Professional Documents

Culture Documents

Clinker Coating Tool

Clinker Coating Tool

Uploaded by

YhaneCopyright:

Available Formats

You might also like

- Raw Mix Design SoftwareDocument6 pagesRaw Mix Design SoftwareIrfan Ahmed100% (1)

- Chemical Formulae and Equations Part 2Document18 pagesChemical Formulae and Equations Part 2Mohd NorihwanNo ratings yet

- Tabela para Cálculo Dos Minerais Normativos Da Norma CIPWDocument1 pageTabela para Cálculo Dos Minerais Normativos Da Norma CIPWguguj348No ratings yet

- Geochemistry & Earth ProcessesDocument27 pagesGeochemistry & Earth ProcessesYoussef OuahziziNo ratings yet

- Raw Mix Design SoftwareDocument6 pagesRaw Mix Design Software张群利No ratings yet

- Lime StoneDocument40 pagesLime StoneCygnus BackofficeNo ratings yet

- Tests On Portland Cement: CompositionDocument27 pagesTests On Portland Cement: CompositionIrma NurrohmahNo ratings yet

- En Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501Document2 pagesEn Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501JGGNo ratings yet

- Slag Fundamentals & Phase DiagramsDocument38 pagesSlag Fundamentals & Phase DiagramsNicole Altamirano Catalán100% (1)

- 1.1table - Mineral ChemistryDocument3 pages1.1table - Mineral Chemistryjako_kcNo ratings yet

- Chemistry Advanced Level Problem Solving (ALPS-9) - SolutionDocument10 pagesChemistry Advanced Level Problem Solving (ALPS-9) - SolutionAnanmay ChauhanNo ratings yet

- Hasil Dan PembahasanDocument5 pagesHasil Dan Pembahasanromando23lumbanrajaNo ratings yet

- Geokimia 3Document60 pagesGeokimia 3Maddey Joeniour Aloene IINo ratings yet

- OREAS 45e CertificateDocument14 pagesOREAS 45e CertificateGilang PamungkasNo ratings yet

- Project 1 7/31/2022Document3 pagesProject 1 7/31/2022hamza A.laftaNo ratings yet

- Ju 001 06 0918 0000 04 Re 0002 - 1Document8 pagesJu 001 06 0918 0000 04 Re 0002 - 1aach17No ratings yet

- Improvement in Internal Soundness of Railway Wheel by Controlling De-Oxidation Practice in Steel-MakingDocument38 pagesImprovement in Internal Soundness of Railway Wheel by Controlling De-Oxidation Practice in Steel-MakingBinod Kumar PadhiNo ratings yet

- 18 10Document5 pages18 10dong16h14No ratings yet

- Glass Composition, Glass TypesDocument4 pagesGlass Composition, Glass TypesKhiZra ShahZadNo ratings yet

- BP Kiln Feed BurnabilityDocument2 pagesBP Kiln Feed BurnabilityJuliano. PQMNo ratings yet

- Portland Cement Cement Clinker and Heat of Hydration of Portland CementDocument28 pagesPortland Cement Cement Clinker and Heat of Hydration of Portland CementJaphet Charles Japhet MunnahNo ratings yet

- Desulphurization by Slag TreatmentDocument22 pagesDesulphurization by Slag TreatmentanandvinaygeraNo ratings yet

- Change in Fly Ash With Thermal TreatmentDocument15 pagesChange in Fly Ash With Thermal TreatmentDũng NguyễnNo ratings yet

- 04 Rock-Eval Ver.1Document29 pages04 Rock-Eval Ver.1khansaNo ratings yet

- Chapter 3-Chemistry and Physics of Clinker Burnin-DrusbaDocument50 pagesChapter 3-Chemistry and Physics of Clinker Burnin-DrusbaCommerciale A.V.No ratings yet

- Dados Termodinâmicos FinalDocument149 pagesDados Termodinâmicos FinalAlmerindo JuniorNo ratings yet

- Quality Control Formulas: 1. Loss On Ignition (LOI) (CO2 From Calcination)Document5 pagesQuality Control Formulas: 1. Loss On Ignition (LOI) (CO2 From Calcination)Dharmendra AmetaNo ratings yet

- Quality Control Formulas 1Document5 pagesQuality Control Formulas 1Dharmendra AmetaNo ratings yet

