structure WorkDocument8 pagesWEP For Steel Structure WorkpalashNo ratings yet

- MBMA Fabricate Erection Tolerance 18 01 10 PDFDocument2 pagesMBMA Fabricate Erection Tolerance 18 01 10 PDFNat Thana AnanNo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- General Specification For Concrete WorksDocument19 pagesGeneral Specification For Concrete WorksNaveed AhmedNo ratings yet

- Bill of Quantities (BOQ)Document1 pageBill of Quantities (BOQ)Azil14No ratings yet

- QAP-KGN-CIAL-001, Rev00Document2 pagesQAP-KGN-CIAL-001, Rev00iftekhar ahmedNo ratings yet

- UMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentFrom EverandUMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentNo ratings yet

- Astm B584Document7 pagesAstm B584Francisco Villasmil OlivaresNo ratings yet

- Hot Dip Galvanizing Design ConsiderationsDocument22 pagesHot Dip Galvanizing Design Considerationsabhi_akNo ratings yet

- Roll Power: How Much Power Is Required To Run The Rollers?Document18 pagesRoll Power: How Much Power Is Required To Run The Rollers?Foley OmoniyiNo ratings yet

- Helical Machining GuidebookDocument70 pagesHelical Machining Guidebookhappydude7632No ratings yet

- Metal Cutting and Machine ToolsDocument244 pagesMetal Cutting and Machine ToolsChitranganda100% (1)

- National Vocationaltraining Institute: Testing DivisionDocument31 pagesNational Vocationaltraining Institute: Testing Divisionairbuk doeingNo ratings yet

- CWC Mec DTS P002abDocument8 pagesCWC Mec DTS P002abAlonso1593No ratings yet

- Unit 3Document71 pagesUnit 3kartik guptaNo ratings yet

- HOERBIGER Friction Systems Ideal Solutions For Any ApplicationDocument5 pagesHOERBIGER Friction Systems Ideal Solutions For Any ApplicationR KathirasanNo ratings yet

- HD Leviat 20-EDocument48 pagesHD Leviat 20-EAndreea RoxanaNo ratings yet

- Product Features: Securon ® 540Document2 pagesProduct Features: Securon ® 540raju_hosssenNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- A Step-By-Step Guide To SMT Step SolderingDocument4 pagesA Step-By-Step Guide To SMT Step SolderingjackNo ratings yet

- Checklist For Fabrication & Erection of Structural Steel WorkDocument1 pageChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuNo ratings yet

- Aerospace MaterialsDocument21 pagesAerospace MaterialsrkneyveliNo ratings yet

- HV Juice Apr-May2015 WebDocument8 pagesHV Juice Apr-May2015 WebFerran MunyósNo ratings yet

- WG 101Document1 pageWG 101'Lampa'No ratings yet

- Computer Aided Design and Analysis of Swing Jaw Plate of Jaw CrusherDocument4 pagesComputer Aided Design and Analysis of Swing Jaw Plate of Jaw CrusherSreeni Vas KopparapuNo ratings yet

- WPS-PQR Gr. CF8MDocument9 pagesWPS-PQR Gr. CF8Mansarmulla711No ratings yet

- The Box Tube MAC-11: The Ultimate DIY Machine PistolDocument24 pagesThe Box Tube MAC-11: The Ultimate DIY Machine PistolPatrick Peres100% (1)

- Facts About ForgingDocument7 pagesFacts About ForgingRikhil YalamanchiNo ratings yet

- Lathe MachineDocument4 pagesLathe MachineIman SadeghiNo ratings yet

- Bonaiti InvisibleDocument19 pagesBonaiti Invisiblematrice.sara.silvaNo ratings yet

- Lution 169 gt2Document5 pagesLution 169 gt2Gustava LafavaNo ratings yet

- CV Format 2022 NEW Rodreick PerezDocument5 pagesCV Format 2022 NEW Rodreick PerezMacky EscaladaNo ratings yet

- Corus Stock RangeDocument75 pagesCorus Stock RangeBartlomiej KuczynskiNo ratings yet