Professional Documents

Culture Documents

013 Chemical Handling

013 Chemical Handling

Uploaded by

Ikman FarizyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

013 Chemical Handling

013 Chemical Handling

Uploaded by

Ikman FarizyCopyright:

Available Formats

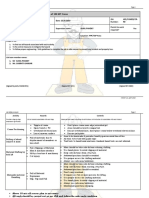

JOB SAFETY ANALYSIS

Job/Operation JSA No.: Date:

Title: 013 6/5/2016

Chemical Handling

Department/Division/Section: Location(s): Job Start Analysis Developed By:

All Departments All Locations Date: Heather Becker - HSE Manager

Person(s) Performing This Job: Supervisor: Duration: Analysis Reviewed By:

All Employees All Management and Always Heather Becker

Leads

Heather Becker – HSE Manager 6/5/2016

Task/Step Potential Hazards Recommended Safe Job Procedures

1. Identify chemicals and read 1. CHEMICALS USED FOR Identify all chemicals that are needed for the task to be performed.

SDS. HOUSEKEEPING CLEANING / Read the SDS for the chemicals before handling the chemicals.

SANITATION Identify the correct PPE that needs to be worn.

2. CHEMICALS USED FOR KITCHEN

CLEANING / SANITATION

3. CHEMICALS USED FOR

MAINTENANCE PURPOSES

2. Read the manufacturer’s 1. CHEMICALS USED FOR Read the manufacturer’s instructions on the correct mixing and usage

instructions on the proper HOUSEKEEPING CLEANING / of the chemical.

mixing and usage of the SANITATION

chemical. 2. CHEMICALS USED FOR KITCHEN

CLEANING / SANITATION

3. CHEMICALS USED FOR

MAINTENANCE PURPOSES

3. Apply Proper PPE 1. Compressed gas Inspect all PPE for cleanliness or damage before usage. If PPE is

2. Construction materials (wet cement, epoxy damaged do not use. Get new PPE to wear. Put on all PPE according

resins, cement dusts, alcohols, lime, toluene, to the SDS recommendations for the chemical being used.

metalworking fluids, turpentine, paints, xylene

adhesives)

3. Corrosive materials

1

Task/Step Potential Hazards Recommended Safe Job Procedures

4. Explosive materials

5. Flammable materials and liquids

6. Flammable/reactive chemicals

7. Hot Liquids

8. Ignitable materials and liquids

9. Oxidizers

10. CHEMICALS USED FOR

HOUSEKEEPING CLEANING /

SANITATION

11. CHEMICALS USED FOR KITCHEN

CLEANING / SANITATION

12. CHEMICALS USED FOR

MAINTENANCE PURPOSES

4. Proper labeling 1. Compressed gas Before mixing or pouring any chemical from the labeled master

2. Construction materials (wet cement, epoxy container into a secondary container make sure to properly label the

resins, cement dusts, alcohols, lime, toluene, container for the chemical that it is being used for. Never place any

metalworking fluids, turpentine, paints, xylene chemicals into a secondary container without the proper labeling.

adhesives)

3. Corrosive materials

4. Explosive materials

5. Flammable materials and liquids

6. Flammable/reactive chemicals

7. Hot Liquids

8. Ignitable materials and liquids

9. Oxidizers

10. CHEMICALS USED FOR

HOUSEKEEPING CLEANING /

SANITATION

11. CHEMICALS USED FOR KITCHEN

CLEANING / SANITATION

12. CHEMICALS USED FOR

MAINTENANCE PURPOSES

5. Storing Chemicals 1. Combustible materials All chemicals should be stored in a lock-up that has an impervious

2. Compressed gas floor and is bunded (walled) so that it will contain 110% of the

3. Construction materials (wet cement, epoxy contents of the largest container, should it spill or leak.

resins, cement dusts, alcohols, lime, toluene,

2

Task/Step Potential Hazards Recommended Safe Job Procedures

metalworking fluids, turpentine, paints, xylene Put waste chemicals in sealed containers for hazardous waste