- Metals: Strengthening Mechanisms in Nickel-Copper Alloys: A ReviewDocument18 pagesMetals: Strengthening Mechanisms in Nickel-Copper Alloys: A ReviewLurkswayNo ratings yet

- Semi Soft Coking Coal and PCI CoalDocument2 pagesSemi Soft Coking Coal and PCI CoalYusuff QuadrilateralNo ratings yet

- Bahianite Al SB O (OH) : Crystal DataDocument1 pageBahianite Al SB O (OH) : Crystal DataramzchileNo ratings yet

- Back To Basics - 2Document5 pagesBack To Basics - 2Ahmed Nasr ElbehairyNo ratings yet

- En Assets ANE4 18328 Analysis of Major and Minor Elements in Bauxite Samples Prepared As Fused Beads Tcm50-55499Document2 pagesEn Assets ANE4 18328 Analysis of Major and Minor Elements in Bauxite Samples Prepared As Fused Beads Tcm50-55499JGGNo ratings yet

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Document1 pageAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaNo ratings yet

- Raw Mix Design CementDocument4 pagesRaw Mix Design Cementtariqshah100% (1)

- TRABAJO N°5 Balance MetalurgicoDocument4 pagesTRABAJO N°5 Balance MetalurgicoRolan SuyoNo ratings yet

- Worksheet Exp 3Document2 pagesWorksheet Exp 3KazhvinieNo ratings yet

- Introduction To Iron Making and Blast Furnace TechnologyDocument24 pagesIntroduction To Iron Making and Blast Furnace TechnologyDevansh MankarNo ratings yet

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDocument1 pageSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNo ratings yet

- Phos Cu PDFDocument1 pagePhos Cu PDFLuis BadoffNo ratings yet

- Raw Mix Design-Dalmia Cement LimitedDocument2 pagesRaw Mix Design-Dalmia Cement LimitedNihar Ranjan Tripathy50% (2)

- XRD 001 ReportDocument4 pagesXRD 001 Reportmuhammad akbarNo ratings yet

- Limestone NCS DC60108aDocument1 pageLimestone NCS DC60108aHasanuddin NurdinNo ratings yet

- Hervé Et Al. (2010a)Document22 pagesHervé Et Al. (2010a)Gabriel GonzálezNo ratings yet

- Chemistry Tips and TracksDocument22 pagesChemistry Tips and TracksMuhammad AsifNo ratings yet

- OREAS 401 CertificateDocument7 pagesOREAS 401 Certificateflysch_ukNo ratings yet

- Impact of Fuel Ash On Clinker Quality: Tom LowesDocument3 pagesImpact of Fuel Ash On Clinker Quality: Tom LowesJohn GiannakopoulosNo ratings yet

- Za Buy EliteDocument1 pageZa Buy EliteramzchileNo ratings yet

- How To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition ConditionsDocument2 pagesHow To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition Conditionstaufiq_hidayat_1982No ratings yet

- OREAS 74aDocument23 pagesOREAS 74aSri RatnaNo ratings yet

- Acetaldehyde Production From Ethanol by Eco-Friendly Non-Chromium Catalysts Consisting of Copper and Calcium SilicateDocument6 pagesAcetaldehyde Production From Ethanol by Eco-Friendly Non-Chromium Catalysts Consisting of Copper and Calcium SilicateSARATH BALANo ratings yet

- Appendix 1: Characteristics of Binary Phase DiagramsDocument3 pagesAppendix 1: Characteristics of Binary Phase DiagramsTales FerreiraNo ratings yet

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityDocument93 pages1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelNo ratings yet

- Samples For Malvern XRF TestingDocument1 pageSamples For Malvern XRF TestingLuki ArdhiantoNo ratings yet

- Specification Hydrate FinalDocument6 pagesSpecification Hydrate FinalSanjayNo ratings yet

- Product Specifications Hydrate2018Document6 pagesProduct Specifications Hydrate2018Jayakumar ANo ratings yet

- KatoiteDocument1 pageKatoiteRajuNSanaboinaNo ratings yet

- Dados Termodinâmicos - FinalDocument157 pagesDados Termodinâmicos - FinalAlmerindo JuniorNo ratings yet

- New Frontiers in Asymmetric CatalysisFrom EverandNew Frontiers in Asymmetric CatalysisKoichi MikamiNo ratings yet

