Professional Documents

Culture Documents

Win Progress Co.,Ltd. (Pharkant Branch) Ec290 (BLC, Bprime) Swing Motor Assemble Check Sheet

Win Progress Co.,Ltd. (Pharkant Branch) Ec290 (BLC, Bprime) Swing Motor Assemble Check Sheet

Uploaded by

Ko ZayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Win Progress Co.,Ltd. (Pharkant Branch) Ec290 (BLC, Bprime) Swing Motor Assemble Check Sheet

Win Progress Co.,Ltd. (Pharkant Branch) Ec290 (BLC, Bprime) Swing Motor Assemble Check Sheet

Uploaded by

Ko ZayCopyright:

Available Formats

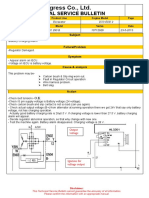

WIN PROGRESS CO.,Ltd.

(Pharkant Branch)

EC290(BLC,BPrime) Swing Motor Assemble Check Sheet

Customer Report No.

Machine Model Service date

Sr;No

Machine Sr;No. Component Sr; No

No.

Working Hour Cause of Problem

Reason Of Overhaul Yes No Remark

Has oil leakage from Motor?

Has Been Dissemblied This Motor?

Flushing?

Resealing?

Abnormal Function In Motor?

Preparation

(i) Prepare the tools as follow

Allen wrench 6mm,14mm,17mm

Spanner wrench 19mm,24mm,27mm,36mm,41mm

Socket Spanner 41mm

Snap ring plie(Inside, Outside)

Driver (-), Hammer

(ii) Clean the motor with cleaning solvent and dry with air

(iii) Make a match mark on head and motor casing

(iv) Put the plastic or paper sheet on the work bench to prevent the parts damage

No Description Torque Status Figure

1 Placing casing

Place casing (301) on the work bench with the valve casing side

downward.

2 Bearing, press

press-fitting

fitting

Assemble snap ring (432), spacer (106) to bearing (443).

Heat the inner race of bearing (443) and press–fit to drive shaft

(101).

Note! Pay attention to the direction of the inner race collar.

O. Output shaft S. Spacer

3 Snap ring, install

Install spacer

p ((106)) and assemble snap p ring

g ((432).

)

4 Roller bearing, install

Using a brass bar, tap the outer race of roller bearing (443)

until the bearing is fully seated

5 Seal, install

This procedure is necessary

Install seal (491) in front cover (304) with a press or seal driver,

until fully seated.

Note! Pay attention the direction of seal. The seal lip

must face towards casing

6 O-ring, install

g ((471)) to casing

Install O-ring g ((301).

)

7 Front cover, install

Install front cover (304) to casing (301) by tapping slightly using

plastic hammer.

Note! Coat the lip of the seal with grease. Be careful

not to damage the lip of the seal, and the outer surface

8 Snap ring, install

Install snap ring (437) to casing (301) using snap ring pliers.

No Description Torque Status Figure

9 Swash plate, install

Set the casing horizontally and assemble swash plate (124)

to casing side.

Note!Insert it with the larger champered side of the swash

plate towards the casing. Coat lightly with grease.

10 Spherical bushing, install(EC290BLC)

Insert push rods12pcs (116) and spacer F (117) to cylinder (111)

and install spherical bushing (113) with the larger

outer diameter towards the cylinder.

Note! Be careful not to damage the sliding surface of the cylinder.

Spherical bushing, install(EC290BP)

Install spherical bushing to cylinder block

11 Piston unit, assembly

Fit piston sub assembly unit (121, 122) to retainer (123).

12 Piston assembly, install

Fit piston sub assembly (121, 122) to retainer (123)

and assemble it with cylinder (111) and install

it on drive shaft (101) aligning the splines.

Note! For easier assembly of drive shaft, align spherical

bushing and cylinder spline phase.

13 Friction plate, install

Set casing (301) with seal cover (305) downward and assemble

th

three mating

ti plates(743)and

l t (743) d ttwo ffriction

i ti plates(742)insequence

l t (742)i

Note! Align 4 teeth to the notches as shown.

