Professional Documents

Culture Documents

Multi-Function Power Meter - A2000

Multi-Function Power Meter - A2000

Uploaded by

C&P GroupOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multi-Function Power Meter - A2000

Multi-Function Power Meter - A2000

Uploaded by

C&P GroupCopyright:

Available Formats

A2000

Multifunctional Power Meter

3-348-980-03

17/1.10

• Measurement of current, voltage, active, reactive and apparent

power, power factor, active and reactive energy, harmonic

distortion and harmonics

• Precision measured values with error limits of 0.25% for U and I

• Depending upon model, capable of communications with Profibus-

DP, LONWORKS interface or RS 485 interface with Modbus RTU

and other protocols

• Front panel dimensions: 144 x 144 mm

• Minimal installation depth of less than 60 mm

• Good legibility thanks to the high contrast, 14 mm LED display

• Continuous recording of selected measured values

for load profile and statistical purposes (optional)

• Interference recording function with high speed recording

QUALITY MANAGEMENT SYSTEM

of events and pre-event history (optional)

• Electrically isolated current inputs

• Two limit value contacts which can be assigned as desired

to measured values

DQS certified per

DIN EN ISO 9001 Reg. No.1262

Applications Applicable Regulations and Standards

The measuring instrument is used for the analysis of alternating IEC/EN 61010-1 / Safety requirements for electrical equipment for

current systems, in particular where conventional analog VDE 0411 Part 1 measurement, control and laboratory use

measuring instruments included in distribution systems no longer DIN 43864 Current interface for pulse transmission between

fulfill continuously growing demands. This is especially applicable impulse meters and tariff devices (for pulse output)

where harmonic distortion and harmonics are crucial in addition DIN EN 61326 Electrical equipment for measurement, control and

to current, voltage and power. VDE 0843 Part 20 laboratory use – EMC requirements

As a further range of applications, the meter is also capable of IEC/EN 60529/VDE 0470 Part 1 Protection provided by enclosures (IP code)

eliminating combined use of measuring instruments which are

operated simultaneously along with conventional recorders and

fault indicators. In combination with current and voltage trans-

formers, the instrument performs the most important measure-

ments required in low and medium-voltage systems. Function and Operational Principle

Analog outputs, limit values and interfaces are available for the

monitoring and processing of measured values. A time curve is The measuring instrument acquires instantaneous values for star-

simultaneously recorded for up to 12 measured values in a fail- connected voltages and currents at three-phase electrical sys-

safe system if the instrument version with integrated memory is tems. If no neutral is available, the instrument automatically creates

utilized. Important measured values can be monitored continu- a virtual neutral point. The speed at which measured values are

ously over a long period of time, or recording can be triggered for logged depends upon the respective line frequency. Each mea-

a specified duration by an event. In the case of event controlled sured value is updated 32 times per period, which allows for the

recording, it is also possible to record the pre-history which lead acquirement of measuring signals of up to the 15th harmonic.

up to the event at the same speed. This provides the user with a After these values have been stored to memory, analysis and cal-

comprehensive overview of the pre-history which has resulted in culation of data such as delta and star-connected currents and

an error. The instrument thus fulfills the function of a fault recorder voltages begin, as well as the determination of parameters for

significantly better than conventional paper chart recorders. power, power factor, energy, harmonic distortion and harmonics.

The values are calculated in accordance with DIN 40110 Part 1

and 2.

All calculated values are available to the display, the serial inter-

face, the analog outputs and the limit value monitoring system.

GMC-I Messtechnik GmbH

A2000

Multifunctional Power Meter

Data Storage Representation of Values for Power and Power Factor According to the

Up to 12 measured values can be selected for storage to mem- Selected Parameters Configuration

ory. The measuring instrument acquires these measured values

once every 300 ms and stores them first to intermediate memory. DIN = calculation of reactive power per DIN 40110

These values are then averaged in accordance with the selected without + or – sign

sampling rate and are stored to permanent memory as mean val-

ues. The sampling rate is adjustable from 300 ms to max. 24

hours. Recording is triggered by means of internally selected limit Q= S2 – P2

values. The duration of the recording can be set within a range of 0

1 minute to 31 days. Several events can thus be stored to mem- PF = cap PF = ind

ory, one after the other. The trigger level which starts the record- P=– P=+

Q=+ Q=+

ing can be set to either 0%, 25%, 50% or 75% for the duration of

any given recording. This provides the user with an overview of EP– 2. Q 1. Q EP+

the pre-history of the event which triggered recording, including EQ– EQ+

1 1

time and date. EP– EP+

3. Q 4. Q

Continuous recording is also possible. EQ– EQ+

The memory has a capacity for up to 250,000 values. The maxi- P=– P=+

mum possible duration of a recording depends upon the number Q=+ Q=+

PF = ind PF = cap

of recorded measured values (1 to 12), and the sampling rate at

which they are to be recorded (0.3 s to 24 h). 0

The memory module is a buffered CMOS RAM. Data integrity is

assured for at least 8 years.