- Novel Carbon Materials and Composites: Synthesis, Properties and ApplicationsFrom EverandNovel Carbon Materials and Composites: Synthesis, Properties and ApplicationsXin JiangNo ratings yet

- What Do You Know About The Kiln Coating?: Jin ZhenDocument11 pagesWhat Do You Know About The Kiln Coating?: Jin ZhenYhaneNo ratings yet

- 4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsDocument10 pages4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsYhaneNo ratings yet

- 4ReasonsWhyBearingsFail 1693328338320Document11 pages4ReasonsWhyBearingsFail 1693328338320YhaneNo ratings yet

- Contamination Technical ArticleDocument18 pagesContamination Technical ArticleYhaneNo ratings yet

- Identifying & Resolving Common Rotary Kiln Processing ChallengesDocument11 pagesIdentifying & Resolving Common Rotary Kiln Processing ChallengesYhaneNo ratings yet

- Cement EnglishonlyDocument12 pagesCement EnglishonlyYhaneNo ratings yet

- Brochure Cleaning Services E-Mkt3Document4 pagesBrochure Cleaning Services E-Mkt3YhaneNo ratings yet

- Optimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsDocument5 pagesOptimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsYhaneNo ratings yet

- 03 Maxilift 17 WsDocument25 pages03 Maxilift 17 WsYhaneNo ratings yet

- FormulaDocument60 pagesFormulaYhaneNo ratings yet

- OptimizingRawMillsPerformance theMaterialsWAY 1670142333901Document17 pagesOptimizingRawMillsPerformance theMaterialsWAY 1670142333901YhaneNo ratings yet

- GasConditioningTowers-RedecamGroup 1664087203547Document3 pagesGasConditioningTowers-RedecamGroup 1664087203547YhaneNo ratings yet

- Common Problems in Cement PlantDocument6 pagesCommon Problems in Cement PlantYhane100% (1)

- OpenCircuit, ShortCircuitandOverloadfault 1670307651977Document28 pagesOpenCircuit, ShortCircuitandOverloadfault 1670307651977YhaneNo ratings yet

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- Infinity For Cement Equipment: Quality & Composition of Cement ClinkerDocument48 pagesInfinity For Cement Equipment: Quality & Composition of Cement ClinkerYhaneNo ratings yet

- CemScanner WEBDocument5 pagesCemScanner WEBYhaneNo ratings yet

- Bus Ele Tech Lib Disconnecting MeansDocument5 pagesBus Ele Tech Lib Disconnecting MeansYhaneNo ratings yet

- What Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsDocument8 pagesWhat Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsYhaneNo ratings yet

- Bucket Elevator Installation Manual 473793 Revised 2016Document77 pagesBucket Elevator Installation Manual 473793 Revised 2016YhaneNo ratings yet

- Clinkerization-CementPlantOptimization 1670139096737Document12 pagesClinkerization-CementPlantOptimization 1670139096737YhaneNo ratings yet

- Electric Motor Problems and SolutionsDocument7 pagesElectric Motor Problems and SolutionsYhaneNo ratings yet

- IncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809Document6 pagesIncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809YhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933YhaneNo ratings yet

- Section Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessDocument27 pagesSection Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessYhaneNo ratings yet

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436YhaneNo ratings yet

- Uguide 1451Document137 pagesUguide 1451YhaneNo ratings yet

- COOLER MANUAL 2 (Process)Document112 pagesCOOLER MANUAL 2 (Process)YhaneNo ratings yet

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- Em 9057Document21 pagesEm 9057getahun esubalewNo ratings yet

- Management of Broiler FarmsDocument47 pagesManagement of Broiler FarmssmoubarakNo ratings yet

- KS3 Sci / 8B 8F Test MC AnswersDocument7 pagesKS3 Sci / 8B 8F Test MC AnswersPaul BurgessNo ratings yet

- Advanced Dairy Chemistry-1 Proteins: January 2003Document45 pagesAdvanced Dairy Chemistry-1 Proteins: January 2003prateek kushwahaNo ratings yet

- Colak Foamed GypsumDocument8 pagesColak Foamed GypsumOnyx XynoNo ratings yet

- Reinforced MasonaryDocument37 pagesReinforced MasonaryRAHULNo ratings yet

- Protection of Steel Reinforcement For ConcreteDocument42 pagesProtection of Steel Reinforcement For ConcretevnilNo ratings yet