adhesives) collection. Find out from your direct supervisor where and how to

4. Corrosive materials dispose of hazardous materials safely.

5. Explosive materials

6. Flammable materials and liquids

7. Flammable/reactive chemicals

8. Heaters and boilers (steam)

9. Hot Liquids

10. Ignitable materials and liquids

11. Oxidizers

12. Pressurized cylinders, lines, or equipment

13. CHEMICALS USED FOR

HOUSEKEEPING CLEANING /

SANITATION

14. CHEMICALS USED FOR KITCHEN

CLEANING / SANITATION

15. CHEMICALS USED FOR

MAINTENANCE PURPOSES

POTENTIAL PHYSICAL HAZARDS OF THIS JOB

Physical Hazards Prob. Sev. Consequences

Combustible materials 2 1 Chemical burns

Compressed gas 2 1 Contact dermatitis

Construction materials (wet cement, epoxy 2 1 Explosion

resins, cement dusts, alcohols, lime, Exposure (inhaling, swallowing, or absorbing) to

toluene, metalworking fluids, turpentine, harmful levels of gases, vapors, aerosols, liquids,

paints, xylene adhesives) fumes, or dust)

Corrosive materials 2 1 Fire

Explosive materials 2 1 Overcome by (harmful levels of gases, vapors,

Flammable materials and liquids 2 1 aerosols, fumes, or dust)

Flammable/reactive chemicals 2 1 Splashed by

Heaters and boilers (steam) 2 1 Suffocation

Hot Liquids 2 1 Thermal burns

Ignitable materials and liquids 2 1

3

POTENTIAL PHYSICAL HAZARDS OF THIS JOB

Oxidizers 2 1

Pressurized cylinders, lines, or equipment 2 1

POTENTIAL CHEMICAL HAZARDS OF THIS JOB

Chemical Hazards Description/Health Hazards

CHEMICALS USED FOR KITCHEN CLEANING / All chemicals that are used pose a physical or health hazard to people who are using them or

SANITATION in an area where they are being used.

()

CHEMICALS USED FOR MAINTENANCE All chemicals that are used pose a physical or health hazard to people who are using them or

PURPOSES in an area where they are being used.

()

CHEMICALS USED FOR HOUSEKEEPING All chemicals that are used pose a physical or health hazard to people who are using them or

CLEANING / SANITATION in an area where they are being used.

()

HAZARD CONTROL MEASURES USED FOR THIS JOB

Administrative Controls: Engineering Controls: Required PPE:

Audits (site or job) Air filtration Clothing - chemical resistant

Competent person Chemical elimination Clothing - long pants

Drug and alcohol policy Chemical reduction Clothing - long sleeve shirt

Emergency procedures Chemical substitution Face protection

Equipment maintenance and servicing manual Ventilation and exhausting Gloves - work gloves

Federal, state, and local regulations Work process change (e.g., use different methods to Gloves outer - chemical-resistant

Housekeeping practices perform work) Latex/Nitrile Gloves

Inspections (ongoing) work areas, equipment, tools, Non-slip Shoes

etc. Personal protective equipment

Inspections (pre-job) - work areas, equipment, tools, Safety glasses

etc. Side shield

Material handling procedures

Safety Data Sheets (SDS)

Notification and communication procedures

Operating instructions (equipment)

Operating procedures (process)

Policy or policies

4

HAZARD CONTROL MEASURES USED FOR THIS JOB

Procedures and/or guidelines (general)

Procedures and/or guidelines (job or activity)

Safety and health plan (site specific)

Safety and health program

Safety checklists (use to document inspections)

Safety meeting (pre-job)

Safety meetings - on-going (e.g., daily or weekly

tailgate safety)

Signage

Trained personnel

Work practices

Required Training: Required Permit(s): Other Information:

Bloodborne pathogens This information applies to all camps;

Emergency plans and fire prevention plans all sites

First aid/CPR

General Safety

Hazard Communication (HAZCOM)

Hazardous materials

Hazardous waste operations (HAZWOPER)

Injury illness prevention

Materials handling and storage

Orientation (site or job)

Personal protective equipment (PPE)

Chemical Description/Health Hazards is from the CAMEO database maintained by the U.S. EPA, NOAA, and the U.S. Coast Guard (www.cameochemicals.noaa.gov). The creator of this JSA is responsible for any edits to this information.

