Professional Documents

Culture Documents

Core Range Adhesive Bonding Considerations

Core Range Adhesive Bonding Considerations

Uploaded by

vinothp53Copyright:

Available Formats

You might also like

- Radar Plotting SheetDocument1 pageRadar Plotting SheetCl dubeyNo ratings yet

- Ziehm Solo FD Service ManualDocument442 pagesZiehm Solo FD Service Manualdrakon100% (1)

- Bonding Optics To MetalsDocument8 pagesBonding Optics To MetalscavadavNo ratings yet

- Sakurai Solutions 5-1 5-2Document8 pagesSakurai Solutions 5-1 5-2Raza Ali RazaNo ratings yet

- Sanisol - SdsDocument6 pagesSanisol - SdsMohamad Arta100% (1)

- The Complete Technical Guide For AdhesivesDocument114 pagesThe Complete Technical Guide For Adhesivesbenkendimbizzat56No ratings yet

- Ebook - Why Do Bolts Loosen PDFDocument24 pagesEbook - Why Do Bolts Loosen PDFEduardo IvánNo ratings yet

- Airbase 753Document8 pagesAirbase 753Jagdish PatelNo ratings yet

- 3M Final Structural Adhesive Selection Guide-LoResDocument28 pages3M Final Structural Adhesive Selection Guide-LoRessambhav_iitkgpNo ratings yet

- Failure Bonded StructuresDocument71 pagesFailure Bonded StructuresPrasanthNo ratings yet

- 3M Adhesives Ref Guide PDFDocument40 pages3M Adhesives Ref Guide PDFNickpetriNo ratings yet

- Fastener TheoryDocument4 pagesFastener TheoryAnonymous OFP2ygPIdNo ratings yet

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument7 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Formarjan banooNo ratings yet

- 3M Industrial Adhesives and Tapes - Bonding SolutionsDocument40 pages3M Industrial Adhesives and Tapes - Bonding Solutionshadang.msdmNo ratings yet

- Seals and GuidesDocument64 pagesSeals and GuidespeterbweqrqNo ratings yet

- 3M Adesivos EstruturaisDocument28 pages3M Adesivos EstruturaisAnonymous mq0U43UsPNo ratings yet

- Savage 2007Document28 pagesSavage 2007Ali CiritNo ratings yet

- Strong Adhesive vs. Conventional Tagging: Articles From Website. ReadDocument1 pageStrong Adhesive vs. Conventional Tagging: Articles From Website. ReadWilmer CarreroNo ratings yet

- Bonded Joints PresentationDocument19 pagesBonded Joints Presentationmartin_calmonNo ratings yet

- Customer Information: Fastening Technology Efficient, Secure, SafeDocument18 pagesCustomer Information: Fastening Technology Efficient, Secure, SafebladdeeNo ratings yet

- Technical Specification For Dow Corning 789Document2 pagesTechnical Specification For Dow Corning 789Akash SharmaNo ratings yet

- Adhesive and SealantDocument36 pagesAdhesive and Sealantlaylayden kaNo ratings yet

- Astm C 794-2010Document7 pagesAstm C 794-2010zeqs9No ratings yet

- ID-7385C TDS May 11Document2 pagesID-7385C TDS May 11febrin rohmanNo ratings yet

- Molykote G RapidDocument2 pagesMolykote G RapidSukhDeolNo ratings yet

- Bonding Alternatives For Structural Requirements.Document6 pagesBonding Alternatives For Structural Requirements.Eduardo Javier Granados SanchezNo ratings yet

- Sealants 2Document6 pagesSealants 2Như HồNo ratings yet

- Dokumen - Tips Loctite Catalogue BondingDocument94 pagesDokumen - Tips Loctite Catalogue BondingdungdhtsNo ratings yet

- Choosing Between "Component" and "Cartridge" Mechanical SealsDocument3 pagesChoosing Between "Component" and "Cartridge" Mechanical SealsGonzalo VargasNo ratings yet

- Bosses: Figure 7: Boss Design GuidelinesDocument3 pagesBosses: Figure 7: Boss Design GuidelinesAaselNo ratings yet

- Starch TroubleshootingDocument4 pagesStarch Troubleshootingdgovender31No ratings yet

