Professional Documents

Culture Documents

Instruction Manual: Deckma Hamburg GMBH

Instruction Manual: Deckma Hamburg GMBH

Uploaded by

Miroslaw LabudaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction Manual: Deckma Hamburg GMBH

Instruction Manual: Deckma Hamburg GMBH

Uploaded by

Miroslaw LabudaCopyright:

Available Formats

INSTRUCTION MANUAL

Electric Sample and Fresh Water Valve for OMD-2008

EV-2008

DECKMA HAMBURG GmbH

Kieler Straße 316, D-22525 Hamburg - Germany

Tel.: +49 (0) 40 54 88 76-0, Fax: +49 (0) 40 54 88 76-10

Internet: www.deckma.com eMail: post@deckma.com

DECKMA HAMBURG GmbH

IMPORTANT NOTICE

Replacement components for 15ppm Bilge Alarms.

General

All monitors in our range are inspected and tested to the related I.M.O. requirements at

our factories prior to delivery.

In normal use the units should operate correctly and without fault over a long period of

time requiring only small amounts of maintenance to be carried out as outlined in the

instruction manuals.

Service Exchange Units

In the event of a monitor malfunction due to electrical or electronic component failure it

is our recommendation that a service exchange unit be ordered.

The defective instrument should be returned to our works within 30 days of supplying

the service exchange unit, then only the repair charge is payable. Otherwise the whole

cost of a service exchange unit becomes payable.

This procedure is by far the easiest and most cost effective way of ensuring the monitor

on board conforms to I.M.O. resolution MEPC.107 (49).

Remark:

According the MEPC.107(49) § 4.2.11 the unit has to be checked at IOPP Certificate

renewal survey by the manufacturer or persons authorized by the manufacturer.

Alternatively the unit may be replaced by a calibrated 15 ppm Bilge Alarm. The OMD-

2008 is designed in that way, that only the measuring cell needs to be changed, as this

unit carry the calibration onboard. The Calibration Certificate with the date of the last

calibration check should be retained onboard for inspection purposes.

If for some reasons the computer unit needs to be changed, it has to make sure, that

the memory card will remain on board for at least 18 month. The new computer unit will

carry its own memory card. The old card can be insert into the new unit only for reading.

Writing is only possible with the card delivered with the new computer unit. For details

see section 13.1.

Warranty

Our warranty terms are12 months after installation but maximal 18 months after delivery

ex works. The maker undertakes to remedy any defect resulting from faulty materials of

workmanship except wearing parts.

The maker's obligation is limited to the repairs or replacement of such defective parts by

his own plant or one of his authorized service stations.

The purchaser shall bear the cost and risk of transport of defective parts and repaired

parts supplied in replacement of such defective parts.

ANY DISMANTLING OR BREAKING OF A SEAL WILL VOID THE WARRANTY

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 2 of 14

DECKMA HAMBURG GmbH

CONTENTS

SECTION TITLE PAGE

1.0 Introduction 4

2.0 Important Notes 4

3.0 Principle of Operation 5

3.1 Operating Principle 5

3.2 Features 5

3.3 Adjustment 5

4.0 Specification 6

6.0 Installation 6

7.0 Piping 8

8.0 Wiring 9

8.1 Remote Fresh Water Switching 11

9.0 Power Supply 11

10.0 Commissioning 11

10.1 Electrical 11

10.2 Piping 11

10.3 Functional Tests 12

10.4 Programming Mode 12

11.0 Operating Instructions 13

12.0 Operator Maintenance 13

13.0 Fault Finding 13

15.0 Spare Parts 13

15.1 Recommended On Board Spares 13

16.0 Remarks 14

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 3 of 14

DECKMA HAMBURG GmbH

1.0 INTRODUCTION

The Electric Switchover Valve for the OMD-2008 Bilge Alarm has been designed

specifically for use in conjunction with the OMD-2008 Bilge Alarm Measuring

Cell. The Electrical Valve allows to switch the instrument from the sample stream

to a supply of clean, oilfree water. The fresh water can be used for cleaning and

flushing the measuring cell. The instrument will switch over to alarm condition,

but will also continue to display the measurement result. This allows a quick test

for cleanlyness and perfomance of the measuring cell.

The Electric Switchover Valve also allows remote controll for flushing.

Please note that this manual does not describe the operation of the OMD-2008

Bilge Alarm itself. Within this document the differences to the standard OMD-

2008 installation and operation are described. Refer to the OMD-2008 Manual

wherever necessary.