- General Science Ability NotesDocument25 pagesGeneral Science Ability NotesZulfiqar Ali TunioNo ratings yet

- Sulfated Ash From Lubricating Oils and Additives: Standard Test Method ForDocument5 pagesSulfated Ash From Lubricating Oils and Additives: Standard Test Method ForDennise ChicaizaNo ratings yet

- SdfasdfDocument5 pagesSdfasdfMarman Fabro Anga-AnganNo ratings yet

- Shrinkage in Concrete, Definition, Types, and Factors Affecting Concrete ShrinkageDocument13 pagesShrinkage in Concrete, Definition, Types, and Factors Affecting Concrete Shrinkagevishnu ksNo ratings yet

- FFCTitanium TMS2007Document29 pagesFFCTitanium TMS2007ildaNo ratings yet

- Chapter 4 PDFDocument25 pagesChapter 4 PDFChuahSiewHoonNo ratings yet

- Fluid Mechanics 8th Edition White Solutions ManualDocument25 pagesFluid Mechanics 8th Edition White Solutions ManualHannahMendozajtykNo ratings yet

- Flame Test Chem 04 05Document2 pagesFlame Test Chem 04 05anon-579447No ratings yet

- Calcium Gluconate Dosage PlusDocument8 pagesCalcium Gluconate Dosage PlusJaved ArifNo ratings yet

- Cambridge O Level: Chemistry 5070/22 October/November 2020Document11 pagesCambridge O Level: Chemistry 5070/22 October/November 2020Islamabad ALMA SchoolNo ratings yet

- Ferro AlloysDocument17 pagesFerro AlloysNarasimha Murthy InampudiNo ratings yet

- Artigo CientificoDocument30 pagesArtigo CientificoAndreia AnjosNo ratings yet

- Doherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysDocument8 pagesDoherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysMolly0630No ratings yet

- 0620 m15 Ms 22Document6 pages0620 m15 Ms 22sookchinNo ratings yet

- Juice Sulphitation Process - Methods of Sugar Cane Juice SulphitationDocument6 pagesJuice Sulphitation Process - Methods of Sugar Cane Juice SulphitationYounas Sardar0% (1)

- Unified Test Third Periodical Examination Science 8Document5 pagesUnified Test Third Periodical Examination Science 8Benjan100% (1)

- SS1 Chemistry First, Second, and Third Term NotesDocument225 pagesSS1 Chemistry First, Second, and Third Term NotesSochi0% (1)

- Section 01 Cold Lime SofteningDocument6 pagesSection 01 Cold Lime SofteningSheikh SahabNo ratings yet

- Chemie Dampf enDocument16 pagesChemie Dampf enmishtinilNo ratings yet

- Surface Irrigation ADAMADocument123 pagesSurface Irrigation ADAMAGirma JankaNo ratings yet

- 0620 s04 QP 1Document16 pages0620 s04 QP 1Varun PanickerNo ratings yet

- Mine SpecificationDocument8 pagesMine SpecificationRizal TengkuNo ratings yet

Clinker Coating Tool

Clinker Coating Tool

Uploaded by

YhaneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clinker Coating Tool

Clinker Coating Tool

Uploaded by

YhaneCopyright:

Available Formats

sample (1)

Sample 1 GUANGZHOU

Date: 22/06/2005 Time: aver.

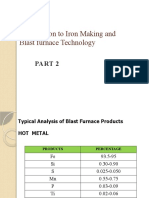

Analysis CaO SiO2 Al2O3 Fe2O3 SO3 K2O Na2O MgO CaOfree

65,59 21,72 5,30 3,55 0,96 0,45 0,07 0,54 0,99

L.O.I. total [%]

Description Formula Value Remarks 0,24 98,43

Alite C3 S 58,53 45...65

Belite C2 S 16,06 10...30 Clinker of usual composition

Aluminate phase C3 A 8,04 5...15

Ferrite phase C4AF 10,80 5...12

Calcium-Ferrit C2 F 0,00

Silica-Ratio S.R. 2,45 2,0...3,0 good range

Alumina-Iron-Ratio A.R. 1,49 1,3...2,5 viscosity of liquid-phase in good range

Silicic-Acid-Ratio S.A. 4,10 2,5...3,5 out of range! (coatability!)

