Professional Documents

Culture Documents

ACEGrid-Brochure-HR-final 3

ACEGrid-Brochure-HR-final 3

Uploaded by

Anonymous 0x2pwMCWgjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACEGrid-Brochure-HR-final 3

ACEGrid-Brochure-HR-final 3

Uploaded by

Anonymous 0x2pwMCWgjCopyright:

Available Formats

the challenge

Road and geotechnical design engineers are facing an increasing challenge throughout Australia of building roads, retaining

structures and related structures with a wide range of soil types and over problematic soil conditions. Relatively low shear

capacity soils benefit significantly with the inclusion of an appropriate geosynthetic. ACEGrid® provides engineers with a cost

effective, proven alternative to the importation of expensive fills and allows structures to be built relatively economically than

would normally be possible.

meeting the challenge

Quality

Ace Geosynthetics have a commitment to using the latest technology in weaving processes that delivers

highest strengths possible at low soil compatible strains. Quality control within the manufacturing process

ensures consistency of manufacture at all times. Ace Geosynthetics hold a number of internationally recognised

accreditation approvals for their manufacturing processes.

materials

Ace Geosynthetics use the best available polymers and the highest tenacity yarn to make the ACEGrid® product.

of importance is the choice of polymer used to make the ACEGrid® structural geogrid. polyester polymer, in such

applications of structural reinforcement, is the most resistant to loss of strength through creep effects over very

long periods of time. the use of low carboxyl end group, high molecular weight, base polymer, has been proven

to withstand the effects of hydrolysis and subsequent loss of strength in alkaline environments. polyester polymer

is the least susceptible to long term temperature effects.

testing

Ace Geosynthetics have a commitment to fully understand the short term and long term behavior of their product.

significant internal and external testing has been carried out at some of the world’s most well recognised research

and test facilities to independently verify product performance when subjected to physical damage, chemical

resistance, load and temperature effects. both real time and accelerated test methods have been performed to

ensure that the ACEGrid® product performance is understood over design lives in excess of 120 years.

History

Ace Geosynthetics high performance geogrid has been used for years on many Australian soil reinforcement

projects with outstanding success. ACEGrid® geogrid is stocked locally with larger requirements made to order

with speedy lead times to suit construction requirements. ACEGrid® can be custom manufactured to suit specific

project demands such as roll width or length. ACEGrid® product is supported in Australia, new Zealand and the

south pacific by Global synthetics engineers. ACEGrid® geogrid has been approved for use under the nsW rms

r57 specification process. similarly this approval is accepted by the Queensland Department of transport and

main roads. international approvals are held with the product accredited with bbA (british board of Agreement)

for applications of basal and slope reinforcement. product evaluations have been carried out in the usA through

the AAsHto- ntpEp programme.

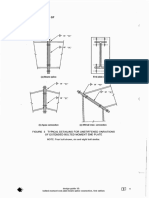

the use of ACEGrid® as a front wrapped reinforcement treatment and after completion showing the vegetated structure.

You might also like

- Original PDF Essential Communication by Ronald Adler PDFDocument41 pagesOriginal PDF Essential Communication by Ronald Adler PDFmary.burklow183100% (34)

- GYP547 ResGuide 2011 - 557fDocument56 pagesGYP547 ResGuide 2011 - 557fduckman2009No ratings yet

- GRG Technical SpecificationDocument6 pagesGRG Technical SpecificationHarsh AsthanaNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 22Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 22Anonymous 0x2pwMCWgj50% (2)

- Woven Polyester High Strength Geotextile Acetex The Proven Choice ForDocument8 pagesWoven Polyester High Strength Geotextile Acetex The Proven Choice ForSamir SabnisNo ratings yet

- Steel Frame Wall Systems Installation GuideDocument48 pagesSteel Frame Wall Systems Installation Guide陳宗煌No ratings yet

- Main GeofabricsDocument16 pagesMain GeofabricsThota RevanthNo ratings yet

- Case Study: Wastewater Pond Berm Reinforcement Bogle Winery, Clarksberg CA Miragrid 8XT Geogrid (180,000 SY)Document2 pagesCase Study: Wastewater Pond Berm Reinforcement Bogle Winery, Clarksberg CA Miragrid 8XT Geogrid (180,000 SY)frankytgNo ratings yet