2.0 IMPORTANT NOTES

a) This equipment must be installed and operated in strict accordance with the

instructions contained in this manual. Failure to do so will impair the protection

provided.

b) Installation and servicing must be undertaken by a competent and suitable

skilled person.

c) The equipment must be connected to the ground according relevant

requirements.

d) The unit must be isolated from the electrical supply before any maintenance of

the equipment is attempted.

e) All National or local codes of practice or regulations must be observed and,

where applicable, are deemed to take precedence over any directive or

information contained in this manual.

f) In case of freezing conditions the device should be emptied complete.

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 4 of 14

DECKMA HAMBURG GmbH

3.0 PRINCIPLE OF OPERATION

3.1 Operating Principle

An electric valve, the EV-2008, is operated directly by the OMD-2008 Bilge

Alarm. Whenever fresh water is allowed to flow to the measuring cell, the OMD-

2008 will switch over to alarm condition as reqired by MEPC.107(49). The EV-

2008 setup replaces the manual valve setup for the standard OMD-2008.

3.2 Features

• Robust construction

• Low maintenance

• Easy installation

• Constant readiness

• Low spare part stock holding

• Easy settings via menu

3.3 Adjustment

No adjustment is required.

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 5 of 14

DECKMA HAMBURG GmbH

4.0 SPECIFICATION EV-2008

Sample pressure: 0 - 6 bar

Fresh Water pressure: 0 - 6 bar

Input connetions: R ¼" Female

Operating Voltage: 24 V, supplied by OMD-2008

Consumption: < 15 VA

(including OMD-2008)

Dimensions (with Mesuring Cell): 140 mm W x 160 mm H x 120 mm D

Weight (with Measuring Cell): 1.5 kg

Distance Up to 0.5m

(Computer Unit to Measuring Cell) Option: up to 5m upon request

Degree of Protection: IP 65

Ambient Temperature: + 1 to + 55° C

Sample Water Temperature: + 1 to + 65° C

Technical specifications are subject to change without notification

6.0 INSTALLATION (Refer to Fig. 2 and Fig. 3)

See Section 2 for important notes concerning installation.

The EV-2008 is mounted on a stainless steel support similar to the OMD-2008

measuring cell support, but with slightly different positions of the conncetion

points for both the sample stream and the clean water stream. The outlet

connection to the Measuring Cell is in the identical position. The very same

considerations as for the standard OMD-2008 would have to be recognized.

Mount the EV-2008 with the Measuring Cell onto the OMD-2008 Backplane

instead of the original Measuring Cell valve arrangement.

Care must be taken at mounting of the pipes connections to avoid any torsion of

the housing and damage of the instrument.

The Connector on top of the valve must not be removed under any

circumstances, as that requires the breaking of a seal.

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 6 of 14

DECKMA HAMBURG GmbH

360

160 160

OUTLET

ESC

+ 1/4" female

- OK

240

220

TEST SET

ON AL1 AL2 SYS

LOG

OMD-2008

CLEAN WATER

SAMPLE 1/4" female

WATER

1/4" female

ø9

Fig. 2

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 7 of 14

DECKMA HAMBURG GmbH

7.0 PIPING (Refer to Fig. 3)

Connect the Sample line to the left side input of the EV-2008. Connect the clean

water line to the right hand side input of the valve. Both inputs have 1/4” female

threads. It is recommended to employ 10 mm OD copper or stainless steel pipe.

If possible it is recommended to install a manual valve into the clean water line

next to the OMD-2008. This allows to stop any water flow through the instrument

for easy manual cleaning. No additional valve in the sample line can be allowed.

For details concerning the sampling point refer to the OMD-2008 manual.

Automatic Recirculating

Stopping Device Facilities

Overboard discharge

To Bilge To Bilge

Pressure relief valve

(if required)

Vacuum breaker

Outlet *

+

-

Separator 10 X 1mm

Copper Tube

Clean Water

Supply (Option)

Outlet Separator

To Bilge

* Inlet & Outlet connections R1/4" Female

Fig. 3

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 8 of 14

DECKMA HAMBURG GmbH

8.0 WIRING (Refer to Fig. 4 + 5)

See Section 2 for important notes concerning wiring.

The EV-2008 should be connected to the OMD-2008 via the free M16 opening.

In the case that this opening is allready occupied any of the M20 openings

should be used.