Lime Standard (Kühl) LST II 94,54 90...98

Lime Saturation Fac. LSF 0,94 0,9...1,15

0

Burning Temp. (min) C 1 397 <1.450 0C easy burning condition

0

Burning Temp. (min) F 2 547 <2,640 0F

Coating Index C.I. 29,15 25...30 stable coating

Liqu.-Ph. (LEA) 1.4000C/2,5500F 25,47 23...28 liquid phase in a good range

Burnability-Index B.I. 3,11 2,6...4,5 good range ---> lower = better

Burnability-Factor B.F. 116 108 (105...110)

-

CL - Alkali-Ratio Cl- / A 0,04 <1,0

Alkali-Sulphate-Ratio ASR(VT10) 203,02 95 - 105 SO3-excess, possible CaSO4-formation

Alkali-Sulphate-Ratio ASR(MR) 0,48 0,8 - 1,2 SO3-excess, possible CaSO4-formation

Alkali-Equivalent A.E. 0,37 <1,0

Clinker_Coating_Tool 04/02/2019

You might also like

- Raw Mix Design SoftwareDocument6 pagesRaw Mix Design SoftwareIrfan Ahmed100% (1)

- Chemical Formulae and Equations Part 2Document18 pagesChemical Formulae and Equations Part 2Mohd NorihwanNo ratings yet

- Tabela para Cálculo Dos Minerais Normativos Da Norma CIPWDocument1 pageTabela para Cálculo Dos Minerais Normativos Da Norma CIPWguguj348No ratings yet

- Geochemistry & Earth ProcessesDocument27 pagesGeochemistry & Earth ProcessesYoussef OuahziziNo ratings yet

- Raw Mix Design SoftwareDocument6 pagesRaw Mix Design Software张群利No ratings yet

- Lime StoneDocument40 pagesLime StoneCygnus BackofficeNo ratings yet

- Tests On Portland Cement: CompositionDocument27 pagesTests On Portland Cement: CompositionIrma NurrohmahNo ratings yet

- En Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501Document2 pagesEn Assets ANE4 18328 Analysis of Major and Minor Elements in Cement Pressed Powders Tcm50-55501JGGNo ratings yet

- Slag Fundamentals & Phase DiagramsDocument38 pagesSlag Fundamentals & Phase DiagramsNicole Altamirano Catalán100% (1)

- 1.1table - Mineral ChemistryDocument3 pages1.1table - Mineral Chemistryjako_kcNo ratings yet

- Chemistry Advanced Level Problem Solving (ALPS-9) - SolutionDocument10 pagesChemistry Advanced Level Problem Solving (ALPS-9) - SolutionAnanmay ChauhanNo ratings yet

- Hasil Dan PembahasanDocument5 pagesHasil Dan Pembahasanromando23lumbanrajaNo ratings yet

- Geokimia 3Document60 pagesGeokimia 3Maddey Joeniour Aloene IINo ratings yet

- OREAS 45e CertificateDocument14 pagesOREAS 45e CertificateGilang PamungkasNo ratings yet

- Project 1 7/31/2022Document3 pagesProject 1 7/31/2022hamza A.laftaNo ratings yet

- Ju 001 06 0918 0000 04 Re 0002 - 1Document8 pagesJu 001 06 0918 0000 04 Re 0002 - 1aach17No ratings yet

- Improvement in Internal Soundness of Railway Wheel by Controlling De-Oxidation Practice in Steel-MakingDocument38 pagesImprovement in Internal Soundness of Railway Wheel by Controlling De-Oxidation Practice in Steel-MakingBinod Kumar PadhiNo ratings yet

- 18 10Document5 pages18 10dong16h14No ratings yet

- Glass Composition, Glass TypesDocument4 pagesGlass Composition, Glass TypesKhiZra ShahZadNo ratings yet

- BP Kiln Feed BurnabilityDocument2 pagesBP Kiln Feed BurnabilityJuliano. PQMNo ratings yet

- Portland Cement Cement Clinker and Heat of Hydration of Portland CementDocument28 pagesPortland Cement Cement Clinker and Heat of Hydration of Portland CementJaphet Charles Japhet MunnahNo ratings yet

- Desulphurization by Slag TreatmentDocument22 pagesDesulphurization by Slag TreatmentanandvinaygeraNo ratings yet

- Change in Fly Ash With Thermal TreatmentDocument15 pagesChange in Fly Ash With Thermal TreatmentDũng NguyễnNo ratings yet

