Professional Documents

Culture Documents

CONN-MacauV2 - 1226R1-2C Tie Beam

CONN-MacauV2 - 1226R1-2C Tie Beam

Uploaded by

chirathip vasuvattakulCopyright:

Available Formats

You might also like

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Padeye DesignDocument2 pagesPadeye DesignChiedu Okondu100% (2)

- CONN-MacauV2 - 1226R1-H500 Brace BeamDocument1 pageCONN-MacauV2 - 1226R1-H500 Brace Beamchirathip vasuvattakulNo ratings yet

- CONN MacauV2 - 1226R1 LugDocument1 pageCONN MacauV2 - 1226R1 Lugchirathip vasuvattakulNo ratings yet

- One Side Beam-Beam ConnectionDocument1 pageOne Side Beam-Beam Connectionsamon.itc2019No ratings yet

- Bracing Connection Design PDFDocument3 pagesBracing Connection Design PDFriaz16shaik100% (1)

- Fin Plate ConnectionDocument2 pagesFin Plate ConnectionSudhakar Krishnamurthy100% (2)

- Bracing ConnectionsDocument3 pagesBracing ConnectionspradeeshNo ratings yet

- Isolated & Combined Footing Design BS8110.1985Document7 pagesIsolated & Combined Footing Design BS8110.1985carlosNo ratings yet

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- Shear Connections AISC 360Document64 pagesShear Connections AISC 360jatinNo ratings yet

- 0.1 Eingangskennwerte: 0.1.1 AllgemeinesDocument7 pages0.1 Eingangskennwerte: 0.1.1 AllgemeineslöliNo ratings yet

- Splice ConnectionDocument18 pagesSplice ConnectionAhmad Pooladi0% (1)

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Document30 pagesDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212No ratings yet

- Beam - Column Steel SpliceDocument22 pagesBeam - Column Steel Splicerelu59No ratings yet

- Design of Isolated Footing For Security Room: Node No. XDDocument12 pagesDesign of Isolated Footing For Security Room: Node No. XDvenu manikantaNo ratings yet

- DESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomDocument11 pagesDESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomAsaru DeenNo ratings yet

- 3 B1 B2 MeanDocument1 page3 B1 B2 MeanMaumoon SaleemNo ratings yet

- DESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Document4 pagesDESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Mahananda RKNo ratings yet

- Calc. Fillet Weld Transverse Load-Jacket ClosureDocument6 pagesCalc. Fillet Weld Transverse Load-Jacket ClosureAsep MulyadiNo ratings yet

- Isolated & Combined Footing Design Bs8110.1985Document6 pagesIsolated & Combined Footing Design Bs8110.1985EdwinNo ratings yet

- 2.2.1 - DQR EM Capacity Rev BDocument61 pages2.2.1 - DQR EM Capacity Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- RC Beam Design Using ACIDocument1 pageRC Beam Design Using ACIdantevariasNo ratings yet

- Moment Connection Design (Ver-6)Document4 pagesMoment Connection Design (Ver-6)Saurabh GuptaNo ratings yet

- IA-PB-15141-CP-1Document37 pagesIA-PB-15141-CP-1Aamir SuhailNo ratings yet

- Base Plate - Connection Plate Design-B401 - 12.08.2019Document12 pagesBase Plate - Connection Plate Design-B401 - 12.08.2019Siddharth TiwariNo ratings yet

- Beam - Column Steel SpliceDocument20 pagesBeam - Column Steel SpliceAnsh SharmaNo ratings yet

- Isolated Footing (4 Sides Wind)Document4 pagesIsolated Footing (4 Sides Wind)saiNo ratings yet

- BoltDocument1 pageBoltvishal tomarNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- PS-3 Rebar Anchoring Calculation - R01 - 21.11.2023Document1 pagePS-3 Rebar Anchoring Calculation - R01 - 21.11.2023anandswarupNo ratings yet