- FL Exothane 27: Polyurethane Construction SealantDocument3 pagesFL Exothane 27: Polyurethane Construction Sealantcremildo maetinhoNo ratings yet

- Grouting ManualDocument36 pagesGrouting ManualJorgeaul100% (1)

- CellrodDocument2 pagesCellrodjude tallyNo ratings yet

- Causes & Costs of Gasket FailureDocument1 pageCauses & Costs of Gasket FailureandrewvermaakNo ratings yet

- Cemtec Arbosil LMDocument2 pagesCemtec Arbosil LMlinsonNo ratings yet

- C StructuralPractices ZieglerDocument3 pagesC StructuralPractices ZieglerLingkaNo ratings yet

- Gluing Components: Practical GluesDocument4 pagesGluing Components: Practical GluesonafetsNo ratings yet

- 3M AdhesiveDocument100 pages3M AdhesiveRiki Nurzaman100% (2)

- Adhesive Bonding TechnologyDocument26 pagesAdhesive Bonding TechnologymichaelbaroneNo ratings yet

- 3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111Document4 pages3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111HugoNo ratings yet

- Finish Coatings System Adhesion and Test Methods: Ask The ExpertDocument3 pagesFinish Coatings System Adhesion and Test Methods: Ask The ExpertJose CuellarNo ratings yet

- EHC Global Joint Problems The Raw Truth About Handrail SplicingDocument2 pagesEHC Global Joint Problems The Raw Truth About Handrail SplicingTon marquesNo ratings yet

- Abe. Flex: Polymer Bonded E-Glass YarnDocument1 pageAbe. Flex: Polymer Bonded E-Glass Yarncremildo maetinhoNo ratings yet

- Project Report On Fabric AdhesiveDocument5 pagesProject Report On Fabric AdhesiveEIRI Board of Consultants and PublishersNo ratings yet

- Kapitel 07 DINO Techn TeilDocument5 pagesKapitel 07 DINO Techn Teilalecandro_90No ratings yet

- Determination of Re-Tack Ability of Carpet Adhesives: Standard Practice ForDocument2 pagesDetermination of Re-Tack Ability of Carpet Adhesives: Standard Practice ForAngel CamberoNo ratings yet

- Back To Basics: Mechanical Seals: Sealing SenseDocument4 pagesBack To Basics: Mechanical Seals: Sealing SensemusaNo ratings yet

- Coatings and Adhesive Mixing With Process ControlDocument4 pagesCoatings and Adhesive Mixing With Process ControlibssalesNo ratings yet

- VINNAPAS 537 ED en 2022.06.21 v2Document4 pagesVINNAPAS 537 ED en 2022.06.21 v2TagmoutiNo ratings yet

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDocument1 pageBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNo ratings yet

- Future-Proofing Fenders WhitepaperDocument9 pagesFuture-Proofing Fenders WhitepaperShannel VendiolaNo ratings yet

- 3MLiquidTapeAdhesives WP JR 10242018 PDFDocument3 pages3MLiquidTapeAdhesives WP JR 10242018 PDFCarlos H. CarneiroNo ratings yet

- Flexseal GA777Document2 pagesFlexseal GA777osama mohNo ratings yet

- OchureDocument13 pagesOchureFabian CampañaNo ratings yet

- Sealing Concept-RwDocument20 pagesSealing Concept-RwnuradiadnanNo ratings yet

- Dura. Cord & Dura. Sheet 40/100: Closed Cell Polyethylene Joint Formers & Back Up MaterialDocument2 pagesDura. Cord & Dura. Sheet 40/100: Closed Cell Polyethylene Joint Formers & Back Up Materialcremildo maetinhoNo ratings yet

- Concrete Bonder & Fortifier: SafetyDocument1 pageConcrete Bonder & Fortifier: SafetyBrianNo ratings yet

- Adhesives Retain With Confidence Tech ArticleDocument4 pagesAdhesives Retain With Confidence Tech ArticlegobajasaeindiaNo ratings yet

- Ais 18Document4 pagesAis 18Eslam NaseebNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Torsion Bar Rate ChartDocument1 pageTorsion Bar Rate Chartvinothp53No ratings yet

- NASA Fastener TrainingDocument14 pagesNASA Fastener Trainingvinothp53No ratings yet