- 04 Rock-Eval Ver.1Document29 pages04 Rock-Eval Ver.1khansaNo ratings yet

- Chapter 3-Chemistry and Physics of Clinker Burnin-DrusbaDocument50 pagesChapter 3-Chemistry and Physics of Clinker Burnin-DrusbaCommerciale A.V.No ratings yet

- Dados Termodinâmicos FinalDocument149 pagesDados Termodinâmicos FinalAlmerindo JuniorNo ratings yet

- Quality Control Formulas: 1. Loss On Ignition (LOI) (CO2 From Calcination)Document5 pagesQuality Control Formulas: 1. Loss On Ignition (LOI) (CO2 From Calcination)Dharmendra AmetaNo ratings yet

- Quality Control Formulas 1Document5 pagesQuality Control Formulas 1Dharmendra AmetaNo ratings yet

- Metals: Strengthening Mechanisms in Nickel-Copper Alloys: A ReviewDocument18 pagesMetals: Strengthening Mechanisms in Nickel-Copper Alloys: A ReviewLurkswayNo ratings yet

- Semi Soft Coking Coal and PCI CoalDocument2 pagesSemi Soft Coking Coal and PCI CoalYusuff QuadrilateralNo ratings yet

- Bahianite Al SB O (OH) : Crystal DataDocument1 pageBahianite Al SB O (OH) : Crystal DataramzchileNo ratings yet

- Back To Basics - 2Document5 pagesBack To Basics - 2Ahmed Nasr ElbehairyNo ratings yet

- En Assets ANE4 18328 Analysis of Major and Minor Elements in Bauxite Samples Prepared As Fused Beads Tcm50-55499Document2 pagesEn Assets ANE4 18328 Analysis of Major and Minor Elements in Bauxite Samples Prepared As Fused Beads Tcm50-55499JGGNo ratings yet

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Document1 pageAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaNo ratings yet

- Raw Mix Design CementDocument4 pagesRaw Mix Design Cementtariqshah100% (1)

- TRABAJO N°5 Balance MetalurgicoDocument4 pagesTRABAJO N°5 Balance MetalurgicoRolan SuyoNo ratings yet

- Worksheet Exp 3Document2 pagesWorksheet Exp 3KazhvinieNo ratings yet

- Introduction To Iron Making and Blast Furnace TechnologyDocument24 pagesIntroduction To Iron Making and Blast Furnace TechnologyDevansh MankarNo ratings yet

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDocument1 pageSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNo ratings yet

- Phos Cu PDFDocument1 pagePhos Cu PDFLuis BadoffNo ratings yet

- Raw Mix Design-Dalmia Cement LimitedDocument2 pagesRaw Mix Design-Dalmia Cement LimitedNihar Ranjan Tripathy50% (2)

- XRD 001 ReportDocument4 pagesXRD 001 Reportmuhammad akbarNo ratings yet

- Limestone NCS DC60108aDocument1 pageLimestone NCS DC60108aHasanuddin NurdinNo ratings yet

- Hervé Et Al. (2010a)Document22 pagesHervé Et Al. (2010a)Gabriel GonzálezNo ratings yet

- Chemistry Tips and TracksDocument22 pagesChemistry Tips and TracksMuhammad AsifNo ratings yet

- OREAS 401 CertificateDocument7 pagesOREAS 401 Certificateflysch_ukNo ratings yet

- Impact of Fuel Ash On Clinker Quality: Tom LowesDocument3 pagesImpact of Fuel Ash On Clinker Quality: Tom LowesJohn GiannakopoulosNo ratings yet

- Za Buy EliteDocument1 pageZa Buy EliteramzchileNo ratings yet

- How To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition ConditionsDocument2 pagesHow To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition Conditionstaufiq_hidayat_1982No ratings yet

- OREAS 74aDocument23 pagesOREAS 74aSri RatnaNo ratings yet

- Acetaldehyde Production From Ethanol by Eco-Friendly Non-Chromium Catalysts Consisting of Copper and Calcium SilicateDocument6 pagesAcetaldehyde Production From Ethanol by Eco-Friendly Non-Chromium Catalysts Consisting of Copper and Calcium SilicateSARATH BALANo ratings yet

- Appendix 1: Characteristics of Binary Phase DiagramsDocument3 pagesAppendix 1: Characteristics of Binary Phase DiagramsTales FerreiraNo ratings yet