- Modified RatiosDocument3 pagesModified RatiosBassem KhaledNo ratings yet

- Tailing Frame DesignDocument5 pagesTailing Frame DesignfkamunityNo ratings yet

- En - 13121 - Rectangular Tank DesignDocument7 pagesEn - 13121 - Rectangular Tank DesignMAYANK CHAUHANNo ratings yet

- HR Quaters - Pad FootingsDocument14 pagesHR Quaters - Pad FootingsanushyasanjeevaniNo ratings yet

- Stub ColumnDocument4 pagesStub ColumnCHRISTOPHER EKIRAPANo ratings yet

- Splice Plate - F13.5extDocument6 pagesSplice Plate - F13.5extManish DuggadNo ratings yet

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- PS-3 Rebar Anchoring Calculation - 21.11.2023Document1 pagePS-3 Rebar Anchoring Calculation - 21.11.2023anandswarupNo ratings yet

- Base Plate (ML Gambhir)Document6 pagesBase Plate (ML Gambhir)Prakash SinghNo ratings yet

- Sheet1: Rapp Buckling Strength of Stiffened Flat Plates SH92 3014Document8 pagesSheet1: Rapp Buckling Strength of Stiffened Flat Plates SH92 3014ding liuNo ratings yet

- Review Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsDocument2 pagesReview Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsJoseph LantoNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Inner Members DesignDocument4 pagesInner Members DesignARSENo ratings yet

- Rectangular Footing F1Document4 pagesRectangular Footing F1haroon alikhanNo ratings yet

- Chumbadouros Portico Contraventamento FachadaDocument3 pagesChumbadouros Portico Contraventamento FachadaNunoSilvaNo ratings yet

- BP01Document4 pagesBP01Kumar Prasanna HNNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Circular Base PlateDocument6 pagesCircular Base Platesaptha7giriNo ratings yet

- Clip Angle Connection: Design ForcesDocument3 pagesClip Angle Connection: Design ForcesSIVAKUMARNo ratings yet

- REVIEW-MODULE 40-STRUCTURAL-ENGINEERING-Bolted-and-Welded-Connections-Review-Module-NOV2020Document3 pagesREVIEW-MODULE 40-STRUCTURAL-ENGINEERING-Bolted-and-Welded-Connections-Review-Module-NOV2020Ma Ella Mae Logronio100% (1)

- Фланцевые соединения dast v4.3 - EDocument3 pagesФланцевые соединения dast v4.3 - EZdrobau VitalieNo ratings yet

- Vertical Thrust Block Design (DN700&DN 800)Document28 pagesVertical Thrust Block Design (DN700&DN 800)ARSENo ratings yet

- Design of FootingDocument19 pagesDesign of Footingmohammad danishNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- LUG Connection160727Document1 pageLUG Connection160727chirathip vasuvattakulNo ratings yet

- CONN MacauV2 - 1226R1 LugDocument1 pageCONN MacauV2 - 1226R1 Lugchirathip vasuvattakulNo ratings yet

- CONN-MacauV2 - 1226R1-H500 Brace BeamDocument1 pageCONN-MacauV2 - 1226R1-H500 Brace Beamchirathip vasuvattakulNo ratings yet

- Member Design Eurocode-MacauDocument1 pageMember Design Eurocode-Macauchirathip vasuvattakulNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakulNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakul100% (1)

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakulNo ratings yet

- NB 06 Cat9200 Ser Data Sheet Cte enDocument42 pagesNB 06 Cat9200 Ser Data Sheet Cte enrobin11111111No ratings yet

- Gun Carriage Factory Jabalpur: Presented ByDocument17 pagesGun Carriage Factory Jabalpur: Presented Byparag_mitNo ratings yet

- Sanyog Mahajan Resume UpdatedDocument1 pageSanyog Mahajan Resume UpdatedSanyog MahajanNo ratings yet

- Osw Assignment 3Document15 pagesOsw Assignment 3DebarchanNo ratings yet

- Intl Orgs AukusDocument3 pagesIntl Orgs AukusDeepak PatilNo ratings yet

- Ped GuidelinesDocument225 pagesPed GuidelinesMatteo PeddisNo ratings yet

- ANL312 SU1 v2Document44 pagesANL312 SU1 v2Google UserNo ratings yet

- Third Product Theme Blutooth Dual SIM AdapterDocument7 pagesThird Product Theme Blutooth Dual SIM Adapterabbasarslan221No ratings yet