- NASA Fastener TrainingDocument14 pagesNASA Fastener Trainingvinothp53No ratings yet

- Bighead Terminology Guide: Product Features Associated TerminologyDocument5 pagesBighead Terminology Guide: Product Features Associated Terminologyvinothp53No ratings yet

- Vibratory Residual Stress Relieving-A Review: S. N. ShaikhDocument4 pagesVibratory Residual Stress Relieving-A Review: S. N. Shaikhsrinathgudur11No ratings yet

- 5th Fancy BreadDocument7 pages5th Fancy BreadMera Funportal0% (1)

- Outsmart Your Anxious Brain - Worksheet Diagnosis Guide ExercisesDocument6 pagesOutsmart Your Anxious Brain - Worksheet Diagnosis Guide Exercisesdoppler_100% (1)

- BCGS MP-86Document511 pagesBCGS MP-86Valentina Renza PinoNo ratings yet

- Performance KPI's Optimization TipsDocument17 pagesPerformance KPI's Optimization TipsShekh Mohammad NasimNo ratings yet

- Remedial Uas B.ing LM (Intani Julien Putri Xii Ipa 6)Document9 pagesRemedial Uas B.ing LM (Intani Julien Putri Xii Ipa 6)Intani JulienNo ratings yet

- P2 Chp2 Section 2.1ADocument3 pagesP2 Chp2 Section 2.1APaing Khant KyawNo ratings yet

- Color TheoryDocument4 pagesColor TheoryJoshua OdonioNo ratings yet

- Fluid Mechanics PDFDocument48 pagesFluid Mechanics PDFrakib hasanNo ratings yet

- Direction TestDocument3 pagesDirection TestprascribdNo ratings yet

- Novilyn C. Pataray BSN - Ii Thalassemia Major: St. Paul College of Ilocos SurDocument1 pageNovilyn C. Pataray BSN - Ii Thalassemia Major: St. Paul College of Ilocos SurCharina Aubrey0% (1)

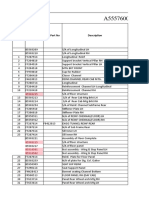

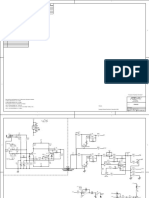

- A5557600PH79Document31 pagesA5557600PH79Sridharan VenkatNo ratings yet

- End-Of-Year Test: ListeningDocument3 pagesEnd-Of-Year Test: ListeningRox Purdea0% (1)

- Reimagine RTS Final ReportDocument88 pagesReimagine RTS Final ReportWXXI NewsNo ratings yet

- ENV 107L.15 Assignment 1 Analysis of The Ecological Condition of A PondDocument4 pagesENV 107L.15 Assignment 1 Analysis of The Ecological Condition of A Pondsafwan shamsNo ratings yet

- Panel Features: Square-D Fabricator and Control Systems EnterpriseDocument1 pagePanel Features: Square-D Fabricator and Control Systems EnterpriseCallista CollectionsNo ratings yet

- Construction Terms - English-FilipinoDocument1 pageConstruction Terms - English-FilipinoRhomayne Triz LapuzNo ratings yet

- TechNote CableModellingDocument12 pagesTechNote CableModellingLeonardo LeonNo ratings yet

- SyllogismDocument25 pagesSyllogismSunil GahlotNo ratings yet

- Inspiratory Muscle TrainingDocument15 pagesInspiratory Muscle Trainingulfapanjaitan100% (2)

- Week 4 - Column Interaction DiagramDocument8 pagesWeek 4 - Column Interaction DiagramMAYHAY, ADRIAN PAULNo ratings yet

- GSB PDFDocument4 pagesGSB PDFsachin sNo ratings yet

- Parts Catalog ARDFDocument30 pagesParts Catalog ARDFUlmanu ValentinNo ratings yet

- Updating The Canadian Standards Association Offshore Structures CodeDocument6 pagesUpdating The Canadian Standards Association Offshore Structures CodenabiloucheNo ratings yet

- Peavey Xr8000 SCHDocument12 pagesPeavey Xr8000 SCHLisandro Orrego SalvadorNo ratings yet

- Scapula Setting AnaIsabel AlmeidaDocument1 pageScapula Setting AnaIsabel AlmeidaPeter ZachNo ratings yet