Sign= calculation of reactive power with + or – sign

TN

u t i t – -----4- dt

1

Q = ------

TN

TN

0

Safety Display User Interface 0

Impedance

Lock PF = ind PF = ind

P=– P=+

Parameters

RS-232

Vol- L1 Q=+ Q=+

tage

Memory RS-485

CPU

Inputs L2 16 Bit EP– 2. Q 1. Q EP+

L3 Mux ADC LON EQ+ EQ+

12 Bit (alternative to RS-485 1 1

N and Profibus-DP) EP– EP+

3. Q 4. Q

Profibus-DP EQ– EQ–

Cur- I1

rent (alternative to RS-485

I2 and LON) P=– P=+

Inputs

I3 Q=– Q=–

PF = cap PF = cap

Synchronizing

(Option)

Input 0

230 V / Power Pulse

(Option)

115 V Outputs

supply Comp= compensating reactive power

or (reactive power is only produced if current

20 ... 69 V / 20 ... 72 V

or

and voltage have different + or – signs)

}

Analog

73 ... 264 V / 73 ... 276 V (Option) Outputs

TN

u t i t dt

(not with 2

U

Q = – ------

I

Profibus-DP TN

and partly not 0

with LON) for u(t) · i(t) < 0

PF = 1.0 PF = ind

P=– P=+

Q=0 Q=+

Limit

Values EP– EP+

2. Q 1. Q

EQ+ EQ+

1 1

EP– EP+

3. Q 4. Q

EQ– EQ–

P=– P=+

Q=0 Q=–

PF = 1.0 PF = cap

0

Fig. 1 Schematic Diagram

Fig. 2 Values for Power and Power Factor

2 GMC-I Messtechnik GmbH

A2000

Multifunctional Power Meter

Energy Display 126, and can thus be used to allow for the assignment of an

address to the instrument via the Profibus.

The instrument is equipped with eight energy meters for the The selected baud rate only applies to the RS 232 interface for

display of energy values. The following energy values appear at these instrument versions. The master determines transmission

these displays upon shipment from the factory: speed for the Profibus. The A2000 can be operated at the

– Active energy for phases 1, 2 and 3, Profibus DP at transmission speeds of up to 12 mega-baud.

as well as for the overall system

– Reactive energy for phases 1, 2 and 3, LONWORKS Interface

as well as for the overall system The power meters can be alternatively equipped with a LON inter-

The meters can be reconfigured to display the following energy face. In this case, the LONWORKS interface replaces the RS 485.

values during instrument configuration: The RS 232 interface is still used for configuring parameters and

for reading out the contents of the data memory. The optional

Active energy, high tariff, import for the overall system

data logger can be used with these instrument versions as well, in

Active energy, low tariff, import for the overall system

which case the read-out of recorded data is accomplished via the

Active energy, high tariff, export for the overall system

RS 232 interface.

Active energy, low tariff, export for the overall system

Reactive energy, high tariff, import for the overall system

Reactive energy, low tariff, import for the overall system Profibus DP

Reactive energy, high tariff, export for the overall system All measurement data, except for values stored to the data logger,

Reactive energy, low tariff, export for the overall system can be read out via the bus link. Transmission speeds of up to

Switching from high to low tariff can be accomplished either by 12 mega-baud are possible. The standard Profibus 9-pin plug is

means of the synchronization input, an external contact or the used to connect these measuring instruments to the Profibus DP.

data logger’s internal clock (only possible if the instrument version

with data logger is utilized).

Programming

Harmonic Analysis The instrument can be programmed either with the keys at the

front panel or via serial interface. All selected values remain in

Harmonic analysis is performed approximately once per second memory, even if mains failure should occur.

using the 32 averaged, sampled values per signal and mains All programmed parameters, except for the limit values, can be

period. FFT (fast Fourier transformation) provides components up protected against inadvertent change with a switch (LOCK) at the

to the 15th harmonic to this end. These are used to calculate the instrument’s rear panel.

RMS values of the fundamental harmonic (HD 1) and the This assures that the instrument configuration is not changed dur-

individual higher harmonics (HD 2 ... 15), as well as total harmonic ing limit value selection.

distortion (THD). These effective values are displayed for the Alternatively, the LOCK switch can be programmed to protect all

phase currents, and harmonic distortion is displayed for the parameters, including the limit values, against unauthorized modi-

phase voltages (RMS values with reference to the RMS value for fication.

the overall signal).

Due to the fact that the A2000 is not equipped with a special

The following values can be set during programming:

antialiasing filter, distortion in excess of the 17th order may

influence measurement results for the higher harmonics.

Type of Electrical System

4-wire unbalanced load or

3-wire unbalanced load or

3-wire balanced load

Serial Interfaces

As standard equipment, the measuring instrument is provided The energy meters can be configured to display active and

with an RS 232 and an RS 485 interface. Both interfaces use the reactive energy for phases L1, L2 and L3, as well as for the overall

same protocol, which can be selected as desired. system, or active and reactive energy for the overall system sub-

divided into energy import and export, and high and low tariff.