- Seminar Affordable Rapid Mass Housing Using GFRG PanelsDocument17 pagesSeminar Affordable Rapid Mass Housing Using GFRG PanelsBasavaraj M PatilNo ratings yet

- Practical Design Guide For Glass Reinforced ConcreteDocument98 pagesPractical Design Guide For Glass Reinforced ConcreteThompson LaiNo ratings yet

- EcoCast BrochureDocument4 pagesEcoCast BrochurePeterLOW0218No ratings yet

- Brosure Agro Yasa Lestari New2Document26 pagesBrosure Agro Yasa Lestari New2Anang BagusNo ratings yet

- Brochure ConcreteProtection 2019Document10 pagesBrochure ConcreteProtection 2019cesarfelipenardyNo ratings yet

- GYPROCK 544 Steel Frame Wall Systems 201201Document48 pagesGYPROCK 544 Steel Frame Wall Systems 201201Karla Anna KovacsNo ratings yet

- Bridge Deck Brochure2Document4 pagesBridge Deck Brochure2HevertNo ratings yet

- GSE HD ApplicationsDocument4 pagesGSE HD ApplicationsophytlNo ratings yet

- TA Basal Reinforcement With ArmaLynkDocument4 pagesTA Basal Reinforcement With ArmaLynksasaNo ratings yet

- Laguna Beach - Pearl Street - Case StudyDocument4 pagesLaguna Beach - Pearl Street - Case StudySD Impresos ExpressNo ratings yet

- SigmaprimeDocument8 pagesSigmaprimeHaresh BhavnaniNo ratings yet

- Keller Phi - 1000 12E - Retaining Structures PDFDocument16 pagesKeller Phi - 1000 12E - Retaining Structures PDFluisNo ratings yet

- Gulf Precast BrochureDocument13 pagesGulf Precast BrochureMohammad Abu-RadiNo ratings yet

- PPG Track RecordDocument73 pagesPPG Track RecordFernando Emmanuel Benitez100% (1)

- ABG Roofdrain 25SRXSSg v2019 04Document56 pagesABG Roofdrain 25SRXSSg v2019 04Che Hoo ToNo ratings yet

- Geosynthetics in Road ConstructionDocument45 pagesGeosynthetics in Road ConstructionMahaManthra100% (1)

- Geosynthetics in Road ConstructionDocument45 pagesGeosynthetics in Road ConstructionMrutyunjaya BeheraNo ratings yet

- Case Study Various ProjectsDocument33 pagesCase Study Various ProjectsAaron100% (1)

- GYPROCK 547 Residential - Installation - Guide 201111 PDFDocument56 pagesGYPROCK 547 Residential - Installation - Guide 201111 PDFduckeNo ratings yet

- 2013 Glasby-Earth Friendly Concrete - A Sustainable Option For Tunnels Requiring High DurabilityDocument11 pages2013 Glasby-Earth Friendly Concrete - A Sustainable Option For Tunnels Requiring High DurabilityChi ĐặngNo ratings yet

- Tech Geosynthetics: Nrrda, New DelhiDocument99 pagesTech Geosynthetics: Nrrda, New DelhiRavi YadavNo ratings yet

- 345 GE SS Subsea Trees Pages 280113 PDFDocument16 pages345 GE SS Subsea Trees Pages 280113 PDFazhariNo ratings yet

- Liquid Granite BrochureDocument0 pagesLiquid Granite BrochureLak ChauhanNo ratings yet

- Aquarian Cladding Brochure 2013Document16 pagesAquarian Cladding Brochure 2013Jamie WilliamsNo ratings yet

- Sample Construction and Material SpecificationsDocument10 pagesSample Construction and Material Specificationsrasputin0780803494No ratings yet

- Precision Grouting of TurbomachineryDocument16 pagesPrecision Grouting of TurbomachineryReyes SanchezNo ratings yet

- LTDS of GeotextilesDocument15 pagesLTDS of GeotextilesthadikkaranNo ratings yet

- Profile BFL (NEW)Document18 pagesProfile BFL (NEW)Nurhasan TalukdarNo ratings yet

- Geotextile Specifications Made SimpleDocument6 pagesGeotextile Specifications Made Simplelaiju p bNo ratings yet

- GSE Root Barrier v2019 11Document56 pagesGSE Root Barrier v2019 11Che Hoo ToNo ratings yet