Measuring Cell Connector

M20 M20 M16

M20 M16

Cable Gland

for Valve

Fig. 4

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 9 of 14

DECKMA HAMBURG GmbH

1-2 Power Supply Power Supply Air Supply

3-4 PilotVoltage Output (Sameas Power Supply) 24V-240V AC/DC

5-7 Potential free Output Alarm 1 (Change over contact)

8-10 Potential freeOutput Alarm 2 (Change over contact)

11-12 Input Status Switch from Separator (Close when running)

13-14 Input Reserved for future use FUSE T2A

15-16 Input Flow Direction Switch (Deckma Delivery) Solenoid Valve

17-18 (Optional) Signal Output 0(4) to 20 mA 3/2 Way Valve

19-20 Input External Fresh Water Usage Request Automatic Stopping Device

21-22 Output External Fresh Water Usage Feedback

23-25 Potential free Output System Fault (Change over contact)

To Alarmsystem

(optional)

24V-240V AC/DC ALARM 1 ALARM 2

PILOT OUT

PILOT OUT

POWER SUPPLY MUST HAVE FUSE T2A

SUPPLY

SUPPLY

COM

COM

NO

NO

NC

NC

PE

PE

POWER SUPPLY 24V-240V AC/DC

LINK TERMINALS 15&16 IF NO FLOW

1 2 PE 3 4 PE 5 6 7 8 9 10

SWITCH IS PRESENT

11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

EXAMPLE

NO

COM

NC

Connections may vary

NO

COM

OUTPUT +

RESERVE

RESERVE

with different separator

OUTPUT -

STATUS

STATUS

SYSTEM

EXTERNAL REQUEST

FEEDBACK

FLOW

FLOW

FW VALVE FAULT

control boxes INPUTS

FW VALVE

Status Link if no Signal To Alarmsystem

Separator Flow Switch Output (optional)

is present 0(4)-20 mA

Fig. 5

Close front cover completly after electrical installation. Water inside the

instrument may result in corrosion and malfunction.

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 10 of 14

DECKMA HAMBURG GmbH

8.1 Remote fresh water switching

The EV-2008 allows to remotely controll the valve operation. To switch the EV-

2008 to clean water terminals 19&20 have to be linked. The OMD-2008 will

switch as requested within 20 seconds.. The EV-2008 will stay in clean water

condition, and the OMD-2008 will remain in alarm condition, as long as the link

(terminals 19&20) is present. It is recommended to use a potential free relay

switch for the link to electrically insulate the OMD-2008 from any external

voltages.

The OMD-2008 will close the FW-Valve Feedback contact (Terminals 21&22)

whenever the FW valve is set to clean water usage. The Feedback contact will

remain open (deenergized) in Sysfault conditions.

9.0 POWER SUPPLY

See Section 2 for important notes.

The EV-2008 is fully supplied from the OMD-2008.

The OMD-2008 is designed for a power supply of 24 V – 240V AC or DC. The

power supply must have a fuse rated no more then 2A.

10.0 COMMISSIONING

See Section 2 for important notes.

On completion of the installation, wiring and piping carry out the following checks:

10.1 Electrical

a) Check that the grounding has been made according to the relevant

regulations.

b) Check that the connector on top of the valve is firmly in place. Tampering with

this connector may be interpreted as an attempt for willfull manipulation of the

15ppm Bilge Alarm.

10.2 Piping

a) Check all piping connections for leaks and rectify as appropriate.

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 11 of 14

DECKMA HAMBURG GmbH

10.3 Functional Tests

a) Check sample flow with EV-2008 in sample condition. Refer to the OMD-2008

manual for details.

b) Check if there is sufficient flow in fresh water condition. If the clean water supply

is obtained from a high pressure source, the flow rate will be higher than from the

sample point.

c) During oil free water is running through the monitor check the Zero adjustment.

The display should be "0" to “2” and the status will show “FW”. If the display

varies by greater amounts, it may be that air entrainment is present. If this is the

case, the cause must be located and rectified.

d) If the Zero need to be adjusted, this can be done in the programming mode as

described in OMD-2008 manual, section 10.4. (Settings – Offset)

10.4 Programming Mode

When operated via the front panel the EV-2008 will automatically be set back to

normal operation (sample measurement) after 2 minutes of clean water flushing.