The GMC device bus per DIN draft 19244, protocol per EN

60870 and Modbus RTU are available. A baud rate or 1200,

Inputs

2400, 4800, 9600 or 19,200 can be selected. The address can

be set within a range of 0 to 254, and parity can be set to even, Secondary Transformer Current 5 A or 1 A

odd, none or space. Primary Transformer Current 1A

Several measured values are always transmitted with one data 5 A to 5000 A in 5 A steps

word, allowing for especially fast transmission. to 50000 A in 50 A steps

In the versions with LONWORKS interface the serial interface to 150000 A in 500 A steps

RS 485 has been dimensioned for the LONWORKS interface. No Secondary Transformer Voltage From 100 V to 500 V

additional settings are required for LON. in 1 V steps

In the versions with Profibus DP the serial interface RS 485 has Primary Transformer Voltage From 100 V to 100 kV

been dimensioned for the Profibus DP. The selected address is in 100 V steps

valid for the RS 232, as well as for the Profibus DP. Addresses to 800 kV in 1 kV steps

greater than or equal to 126 are interpreted as Profibus address

GMC-I Messtechnik GmbH 3

A2000

Multifunctional Power Meter

Time Period for Type of Electrical System

Mean Power Values External via synchronizing input Configuration 4-wire unbalanced

or internally adjustable from 1 to

(The energy meters display

60 minutes

active and reactive energy for

Synchronizing Input External, or operation with inter- phases L1, L2 and L3, as well

nal mean value generation, as for the overall system.)

adjustable from 1 to 60 minutes

Synchronizing Input Function Synchronization of mean values, Inputs

tariff switching or external

Current second. transformer current 5 A

control of the limit values relays

primary current same as

secondary (= ratio 1:1)

Outputs

Voltage secondary phase conductor

Limit Value Monitoring – Monitored measured voltage at the transformer 500 V

values (sources) primary phase conductor

– Min-max characteristics voltage same as secondary

– Hysteresis (= ratio 1:1)

– Alarm message storage, on/off

Synchronizing Pulse internal, mean value over 15 min.

– Limit value

2 or 4 Analog Outputs – Measured values which Outputs

influence the analog outputs

– Output range 4 ... 20 mA, Limit Value 1 Measured value: IL1

0 ... 20 mA, 20 mA, set to: 5A

10 mA No hysteresis

0 ... 10 V, 2 ... 10 V, 10 V or Relay closes when exceeded

5V No storage of alarm messages

– Analog range with lower and Limit Value 2 Measured value: U L1

upper rang values (indepen- set to: 240 V

dent of measuring range) No hysteresis

Pulse Outputs – Export, Import Relay closes when exceeded

for Active or Reactive Energy – Overall energy or energy No storage of alarm messages

from the individual phase Analog Output 1 Meas. value: Overall active

conductors power

– Active or reactive energy Range: Import

– Pulse rate: 0 ... 2000 W

1 ... 1000 pulses per kWh Output Value: 4 ... 20 mA

in steps of 1 Analog Output 2 Meas. value: Overall

1000 ... 5000 pulses per kWh reactive power

in steps of 10 Range: Import

The same pulse rates can be 0 ... 1000 Var

used for MWh as well. Output Value: 4 ... 20 mA

Serial Interfaces Either GMC device bus, Analog Output 3 (optional) Meas. value: I L2

EN 60870 or Modbus RTU Range 0 ... 5 A

protocol Output Value: 4 ... 20 mA

Analog Output 4 (optional) Meas. value: U L2

Attention: RS 232 and RS 485 Range: 0 ... 250 V

use the same protocol. Output Value: 4 ... 20 mA

Pulse Output 1 (optional) Meas. value: overall system

Addresses with values ranging Active Energy Import

from 0 to 254 10 pulses per kWh

Baud rate: 1200, 2400, 4800,

Pulse Output 2 (optional) Meas. value: overall system

9600 or 19,200

Active Energy Export

Parity: even, odd, none or space

10 pulses per kWh

The measuring instrument is configured with the following Serial Interfaces

parameters at the factory:

Address 250

All parameters can be subsequently changed by the user.

Baud Rate 9600

The encoding switch for securing selected parameters against

change is set at the factory to allow for parameter changes. Protocol GMC device bus

Parity even

4 GMC-I Messtechnik GmbH

A2000

Multifunctional Power Meter

Characteristic Values Relay Outputs

Switching Capacity / 250 V, 2 A, 500 VA / 50 W

Measurement Inputs (nominal load)

Voltage Inputs Service Life > 500000 switching cycles

Phase – Phase 0 ... 500 ... 550 V, 40 ... 70 Hz

Phase – N (ground) 0 ... 290 ... 320 V, 40 ... 70 Hz Display

Overload 1.2-fold Type 7-Segment LED

Intrinsic Impedance > 290 k Display Color red

Power Consumption < 1.1 W Character Height 13.2 mm

Current Inputs 0 ... 1 ... 1.2 A, 0 ... 5 ... 6 A Display Range

Overload 1.4-fold cont. Energy 999999999

30 A / 10 s, 100 A / 3 s Power Factor 1.00

Power Consumption < 150 mW Other Quantities 9999

Sampling Rate 32 samples per period and measured value Internal Clock (only for version with data logger, LON or Profibus)

Measuring Error NV = nominal value, MV = measured value Accuracy < 2.5 s/day

Current (0.25 % of NV + 1 digit) Power Supply lithium cell,

for MV 2 % of NV service life > 8 years

Voltage (0.25 % of NV + 1 digit) Power Supply

Power, Energy (0.5 % of NV + 1 digit) Supply Voltage

Power Factor 0.02 for U, I > 10 % of NV Feature H0 230 V / 115 V ± 10%, 45 ... 65 Hz

Frequency 0.02 Hz Feature H1 20 ... 69 V 45...450 Hz

4-Quadrant Operation Measurement: import and export, 20 ... 72 V

inductive and capacitive Feature H2 73 ... 264 V 45...450 Hz

Interfaces RS-232 and RS-485 73 ... 276 V

alternatively: Feature H3 20 ... 27 V 45 ... 450 Hz

RS-232 and LON or 20 ... 36 V

RS-232 and Profibus-DP Power Consumption max. 15 VA

Baud Rate 1200, 2400, 4800, 9600, 19200 baud The instrument is not equipped with an integrated circuit breaker.