- Adding Value To ConcreteDocument16 pagesAdding Value To ConcreteFrancois KokNo ratings yet

- Plexus Selector Chart EMEADocument5 pagesPlexus Selector Chart EMEALin LinNo ratings yet

- SecutexDocument4 pagesSecutexam23iNo ratings yet

- WFT10315Document8 pagesWFT10315rodrigojuliNo ratings yet

- Soil Nailing ThesisDocument8 pagesSoil Nailing Thesisamandawilliamscolumbia100% (2)

- Plexus Selector Chart North AmericaDocument5 pagesPlexus Selector Chart North AmericaLin LinNo ratings yet

- GRP Product GuideDocument20 pagesGRP Product Guidedp75No ratings yet

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemQ8123No ratings yet

- Study On Geopolymer Concrete Used For Paving BlocksDocument5 pagesStudy On Geopolymer Concrete Used For Paving BlocksIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Masterflow Solutions BASF ProfileDocument8 pagesMasterflow Solutions BASF ProfileKannan MurugesanNo ratings yet

- StrataBlock Case Study - Surat BharuchDocument2 pagesStrataBlock Case Study - Surat Bharuchweb6009No ratings yet

- Dock Guard FendersDocument33 pagesDock Guard FendersrakhbirNo ratings yet

- Welcome To Grcuk One of EuropeDocument8 pagesWelcome To Grcuk One of EuropeIqbal F AwaluddinNo ratings yet

- 8 - SOG Company Profile - 2018Document3 pages8 - SOG Company Profile - 2018Masood KhanNo ratings yet

- Practical Design Guide For GRCDocument98 pagesPractical Design Guide For GRCrencydNo ratings yet

- GRC SpecDocument8 pagesGRC SpecOttawa CanadaNo ratings yet

- BidimDocument5 pagesBidimrolandchalfounNo ratings yet

- Geotextile Specifications 2Document6 pagesGeotextile Specifications 2HRCNo ratings yet

- Precision Grouting Guide 05-23Document20 pagesPrecision Grouting Guide 05-23Malak HindiNo ratings yet

- CS E10:2014: Guidelines on Design Loads for Skyrise GreeneryFrom EverandCS E10:2014: Guidelines on Design Loads for Skyrise GreeneryNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- CS E11:2014: Guidelines on Design for Safety of Skyrise GreeneryFrom EverandCS E11:2014: Guidelines on Design for Safety of Skyrise GreeneryNo ratings yet

- Closed Sections Capacity 1Document1 pageClosed Sections Capacity 1Anonymous 0x2pwMCWgjNo ratings yet

- Mc815c Printdata CeDocument2 pagesMc815c Printdata CeAnonymous 0x2pwMCWgjNo ratings yet

- 4AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page4AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- 5AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page5AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- 1AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page1AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- Unit 10Document3 pagesUnit 10Anonymous 0x2pwMCWgjNo ratings yet

- Leviat Ancon Keybox Reinforcement Continuity Systems (1) 1Document1 pageLeviat Ancon Keybox Reinforcement Continuity Systems (1) 1Anonymous 0x2pwMCWgjNo ratings yet

- Displacement-Based - Seismic - Design - of - Structures 22Document1 pageDisplacement-Based - Seismic - Design - of - Structures 22Anonymous 0x2pwMCWgjNo ratings yet

- 3AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page3AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- 2AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page2AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- ACEGrid Brochure HR Final 4Document1 pageACEGrid Brochure HR Final 4Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjNo ratings yet

- Volume 2 - Hollow Sections Second Edition 4Document1 pageVolume 2 - Hollow Sections Second Edition 4Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 23Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 23Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 18Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 18Anonymous 0x2pwMCWgjNo ratings yet

- ACEGrid Brochure HR Final 6Document1 pageACEGrid Brochure HR Final 6Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 20Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 20Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Anonymous 0x2pwMCWgjNo ratings yet

- Design Guide 10: Bolted Moment End Plate Beam Splice Connection, First EditionDocument1 pageDesign Guide 10: Bolted Moment End Plate Beam Splice Connection, First EditionAnonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 11Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 11Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Anonymous 0x2pwMCWgjNo ratings yet

- 4-T-Tij H - . - : Design Guide 10: Bolted Moment End Plate Beam Splice Connection. First EditionDocument1 page4-T-Tij H - . - : Design Guide 10: Bolted Moment End Plate Beam Splice Connection. First EditionAnonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 12Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 12Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 17Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 17Anonymous 0x2pwMCWgjNo ratings yet