Core Range Adhesive Bonding Considerations

Core Range Adhesive Bonding Considerations

Uploaded by

vinothp53Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Core Range Adhesive Bonding Considerations

Core Range Adhesive Bonding Considerations

Uploaded by

vinothp53Copyright:

Available Formats

Adhesive bonding considerations

Quick reference for Core range products

Post-process integration of bigHeads by adhesive bonding

We refer to adhesive bonding as post-process integration; it typically takes place after the component has

undergone the principal manufacturing or forming process. Depending on the adhesive used, it is possible

to adhesively bond bigHeads prior to painting or finishing. Whilst we offer guidance relating to adhesively

bonding bigHeads, application suitability must always be determined by consultation with the adhesive

manufacturer or supplier, or by appropriate testing.

Adhesive application bigHead integration Adhesively bonded bigHead

We do not specify whether you This can be done manually or using It is important to observe the

should put the adhesive onto the automated techniques recommended fixture time of the

substrate/ component, the bigHead, adhesive before attempting to

Simple markings, surface features

or both - if in doubt, consult your handle or load the bigHead after

on the component, physical fixtures

adhesive supplier adhesive bonding

or laser projection can all assist

Adhesives can be applied manually with accurate location during This is not always the same as, and

or using automated techniques manual operations is usually longer than, the working

time of the adhesive

Generic loading considerations for adhesively bonded bigHeads

The terminology used to Tensile loading Shear loading Torsion loading

describe mechanical Opposing forces acting Opposing forces acting Forces acting in opposing

loading of adhesively perpendicular to the parallel to the surface directions, rotating about

bonded bigHeads may surface plane and along plane and perpendicular the fastener axis - expect

vary from other fasteners the fastener axis - expect to the fastener axis - 1 Nm to 70 Nm

or fastening technologies 0.25 kN to 3.75 kN expect 0.1 kN to 5 kN depending on the

depending on the depending on the bigHead & adhesive used

bigHead & adhesive used bigHead & adhesive used BE AWARE: this does

not imply tightening

torque capabilities

The information within this document is for guidance purposes only and does not constitute a guarantee

or warranty of any kind. bigHead cannot accept liability for performance arising from use of these

products. Application suitability should always be determined by appropriate testing and evaluation. © Copyright bigHead 2020 Page 1 of 2

Drawings and diagrams are for illustrative purposes only and may differ from actual products.

For technical inquiries, please contact bigHead on +44 (0) 1202 574 601 or visit www.bigHead.co.uk.

Adhesive bonding considerations

Quick reference for Core range products

Critical issues and guidance topics for adhesive bonding of bigHeads

Surface preparation and cleaning

The exact requirements vary between adhesives,

but our general advice is to take necessary steps to

remove any dust, moisture, release agent or other

contaminants from the component surface prior to

bonding a bigHead in place. Abrasion is not always

necessary, but cleaning is always recommended.

Controlling adhesive overspill

Large lumps of adhesive spilling out of perforation holes

can interfere with assembly, and increase adhesive

wastage. To stop this, we recommended considering the

application of a thin (50~100 μm) transparent self-

adhesive film on the upper side of the bigHead prior to

bonding. We do this with our test specimens, and we are

happy to advise on suitable cutting sizes.

Beware of assembly gaps

The tightening forces generated during assembly Adhesive

can be enough to separate an adhesively bonded bondline thickness

bigHead from the component surface. To avoid this,

recommendations © Cranfield University

especially in cases where there are gaps between

the fastened components, ensure that tightening

torques do not create resultant forces above the Be aware of factors that affect the adhesive

tensile load capability of the adhesive or the performance and proper cure

bigHead. Adhesives generally have an ideal bond-line thickness for

achieving proper cure and optimum mechanical

performance - be sure to maintain this, and observe the

adhesive manufacturer’s recommended cure parameters

Always follow the adhesive manufacturer’s when bonding bigHeads.

instructions and recommendations. Usage of an Carbon steel bigHead products are supplied with a Zinc

adhesive product by bigHead does not imply any electroplate finish, which can interfere with the cure of

kind of endorsement or approval. some adhesive products - always check adhesive

compatibility or perform tensile tests on bonded bigHeads

to determine compatibility.