Parity even, odd, space, no Therefore, during installation, care should be taken to ensure that

Protocol for – the building where the instrument is installed includes a circuit

RS-232 and RS-485 selectable: breaker,

GMC device bus (DIN draft 19244),

EN 60870 or Modbus (RTU) – the circuit breaker is positioned in close proximity to the instrument

Synchronizing input and is easily accessible to the operator,

On short-circuited with R < 10 – it is clearly marked as a circuit breaking device for the instrument.

Off open with R > 10 M Electrical Safety

Pulse Outputs Variants IEC 61010-1 / EN 61010-1

Contact open collector Protection Class II

Current ON 10 mA ... 27 mA Measurement

OFF < 2 mA Category inputs: III, relays: II

External Voltage 8 ... 30 V Pollution Degree 2

Pulse Duration adjustable: 100 ms ... 800 ms Operating Voltage 300 V /

Interpulse Period 10 ms Test Voltage measuring inputs: 3.7 kV

Protection IEC 60529 / EN 60529

Analog Outputs Front Panel IP 52

Output Quantity configurable Housing IP 30

Terminals IP 20

Current Fuses

Ranges 0 – 20 mA, 4 – 20 mA, ± 20 mA, ± 10 mA The supply circuit is protected by an internally soldered fuse.

Load max. 500 Feature H0 T160mA/250V

Load Effect < 0.8 A / (0 ... 250 ... 500 ) Feature H1 T1A/250V

Resolution 0.1% of control range Feature H2 T250mA/250V

Error Limit 0.5 % of final value Feature H3 T1.25A/250V

Voltage EMC

Ranges 0 – 10 V, 2 – 10 V, 10 V, 5 V

Interference Emission/

Load < 20 mA Interference Immunity IEC 61326 / EN 61326

Load Effect no effect to > 10 K

Resolution 0.1% of control range Ambient Conditions

Error Limit 1.0% of final value Operating Temp. 0 ... 50 °C

where control range = upper range limit – lower range limit, Storage Temp. – 25 ... 70 °C

e.g. 1200 W = 1500 W – 300 W (freely selectable values) Relative Humidity 75%, no condensation allowed

GMC-I Messtechnik GmbH 5

A2000

Multifunctional Power Meter

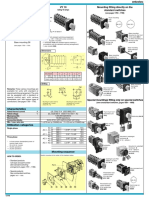

Terminal Assignments Terminals

Screw clamps for wires/cords up to 2.5 mm²

Current Inputs and/or two-core wire-end ferrules for 2 x 1.0 mm²

Connection with 3 Current Transformers

Variants with RS 232 and RS 485 Serial Interface, or with LON and RS 232

in 3 or 4-Phase Mains System (4L) 13 14 15

L3 k l N 115V 230V

L2 k l ±10% 45...65 Hz

Supply voltage 20...69 V

L1 k l (power supply) 20...72 V

see marking on

N name plate 73...264 V

Relay 1 Relay 2 I1 I2 I3 N L1 L2 L3 73...276 V

1 3 4 6 7 9 11 2 5 8 k l k l k l

51 52 53 55 56 57 1 3 4 6 7 9 11 2 5 8 13 14 15 Power supply

max. 15 VA

RELAY 1RELAY 2 I1 I2 I3 N L1 L2 L3 Power

supply

Connection with 2 Current Transformers

in 3-Phase Mains System (3L)

L3 k l

L2

L1 k l

46 45 44 43 42 41 38 37 35 33 31 24 23 22 21 20

1 3 4 6 7 9 2 5 8 B A

LON

RxD A1 A2 A3 A4 Sync.- S01 +

RELAY 1RELAY 2 I1 TxD C B A S02

I2 I3 N L1 L2 L3 Power Analog Input

supply RS-232 RS-485 Output Pulse

Output

Please observe permissible feature combinations when ordering

Connection with 1 Current Transformer

Design with Profibus-DP and RS-232 Serial Interface

in 4-Phase Mains System (identical load, IN = 0) 13 14 15

(3L-1) L3

N 115V 230V

L2

±10% 45...65 Hz

L1 k l Supply voltage 20...69 V

(power supply) 20...72 V

N see marking on

name plate 73...264 V

Relay 1 Relay 2 I1 I2 I3 N L1 L2 L3 73...276 V

1 3 11 2

k l k l k l

Power supply

RELAY 1RELAY 2 I1 I2 I3 N L1 L2 L3 Power

51 52 53 55 56 57 1 3 4 6 7 9 11 2 5 8 13 14 15

max. 15 VA

supply

Connection with 1 Current Transformer

in 3-Phase Mains System (identical load)

(3L-1) L3

L2

L1 k l

1 3 2 5 8 46 45 44 24 23 22 21 20

RELAY 1RELAY 2 I1 I2 I3 N L1 L2 L3 Power

RxD Sync.- S01 +

Supply TxD Input S02

Profibus-DP

COM 2 RS-232 Pulse

Output

6 GMC-I Messtechnik GmbH

A2000

Multifunctional Power Meter

Mechanical Design Accessory Software

Front dimensions 144 x 144 mm METRAwin10/A2000

Panel cutout 138 +1 x 138 +1 mm Software for read-out and processing of measured values as they

Bezel height 8 mm occur, or values from the data logger in the A2000 multifunctional

Installation depth 59.1 mm power meter, and for configuring parameters at the A200.