R : Rebound damping valve side.

14 O-ring, install

Mount O-ring (706, 707) to casing (301).

Note! Coat the O-rings with grease.

15 Brake piston, install

Assemble brake piston (702) to casing (301).

a. Brake piston

b. Hole (Opposite side)

c. Mounting side

Note!Place 4 notches of the brake piston as shown left.

The piston is difficult to assemble because of the restriction of

the O-ring : screw two M 8 bolts into the brake piston and tap

them gently.

16 Brake spring, install

Assemble brake spring20pcs (712) into brake piston (702).

17 Outer race, install

Install the outer race of roller bearing (444) in valve casing (303)

while tapping it lightly.

Note! Tap evenly on the outer diameter of the outer race

with a brass bar until it is fully seated.

seated

18 Valve plate, install

Assemble valve plate (131) to valve casing (303) and fit O-ring(472)

Valve casing, assembly

a.Flange side

b.Hole

Note! Coat lightly with grease. Ensure dowel pins (451)

are installed in the valve casing. g

No Description Torque Status Figure

19 Valve casing, install

Mount valve casing (303) to casing (301) and tighten screws (401) 316.7

to the specified torque. lbf-ft

Note!Be careful to note the mounting direction of the valve casing.

Be careful not to drop the valve plate or let the brake springs

pop out. Tighten the bolts evenly.

20 Spool and spring, install

Insert plunger and spring (355) into the valve casing and install

Ro plug (469) with O-ring (488). 162.5

Note! Confirm the smooth movement of the spool before lbf-ft

installing the plug.

21 Relief valve, install

Assemble relief valve (051) with back-up ring (162) and O-ring (161) 130

to valve casing (303). lbf-ft

22 Plug, install

Assemble plug (468) with O-ring (487) to valve casing (303) and 27

assemble pplugg ((464)) with O-ring

g ((485)) to casing

g ((301).

) lbf-ft

23 Delay valve and Rebound Dumping valve, install 21.67

Assemble delay valve (031) to casing (301) by screw. lbf-ft

Assemble rebound damping valve block with O-rings (162, 163) 50.83

to valve casing (303) by screws (171). lbf-ft

Service person Sign_ _ _ _ _ _ _ _ Supervisor Sign_ _ _ _ _ _ _ _

Service person Name_ _ _ _ _ _ _ _ Supervisor Name_ _ _ _ _ _ _ _

You might also like

- 862-Service-Manual. 6.2L FordDocument254 pages862-Service-Manual. 6.2L FordKraken AudioCar100% (1)

- International DT 466Document520 pagesInternational DT 466jose cardoso dos santos neto100% (12)

- SM 35 PDFDocument434 pagesSM 35 PDFjaciel leonNo ratings yet

- Chery - SQR477F 1.5L 16V Sohc L4Document4 pagesChery - SQR477F 1.5L 16V Sohc L4ferran_alfonso0% (2)

- EVK Seal ManualDocument18 pagesEVK Seal Manualgelo_17100% (1)

- Trans Tec AUTOMATIC TRANSMISSIONDocument19 pagesTrans Tec AUTOMATIC TRANSMISSIONrobertoperez525100% (1)

- Piaggio Historical Catalogs 1998-2005 CiaoDocument46 pagesPiaggio Historical Catalogs 1998-2005 CiaoDinkoKečalović100% (1)

- Labor Guide DRAFT - ForkliftDocument8 pagesLabor Guide DRAFT - Forkliftcarlos javierNo ratings yet

- 360 BP'MCV, AssDocument6 pages360 BP'MCV, AssAimHighNo ratings yet

- Flow Doc 2 PDFDocument18 pagesFlow Doc 2 PDFJozefNo ratings yet

- 2014 Subaru Outback 8 Front StrutDocument6 pages2014 Subaru Outback 8 Front StrutLeslie CooperNo ratings yet

- Informacion Motor KomatsuDocument8 pagesInformacion Motor KomatsuKike HernandezNo ratings yet

- Pump, Assembly: Service InformationDocument5 pagesPump, Assembly: Service InformationNaing Min HtunNo ratings yet