- Presentation On Project: Presented byDocument26 pagesPresentation On Project: Presented byAnujNo ratings yet

- Handling of Welding Consumables Procedure: Tebbin Plant Quality ControlDocument3 pagesHandling of Welding Consumables Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- Fcteg 02 632417Document5 pagesFcteg 02 632417mda mpsNo ratings yet

- Procedimiento de Embalaje y Envío de VálvulasDocument6 pagesProcedimiento de Embalaje y Envío de VálvulasБехар ТиагоNo ratings yet

- 12290/Csmt Duronto Exp Third Ac (3A)Document2 pages12290/Csmt Duronto Exp Third Ac (3A)21f1000067No ratings yet

- MIL Orinay Module2Document5 pagesMIL Orinay Module2Alexandrea OrinayNo ratings yet

- Distributed Computer ControlDocument124 pagesDistributed Computer ControlManjula SutagundarNo ratings yet

- BAMBALPITIYA PUMPING STATION - Outstanding WorkDocument3 pagesBAMBALPITIYA PUMPING STATION - Outstanding WorkShabeer Shaarim Abdul JabbarNo ratings yet

- A Discussion On Some of The Factors Affecting Well Spacing : F. M. D. CDocument10 pagesA Discussion On Some of The Factors Affecting Well Spacing : F. M. D. CHichem FakhfekhNo ratings yet

- Wiring Diagram: Keyless Entry System - Power Door Locks - Super Locking SystemDocument1 pageWiring Diagram: Keyless Entry System - Power Door Locks - Super Locking SystemAlexgavgray GNo ratings yet

- ENGDAT1 Module1 PDFDocument34 pagesENGDAT1 Module1 PDFLawrence BelloNo ratings yet

- Cullen v. Zoom Video Communications, Inc., Case 5:20-cv-02155-SVK (Northern District of California)Document23 pagesCullen v. Zoom Video Communications, Inc., Case 5:20-cv-02155-SVK (Northern District of California)Law&CrimeNo ratings yet

- 2, 5 Inch Side Door Stripper PDFDocument16 pages2, 5 Inch Side Door Stripper PDFOvRrj AhmedNo ratings yet

- Apana Black Book ProjectDocument35 pagesApana Black Book Projectpradeep dhobiNo ratings yet

- Manual Aire Acondicionado HaierDocument48 pagesManual Aire Acondicionado Haierjguerrero.067100% (3)

- Thesis Ict in EducationDocument7 pagesThesis Ict in EducationMary Calkins100% (2)

- International Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonDocument17 pagesInternational Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonGURUDAS KARNo ratings yet

- 4D Printing Technology - A ReviewDocument9 pages4D Printing Technology - A ReviewAngel Guanipa OrtizNo ratings yet

- Rodillo Tandem BomagDocument4 pagesRodillo Tandem BomagyasserNo ratings yet

- Environmental Management System ImplementationDocument40 pagesEnvironmental Management System Implementationkashif ManzoorNo ratings yet

- If The Coefficients of An Equation Are All Positive Then The Equation Has No Positive RootDocument1 pageIf The Coefficients of An Equation Are All Positive Then The Equation Has No Positive RootshantabaiNo ratings yet

- Data Science EssayDocument2 pagesData Science EssayHina ShahzadiNo ratings yet

CONN-MacauV2 - 1226R1-2C Tie Beam

CONN-MacauV2 - 1226R1-2C Tie Beam

Uploaded by

chirathip vasuvattakulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CONN-MacauV2 - 1226R1-2C Tie Beam

CONN-MacauV2 - 1226R1-2C Tie Beam

Uploaded by

chirathip vasuvattakulCopyright:

Available Formats

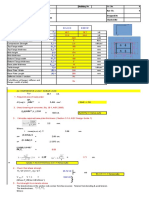

Connection Design according to Macau Design Code

Member MK. 2C-100x48x5.3x8.5

1.Properties

Bolt Intermediate plate Parameters of connection

Bolt size (d) 20 mm Plate thickness (tp) 12 mm End distance (e1) 30 mm

class 8.8 Ultimate tensile strength (fu,p) 310 N/mm2 Edge distance (e2) 50 mm

Number of bolts (n) 2 Yield strength (fy,p) 215 N/mm2 Longitudinal Bolts spacing (p1) 60 mm

αv 0.6 Tranverse Bolts spacing (p2) 0 mm

Ultimate tensile strength of bolts (fub) 800 N/mm2 Gusset plate Height of plate (hp) min. 120 mm

Tensile stress area (At) 245.0 mm2 Gusset plate thickness (tw,b1) 12 mm Gap (gh) 20 mm

Full bolt area (As) 314.3 mm2 Depth (H) 200 mm End distance (to edge of beam e1,b) 30 mm

Hole diameter (d0) 22 mm Ultimate tensile strength (fu,b1) 310 N/mm2 Edge distance (to edge of beam e2,b) 50 mm

Number of horizontal bolt lines (n1) 2 Yield strength (fy,b1) 215 N/mm2 Supporting to centre of bolt group (z) 70 mm

Number of vertical bolt lines (n2) 1 Partial safety factors (γm0) 1.1

2.Ultimate Design Load Partial safety factors (γm2) 1.25

Axial force = 16 KN

3.Check shear capacity of bolts (Thread excluded in shear plane) 9.Check bearing capacity of supported beam

α = Z p2 / 2I = 0 Horizontal resistance ( Fb,Rd,hor ) = k1 αb fu,b1 d tw,b1 / γm2 = 95.51 KN

b = (n2= 1: 6z / n (n+1) p1 , n2=2 :z p1(n1-1)/2I) = 1.17 αb = min ( e2,b/3do ; fub / fu,b1 ; 1) = 0.76

2 2 2

I = 0.5 n1 p2 + n1( n1 -1) p1 /6 = 3600 mm2 k1 = min ( 1.4 p1/do - 1.7 ; 2.5) = 2.12

shear resistance of a single bolt ( Fv,Rd ) = αv fub A /γm2 = 120.69 KN NRd,7 = n Fb,Rd,hor = 191.02 KN > 16 OK!

NRd,1 = n Fv,Rd = 241.37 KN > 16 OK!

10.Check net section tension capacity of supported beam

4.Check bearing capacity of plate Anet = tw,b1 ( hw,b1 - n1 d0) = 912 mm2

Horizontal bearing resistance ( Fb,Rd,hor ) = k1 αb fu,p d tp / γm2 = 95.51 KN NRd,8 = 0.9 Anet fu,b1 / ( γm2) = 203.56 KN > 16 OK!

αb = min ( e2/3do ; fub / fup ; 1) = 0.76

k1 = min ( 2.8 e1/do - 1.7 ; 1.4 p1/do - 1.7 ; 2.5) = 2.12 11.Check Block shear capacity of supported beam

NRd,2 = n Fb,Rd,hor = 191.02 KN > 16 OK! Net area subjected to tension Ant = tw,b1 ( e2 - 0.5d0) = 468 mm2

Net area subjected to shear Anv = tw,b1 ( e1+ p1- (n1-0.5) d0) = 684 mm2

5.Check net section tension capacity of plate NRd,9 = , + , = 193.25 KN > 16 OK!

√

Ap,net = tp ( hp - n1 d0) = 912 mm2

NRd,3 = 0.9 Anet fu,p / ( γm2) = 203.56 KN > 16 OK! 12.Check welds (2C connected to intermediate plate)

Weld size = 6 mm

6.Check Block shear capacity of plate Throat size (a) = 4.24 mm

Net area subjected to tension Ant = tp ( e2 - 0.5d0) = 468 mm2 Weld Length = 400.00 mm min.100x2x2

Net area subjected to shear Anv = tp ( e1+ p1- (n1-0.5) d0) = 684 mm2 Correlation factor ( βw) = 0.9

NRd,4 = , + , = 222.44 KN > 16 OK! Design strength of weld (Fvw.d) = = 159.09 N/mm2

√

shear capacity (Fw,Rd) = Fvw.d a L = 269.95 KN > 16 OK!

