Professional Documents

Culture Documents

Gears Spur Agma SI v0

Gears Spur Agma SI v0

Uploaded by

PuBg PrO0 ratings0% found this document useful (0 votes)

11 views5 pagesThe document contains technical specifications and calculations for gear design using the AGMA method, including properties of the pinion and gear such as number of teeth, module, material properties, and factors used to calculate stresses and safety factors. Computations are shown for transmitted load, bending stresses, contact stresses, and safety factors for both the pinion and gear. Charts are also included providing coefficients for different types of gear configurations.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document contains technical specifications and calculations for gear design using the AGMA method, including properties of the pinion and gear such as number of teeth, module, material properties, and factors used to calculate stresses and safety factors. Computations are shown for transmitted load, bending stresses, contact stresses, and safety factors for both the pinion and gear. Charts are also included providing coefficients for different types of gear configurations.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views5 pagesGears Spur Agma SI v0

Gears Spur Agma SI v0

Uploaded by

PuBg PrOThe document contains technical specifications and calculations for gear design using the AGMA method, including properties of the pinion and gear such as number of teeth, module, material properties, and factors used to calculate stresses and safety factors. Computations are shown for transmitted load, bending stresses, contact stresses, and safety factors for both the pinion and gear. Charts are also included providing coefficients for different types of gear configurations.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 5

Notes:

Shigley's Mech Engg Design 10th Edition

Enter data in cells with this background color

Results are displayed in cells with this background color

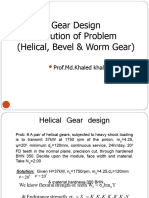

Gear design AGMA method

pressure angle, fn 20 ° 0.349 rads sin(f) 0.342 cos(f) 0.940

Number of Pinion Teeth, NP 25

Number of Gear Teeth, NG 85

Module, m 2 mm

Power transmitted, H 240 W

Speed of pinion, n 150 rpm

Material, Grade 1

Face width, b 20 mm

Brinnel Hardness no. of pinion, (HB)P 225

Brinnel Hardness no. of Gear, (HB)G 225

Quality number, Qv 6

Life in number of cycles, N 1.00E+08 cycles

Reliability, R 0.99

Speed ratio, mG 3.4

Pitch diameter of Pinion, dP 50 mm

Pitch diameter of Gear, dG 170 mm

pitch line velocity, V 0.2617994 m/sec

Transmitted load, Wt 611.15498 N Eq 13-36

Temperature factor, Yq 1

Overload factor, Ko 1

Surface condition factor, ZR 1

Rim-thickness factor, KB 1

B 0.8254818 𝐴=50+56(1−𝐵)

Eq 14-28 𝐵=0.25(12−𝑄_𝑣 )^(2/3)

A 59.772

Velocity factor, Kv 1.0989243 𝐾_𝑣={((𝐴+√𝑉)/𝐴)^𝐵¦((𝐴+√200𝑉)/𝐴)^𝐵

Eq 14-27 (𝑉 "in ft/min" )¦(𝑉 "in m/sec" )┤

Maximum pitch line velocity, (Vt)max 19.70162 OK Eq 14-29

Lewis shape factor for Pinion, (Y)P 0.365

Tbl 14-2

Lewis shape factor for Gear, (Y)G 0.4225 interpolate

Size factor, (Ks)P 1.000

Size factor, (Ks)G 1.004

Ce 1 Eq 14-35

Cpm 1 Eq 14-33

Cpf 0.025 Eq 14-32

Cmc 1 Eq 14-31

A 0.247

B 0.0167 Tbl 14-9

C 0.765

Cma 0.2601022 Eq 14-34

KH 1.2851022 Eq 14-30

Stress cycle factor for Pinion, (YN)P 0.977

Fig 14-14

Stress cycle factor for Gear, (YN)G 0.998

Bending-Strength Geometry Factor for Pinion, (YJ)P 0.33

Fig 14-6

Bending-Strength Geometry Factor for Gear, (YJ)G 0.38

Reliability factor, YZ 1.008 Eq 14-38

Load sharing ratio, mN 1.000 for Spur gears, in case of helical gears Eq 14-21 to Eq 14-26 are applied