The information within this document is for guidance purposes only and does not constitute a guarantee

or warranty of any kind. bigHead cannot accept liability for performance arising from use of these

products. Application suitability should always be determined by appropriate testing and evaluation. © Copyright bigHead 2020 Page 2 of 2

Drawings and diagrams are for illustrative purposes only and may differ from actual products.

For technical inquiries, please contact bigHead on +44 (0) 1202 574 601 or visit www.bigHead.co.uk.

You might also like

- Radar Plotting SheetDocument1 pageRadar Plotting SheetCl dubeyNo ratings yet

- Ziehm Solo FD Service ManualDocument442 pagesZiehm Solo FD Service Manualdrakon100% (1)

- Bonding Optics To MetalsDocument8 pagesBonding Optics To MetalscavadavNo ratings yet

- Sakurai Solutions 5-1 5-2Document8 pagesSakurai Solutions 5-1 5-2Raza Ali RazaNo ratings yet

- Sanisol - SdsDocument6 pagesSanisol - SdsMohamad Arta100% (1)

- The Complete Technical Guide For AdhesivesDocument114 pagesThe Complete Technical Guide For Adhesivesbenkendimbizzat56No ratings yet

- Ebook - Why Do Bolts Loosen PDFDocument24 pagesEbook - Why Do Bolts Loosen PDFEduardo IvánNo ratings yet

- Airbase 753Document8 pagesAirbase 753Jagdish PatelNo ratings yet

- 3M Final Structural Adhesive Selection Guide-LoResDocument28 pages3M Final Structural Adhesive Selection Guide-LoRessambhav_iitkgpNo ratings yet

- Failure Bonded StructuresDocument71 pagesFailure Bonded StructuresPrasanthNo ratings yet

- 3M Adhesives Ref Guide PDFDocument40 pages3M Adhesives Ref Guide PDFNickpetriNo ratings yet

- Fastener TheoryDocument4 pagesFastener TheoryAnonymous OFP2ygPIdNo ratings yet

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument7 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Formarjan banooNo ratings yet

- 3M Industrial Adhesives and Tapes - Bonding SolutionsDocument40 pages3M Industrial Adhesives and Tapes - Bonding Solutionshadang.msdmNo ratings yet

- Seals and GuidesDocument64 pagesSeals and GuidespeterbweqrqNo ratings yet

- 3M Adesivos EstruturaisDocument28 pages3M Adesivos EstruturaisAnonymous mq0U43UsPNo ratings yet

- Savage 2007Document28 pagesSavage 2007Ali CiritNo ratings yet

- Strong Adhesive vs. Conventional Tagging: Articles From Website. ReadDocument1 pageStrong Adhesive vs. Conventional Tagging: Articles From Website. ReadWilmer CarreroNo ratings yet

- Bonded Joints PresentationDocument19 pagesBonded Joints Presentationmartin_calmonNo ratings yet

- Customer Information: Fastening Technology Efficient, Secure, SafeDocument18 pagesCustomer Information: Fastening Technology Efficient, Secure, SafebladdeeNo ratings yet

- Technical Specification For Dow Corning 789Document2 pagesTechnical Specification For Dow Corning 789Akash SharmaNo ratings yet

- Adhesive and SealantDocument36 pagesAdhesive and Sealantlaylayden kaNo ratings yet

- Astm C 794-2010Document7 pagesAstm C 794-2010zeqs9No ratings yet

- ID-7385C TDS May 11Document2 pagesID-7385C TDS May 11febrin rohmanNo ratings yet

- Molykote G RapidDocument2 pagesMolykote G RapidSukhDeolNo ratings yet

- Bonding Alternatives For Structural Requirements.Document6 pagesBonding Alternatives For Structural Requirements.Eduardo Javier Granados SanchezNo ratings yet

- Sealants 2Document6 pagesSealants 2Như HồNo ratings yet

- Dokumen - Tips Loctite Catalogue BondingDocument94 pagesDokumen - Tips Loctite Catalogue BondingdungdhtsNo ratings yet

- Choosing Between "Component" and "Cartridge" Mechanical SealsDocument3 pagesChoosing Between "Component" and "Cartridge" Mechanical SealsGonzalo VargasNo ratings yet