For operating the Electric FW valve press the “ON” button, select “FW FLUSH”,

change the Status to “ON”. The EV-2008 will switch over to fresh water

immediatedly, and remain in fresh water setting for 2 minutes before switching

back to normal operation. If a prolonged flushing is desired, it can be retriggered

within the 2 minutes, or repeated afterwards.

Anytime the EV-2008 is switched to fresh water, the OMD-2008 will be in alarm

condition, as required by IMO MEPC.107(49).

ON

Pressing the ON button directly Select “FW flush” if you want to To change to “ON”, press the “+”

leads into the activate the (optional) clean button. Confirm with “OK” to activate

SYSTEM-OPTIONS menu. water valve or if additional the optional clean water valve for a

information should be displayed. limited time (2 min).

Exit from information display by

pressing the ESC button.

NB: Changed values have to be confirmed by pressing the " OK " button. Otherwise the

existing values remain valid.

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 12 of 14

DECKMA HAMBURG GmbH

11.0 OPERATING INSTRUCTIONS

Instead of the manual valve for sample and clean water at the standard OMD-

2008, an OMD-2008 with EV-2008 has no manually operable valve handles. Any

operation is triggered via the front panel, or triggered remotely. The OMD-2008

will only allow overboard discharge in Normal Operation setting of the EV-2008.

12.0 Operator maintenance

See Section 2 for important notes.

The EV-2008 requires no additional operator maintenance. For OMD-2008

operator maintenance refer to the OMD-2008 manual.

13.0 Fault finding

The OMD-2008 will indicate several malfunctions in the status line of the display.

Pressing the “OK” button will lead into an information window, similar to the items

listed in the table below. For OMD-2008 error messages check the OMD-2008

manual.

The EV-2008 operation may introduce one additional error condition, a persistent

“FW!” status message with OMD-2008 Alarm condition.

Status Reading System-Alarm- Alarm- Reason Servicing

LED circuit 1,2

FW ! 0..49 / EE Green / Blinking Alarm remote freshwater input remove/check external

is linked wiring

(Terminals 19&20)

EVALVE? any red Alarm FW valve position not check connectors and

detected wiring

15.0 spare parts

When ordering spares, it is important to supply details of the type of monitor, part

number of each spare required, its description and any relevant serial number.

The EV-2008 should not be dismanteled, in case of any malfunction it should be

replaced.

DESCRIPTION ART-NUMBER

Electric Valve for OMD-2008 EV-2008 13218

15.1 Recommended On Board Spares

The EV-2008 should not be dismanteled. In case of any malfunction it should be

replaced.

DESCRIPTION ART-NUMBER

Electric Valve for OMD-2008 EV-2008 13218

16.0 REMARKS

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 13 of 14

DECKMA HAMBURG GmbH

All the modifications and deviations from the standard form, which have to be

carried out in the supply, should be attached at this paragraph.

Commissioned on: ............................. by: ..........................................

Date Firm's Name

Remarks:

Issue: 02.06.2010 Prelimnary Instruction Manual EV-2008 Page 14 of 14

You might also like

- 1102v-4g EuropaDocument75 pages1102v-4g EuropaΜερκουρηςκαπαNo ratings yet

- Instruction Manual - ADB MCR3Document150 pagesInstruction Manual - ADB MCR3Daniel Chan100% (2)

- CONTROL UNIT TMC - 230 - /11: DM - TurretsDocument22 pagesCONTROL UNIT TMC - 230 - /11: DM - TurretsVladimir100% (4)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Panamatic Optima 2 ExportDocument59 pagesPanamatic Optima 2 ExportmichelRamirez100% (3)

- Statement From Head of School John McWilliamsDocument5 pagesStatement From Head of School John McWilliamsMontgomery AdvertiserNo ratings yet

- The Woman Speaks To The Man Who Has Employed Her SonDocument3 pagesThe Woman Speaks To The Man Who Has Employed Her SonSerena SulawammotNo ratings yet

- Manual SmartcellDocument34 pagesManual Smartcelldwight ferrer100% (1)

- SR03 01Mk2 DataSheet Rev4Document4 pagesSR03 01Mk2 DataSheet Rev4Miroslaw LabudaNo ratings yet

- Hydraulic Axial Piston Eaton Vickers PVB Pump: - Basic CharacteristicsDocument13 pagesHydraulic Axial Piston Eaton Vickers PVB Pump: - Basic Characteristicsjose alberto olvera gomezNo ratings yet

- Instruction Manual: Deckma Hamburg GMBHDocument14 pagesInstruction Manual: Deckma Hamburg GMBHLuke WilsonNo ratings yet