Surface-Strength Geometry Factor, ZI 0.124 Eq 14-23 External gears

Elastic coefficient, ZE 191 sqrt(MPa) Tbl 14-8

Allowable Bending stress Number for Pinion, (St)P 208.225 MPa 0.533

Fig 14-2

Allowable Bending stress Number for Gear, (St)G 208.225 MPa 88.3

Allowable Contact stress Number for Pinion, (St)P 699.5 MPa 2.22

Fig 14-5

Allowable Contact stress Number for Gear, (St)G 699.5 MPa 200

Stress cycle factor for Pinion, (ZN)P 0.948 1.4488

Fig 14-15

Stress cycle factor for Gear, (ZN)G 0.976 -0.0230

Hardness-Ratio Factor, Zw 1 Fig 14-12

Pinion tooth Bending Stress, (s)P 65.39 MPa Eq 14-15

Gear tooth Bending Stress, (s)G 57.00 MPa Eq 14-15

Pinion tooth Safety Factor against Bending Stress, (SF)P 3.09 Eq 14-41

Gear tooth Safety Factor against Bending Stress, (SF)G 3.62 Eq 14-41

Pinion tooth Contact Stress, (sc)P 503.55 MPa Eq 14-16

Gear tooth Contact Stress, (sc)G 504.53 MPa Eq 14-16

Pinion tooth Safety Factor against Contact Stress, (SH)P 1.31 Eq 14-42

Gear tooth Safety Factor against Contact Stress, (SH)G 1.34 Eq 14-42

A B C

Open gearing 0.247 6.57E-04 -1.19E-07

AGMA-2101-

Commercial, enclosed units 0.127 6.22E-04 -1.69E-07

D04 pg. 22

Precision, enclosed units 0.0675 5.04E-04 -1.44E-07

Extraprecision enclosed gear units 0.038 4.02E-04 -1.27E-07

You might also like

- Trach Care ChecklistDocument2 pagesTrach Care ChecklistZycerlyn Alicaway100% (4)

- The Breakup CureDocument168 pagesThe Breakup CureMladen Muskinja100% (2)

- Gear Agma IIDocument49 pagesGear Agma IInathNo ratings yet

- 4 - Spur GearsDocument8 pages4 - Spur GearsAnil YildizNo ratings yet

- Worm Gear Efficiency CalculationDocument6 pagesWorm Gear Efficiency CalculationVenkateswaran venkateswaranNo ratings yet

- MMB411-Tutorial Gears04 SpurGears-Bending&Fatigue PDFDocument26 pagesMMB411-Tutorial Gears04 SpurGears-Bending&Fatigue PDFNdivhuwo NdivhuwoNo ratings yet

- Chap 7 - Worm DriveDocument33 pagesChap 7 - Worm DriveHuỳnh Nguyễn Thiên TânNo ratings yet

- AISC (ASD) Shear Connection - Cleat AngleDocument15 pagesAISC (ASD) Shear Connection - Cleat AngleMANOJNo ratings yet

- Chapter 14 PDFDocument6 pagesChapter 14 PDFRui JiNo ratings yet

- Column Design ExcelDocument10 pagesColumn Design ExcelMasoud OsamyNo ratings yet

- Bending Stress CalculationsDocument4 pagesBending Stress Calculationsschaali100% (5)

- TSV CalculationDocument3 pagesTSV CalculationAymen Khlifi100% (1)

- Stress ClsDocument3 pagesStress ClsSivaramanNo ratings yet

- POT Design R0Document9 pagesPOT Design R0VB665No ratings yet

- Worm Gear Efficiency and Motor Stall Torque Relation CalculationDocument8 pagesWorm Gear Efficiency and Motor Stall Torque Relation CalculationVenkateswaran venkateswaranNo ratings yet

- DC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525Document1 pageDC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525NewsUPdateNo ratings yet

- Part BDocument3 pagesPart BbshahihdNo ratings yet

- LiftingLug TrunnionDocument22 pagesLiftingLug Trunnionrichardchiam100% (2)

- ColumnDocument123 pagesColumnMaheshNo ratings yet

- Shaft Calculations As Per Shigley - 17.01.17Document10 pagesShaft Calculations As Per Shigley - 17.01.17gopi_ggg20016099No ratings yet

- Base Plate Design by Is CodeDocument134 pagesBase Plate Design by Is CodeStructural Spreadsheets100% (1)

- Spur Gear CalculationsDocument7 pagesSpur Gear Calculationsaniket patilNo ratings yet

- Group 1 Gearbox Design ReportDocument15 pagesGroup 1 Gearbox Design Reportapi-598255067No ratings yet

- Aisc 360Document10 pagesAisc 360ramon rodriguezNo ratings yet

- Calc. AF-28.00-0300-WN-001 20150518 OSF Rev.1 It3-4Document1 pageCalc. AF-28.00-0300-WN-001 20150518 OSF Rev.1 It3-4andi suntoroNo ratings yet

- Piling CaaaaapacitiDocument1 pagePiling Caaaaapacitiprompt consortiumNo ratings yet

- Theory and Design of Mechanical Systems ProjectDocument27 pagesTheory and Design of Mechanical Systems ProjectSneha Girish ShirsatNo ratings yet

- Perhitungan Shaft Pulley ConveyorDocument5 pagesPerhitungan Shaft Pulley ConveyorRiska DamayantiNo ratings yet