Weight 1 kg (without packaging) This software runs under Windows 95/98/ME, Windows NT, 2000

and XP.

Mounting DIN screw clamps

Terminals Screw clamp terminal blocks • Read-out of measured values

from the power meter’s data logger

Dimensional Drawing • Continuous recording of measured values

over a given period of time

max. 25.4

• Display of measured values

144 – as a function of time in line recorder format,

– in tabular form,

– digitally as individual values or

– analog as bar graphs

• Freely selectable time intervals

• Identification of curves for the recognition of individual

144

measured value sequences

• Simple, clear parameters configuration for the A2000

• Parameters configurations

for frequently recurring setups can be saved to memory

• Measured values can be exported

to other Windows programs

151.1 8 • Mathematical functions

59.1

Panel Cutout

138 + 1 x 138 + 1 Software Description

Data Acquisition and Display

METRAwin10/A2000 provides for an unambiguous display of

the contents of the data memory from the A2000. Alternatively,

All Dimensions in mm measured values can be continuously queried from the measuring

instrument by the software, and stored to a data file.

METRAwin10/A2000 summarizes values from the data logger or

online recorded values in tabular form, and documents minimum

Standard Equipment and maximum values with date and time as well.

Power meters without data memory All measured values can be plainly represented as a function of

(without optional data logger): time with a y-t graph. The time scale can be expanded or

Measuring instruments without data logger are shipped with contracted to allow for optimal representation. The cursor can be

operating instructions in either German, English or French. placed at the corresponding position within the time scale for

precision readings.

Power meters with data memory Measured values can also be displayed digitally. Up to four mea-

(with optional data logger): sured values can be displayed at the monitor simultaneously in

digital form.

In addition to the measuring instrument and operating instruc-

tions, in either German, English or French, power meters with

data logger also include a floppy disk with METRAwin10/A2000 Instrument Configuration with METRAwin10/A2000

software and an adapter with a subminiature plug (for connection METRAwin10/A2000 plainly displays all of the functions and

to a PC via extension cable). possible settings included in the power meter in various windows.

The desired parameter values are entered to the corresponding

fields and are subsequently uploaded to the power meter.

GMC-I Messtechnik GmbH 7

A2000

Multifunctional Power Meter

Order Information

Designation Configuration Options Article Number / Feature

A2000 Multifunctional Power Meter A2000 A2000 A2000

Serial Interface with RS-232 and RS-485 L0 – –

with LON and RS-232 – L1 –

with Profibus-DP and RS-232 – – L2

Analog Outputs 2 analog outputs A0 A0 –

4 analog outputs A1 1) – –

without analog output – – A2

Data Logger without data logger R0 R0 R0

with data logger R1 1) 2) R1 1) R1 1)

Pulse Output / Synchronizing Input without pulse output and without synchronizing input P0 – P0

2 pulse outputs and 1 synchronizing input P1 P1 P1

Supply Voltage 230 / 115 V H0 H0 H0

20 69 V / 20 72 V H1 H1 H1

73 264 V / 73 276 V H2 H2 H2

20 27 V / 20 36 V H3 H3 H3

Manufacturer’s Certificate / without certificate U0 U0 U0

Test Report with certificate and test report U1 U1 U1

Operating Instructions in print: German and English / on CD-ROM: German, English, French, Spanish and Italian

Interface Description on CD-ROM: German, English

Software METRAwin10/A2000: on CD-ROM

1) 2)

only in combination with Feature P1 only in combination with Feature A1

A2000 Mobile Set

Designation Feature Combination Article Number

A2000 Mobile Set A2000 H0 A0P1R1L0U0 A202A

Accessories for A2000 and A2000 Mobile Set

Designation Article Number

Adapter (Screw clamp A2000 on 9-pin sub-D for PC) with METRAwin10/A2000 (software for transmission of meas. values and instrument configuration) Z305A

Interface cable RS-232, approx. 2 m long GTZ3241000R0001

Standard Units

The following measuring instruments can be shipped as standard units. Only the article number needs to be indicated.