- Instruction Manual: Deckma Hamburg GMBHDocument28 pagesInstruction Manual: Deckma Hamburg GMBHSarath MoozhiyilNo ratings yet

- Manual Omd-24ev Eng Mai2014Document28 pagesManual Omd-24ev Eng Mai2014sajeev vinuNo ratings yet

- Manual Inst Ows Amita 1Document29 pagesManual Inst Ows Amita 1Shahrul ShafiqNo ratings yet

- nvf2gs SeriesDocument115 pagesnvf2gs SeriesGerardoNo ratings yet

- NVF2G-S User ManualDocument116 pagesNVF2G-S User Manualreygnzlz157No ratings yet

- OMD 2005 ManualDocument33 pagesOMD 2005 ManualFootie11No ratings yet

- Omd 11 eDocument22 pagesOmd 11 eBenja87100% (3)

- Varia Dor HLP Vho LipDocument175 pagesVaria Dor HLP Vho LipJOHN HARVEY LOPEZ A.No ratings yet

- SDS 4000 PDFDocument76 pagesSDS 4000 PDFAdan SolanoNo ratings yet

- CM501 ElectricDocument28 pagesCM501 ElectricWaldo GutierrezNo ratings yet

- A500 Ista500 r1Document72 pagesA500 Ista500 r1Orlando Ossandon G.No ratings yet

- Mod 3-15ktl3-x User Manual en 202303Document34 pagesMod 3-15ktl3-x User Manual en 202303whoru320No ratings yet

- Freno Electronico Man - VB400-6 - 25 - 30LT - GBDocument26 pagesFreno Electronico Man - VB400-6 - 25 - 30LT - GBDiego DiegoNo ratings yet

- China Deyuan Marine Fitting Co., LTDDocument15 pagesChina Deyuan Marine Fitting Co., LTDAicky IkrackNo ratings yet

- SE Minera GMX Oil Transformer Installation O&M ManualDocument20 pagesSE Minera GMX Oil Transformer Installation O&M ManualnooruddinkhanNo ratings yet

- Rivertrace Manual 2015 - SseDocument44 pagesRivertrace Manual 2015 - SseRomankoNo ratings yet

- Softstarter Versistart Ii 3 ... 15L.. Assembly-And Commissioning InstructionsDocument22 pagesSoftstarter Versistart Ii 3 ... 15L.. Assembly-And Commissioning InstructionsmiksuamarNo ratings yet

- Installation and Operation Manual - Growatt - MOD 3 15KTL3 X - Inverters - 2021 - ENGDocument30 pagesInstallation and Operation Manual - Growatt - MOD 3 15KTL3 X - Inverters - 2021 - ENGMarius Constantin VochinNo ratings yet

- 5 - Manual Software DuplomaticDocument53 pages5 - Manual Software DuplomaticLuiz Gustavo Pastrello100% (1)

- Service: Mammolux R2Document46 pagesService: Mammolux R2man12757No ratings yet

- Manual US DeyeDocument56 pagesManual US DeyeRoman Mikhail Pak Balitskiy100% (1)

- MHC-V9W-D2N8 Owners Installation Manual ENGDocument91 pagesMHC-V9W-D2N8 Owners Installation Manual ENGZSOLT PULAINo ratings yet

- Pump Condition MonitorDocument30 pagesPump Condition Monitorsan droidNo ratings yet

- Moog ServoDrives DS2000 Manual enDocument142 pagesMoog ServoDrives DS2000 Manual enBojan MarkovićNo ratings yet

- Sun 5 25k sg01hp3 Eu Am2Document54 pagesSun 5 25k sg01hp3 Eu Am2badze1974No ratings yet

- Manual SA-MAX500 Manual de Servicio PDFDocument133 pagesManual SA-MAX500 Manual de Servicio PDFAbel GaunaNo ratings yet

- MOD 3-15KTL3-X User ManualDocument31 pagesMOD 3-15KTL3-X User ManualZain RizviNo ratings yet

- Panasonic Sa-Akx77lm-K SMDocument104 pagesPanasonic Sa-Akx77lm-K SMLesther GonzálezNo ratings yet

- 【b】30240301001283 使用说明书 储能单相 sun (5 8) k sg01lp1 us eu 德业英文Document56 pages【b】30240301001283 使用说明书 储能单相 sun (5 8) k sg01lp1 us eu 德业英文nguyenvancuong12051999No ratings yet