12.Check welds (Gusset plate connected to BX400x500x270)

Weld size = 8 mm

Throat size (a) = 5.66 mm

Weld Length = 400.00 mm min. 200x2

Correlation factor ( βw) = 0.9

Design strength of weld (Fvw.d) = = 159.09 N/mm2

shear capacity (Fw,Rd) = Fvw.d a L = 359.93 KN > 16 OK!

Capacity Ratio = 0.08

You might also like

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Padeye DesignDocument2 pagesPadeye DesignChiedu Okondu100% (2)

- CONN-MacauV2 - 1226R1-H500 Brace BeamDocument1 pageCONN-MacauV2 - 1226R1-H500 Brace Beamchirathip vasuvattakulNo ratings yet

- CONN MacauV2 - 1226R1 LugDocument1 pageCONN MacauV2 - 1226R1 Lugchirathip vasuvattakulNo ratings yet

- One Side Beam-Beam ConnectionDocument1 pageOne Side Beam-Beam Connectionsamon.itc2019No ratings yet

- Bracing Connection Design PDFDocument3 pagesBracing Connection Design PDFriaz16shaik100% (1)

- Fin Plate ConnectionDocument2 pagesFin Plate ConnectionSudhakar Krishnamurthy100% (2)

- Bracing ConnectionsDocument3 pagesBracing ConnectionspradeeshNo ratings yet

- Isolated & Combined Footing Design BS8110.1985Document7 pagesIsolated & Combined Footing Design BS8110.1985carlosNo ratings yet

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- Shear Connections AISC 360Document64 pagesShear Connections AISC 360jatinNo ratings yet

- 0.1 Eingangskennwerte: 0.1.1 AllgemeinesDocument7 pages0.1 Eingangskennwerte: 0.1.1 AllgemeineslöliNo ratings yet

- Splice ConnectionDocument18 pagesSplice ConnectionAhmad Pooladi0% (1)

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Document30 pagesDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212No ratings yet

- Beam - Column Steel SpliceDocument22 pagesBeam - Column Steel Splicerelu59No ratings yet

- Design of Isolated Footing For Security Room: Node No. XDDocument12 pagesDesign of Isolated Footing For Security Room: Node No. XDvenu manikantaNo ratings yet

- DESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomDocument11 pagesDESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomAsaru DeenNo ratings yet

- 3 B1 B2 MeanDocument1 page3 B1 B2 MeanMaumoon SaleemNo ratings yet

- DESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Document4 pagesDESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Mahananda RKNo ratings yet

- Calc. Fillet Weld Transverse Load-Jacket ClosureDocument6 pagesCalc. Fillet Weld Transverse Load-Jacket ClosureAsep MulyadiNo ratings yet

- Isolated & Combined Footing Design Bs8110.1985Document6 pagesIsolated & Combined Footing Design Bs8110.1985EdwinNo ratings yet

- 2.2.1 - DQR EM Capacity Rev BDocument61 pages2.2.1 - DQR EM Capacity Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- RC Beam Design Using ACIDocument1 pageRC Beam Design Using ACIdantevariasNo ratings yet

- Moment Connection Design (Ver-6)Document4 pagesMoment Connection Design (Ver-6)Saurabh GuptaNo ratings yet

- IA-PB-15141-CP-1Document37 pagesIA-PB-15141-CP-1Aamir SuhailNo ratings yet

- Base Plate - Connection Plate Design-B401 - 12.08.2019Document12 pagesBase Plate - Connection Plate Design-B401 - 12.08.2019Siddharth TiwariNo ratings yet

- Beam - Column Steel SpliceDocument20 pagesBeam - Column Steel SpliceAnsh SharmaNo ratings yet