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityDocument93 pages1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelNo ratings yet

- Samples For Malvern XRF TestingDocument1 pageSamples For Malvern XRF TestingLuki ArdhiantoNo ratings yet

- Specification Hydrate FinalDocument6 pagesSpecification Hydrate FinalSanjayNo ratings yet

- Product Specifications Hydrate2018Document6 pagesProduct Specifications Hydrate2018Jayakumar ANo ratings yet

- KatoiteDocument1 pageKatoiteRajuNSanaboinaNo ratings yet

- Dados Termodinâmicos - FinalDocument157 pagesDados Termodinâmicos - FinalAlmerindo JuniorNo ratings yet

- New Frontiers in Asymmetric CatalysisFrom EverandNew Frontiers in Asymmetric CatalysisKoichi MikamiNo ratings yet

- Novel Carbon Materials and Composites: Synthesis, Properties and ApplicationsFrom EverandNovel Carbon Materials and Composites: Synthesis, Properties and ApplicationsXin JiangNo ratings yet

- What Do You Know About The Kiln Coating?: Jin ZhenDocument11 pagesWhat Do You Know About The Kiln Coating?: Jin ZhenYhaneNo ratings yet

- 4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsDocument10 pages4 Reasons You Have Entrained Air in Your Pumping System: - 2 Min Read PumpsYhaneNo ratings yet

- 4ReasonsWhyBearingsFail 1693328338320Document11 pages4ReasonsWhyBearingsFail 1693328338320YhaneNo ratings yet

- Contamination Technical ArticleDocument18 pagesContamination Technical ArticleYhaneNo ratings yet

- Identifying & Resolving Common Rotary Kiln Processing ChallengesDocument11 pagesIdentifying & Resolving Common Rotary Kiln Processing ChallengesYhaneNo ratings yet

- Cement EnglishonlyDocument12 pagesCement EnglishonlyYhaneNo ratings yet

- Brochure Cleaning Services E-Mkt3Document4 pagesBrochure Cleaning Services E-Mkt3YhaneNo ratings yet

- Optimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsDocument5 pagesOptimization of Air Distribution in A Baghouse Filter Using Computational Fluid DynamicsYhaneNo ratings yet

- 03 Maxilift 17 WsDocument25 pages03 Maxilift 17 WsYhaneNo ratings yet

- FormulaDocument60 pagesFormulaYhaneNo ratings yet

- OptimizingRawMillsPerformance theMaterialsWAY 1670142333901Document17 pagesOptimizingRawMillsPerformance theMaterialsWAY 1670142333901YhaneNo ratings yet

- GasConditioningTowers-RedecamGroup 1664087203547Document3 pagesGasConditioningTowers-RedecamGroup 1664087203547YhaneNo ratings yet

- Common Problems in Cement PlantDocument6 pagesCommon Problems in Cement PlantYhane100% (1)

- OpenCircuit, ShortCircuitandOverloadfault 1670307651977Document28 pagesOpenCircuit, ShortCircuitandOverloadfault 1670307651977YhaneNo ratings yet

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- Infinity For Cement Equipment: Quality & Composition of Cement ClinkerDocument48 pagesInfinity For Cement Equipment: Quality & Composition of Cement ClinkerYhaneNo ratings yet

- CemScanner WEBDocument5 pagesCemScanner WEBYhaneNo ratings yet

- Bus Ele Tech Lib Disconnecting MeansDocument5 pagesBus Ele Tech Lib Disconnecting MeansYhaneNo ratings yet

- What Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsDocument8 pagesWhat Is The Root Cause of High Vibration On Id Fan: MaintenanceforumsYhaneNo ratings yet

- Bucket Elevator Installation Manual 473793 Revised 2016Document77 pagesBucket Elevator Installation Manual 473793 Revised 2016YhaneNo ratings yet

- Clinkerization-CementPlantOptimization 1670139096737Document12 pagesClinkerization-CementPlantOptimization 1670139096737YhaneNo ratings yet

- Electric Motor Problems and SolutionsDocument7 pagesElectric Motor Problems and SolutionsYhaneNo ratings yet

- IncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809Document6 pagesIncreaseYourMachinesEnergyEfficiency Insight AcornIndustrialServicesltd 1670396101809YhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd 1670395912933YhaneNo ratings yet

- Section Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessDocument27 pagesSection Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessYhaneNo ratings yet