Severity Probability

S-1 = High P-1 = High

S-2 = Medium P-2 = Medium

S-3 = Low P-3 = Low

You might also like

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar Kashinath100% (1)

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- Safe WorkDocument4 pagesSafe WorkRamalingam PrabhakaranNo ratings yet

- Safe Work Method Statement - Part 1: Company DetailsDocument11 pagesSafe Work Method Statement - Part 1: Company DetailsAa YusriantoNo ratings yet

- Tbam: Dikkowita Fisheries HarbourDocument8 pagesTbam: Dikkowita Fisheries HarbourkskahatadeniyaNo ratings yet

- Job Safety AnalysisDocument1 pageJob Safety AnalysisWati KaNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedDocument2 pagesJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisSenthooran Srikandaraj100% (1)

- JSA #34 - N2 PurgingDocument1 pageJSA #34 - N2 PurgingHelza RahmanniaNo ratings yet

- SWMS Power FloatDocument10 pagesSWMS Power FloatSam LimNo ratings yet

- R1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingDocument3 pagesR1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingVineet Agrawal100% (1)

- Job Hazard Analysis (JHA) Report: Rev: 01 Page 1 of 1Document1 pageJob Hazard Analysis (JHA) Report: Rev: 01 Page 1 of 1Siddharth RanaNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- 6-R A For Handling, Storage and Use of Gas CylindersDocument4 pages6-R A For Handling, Storage and Use of Gas CylindersMohamedSaidNo ratings yet

- Scaffolding Staging Tower For Concr PumpDocument1 pageScaffolding Staging Tower For Concr Pumpasimnaqvi2008No ratings yet

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocument1 pageRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig740% (1)

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument20 pagesJSA For Scaffolding Erection Dismantling and Modification Workbagas prakoso100% (1)

- Chemical Register Chec MacfeamDocument2 pagesChemical Register Chec MacfeamBekmengNo ratings yet

- Risk Assessment-Lifting OperationsDocument5 pagesRisk Assessment-Lifting OperationsMuhammad Shahid IqbalNo ratings yet

- JSA For Cleaning Exchanger Channel Head by High Pressure Water JettingDocument17 pagesJSA For Cleaning Exchanger Channel Head by High Pressure Water JettingThái Đạo Phạm LêNo ratings yet

- JSA-G3 'Portable Fire Extinguisher Usage'Document2 pagesJSA-G3 'Portable Fire Extinguisher Usage'nathan schaalNo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- Risk Assessment - Pipe Fit Up - Hot WorkDocument7 pagesRisk Assessment - Pipe Fit Up - Hot WorkHanu JemberNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- Welding JSADocument2 pagesWelding JSAMD AbdullahNo ratings yet

- Jsa For WeldingDocument2 pagesJsa For WeldingMohamed Samir50% (2)

- TRA Welding and Stringing 6 PipelineDocument2 pagesTRA Welding and Stringing 6 PipelineAhmedAmer1No ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- Mid West Ports Authority 4.6 Working On, Over or Near WaterDocument9 pagesMid West Ports Authority 4.6 Working On, Over or Near Waterqualiman1No ratings yet

- 3-WD 40 Spray (Anti Rust)Document2 pages3-WD 40 Spray (Anti Rust)MainrajNo ratings yet

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorNo ratings yet

- SWP Working Safely at Height Version 2.01Document7 pagesSWP Working Safely at Height Version 2.01marvinNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Safety Signs On Construction SiteDocument1 pageSafety Signs On Construction SiteBëBå Wossen AssefaNo ratings yet

- Grating Control ProcedureDocument25 pagesGrating Control ProcedureMuneeb Rehman100% (1)

- JSA - Blind Lifting Operations Using Special Mini Container From Lay Down Into 1st - 2nd Deck Double Bottom Hull Using Starboard Side Crane - VV - March 2018Document3 pagesJSA - Blind Lifting Operations Using Special Mini Container From Lay Down Into 1st - 2nd Deck Double Bottom Hull Using Starboard Side Crane - VV - March 2018ari100% (1)

- Confined Space SapDocument2 pagesConfined Space SapfairusNo ratings yet

- Hirac 1Document1 pageHirac 1Agape PrintshopNo ratings yet

- JHA Rendering Works For BuildingsDocument2 pagesJHA Rendering Works For BuildingsHany Seif-Aldien NasserNo ratings yet

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- JSA For Scaffolding.Document16 pagesJSA For Scaffolding.jeswinimanualNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- JSA Fiber Tank LiftingDocument4 pagesJSA Fiber Tank LiftingEngismail KhanNo ratings yet

- SOP ChemicalStorageGuidelinesDocument10 pagesSOP ChemicalStorageGuidelinesRodrigoNo ratings yet

- Chemistry For EngineersDocument18 pagesChemistry For EngineersEunice AlonzoNo ratings yet

- SOP ChemicalStorageGuidelinesDocument5 pagesSOP ChemicalStorageGuidelinesisjglfdskNo ratings yet

- Chemical Handling - HiraDocument6 pagesChemical Handling - HiraVENKATESAN MNo ratings yet