- Isolated Footing (4 Sides Wind)Document4 pagesIsolated Footing (4 Sides Wind)saiNo ratings yet

- BoltDocument1 pageBoltvishal tomarNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- PS-3 Rebar Anchoring Calculation - R01 - 21.11.2023Document1 pagePS-3 Rebar Anchoring Calculation - R01 - 21.11.2023anandswarupNo ratings yet

- Modified RatiosDocument3 pagesModified RatiosBassem KhaledNo ratings yet

- Tailing Frame DesignDocument5 pagesTailing Frame DesignfkamunityNo ratings yet

- En - 13121 - Rectangular Tank DesignDocument7 pagesEn - 13121 - Rectangular Tank DesignMAYANK CHAUHANNo ratings yet

- HR Quaters - Pad FootingsDocument14 pagesHR Quaters - Pad FootingsanushyasanjeevaniNo ratings yet

- Stub ColumnDocument4 pagesStub ColumnCHRISTOPHER EKIRAPANo ratings yet

- Splice Plate - F13.5extDocument6 pagesSplice Plate - F13.5extManish DuggadNo ratings yet

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- PS-3 Rebar Anchoring Calculation - 21.11.2023Document1 pagePS-3 Rebar Anchoring Calculation - 21.11.2023anandswarupNo ratings yet

- Base Plate (ML Gambhir)Document6 pagesBase Plate (ML Gambhir)Prakash SinghNo ratings yet

- Sheet1: Rapp Buckling Strength of Stiffened Flat Plates SH92 3014Document8 pagesSheet1: Rapp Buckling Strength of Stiffened Flat Plates SH92 3014ding liuNo ratings yet

- Review Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsDocument2 pagesReview Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsJoseph LantoNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Inner Members DesignDocument4 pagesInner Members DesignARSENo ratings yet

- Rectangular Footing F1Document4 pagesRectangular Footing F1haroon alikhanNo ratings yet

- Chumbadouros Portico Contraventamento FachadaDocument3 pagesChumbadouros Portico Contraventamento FachadaNunoSilvaNo ratings yet

- BP01Document4 pagesBP01Kumar Prasanna HNNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Circular Base PlateDocument6 pagesCircular Base Platesaptha7giriNo ratings yet

- Clip Angle Connection: Design ForcesDocument3 pagesClip Angle Connection: Design ForcesSIVAKUMARNo ratings yet

- REVIEW-MODULE 40-STRUCTURAL-ENGINEERING-Bolted-and-Welded-Connections-Review-Module-NOV2020Document3 pagesREVIEW-MODULE 40-STRUCTURAL-ENGINEERING-Bolted-and-Welded-Connections-Review-Module-NOV2020Ma Ella Mae Logronio100% (1)

- Фланцевые соединения dast v4.3 - EDocument3 pagesФланцевые соединения dast v4.3 - EZdrobau VitalieNo ratings yet

- Vertical Thrust Block Design (DN700&DN 800)Document28 pagesVertical Thrust Block Design (DN700&DN 800)ARSENo ratings yet

- Design of FootingDocument19 pagesDesign of Footingmohammad danishNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- LUG Connection160727Document1 pageLUG Connection160727chirathip vasuvattakulNo ratings yet

- CONN MacauV2 - 1226R1 LugDocument1 pageCONN MacauV2 - 1226R1 Lugchirathip vasuvattakulNo ratings yet

- CONN-MacauV2 - 1226R1-H500 Brace BeamDocument1 pageCONN-MacauV2 - 1226R1-H500 Brace Beamchirathip vasuvattakulNo ratings yet

- Member Design Eurocode-MacauDocument1 pageMember Design Eurocode-Macauchirathip vasuvattakulNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakulNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakul100% (1)

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakulNo ratings yet

- NB 06 Cat9200 Ser Data Sheet Cte enDocument42 pagesNB 06 Cat9200 Ser Data Sheet Cte enrobin11111111No ratings yet

- Gun Carriage Factory Jabalpur: Presented ByDocument17 pagesGun Carriage Factory Jabalpur: Presented Byparag_mitNo ratings yet