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- 12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436Document8 pages12reasonsforcouplingfailureandhowtoavoidthem Insight AcornIndustrialServicesltd - 1670396292436YhaneNo ratings yet

- Uguide 1451Document137 pagesUguide 1451YhaneNo ratings yet

- COOLER MANUAL 2 (Process)Document112 pagesCOOLER MANUAL 2 (Process)YhaneNo ratings yet

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- Em 9057Document21 pagesEm 9057getahun esubalewNo ratings yet

- Management of Broiler FarmsDocument47 pagesManagement of Broiler FarmssmoubarakNo ratings yet

- KS3 Sci / 8B 8F Test MC AnswersDocument7 pagesKS3 Sci / 8B 8F Test MC AnswersPaul BurgessNo ratings yet

- Advanced Dairy Chemistry-1 Proteins: January 2003Document45 pagesAdvanced Dairy Chemistry-1 Proteins: January 2003prateek kushwahaNo ratings yet

- Colak Foamed GypsumDocument8 pagesColak Foamed GypsumOnyx XynoNo ratings yet

- Reinforced MasonaryDocument37 pagesReinforced MasonaryRAHULNo ratings yet

- Protection of Steel Reinforcement For ConcreteDocument42 pagesProtection of Steel Reinforcement For ConcretevnilNo ratings yet

- General Science Ability NotesDocument25 pagesGeneral Science Ability NotesZulfiqar Ali TunioNo ratings yet

- Sulfated Ash From Lubricating Oils and Additives: Standard Test Method ForDocument5 pagesSulfated Ash From Lubricating Oils and Additives: Standard Test Method ForDennise ChicaizaNo ratings yet

- SdfasdfDocument5 pagesSdfasdfMarman Fabro Anga-AnganNo ratings yet

- Shrinkage in Concrete, Definition, Types, and Factors Affecting Concrete ShrinkageDocument13 pagesShrinkage in Concrete, Definition, Types, and Factors Affecting Concrete Shrinkagevishnu ksNo ratings yet

- FFCTitanium TMS2007Document29 pagesFFCTitanium TMS2007ildaNo ratings yet

- Chapter 4 PDFDocument25 pagesChapter 4 PDFChuahSiewHoonNo ratings yet

- Fluid Mechanics 8th Edition White Solutions ManualDocument25 pagesFluid Mechanics 8th Edition White Solutions ManualHannahMendozajtykNo ratings yet

- Flame Test Chem 04 05Document2 pagesFlame Test Chem 04 05anon-579447No ratings yet

- Calcium Gluconate Dosage PlusDocument8 pagesCalcium Gluconate Dosage PlusJaved ArifNo ratings yet

- Cambridge O Level: Chemistry 5070/22 October/November 2020Document11 pagesCambridge O Level: Chemistry 5070/22 October/November 2020Islamabad ALMA SchoolNo ratings yet

- Ferro AlloysDocument17 pagesFerro AlloysNarasimha Murthy InampudiNo ratings yet

- Artigo CientificoDocument30 pagesArtigo CientificoAndreia AnjosNo ratings yet

- Doherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysDocument8 pagesDoherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysMolly0630No ratings yet

- 0620 m15 Ms 22Document6 pages0620 m15 Ms 22sookchinNo ratings yet

- Juice Sulphitation Process - Methods of Sugar Cane Juice SulphitationDocument6 pagesJuice Sulphitation Process - Methods of Sugar Cane Juice SulphitationYounas Sardar0% (1)

- Unified Test Third Periodical Examination Science 8Document5 pagesUnified Test Third Periodical Examination Science 8Benjan100% (1)

- SS1 Chemistry First, Second, and Third Term NotesDocument225 pagesSS1 Chemistry First, Second, and Third Term NotesSochi0% (1)

- Section 01 Cold Lime SofteningDocument6 pagesSection 01 Cold Lime SofteningSheikh SahabNo ratings yet

- Chemie Dampf enDocument16 pagesChemie Dampf enmishtinilNo ratings yet

- Surface Irrigation ADAMADocument123 pagesSurface Irrigation ADAMAGirma JankaNo ratings yet

- 0620 s04 QP 1Document16 pages0620 s04 QP 1Varun PanickerNo ratings yet

- Mine SpecificationDocument8 pagesMine SpecificationRizal TengkuNo ratings yet