- Pistons and Connecting Rods - AssembleDocument5 pagesPistons and Connecting Rods - Assembleeshopmanual limaNo ratings yet

- CWP OverhaulingDocument4 pagesCWP OverhaulingJINDE VINAYNo ratings yet

- 950 Service BulletinDocument13 pages950 Service Bulletinawoodward087No ratings yet

- 11 Trans ReassemDocument44 pages11 Trans ReassemAnangtri WahyudiNo ratings yet

- RENR492704Document3 pagesRENR492704Victor NoschangNo ratings yet

- Assembly ProcedureDocument115 pagesAssembly ProcedureAlex Castillo100% (1)

- Front Drive Shaft: ComponentsDocument7 pagesFront Drive Shaft: Componentsfrankhil ramosNo ratings yet

- Rs Service InstructionsDocument2 pagesRs Service InstructionsCentral HydraulicsNo ratings yet

- Propeller Shaft PDFDocument11 pagesPropeller Shaft PDFAndrey Gladyshev100% (1)

- Propeller ShaftDocument17 pagesPropeller ShaftdwcdiscoNo ratings yet

- EC380 - Track Motor, AssemblyDocument14 pagesEC380 - Track Motor, Assemblymaintenance 2kpbNo ratings yet

- Instalación de Piston y BielaDocument3 pagesInstalación de Piston y BielaBrayan Sánchez ParedesNo ratings yet

- cirrusSR22 32-20Document22 pagescirrusSR22 32-20Dario ForestiereNo ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddolphi_742078No ratings yet

- Toyota Tercel 1986Document885 pagesToyota Tercel 1986yorgo7002No ratings yet

- 10.manual de Instalacion y Mantenimiento, Pto (Power Take Off) PDFDocument18 pages10.manual de Instalacion y Mantenimiento, Pto (Power Take Off) PDFCamilo SanchezNo ratings yet

- Bof 1.0 inDocument4 pagesBof 1.0 inDurvis RomeroNo ratings yet

- Ajuste Diferencial Dana 44Document21 pagesAjuste Diferencial Dana 44datomarcaNo ratings yet

- Desarmado y Armado Bomba ImplementosDocument13 pagesDesarmado y Armado Bomba ImplementosRafael RodriguezNo ratings yet

- Transfer Gearbox AssemblyEW145BDocument101 pagesTransfer Gearbox AssemblyEW145Bសុខ ប៊ុនណារ៉ង់No ratings yet

- Assembling C32Document24 pagesAssembling C32Muhammad Ramadhan100% (2)

- Toyota Haice TDocument42 pagesToyota Haice TEdgar GuzmanNo ratings yet

- wp1142II XMLDocument1 pagewp1142II XMLaugustinhodjNo ratings yet

- C Molo TM003 eDocument8 pagesC Molo TM003 ejcclaNo ratings yet

- 428f cylinder headDocument1 page428f cylinder headjohnsaad15No ratings yet

- Adjustable Pitch Propeller Taper-Lock HubDocument2 pagesAdjustable Pitch Propeller Taper-Lock HubhaosfNo ratings yet

- Repair Instructions: 3AV 30 To 3AV 430Document11 pagesRepair Instructions: 3AV 30 To 3AV 430KevinNo ratings yet

- Flowserve Pusher Seal ManualDocument16 pagesFlowserve Pusher Seal ManualNikhil Princeton AndradeNo ratings yet

- Air StarterDocument44 pagesAir StarterShakti NaikNo ratings yet

- 2 Stage SF-HD Compressor Assembly BookDocument50 pages2 Stage SF-HD Compressor Assembly BookwalkercadillacNo ratings yet

- VOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFDocument16 pagesVOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFfjjsjekdmme67% (3)

- 428f connecting rod boltsDocument1 page428f connecting rod boltsjohnsaad15No ratings yet

- 23 AssemblyDocument9 pages23 Assemblyhybrid_motorsports_llcNo ratings yet

- 199-538A KitDocument10 pages199-538A KitcarlosNo ratings yet

- Armado Cabeza de PistonDocument4 pagesArmado Cabeza de PistonCRIATHIANNo ratings yet