- Sandy Drifterz, Vcet: Madurai, Tamil NaduDocument15 pagesSandy Drifterz, Vcet: Madurai, Tamil NaduNaveenNo ratings yet

- MASILANG-Module 3 Activity No. 1Document2 pagesMASILANG-Module 3 Activity No. 1PHILIPANTHONY MASILANGNo ratings yet

- Anchor Bolt Design IS Code LSDDocument56 pagesAnchor Bolt Design IS Code LSDajNo ratings yet

- Gearing AgmaDocument17 pagesGearing AgmaDomingos AzevedoNo ratings yet

- Gear - SolutionDocument32 pagesGear - SolutionR PNo ratings yet

- Handrail Coring Check (Calculation)Document56 pagesHandrail Coring Check (Calculation)Rey GonzalesNo ratings yet

- PT10'' BodegaDocument2 pagesPT10'' BodegaIvan PorrasNo ratings yet

- Base Plate Design - Rev-0Document15 pagesBase Plate Design - Rev-0KINGSUK PALNo ratings yet

- Varaible 2Document2 pagesVaraible 2Ivan PorrasNo ratings yet

- Studding FlangeDocument6 pagesStudding FlangeDarshan PanchalNo ratings yet

- Astorga Entrada ConicosDocument3 pagesAstorga Entrada ConicosGadiel BalderasNo ratings yet

- ETABS Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Document2 pagesETABS Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)statikaNo ratings yet

- Project PLTMH Tangka Rev 00 Part Name Steer DesignDocument2 pagesProject PLTMH Tangka Rev 00 Part Name Steer Designyoyok isbanuNo ratings yet

- Base Plate Design - Rev-0Document8 pagesBase Plate Design - Rev-0KINGSUK PALNo ratings yet

- Final ExamDocument6 pagesFinal ExamazoozNo ratings yet

- 7B - Gears-B - (FUE) - Spur GearDocument14 pages7B - Gears-B - (FUE) - Spur GearKNNo ratings yet

- PT8'' EdificioDocument2 pagesPT8'' EdificioIvan PorrasNo ratings yet

- KBC 2016 RHS SectionDocument1 pageKBC 2016 RHS SectionMoon AhaeNo ratings yet

- Example Problem 6.1Document30 pagesExample Problem 6.1rikanazmiliaNo ratings yet

- Tubing Performance Relationship: Input DataDocument30 pagesTubing Performance Relationship: Input DatarikanazmiliaNo ratings yet

- Differential Pressure Flow Element - Case 2-24in - 50000Document3 pagesDifferential Pressure Flow Element - Case 2-24in - 50000Mohammad TaherNo ratings yet

- V-340 OutDocument14 pagesV-340 OutSachin5586No ratings yet

- Ejemplo de Engranajes HelicoidalesDocument2 pagesEjemplo de Engranajes HelicoidalesMijhael Anatholi Romero MamaniNo ratings yet

- T M B D Z M: Pitting StrengthDocument6 pagesT M B D Z M: Pitting StrengthprasannaNo ratings yet

- Mod10 1ToothBendingDocument4 pagesMod10 1ToothBendingMario AndradeNo ratings yet

- Caja Reductora 2da EtapaDocument2 pagesCaja Reductora 2da EtapaEdwin Paco PovedaNo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- Motor SpecsDocument1 pageMotor SpecsDaniel SitumeangNo ratings yet

- Construction and Analysis of Generator Actual Capability Curves Using The New MethodDocument11 pagesConstruction and Analysis of Generator Actual Capability Curves Using The New MethodMuthukumar SivaramanNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu Yangtze0% (1)

- Gas Flow Calculation AGA3Document1 pageGas Flow Calculation AGA3ijaz ahmadNo ratings yet

- Lifting LugDocument8 pagesLifting LugEnrique BarajasNo ratings yet

- ME364-04 Spur Helical GearsDocument67 pagesME364-04 Spur Helical GearsPuBg PrONo ratings yet

- ME364-06a Revision 2 Plane BendingDocument55 pagesME364-06a Revision 2 Plane BendingPuBg PrONo ratings yet

- A Critical Review and Analysis of Pressure Vessel StructuresDocument12 pagesA Critical Review and Analysis of Pressure Vessel StructuresPuBg PrONo ratings yet

- ME364-06 Shafts and ComponentsDocument53 pagesME364-06 Shafts and ComponentsPuBg PrONo ratings yet

- Cafco ® Fendolite Mii: Application GuideDocument27 pagesCafco ® Fendolite Mii: Application GuideAhmed LepdaNo ratings yet

- American MFG Axg FG Axg Parts BookDocument19 pagesAmerican MFG Axg FG Axg Parts BookmarkNo ratings yet