- Sanyog Mahajan Resume UpdatedDocument1 pageSanyog Mahajan Resume UpdatedSanyog MahajanNo ratings yet

- Osw Assignment 3Document15 pagesOsw Assignment 3DebarchanNo ratings yet

- Intl Orgs AukusDocument3 pagesIntl Orgs AukusDeepak PatilNo ratings yet

- Ped GuidelinesDocument225 pagesPed GuidelinesMatteo PeddisNo ratings yet

- ANL312 SU1 v2Document44 pagesANL312 SU1 v2Google UserNo ratings yet

- Third Product Theme Blutooth Dual SIM AdapterDocument7 pagesThird Product Theme Blutooth Dual SIM Adapterabbasarslan221No ratings yet

- Presentation On Project: Presented byDocument26 pagesPresentation On Project: Presented byAnujNo ratings yet

- Handling of Welding Consumables Procedure: Tebbin Plant Quality ControlDocument3 pagesHandling of Welding Consumables Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- Fcteg 02 632417Document5 pagesFcteg 02 632417mda mpsNo ratings yet

- Procedimiento de Embalaje y Envío de VálvulasDocument6 pagesProcedimiento de Embalaje y Envío de VálvulasБехар ТиагоNo ratings yet

- 12290/Csmt Duronto Exp Third Ac (3A)Document2 pages12290/Csmt Duronto Exp Third Ac (3A)21f1000067No ratings yet

- MIL Orinay Module2Document5 pagesMIL Orinay Module2Alexandrea OrinayNo ratings yet

- Distributed Computer ControlDocument124 pagesDistributed Computer ControlManjula SutagundarNo ratings yet

- BAMBALPITIYA PUMPING STATION - Outstanding WorkDocument3 pagesBAMBALPITIYA PUMPING STATION - Outstanding WorkShabeer Shaarim Abdul JabbarNo ratings yet

- A Discussion On Some of The Factors Affecting Well Spacing : F. M. D. CDocument10 pagesA Discussion On Some of The Factors Affecting Well Spacing : F. M. D. CHichem FakhfekhNo ratings yet

- Wiring Diagram: Keyless Entry System - Power Door Locks - Super Locking SystemDocument1 pageWiring Diagram: Keyless Entry System - Power Door Locks - Super Locking SystemAlexgavgray GNo ratings yet

- ENGDAT1 Module1 PDFDocument34 pagesENGDAT1 Module1 PDFLawrence BelloNo ratings yet

- Cullen v. Zoom Video Communications, Inc., Case 5:20-cv-02155-SVK (Northern District of California)Document23 pagesCullen v. Zoom Video Communications, Inc., Case 5:20-cv-02155-SVK (Northern District of California)Law&CrimeNo ratings yet

- 2, 5 Inch Side Door Stripper PDFDocument16 pages2, 5 Inch Side Door Stripper PDFOvRrj AhmedNo ratings yet

- Apana Black Book ProjectDocument35 pagesApana Black Book Projectpradeep dhobiNo ratings yet

- Manual Aire Acondicionado HaierDocument48 pagesManual Aire Acondicionado Haierjguerrero.067100% (3)

- Thesis Ict in EducationDocument7 pagesThesis Ict in EducationMary Calkins100% (2)

- International Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonDocument17 pagesInternational Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonGURUDAS KARNo ratings yet

- 4D Printing Technology - A ReviewDocument9 pages4D Printing Technology - A ReviewAngel Guanipa OrtizNo ratings yet

- Rodillo Tandem BomagDocument4 pagesRodillo Tandem BomagyasserNo ratings yet

- Environmental Management System ImplementationDocument40 pagesEnvironmental Management System Implementationkashif ManzoorNo ratings yet

- If The Coefficients of An Equation Are All Positive Then The Equation Has No Positive RootDocument1 pageIf The Coefficients of An Equation Are All Positive Then The Equation Has No Positive RootshantabaiNo ratings yet

- Data Science EssayDocument2 pagesData Science EssayHina ShahzadiNo ratings yet