- DissertationDocument54 pagesDissertationRakesh Insan100% (1)

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020SabariPandiyanNo ratings yet

- Transducers & Isolators: TR - IsoDocument1 pageTransducers & Isolators: TR - IsoManikandan B100% (1)

- Goblin Slayer v06 PDFDocument174 pagesGoblin Slayer v06 PDFdedajo ddNo ratings yet

- Biblio 3Document1 pageBiblio 3Ian EdwardsNo ratings yet

- Case Studies in Strategy (Catalogue III)Document130 pagesCase Studies in Strategy (Catalogue III)TahseenRanaNo ratings yet

- Problem Cash FlowDocument3 pagesProblem Cash FlowKimberly AnneNo ratings yet

- Maya, Aztec, and Inca Civilizations PDFDocument116 pagesMaya, Aztec, and Inca Civilizations PDFGabriel Medina100% (2)

- Planar TouchstonesDocument5 pagesPlanar TouchstonesA̶l̶b̶e̶r̶t̶h CuaylaNo ratings yet

- Multiple Choice QuestionsDocument6 pagesMultiple Choice QuestionsJamie DayagbilNo ratings yet

- Resume Word OriginDocument5 pagesResume Word Originaflkvapnf100% (1)

- Residence Time Distribution For Chemical ReactorsDocument71 pagesResidence Time Distribution For Chemical ReactorsJuan Carlos Serrano MedranoNo ratings yet

- Form 16 Part B 2016-17Document4 pagesForm 16 Part B 2016-17atulsharmaNo ratings yet

- Digital Control Systems (Elective) : Suggested ReadingDocument1 pageDigital Control Systems (Elective) : Suggested ReadingBebo DiaNo ratings yet

- EU Imports of Organic Agri-Food Products: Key Developments in 2019Document17 pagesEU Imports of Organic Agri-Food Products: Key Developments in 2019Dani FrancoNo ratings yet

- YL Clarity - Chromatography SW: YOUNG IN ChromassDocument4 pagesYL Clarity - Chromatography SW: YOUNG IN Chromasschâu huỳnhNo ratings yet

- S - 5 1 0 L, S - 5 1 0 R: PioneerDocument4 pagesS - 5 1 0 L, S - 5 1 0 R: PioneermiliindianuNo ratings yet

- Installation and Maintenance Manual For The GP Poro-Stone Gas FilterDocument4 pagesInstallation and Maintenance Manual For The GP Poro-Stone Gas FilterMahmoud El-abdNo ratings yet

- Filtrec F040 SeriesDocument8 pagesFiltrec F040 Serieshkhan10No ratings yet

- Background of Money Market in BangladeshDocument5 pagesBackground of Money Market in Bangladeshanamikabhoumik100% (1)

- Ed. William Lane, Arabic-English Lexicon - Vol.7 - 1885Document308 pagesEd. William Lane, Arabic-English Lexicon - Vol.7 - 1885Gagik DanielyanNo ratings yet

- MonotropismQuestionnaire 230510Document5 pagesMonotropismQuestionnaire 230510Javiera AlarconNo ratings yet

- Corporate Nvidia in BriefDocument2 pagesCorporate Nvidia in BriefakesplwebsiteNo ratings yet

- EE210 Hoja Datos SensovantDocument5 pagesEE210 Hoja Datos SensovantCoco SanchezNo ratings yet

- FFS PINNSEF 30 November 2020Document1 pageFFS PINNSEF 30 November 2020teguhsunyotoNo ratings yet

- HVAC Pump Handbook, Second Edition - Access Engineering From McGraw-HillDocument7 pagesHVAC Pump Handbook, Second Edition - Access Engineering From McGraw-HillamigdalNo ratings yet

- City Planning and Neighbourhood Design Case Studies1Document132 pagesCity Planning and Neighbourhood Design Case Studies1shinmiNo ratings yet

- Group 3 CW - Role of NGOs in Socio EconomicDocument9 pagesGroup 3 CW - Role of NGOs in Socio EconomicKisyenene JamusiNo ratings yet

- Final INTERNSHIP Report-AshishDocument66 pagesFinal INTERNSHIP Report-AshishAshish PantNo ratings yet