- Bosses: Figure 7: Boss Design GuidelinesDocument3 pagesBosses: Figure 7: Boss Design GuidelinesAaselNo ratings yet

- Starch TroubleshootingDocument4 pagesStarch Troubleshootingdgovender31No ratings yet

- FL Exothane 27: Polyurethane Construction SealantDocument3 pagesFL Exothane 27: Polyurethane Construction Sealantcremildo maetinhoNo ratings yet

- Grouting ManualDocument36 pagesGrouting ManualJorgeaul100% (1)

- CellrodDocument2 pagesCellrodjude tallyNo ratings yet

- Causes & Costs of Gasket FailureDocument1 pageCauses & Costs of Gasket FailureandrewvermaakNo ratings yet

- Cemtec Arbosil LMDocument2 pagesCemtec Arbosil LMlinsonNo ratings yet

- C StructuralPractices ZieglerDocument3 pagesC StructuralPractices ZieglerLingkaNo ratings yet

- Gluing Components: Practical GluesDocument4 pagesGluing Components: Practical GluesonafetsNo ratings yet

- 3M AdhesiveDocument100 pages3M AdhesiveRiki Nurzaman100% (2)

- Adhesive Bonding TechnologyDocument26 pagesAdhesive Bonding TechnologymichaelbaroneNo ratings yet

- 3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111Document4 pages3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111HugoNo ratings yet

- Finish Coatings System Adhesion and Test Methods: Ask The ExpertDocument3 pagesFinish Coatings System Adhesion and Test Methods: Ask The ExpertJose CuellarNo ratings yet

- EHC Global Joint Problems The Raw Truth About Handrail SplicingDocument2 pagesEHC Global Joint Problems The Raw Truth About Handrail SplicingTon marquesNo ratings yet

- Abe. Flex: Polymer Bonded E-Glass YarnDocument1 pageAbe. Flex: Polymer Bonded E-Glass Yarncremildo maetinhoNo ratings yet

- Project Report On Fabric AdhesiveDocument5 pagesProject Report On Fabric AdhesiveEIRI Board of Consultants and PublishersNo ratings yet

- Kapitel 07 DINO Techn TeilDocument5 pagesKapitel 07 DINO Techn Teilalecandro_90No ratings yet

- Determination of Re-Tack Ability of Carpet Adhesives: Standard Practice ForDocument2 pagesDetermination of Re-Tack Ability of Carpet Adhesives: Standard Practice ForAngel CamberoNo ratings yet

- Back To Basics: Mechanical Seals: Sealing SenseDocument4 pagesBack To Basics: Mechanical Seals: Sealing SensemusaNo ratings yet

- Coatings and Adhesive Mixing With Process ControlDocument4 pagesCoatings and Adhesive Mixing With Process ControlibssalesNo ratings yet

- VINNAPAS 537 ED en 2022.06.21 v2Document4 pagesVINNAPAS 537 ED en 2022.06.21 v2TagmoutiNo ratings yet

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDocument1 pageBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNo ratings yet

- Future-Proofing Fenders WhitepaperDocument9 pagesFuture-Proofing Fenders WhitepaperShannel VendiolaNo ratings yet

- 3MLiquidTapeAdhesives WP JR 10242018 PDFDocument3 pages3MLiquidTapeAdhesives WP JR 10242018 PDFCarlos H. CarneiroNo ratings yet

- Flexseal GA777Document2 pagesFlexseal GA777osama mohNo ratings yet

- OchureDocument13 pagesOchureFabian CampañaNo ratings yet

- Sealing Concept-RwDocument20 pagesSealing Concept-RwnuradiadnanNo ratings yet

- Dura. Cord & Dura. Sheet 40/100: Closed Cell Polyethylene Joint Formers & Back Up MaterialDocument2 pagesDura. Cord & Dura. Sheet 40/100: Closed Cell Polyethylene Joint Formers & Back Up Materialcremildo maetinhoNo ratings yet

- Concrete Bonder & Fortifier: SafetyDocument1 pageConcrete Bonder & Fortifier: SafetyBrianNo ratings yet

- Adhesives Retain With Confidence Tech ArticleDocument4 pagesAdhesives Retain With Confidence Tech ArticlegobajasaeindiaNo ratings yet