Designation Instrument and Features Combination Article Number

A2000 with 230 V / 115 V supply voltage, with 2 analog outputs, with RS-232 and RS-485 interfaces, with A2000 H0 A0 P0 R0 L0 U0 A2000-V001

operating instructions, interface descriptions and software

A2000 with 230 V / 115 V supply voltage, with 4 analog outputs, with 2 pulse outputs and 1 synchronizing input, A2000 H0 A1 P1 R0 L0 U0 A2000-V002

with RS-232 and RS-485 interfaces, with operating instructions, interface descriptions and software

A2000 with 230 V / 115 V supply voltage, with 4 analog outputs, with 2 pulse outputs and 1 synchronizing input, with A2000 H0 A1 P1 R1 L0 U0 A2000-V003

data logger, with RS-232 and RS-485 interfaces, with operating instructions, interface descriptions and software

A2000 with 230 V / 115 V supply voltage, with 2 analog outputs, with 2 pulse outputs and 1 synchronizing input, A2000 H0 A0 P1 R0 L1 U0 A2000-V004

with LON and RS-232 interfaces, with operating instructions, interface descriptions and software

A2000 with 230 V / 115 V supply voltage, with 2 pulse outputs and 1 synchronizing input, with Profibus-DP and A2000 H0 A2 P1 R0 L2 U0 A2000-V005

RS-232, with operating instructions, interface descriptions and software

Edited in Germany • Subject to change without notice • A pdf version is available on the internet

Phone +49 911 8602-111

GMC-I Messtechnik GmbH Fax +49 911 8602-777

Südwestpark 15 E-Mail info@gossenmetrawatt.com

90449 Nürnberg • Germany www.gossenmetrawatt.com

You might also like

- Jibo User GuideDocument37 pagesJibo User GuidesmanodamNo ratings yet

- CPP For Financial Mathematics Cpp-Book-SolutionsDocument11 pagesCPP For Financial Mathematics Cpp-Book-SolutionsEmmanuelDasiNo ratings yet

- AZ-900T0xModule 02core Azure ServicesDocument43 pagesAZ-900T0xModule 02core Azure ServicesAnshul AakotkarNo ratings yet

- A2000 Multifunctional Power Meter: Applications Applicable Regulations and StandardsDocument8 pagesA2000 Multifunctional Power Meter: Applications Applicable Regulations and Standardschock channel 19No ratings yet

- U1602 EcsDocument8 pagesU1602 EcsDD CoupleNo ratings yet

- Grid Meter For Power ExchangeDocument4 pagesGrid Meter For Power ExchangeRichard SyNo ratings yet

- Algodue - UPM6100 - Ds - ENGDocument9 pagesAlgodue - UPM6100 - Ds - ENGwiwikNo ratings yet

- Multifunction Transducer UMT540/MT540:, 12.5 A. Wide Measurement Frequency Range 16 HZ - 400 Hz. Remote DisplayDocument16 pagesMultifunction Transducer UMT540/MT540:, 12.5 A. Wide Measurement Frequency Range 16 HZ - 400 Hz. Remote DisplayJose Jesus MamaniNo ratings yet

- HDF ManualDocument4 pagesHDF ManualANGEL JOY RABAGONo ratings yet

- Rish LM1360 Datasheet Rev PDocument8 pagesRish LM1360 Datasheet Rev PHetauda GridNo ratings yet

- Network Power Analyzer: Standard Operation Program, EnergyDocument2 pagesNetwork Power Analyzer: Standard Operation Program, EnergyAfif Fajar Nurtyanto0% (1)

- MEg 38 CDocument76 pagesMEg 38 Candi.grigoreNo ratings yet

- Profitest pv1500 DB - GBDocument5 pagesProfitest pv1500 DB - GBkenxi2403No ratings yet

- Data Sheet: RISH LM 1350 / LM 1360Document10 pagesData Sheet: RISH LM 1350 / LM 1360Erik Marcelo BarrenecheaNo ratings yet

- ALM 30&32 BrochureDocument4 pagesALM 30&32 BrochureUlhas VajreNo ratings yet

- Product Data: Hand-Arm Vibration Meter - Type 2537Document2 pagesProduct Data: Hand-Arm Vibration Meter - Type 2537jhon vargasNo ratings yet

- CX - PX: Power Quality AnalyserDocument16 pagesCX - PX: Power Quality AnalyserSiva NandhamNo ratings yet

- Technical SpecificationDocument50 pagesTechnical SpecificationMario Strašni100% (1)

- Proq 100: High Precision, Comprehensive Power Quality Measurements Multiple Communications Channels, Easy IntegrationDocument4 pagesProq 100: High Precision, Comprehensive Power Quality Measurements Multiple Communications Channels, Easy IntegrationTeguh WaluyoNo ratings yet

- TD PQBox300 ENDocument12 pagesTD PQBox300 ENRomel Lucero B.No ratings yet

- 1404 E EUC 3 Manual and Automatic Compensation of Reactive PowerDocument20 pages1404 E EUC 3 Manual and Automatic Compensation of Reactive PowerРаденко МарјановићNo ratings yet

- Power Genius Meters PDFDocument2 pagesPower Genius Meters PDFAritheertham SaravananNo ratings yet

- EnerLyzer Live Handout ENUDocument4 pagesEnerLyzer Live Handout ENUtom.grebertNo ratings yet

- Elmeasure Power Quality Analyzer CatalogDocument15 pagesElmeasure Power Quality Analyzer Cataloganoop ajayNo ratings yet

- Datasheet RISH LM 1340Document8 pagesDatasheet RISH LM 1340PT Merapi Trans EnergiNo ratings yet

- A Clear Path To Electrical Power Excellence!Document16 pagesA Clear Path To Electrical Power Excellence!HotdesNo ratings yet

- Elrec ProDocument2 pagesElrec ProcarlosNo ratings yet

- Ade9000Document112 pagesAde9000khedoudjaaouchicheNo ratings yet

- Single 2008 MI 2092 Power Harmonics Analyser AngDocument2 pagesSingle 2008 MI 2092 Power Harmonics Analyser AngJuan José González MorenoNo ratings yet