- Castilla U5 Coupling ManualDocument14 pagesCastilla U5 Coupling Manualantonio mendezNo ratings yet

- Transmission - Assemble.Document20 pagesTransmission - Assemble.David MercadoNo ratings yet

- Clutch Echo 2002Document17 pagesClutch Echo 2002Tomas DominguezNo ratings yet

- 3512B修理资料Document7 pages3512B修理资料lymn linNo ratings yet

- Final Drive AssemblyDocument118 pagesFinal Drive AssemblyKARTHICKRAJ KANDASAMYNo ratings yet

- Flow Doc.1 PDFDocument12 pagesFlow Doc.1 PDFJozefNo ratings yet

- Remoción Llantas 727Document3 pagesRemoción Llantas 727garciasanchezsergio2021370177No ratings yet

- Maintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBDocument10 pagesMaintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBAtaa AssaadNo ratings yet

- Procedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoDocument7 pagesProcedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoadrianvieroNo ratings yet

- Differential Carrier: ComponentsDocument16 pagesDifferential Carrier: Componentspriyankar007No ratings yet

- 1 Despiece Gould PumpsDocument1 page1 Despiece Gould Pumpsjoecold91No ratings yet

- WD Service InstructionsDocument2 pagesWD Service InstructionsCentral HydraulicsNo ratings yet

- K3V K5V ManualDocument8 pagesK3V K5V ManualWaridi Ridi100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Construction - Bicycles, Dicycles Or Otto Type Machines And TricyclesFrom EverandConstruction - Bicycles, Dicycles Or Otto Type Machines And TricyclesNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Performance Test For Zx670-3: Unit Actual Value Standard Value RemarkDocument2 pagesPerformance Test For Zx670-3: Unit Actual Value Standard Value RemarkKo ZayNo ratings yet

- Zaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDDocument13 pagesZaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDKo ZayNo ratings yet

- Common Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDDocument11 pagesCommon Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDKo ZayNo ratings yet

- ReturnDocument27 pagesReturnKo ZayNo ratings yet

- SpecificationsDocument9 pagesSpecificationsKo ZayNo ratings yet

- SpecificationsDocument4 pagesSpecificationsKo ZayNo ratings yet

- Hydraulic SymbolsDocument15 pagesHydraulic SymbolsKo ZayNo ratings yet

- SB020Document2 pagesSB020Ko ZayNo ratings yet

- Specifications Zaxis650LcDocument10 pagesSpecifications Zaxis650LcKo ZayNo ratings yet

- SpecificationsDocument5 pagesSpecificationsKo ZayNo ratings yet

- Upperstructure: Section 2Document193 pagesUpperstructure: Section 2Ko ZayNo ratings yet

- Isuzu Parts Catalog 4HK1Document62 pagesIsuzu Parts Catalog 4HK1Ko Zay100% (1)

- D12C EngAss, Diss (Piston)Document1 pageD12C EngAss, Diss (Piston)Ko ZayNo ratings yet

- Boom Can't DownDocument1 pageBoom Can't DownKo ZayNo ratings yet

- Boom Cylinder Creeping &driftDocument2 pagesBoom Cylinder Creeping &driftKo ZayNo ratings yet

- Boom Raise Function SlowDocument1 pageBoom Raise Function SlowKo ZayNo ratings yet

- 290BPSWING Gear Box DisassDocument2 pages290BPSWING Gear Box DisassKo ZayNo ratings yet

- D12D Eng Ass and Disass (Piston)Document1 pageD12D Eng Ass and Disass (Piston)Ko ZayNo ratings yet

- Boom Cylinder Can't LiftDocument2 pagesBoom Cylinder Can't LiftKo ZayNo ratings yet

- Damage Crank Shaft BearingDocument2 pagesDamage Crank Shaft BearingKo ZayNo ratings yet

- 290BPSWING Gearbox AssDocument2 pages290BPSWING Gearbox AssKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Training Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Document18 pagesTraining Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Ko ZayNo ratings yet