- Ppgj-Pro-Cal-184 Hot Oil Transfer Pump (P-1001 A&b)Document8 pagesPpgj-Pro-Cal-184 Hot Oil Transfer Pump (P-1001 A&b)Tifano KhristiyantoNo ratings yet

- BCH 201Document6 pagesBCH 201Ayomiposi OloyedeNo ratings yet

- (Ijcst-V9i2p6) :p.deepa, V.subitha Varshini, D.vennila, V.harithaDocument4 pages(Ijcst-V9i2p6) :p.deepa, V.subitha Varshini, D.vennila, V.harithaEighthSenseGroupNo ratings yet

- Methodology For Definition of Bending Radius and Pullback Force in HDD Operations Danilo Machado L. Da Silva, Marcos V. Rodrigues, Asle Venås Antonio Roberto de MedeirosDocument8 pagesMethodology For Definition of Bending Radius and Pullback Force in HDD Operations Danilo Machado L. Da Silva, Marcos V. Rodrigues, Asle Venås Antonio Roberto de MedeirosMAHESH CHAND100% (1)

- Data Sheet ST ESTABILIZADORDocument3 pagesData Sheet ST ESTABILIZADORJuan Antonio Barco MorenoNo ratings yet

- FOSG Quality StandardsDocument1 pageFOSG Quality Standardspandey008No ratings yet

- Premio 20 DTDocument35 pagesPremio 20 DThyakueNo ratings yet

- Scouts and Nature: "Nature Study Is The Key Activity in Guiding and Scouting"-Baden PowellDocument5 pagesScouts and Nature: "Nature Study Is The Key Activity in Guiding and Scouting"-Baden PowellDinnar Diandra ATNo ratings yet

- MAR 20 2Q15:: Department of Public Works and HighwaysDocument6 pagesMAR 20 2Q15:: Department of Public Works and HighwaysFaustino AbadNo ratings yet

- CoffeemakerDocument25 pagesCoffeemakersunilsainiNo ratings yet

- The Origin of Evil and The End of The WorldDocument8 pagesThe Origin of Evil and The End of The WorldLloyd Graham100% (4)

- Cirrus 5 Oxygen Concentrator Manual: Important: Make Sure You Read and Understand All of The InformationDocument21 pagesCirrus 5 Oxygen Concentrator Manual: Important: Make Sure You Read and Understand All of The Informationmario pulido benitezNo ratings yet

- Color 1 Color 2 Color 3 Color 4 Color 5: DegradadoDocument4 pagesColor 1 Color 2 Color 3 Color 4 Color 5: DegradadoVentura ArgotaNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument19 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsBendaud bataborNo ratings yet

- Teacher Resource Bank: GCE Physics A Sample A2 ISA: Damped Harmonic Motion - Question PaperDocument9 pagesTeacher Resource Bank: GCE Physics A Sample A2 ISA: Damped Harmonic Motion - Question PaperAbdul-Ahad LockhartNo ratings yet

- ECE 102 Child Development I Prental Infancy NOT VETTED 2Document115 pagesECE 102 Child Development I Prental Infancy NOT VETTED 2Stephen KamandaNo ratings yet

- Food Chain Forest Ecosystem P1Document21 pagesFood Chain Forest Ecosystem P1Allen GeorgeNo ratings yet

- Unit 2 - TAD-DT5Document17 pagesUnit 2 - TAD-DT5Nguyễn Văn HòaNo ratings yet

- Atomization For Spray Drying Unanswered Questions and Industrial NeedsDocument6 pagesAtomization For Spray Drying Unanswered Questions and Industrial NeedsNicolas Pardo AlvarezNo ratings yet

- A Traditional Mexican Alcoholic Fermented Beverage: Historical, Microbiological, and Technical AspectsDocument18 pagesA Traditional Mexican Alcoholic Fermented Beverage: Historical, Microbiological, and Technical AspectsGustavo PachecoNo ratings yet

- VBP Catalog Solenoids Vers4 2 PDFDocument137 pagesVBP Catalog Solenoids Vers4 2 PDFDennis Baumann100% (1)

- 20-Cow Module Buffalo Milk Production: Profi Tability AnalysisDocument45 pages20-Cow Module Buffalo Milk Production: Profi Tability AnalysisNobodyNo ratings yet

- A Brief History of The Corinth CanalDocument2 pagesA Brief History of The Corinth Canalangeliki1992No ratings yet

- Structures ThesisDocument25 pagesStructures ThesisAbhijith SharmaNo ratings yet

- Sony Playstation 3 Cecha00 Cecha01 Sm-Ps3-0013e-02Document45 pagesSony Playstation 3 Cecha00 Cecha01 Sm-Ps3-0013e-02naoyakatsu100% (2)

- Radiology in A Trench Coat PDFDocument238 pagesRadiology in A Trench Coat PDFAnantha KrishnanNo ratings yet