- Ais 18Document4 pagesAis 18Eslam NaseebNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Torsion Bar Rate ChartDocument1 pageTorsion Bar Rate Chartvinothp53No ratings yet

- NASA Fastener TrainingDocument14 pagesNASA Fastener Trainingvinothp53No ratings yet

- NASA Fastener TrainingDocument14 pagesNASA Fastener Trainingvinothp53No ratings yet

- Bighead Terminology Guide: Product Features Associated TerminologyDocument5 pagesBighead Terminology Guide: Product Features Associated Terminologyvinothp53No ratings yet

- Vibratory Residual Stress Relieving-A Review: S. N. ShaikhDocument4 pagesVibratory Residual Stress Relieving-A Review: S. N. Shaikhsrinathgudur11No ratings yet

- 5th Fancy BreadDocument7 pages5th Fancy BreadMera Funportal0% (1)

- Outsmart Your Anxious Brain - Worksheet Diagnosis Guide ExercisesDocument6 pagesOutsmart Your Anxious Brain - Worksheet Diagnosis Guide Exercisesdoppler_100% (1)

- BCGS MP-86Document511 pagesBCGS MP-86Valentina Renza PinoNo ratings yet

- Performance KPI's Optimization TipsDocument17 pagesPerformance KPI's Optimization TipsShekh Mohammad NasimNo ratings yet

- Remedial Uas B.ing LM (Intani Julien Putri Xii Ipa 6)Document9 pagesRemedial Uas B.ing LM (Intani Julien Putri Xii Ipa 6)Intani JulienNo ratings yet

- P2 Chp2 Section 2.1ADocument3 pagesP2 Chp2 Section 2.1APaing Khant KyawNo ratings yet

- Color TheoryDocument4 pagesColor TheoryJoshua OdonioNo ratings yet

- Fluid Mechanics PDFDocument48 pagesFluid Mechanics PDFrakib hasanNo ratings yet

- Direction TestDocument3 pagesDirection TestprascribdNo ratings yet

- Novilyn C. Pataray BSN - Ii Thalassemia Major: St. Paul College of Ilocos SurDocument1 pageNovilyn C. Pataray BSN - Ii Thalassemia Major: St. Paul College of Ilocos SurCharina Aubrey0% (1)

- A5557600PH79Document31 pagesA5557600PH79Sridharan VenkatNo ratings yet

- End-Of-Year Test: ListeningDocument3 pagesEnd-Of-Year Test: ListeningRox Purdea0% (1)

- Reimagine RTS Final ReportDocument88 pagesReimagine RTS Final ReportWXXI NewsNo ratings yet

- ENV 107L.15 Assignment 1 Analysis of The Ecological Condition of A PondDocument4 pagesENV 107L.15 Assignment 1 Analysis of The Ecological Condition of A Pondsafwan shamsNo ratings yet

- Panel Features: Square-D Fabricator and Control Systems EnterpriseDocument1 pagePanel Features: Square-D Fabricator and Control Systems EnterpriseCallista CollectionsNo ratings yet

- Construction Terms - English-FilipinoDocument1 pageConstruction Terms - English-FilipinoRhomayne Triz LapuzNo ratings yet

- TechNote CableModellingDocument12 pagesTechNote CableModellingLeonardo LeonNo ratings yet

- SyllogismDocument25 pagesSyllogismSunil GahlotNo ratings yet

- Inspiratory Muscle TrainingDocument15 pagesInspiratory Muscle Trainingulfapanjaitan100% (2)

- Week 4 - Column Interaction DiagramDocument8 pagesWeek 4 - Column Interaction DiagramMAYHAY, ADRIAN PAULNo ratings yet

- GSB PDFDocument4 pagesGSB PDFsachin sNo ratings yet

- Parts Catalog ARDFDocument30 pagesParts Catalog ARDFUlmanu ValentinNo ratings yet

- Updating The Canadian Standards Association Offshore Structures CodeDocument6 pagesUpdating The Canadian Standards Association Offshore Structures CodenabiloucheNo ratings yet

- Peavey Xr8000 SCHDocument12 pagesPeavey Xr8000 SCHLisandro Orrego SalvadorNo ratings yet

- Scapula Setting AnaIsabel AlmeidaDocument1 pageScapula Setting AnaIsabel AlmeidaPeter ZachNo ratings yet