- Electrical Assessment QuestionsDocument24 pagesElectrical Assessment QuestionsKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument3 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Hitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Document71 pagesHitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Ko Zay100% (1)

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- FS Curtis FAC 28B 28BC Instruction Manual KubotaDocument69 pagesFS Curtis FAC 28B 28BC Instruction Manual KubotaKo ZayNo ratings yet

- 6.section C - ElectricsDocument225 pages6.section C - ElectricsKo Zay100% (5)

- Engine Oil Pressure Alarm 128 Pid 100 FMI 1Document2 pagesEngine Oil Pressure Alarm 128 Pid 100 FMI 1Ko ZayNo ratings yet

- Reciprocating PUMPSDocument15 pagesReciprocating PUMPSRyan LincayNo ratings yet

- SL2019 681 PDFDocument17 pagesSL2019 681 PDFRoman KulikovNo ratings yet

- WARTSILADocument68 pagesWARTSILAAnderson Borges100% (3)

- Massey Ferguson MF 298 TRACTOR (GB) Service Parts Catalogue Manual (Part Number 819711)Document16 pagesMassey Ferguson MF 298 TRACTOR (GB) Service Parts Catalogue Manual (Part Number 819711)qlb898316No ratings yet

- Cylinder HeadDocument55 pagesCylinder Headmadhav sai100% (2)

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Enis MurgicNo ratings yet

- Master Mf8600 WSM 02 enDocument366 pagesMaster Mf8600 WSM 02 enSelmirije2100% (3)

- Efficiency of A New Internal Combustion Engine ConDocument18 pagesEfficiency of A New Internal Combustion Engine ConSiddu KaragarNo ratings yet

- Swissauto 250 - Engine Rebuild PackagesDocument1 pageSwissauto 250 - Engine Rebuild PackagesSimon CooperNo ratings yet

- Penta Wet Kit PDFDocument44 pagesPenta Wet Kit PDFShamoNo ratings yet

- Tilt Cylinders PDFDocument12 pagesTilt Cylinders PDFamineNo ratings yet

- Design of Machine Elements 2 Jan 2018 (2010 Scheme)Document2 pagesDesign of Machine Elements 2 Jan 2018 (2010 Scheme)KishoreNo ratings yet

- Instructions For Parts Books: Note About Country CodesDocument53 pagesInstructions For Parts Books: Note About Country CodesAnonymous AmOgamNo ratings yet

- S60me C8 - 2 Gi PDFDocument413 pagesS60me C8 - 2 Gi PDFStephenson100% (2)

- Which Cars Are Equipped With k9k 808. Engines and Weaknesses of The K9K EngineDocument19 pagesWhich Cars Are Equipped With k9k 808. Engines and Weaknesses of The K9K EngineShalla Balla100% (1)

- 2020 Specific Motor Vehicle DutiesDocument1 page2020 Specific Motor Vehicle DutiesMubangachipoyaNo ratings yet

- Airmix 15C25 & 30C25 Pump: Spare PartsDocument2 pagesAirmix 15C25 & 30C25 Pump: Spare PartsMIGUEL GONZALEZNo ratings yet

- Part Catalog YUCHAI - YC6J125Z-T20 (J8004) PDFDocument80 pagesPart Catalog YUCHAI - YC6J125Z-T20 (J8004) PDFAndre STA100% (1)

- Et 250Document163 pagesEt 250Jeferson SilvaNo ratings yet

- Selection of Gas Compressors - Part 3 PDFDocument5 pagesSelection of Gas Compressors - Part 3 PDFstreamtNo ratings yet

- Hino K13C Valve AdjustingDocument5 pagesHino K13C Valve Adjustinglexin ortega flores50% (2)

- BVA PA Series ManualDocument16 pagesBVA PA Series ManualTitanplyNo ratings yet

- Zurn Aquaflush z6000 ManualDocument8 pagesZurn Aquaflush z6000 ManualrosaearlNo ratings yet

- Catalogo Engimax Motores IsuzuDocument38 pagesCatalogo Engimax Motores IsuzuAlexis SanchezNo ratings yet