- pj500m CDocument110 pagespj500m CJose VelasquezNo ratings yet

- 109080-q Smart Cell - Bilge - ManualDocument29 pages109080-q Smart Cell - Bilge - Manualabuzer1981No ratings yet

- 【b】30240301001390 使用说明书 储能单相 sun (12 16) k sg01lp1 eu 德业英文 封面彩印 封面封底157g 内页70g铜版纸 142.5x210mm ver2.2Document48 pages【b】30240301001390 使用说明书 储能单相 sun (12 16) k sg01lp1 eu 德业英文 封面彩印 封面封底157g 内页70g铜版纸 142.5x210mm ver2.2Fajar Alam PriambudyNo ratings yet

- 109080-x Smart Cell - Bilge - Manual High ResDocument36 pages109080-x Smart Cell - Bilge - Manual High ResDandy IkhwalNo ratings yet

- Instruction Manual: Deckma Hamburg GMBHDocument25 pagesInstruction Manual: Deckma Hamburg GMBHabuzer1981No ratings yet

- SUN 5K 12K - SG04LP3 EU - ManualDocument51 pagesSUN 5K 12K - SG04LP3 EU - Manualmaxim.kov4No ratings yet

- Instructions Sun 5 12k Sg04lp3 Eu 240203 enDocument53 pagesInstructions Sun 5 12k Sg04lp3 Eu 240203 enSyno LogyNo ratings yet

- Profi CN-15-01 - PRXL - SM-22778-002-ENDocument88 pagesProfi CN-15-01 - PRXL - SM-22778-002-ENRui OliveiraNo ratings yet

- Installation and Operation Manual: Cover - MAEN959.fm Page 1 Friday, August 29, 2008 2:23 PMDocument29 pagesInstallation and Operation Manual: Cover - MAEN959.fm Page 1 Friday, August 29, 2008 2:23 PMJorge Nieto PrietoNo ratings yet

- Operating Instructions: VLT HVAC Drive FC 102, 1.1-90 KWDocument94 pagesOperating Instructions: VLT HVAC Drive FC 102, 1.1-90 KWHoàng Xuân DiệmNo ratings yet

- Ho-Np SeriesDocument15 pagesHo-Np SeriespeterNo ratings yet

- MOD 3 10KTL3 XH User Manual ENDocument29 pagesMOD 3 10KTL3 XH User Manual ENAfzaal AhmadNo ratings yet

- 【b】使用说明书 储能单相 sun (3.6 6) k sg03lp1 eu 德业英文 封面彩印 封面封底157g 内页70g铜版纸 142.5x210mm ver2.2 新机壳Document51 pages【b】使用说明书 储能单相 sun (3.6 6) k sg03lp1 eu 德业英文 封面彩印 封面封底157g 内页70g铜版纸 142.5x210mm ver2.2 新机壳Sébastien PaumierNo ratings yet

- Frenic-Eco - Frn-F1: Starting GuideDocument49 pagesFrenic-Eco - Frn-F1: Starting GuideStefan HodanNo ratings yet

- Dutypoint Electromagnetic Water Conditioners OM ManualDocument8 pagesDutypoint Electromagnetic Water Conditioners OM ManualDouglas AraujoNo ratings yet

- Microprocessor Controlled Constant Current Regulator: AM.07.360e Edition 2.1Document150 pagesMicroprocessor Controlled Constant Current Regulator: AM.07.360e Edition 2.1أبو أنس المسلمNo ratings yet

- Sd2ma (E Phaa Esda01)Document111 pagesSd2ma (E Phaa Esda01)ngocanh_songlongNo ratings yet

- VLT HVAC Drive FC 102 Operating InstructionsDocument94 pagesVLT HVAC Drive FC 102 Operating Instructionsduycang NguyentanleNo ratings yet

- 스미토모 리치Document360 pages스미토모 리치01033948385pjhNo ratings yet

- DS400 UkDocument34 pagesDS400 UkGerardo Navarro CastilloNo ratings yet

- D Series - Year 2003 - DL1640CAADocument101 pagesD Series - Year 2003 - DL1640CAAgustavoorsoNo ratings yet

- Dayliff Sunverter B Installation and Operation ManualDocument40 pagesDayliff Sunverter B Installation and Operation ManualKelvinNo ratings yet