- ALPHA Plus Meter 022008Document2 pagesALPHA Plus Meter 022008feng xiaNo ratings yet

- Proq 100Document4 pagesProq 100Shijo ShajiNo ratings yet

- Ion 75007600Document8 pagesIon 75007600Juan Pablo GaeteNo ratings yet

- LandisDocument4 pagesLandisiskandarn_el5735No ratings yet

- Ge Epm 5500PDocument6 pagesGe Epm 5500PRONALDNo ratings yet

- Ad11a DC Ds-En-n.186 CorDocument6 pagesAd11a DC Ds-En-n.186 CorFelipe SaldañaNo ratings yet

- Pv-Kla e PDFDocument2 pagesPv-Kla e PDFHaikalNo ratings yet

- ERI Equipment SpecificationDocument2 pagesERI Equipment SpecificationAnonymous gq7UQAwNo ratings yet

- Power and Energy Logger PEL 103Document4 pagesPower and Energy Logger PEL 103rana haroonNo ratings yet

- Rish LM 13xxDocument28 pagesRish LM 13xxManoj Kumar PanigrahiNo ratings yet

- Product Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667Document12 pagesProduct Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667jhon vargasNo ratings yet

- Plsed310187en (Web)Document8 pagesPlsed310187en (Web)Osama RaufNo ratings yet

- Elrec Pro GBDocument2 pagesElrec Pro GBMaría Eugenia FranzoniNo ratings yet

- P EQxx07 YQxx07 GB 22430080 Ver 4.00Document9 pagesP EQxx07 YQxx07 GB 22430080 Ver 4.00arozmanNo ratings yet

- Acuvim L Power Meter Brochure 1030E1210Document4 pagesAcuvim L Power Meter Brochure 1030E1210skamir moralesNo ratings yet

- Basic Energy Meters (EMS-Series)Document3 pagesBasic Energy Meters (EMS-Series)Jaskaran SinghNo ratings yet

- Fluke 1760Document10 pagesFluke 1760khairy2013No ratings yet

- Ducati: Power AnalyzersDocument5 pagesDucati: Power AnalyzersRitika SenNo ratings yet

- Eng SPQMDocument4 pagesEng SPQMkacemkhalil535No ratings yet

- Cewe Instrument Premier Product RangeDocument8 pagesCewe Instrument Premier Product Rangeye htutkyawme100% (1)

- Intelligent Metering and Control Devices: Applications Summary Features SummaryDocument8 pagesIntelligent Metering and Control Devices: Applications Summary Features SummaryjocemirferstNo ratings yet

- Profitest 204 Tester For DIN EN 60204 and VDE 0113: ApplicationsDocument8 pagesProfitest 204 Tester For DIN EN 60204 and VDE 0113: ApplicationsNikos ZairisNo ratings yet

- PQube 3 Power Analyzer Data Sheet.V3 - enDocument4 pagesPQube 3 Power Analyzer Data Sheet.V3 - enNicky NeoNo ratings yet

- Rishabh DC MeterDocument8 pagesRishabh DC MeterDeepikaNo ratings yet

- Acuvim II Multifunction Power Energy Meter Brochure DatasheetDocument16 pagesAcuvim II Multifunction Power Energy Meter Brochure DatasheetYanuar Tino ANo ratings yet

- Fluke-Direct: 1586A Super-DAQDocument12 pagesFluke-Direct: 1586A Super-DAQQUALITY LABORATORY SALESNo ratings yet

- EMDC Datasheet - EM - DC - 6000 - ReveDocument6 pagesEMDC Datasheet - EM - DC - 6000 - ReveSayan halderNo ratings yet

- Anexa ADD45 AD11A 1-8-1 DS-en-N 147 RDocument4 pagesAnexa ADD45 AD11A 1-8-1 DS-en-N 147 RAndrei SerbanescuNo ratings yet

- Epm9000 Gea12823cDocument8 pagesEpm9000 Gea12823cAulia RahmanNo ratings yet

- Chauvin Arnoux PEL 102-103 Power and Energy LoggersDocument4 pagesChauvin Arnoux PEL 102-103 Power and Energy LoggersIvan Liviu IonNo ratings yet

- Unit 1 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep RaghavDocument144 pagesUnit 1 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep Raghavavikool1708No ratings yet

- Elmeasure Energy Process Monitor CatalogDocument1 pageElmeasure Energy Process Monitor CatalogSEO BDMNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Entrelec SwitchesDocument37 pagesEntrelec SwitchesC&P GroupNo ratings yet

- Dehydrating Breather Messko Mtrab: Operating InstructionsDocument124 pagesDehydrating Breather Messko Mtrab: Operating InstructionsC&P GroupNo ratings yet

- Micomagilep99x Brochure en 2018 05 Grid Ga 0720Document8 pagesMicomagilep99x Brochure en 2018 05 Grid Ga 0720C&P GroupNo ratings yet

- MDL107 EngDocument3 pagesMDL107 EngC&P GroupNo ratings yet

- Harmony XB5 - XB5AW31G5Document6 pagesHarmony XB5 - XB5AW31G5C&P GroupNo ratings yet

- Ferroresonance ECT190Document30 pagesFerroresonance ECT190C&P GroupNo ratings yet