- Manual Soft Starter PSD370 5309699-1Document22 pagesManual Soft Starter PSD370 5309699-1Marcos AldrovandiNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Phe Port Filter Leaflet PDFDocument2 pagesPhe Port Filter Leaflet PDFMiroslaw Labuda100% (1)

- Main Bearing Desing Update Man BWDocument21 pagesMain Bearing Desing Update Man BWMiroslaw LabudaNo ratings yet

- Steps For Welding Railroad Tracks - Railroad Thermite WeldingDocument7 pagesSteps For Welding Railroad Tracks - Railroad Thermite WeldingMiroslaw LabudaNo ratings yet

- Lead Acid Battery Wet SDS 01897 Un2794 01022017Document7 pagesLead Acid Battery Wet SDS 01897 Un2794 01022017Miroslaw LabudaNo ratings yet

- HG50 MCCB EngDocument1 pageHG50 MCCB EngMiroslaw LabudaNo ratings yet

- Sqarede07204 5 6 PDFDocument2 pagesSqarede07204 5 6 PDFMiroslaw LabudaNo ratings yet

- Electrical Wire, Cable, and Cord: 1-99 Ft. $3.84 Per Ft. 100 or More $2.96 Per FTDocument1 pageElectrical Wire, Cable, and Cord: 1-99 Ft. $3.84 Per Ft. 100 or More $2.96 Per FTMiroslaw LabudaNo ratings yet

- 7936A TechdataDocument3 pages7936A TechdataMiroslaw LabudaNo ratings yet

- Belden 4-0 95mm DatashetDocument3 pagesBelden 4-0 95mm DatashetMiroslaw LabudaNo ratings yet

- 731 Nyy oDocument2 pages731 Nyy oMiroslaw LabudaNo ratings yet

- SR03 01Mk2 Summary of FeaturesDocument1 pageSR03 01Mk2 Summary of FeaturesMiroslaw LabudaNo ratings yet

- Save Time and Money: Model SR03-01Mk2Document8 pagesSave Time and Money: Model SR03-01Mk2Miroslaw LabudaNo ratings yet

- DC-DC CONVERTER Pyb20-1312957-SDocument2 pagesDC-DC CONVERTER Pyb20-1312957-SMiroslaw LabudaNo ratings yet

- Series PV Dimensions: Axial Piston PumpDocument2 pagesSeries PV Dimensions: Axial Piston PumpMiroslaw LabudaNo ratings yet

- 482TC/ST: Catalog 4400 US Hydraulic HoseDocument1 page482TC/ST: Catalog 4400 US Hydraulic HoseMiroslaw LabudaNo ratings yet

- 421 and 482TC/ST Braided Hydraulic HoseDocument1 page421 and 482TC/ST Braided Hydraulic HoseMiroslaw LabudaNo ratings yet

- Data Sheet 6ES7331-7KF02-0AB0: Supply VoltageDocument5 pagesData Sheet 6ES7331-7KF02-0AB0: Supply VoltageMiroslaw LabudaNo ratings yet

- Parker Hose 381-2SNDocument1 pageParker Hose 381-2SNMiroslaw LabudaNo ratings yet

- Navtex Connections-SDocument1 pageNavtex Connections-SMiroslaw LabudaNo ratings yet

- Parker Hose 462-492Document1 pageParker Hose 462-492Miroslaw LabudaNo ratings yet

- Parker Hose 471-2SCDocument1 pageParker Hose 471-2SCMiroslaw LabudaNo ratings yet

- Gauge Glass - McMaster-Carr 2Document4 pagesGauge Glass - McMaster-Carr 2Miroslaw LabudaNo ratings yet

- File 725200881303 AM63Document70 pagesFile 725200881303 AM63Miroslaw LabudaNo ratings yet

- 4NES-14Y Bitzer 4NCS-12.2YDocument13 pages4NES-14Y Bitzer 4NCS-12.2YMiroslaw LabudaNo ratings yet

- 15/10 Amp Rating, 300/600 Volts: 70-464-1 SocketDocument3 pages15/10 Amp Rating, 300/600 Volts: 70-464-1 SocketMiroslaw LabudaNo ratings yet

- 12T5. DataSheetDocument7 pages12T5. DataSheetMiroslaw LabudaNo ratings yet

- 75 Watt HE Triple Series DC/DC Converters: FeaturesDocument4 pages75 Watt HE Triple Series DC/DC Converters: FeaturesMiroslaw LabudaNo ratings yet

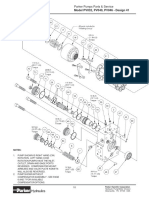

- Exploded View PV032Document7 pagesExploded View PV032Miroslaw LabudaNo ratings yet

- 8.3.5 Supported Interface SentencesDocument1 page8.3.5 Supported Interface SentencesMiroslaw LabudaNo ratings yet

- John White Videos of Spooky2 InterfaceDocument24 pagesJohn White Videos of Spooky2 InterfaceTimothy M HallNo ratings yet

- Interpreting Asphalt Test Results: Danny Gierhart, P.E. Asphalt Institute Regional Engineer Tuttle, OklahomaDocument65 pagesInterpreting Asphalt Test Results: Danny Gierhart, P.E. Asphalt Institute Regional Engineer Tuttle, OklahomaMaríaAlejandraNo ratings yet

- Aisyah Fadiyah - SPEECH DRAFTDocument5 pagesAisyah Fadiyah - SPEECH DRAFTAisyah FawNo ratings yet

- Blue Bead McqsDocument11 pagesBlue Bead Mcqsanu minochaNo ratings yet

- PSP Assignment1Document25 pagesPSP Assignment1B BasitNo ratings yet

- Microsoft Word - ETERSET 2960-2 - MSDSDocument5 pagesMicrosoft Word - ETERSET 2960-2 - MSDSWinsonLimHuiWahNo ratings yet

- Vespa S 125 3V Ie 150 3V Ie UPUTSTVODocument90 pagesVespa S 125 3V Ie 150 3V Ie UPUTSTVOdoughstoneNo ratings yet

- A Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFDocument10 pagesA Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFNocifLyesNo ratings yet

- Thermocouple Calibration FurnaceDocument4 pagesThermocouple Calibration FurnaceAHMAD YAGHINo ratings yet

- Towncall Rural Bank, Inc.: To Adjust Retirement Fund Based On Retirement Benefit Obligation BalanceDocument1 pageTowncall Rural Bank, Inc.: To Adjust Retirement Fund Based On Retirement Benefit Obligation BalanceJudith CastroNo ratings yet

- Training - Cga ApplicationDocument34 pagesTraining - Cga ApplicationSubhan Muhammad100% (1)

- Emotional IntelligenceDocument43 pagesEmotional IntelligenceMelody ShekharNo ratings yet

- Sec3 Well Spud and Guide StructuresDocument15 pagesSec3 Well Spud and Guide StructuresDonald StraubNo ratings yet

- Internet Article Showing Utah DCFS Ordered To Implement Changes in Lawsuit-1Document7 pagesInternet Article Showing Utah DCFS Ordered To Implement Changes in Lawsuit-1Roch LongueépéeNo ratings yet

- American FoodDocument10 pagesAmerican FoodEvan BanksNo ratings yet

- Material Sub Group Item CodeDocument2,818 pagesMaterial Sub Group Item Codegouri gouriNo ratings yet

- BRS TestDocument2 pagesBRS TestMuhammad Ibrahim KhanNo ratings yet

- Mother's Personality and Its Interaction With Child Temperament As Predictors of Parenting BehaviorDocument12 pagesMother's Personality and Its Interaction With Child Temperament As Predictors of Parenting BehaviorMichelle PajueloNo ratings yet

- Ethics in HRMDocument7 pagesEthics in HRMVinay RamaneNo ratings yet

- T N M M T N M M: HE EW Essies Anual HE EW Essies AnualDocument8 pagesT N M M T N M M: HE EW Essies Anual HE EW Essies AnualMunna100% (1)

- Dietary Computation For Pregnant ClientDocument12 pagesDietary Computation For Pregnant ClientLuis WashingtonNo ratings yet

- Frenkel's ExerciseDocument40 pagesFrenkel's ExerciseManiu EmeseNo ratings yet

- S100X220YAJ Panduit Datasheet 5314981Document2 pagesS100X220YAJ Panduit Datasheet 5314981Ilham MaurizaNo ratings yet

- Medical Entrance Exam - 2022: Test No. 3Document20 pagesMedical Entrance Exam - 2022: Test No. 3soyel afridiNo ratings yet

- Chapter4 Questions WithoutSupersonicDocument5 pagesChapter4 Questions WithoutSupersonicsh1999No ratings yet

- Lesson 3 Characteristics of Properly Designed PCBDocument11 pagesLesson 3 Characteristics of Properly Designed PCBJosephine QuinnNo ratings yet