- Lampanaler BSM USM Datablad TillquistDocument24 pagesLampanaler BSM USM Datablad TillquistC&P GroupNo ratings yet

- MCGG Manual RelaypdfDocument20 pagesMCGG Manual RelaypdfC&P GroupNo ratings yet

- Reference - EES Manual and Connection Diagram 2 For H200 and H300Document16 pagesReference - EES Manual and Connection Diagram 2 For H200 and H300C&P GroupNo ratings yet

- R6013e MVTRDocument6 pagesR6013e MVTRC&P GroupNo ratings yet

- Grid Solutions: Auxiliary RelayDocument4 pagesGrid Solutions: Auxiliary RelayC&P Group0% (1)

- Alstom - P642 P643 P645 Cortec and Ordering InformationDocument3 pagesAlstom - P642 P643 P645 Cortec and Ordering InformationC&P GroupNo ratings yet

- Alstom - KVGC202 Cortec and Ordering InformationDocument1 pageAlstom - KVGC202 Cortec and Ordering InformationC&P GroupNo ratings yet

- TSN2101 - Tutorial 3 (Processes and Threads)Document3 pagesTSN2101 - Tutorial 3 (Processes and Threads)MoonNo ratings yet

- LG CM9750Document81 pagesLG CM9750Julian CastilloNo ratings yet

- UNIVET SRL, STR Ion Heliade: QuotationDocument10 pagesUNIVET SRL, STR Ion Heliade: QuotationMarian AntonescuNo ratings yet

- 15 Slides PresentationDocument16 pages15 Slides PresentationF223822 Mohammad Ahmed KamranNo ratings yet

- Network Security Research PaperDocument7 pagesNetwork Security Research PaperPankaj Kumar Jha67% (6)

- Readiness For Flexible Learning Amidst COVID 19 Pandemic of Saint Michael College of Caraga, PhilippinesDocument15 pagesReadiness For Flexible Learning Amidst COVID 19 Pandemic of Saint Michael College of Caraga, PhilippinesckNo ratings yet

- CS - Practical ReportDocument44 pagesCS - Practical ReportLatashree HegdeNo ratings yet

- Boot One Second AltenbergDocument71 pagesBoot One Second AltenbergRaghavadeep ReddyNo ratings yet

- DCC MicroprojectDocument21 pagesDCC MicroprojectSaniya Puchalwar100% (1)

- Matrice 210 210 RTK QSG MultiDocument99 pagesMatrice 210 210 RTK QSG Multikamil.klkogluNo ratings yet

- Search Marketing: Session 5Document93 pagesSearch Marketing: Session 5Zaina ImamNo ratings yet

- 10m Microphone Cable PDFDocument3 pages10m Microphone Cable PDFmasudur rahmanNo ratings yet

- Quick Start FPRB Nokia-Flexi-EdgeDocument30 pagesQuick Start FPRB Nokia-Flexi-EdgePTERENo ratings yet

- Arduino Programming Using MATLAB - Agus KurniawanDocument77 pagesArduino Programming Using MATLAB - Agus KurniawanPablo Colque100% (6)

- T3TAFJ2-Workshop-Install A TAFJ Standalone-R16Document9 pagesT3TAFJ2-Workshop-Install A TAFJ Standalone-R16suchi vedhaNo ratings yet

- The Effective Prototyping Process: Verify RequirementsDocument8 pagesThe Effective Prototyping Process: Verify RequirementsNabbo SainNo ratings yet

- ĐỀ THI THỬ SỐ 12Document6 pagesĐỀ THI THỬ SỐ 12Tâm Dương ThịNo ratings yet

- Professional Obdii/Chip Tuning System For The Recalibration of Stock Ecu Engine Working ParametersDocument20 pagesProfessional Obdii/Chip Tuning System For The Recalibration of Stock Ecu Engine Working ParametersqwertyNo ratings yet

- Visual Studio Code: Getting StartedDocument69 pagesVisual Studio Code: Getting StartedguskarismaNo ratings yet

- IDG Authentication Methods Data SheetDocument8 pagesIDG Authentication Methods Data SheetAlexander RodriguezNo ratings yet

- Estimate Summary: Upfront Cost Monthly Cost Total 12 Months CostDocument2 pagesEstimate Summary: Upfront Cost Monthly Cost Total 12 Months CostKratik JainNo ratings yet

- Digital Audio အကြောင်းသိစရာ - Part 1 and 2Document50 pagesDigital Audio အကြောင်းသိစရာ - Part 1 and 2hein2thawNo ratings yet

- SJ-20120319104909-002-ZXUR 9000 UMTS (V4.11.20) Product DescriptionDocument81 pagesSJ-20120319104909-002-ZXUR 9000 UMTS (V4.11.20) Product Descriptionnn.sandroNo ratings yet

- Student Volunteer Service Program: BrowardDocument1 pageStudent Volunteer Service Program: BrowardluzNo ratings yet

- Cybersecurity: It Specialist Exam ObjectivesDocument3 pagesCybersecurity: It Specialist Exam ObjectivesMercy EbiojoNo ratings yet

- Magsingal National High School Student Last CheckingDocument71 pagesMagsingal National High School Student Last CheckingJan Allen RialubinNo ratings yet

- User Manual For ESP 12e Dev KitDocument17 pagesUser Manual For ESP 12e Dev KitNathan Imig100% (5)