Professional Documents

Culture Documents

P P F F A A F A F A: Lifting of A Large Weight by A Small Force by The Application of Pascal's Principle

P P F F A A F A F A: Lifting of A Large Weight by A Small Force by The Application of Pascal's Principle

Uploaded by

Ehtisham RiazCopyright:

Available Formats

You might also like

- Solution Manual For Engineering and Chemical Thermodynamics 2nd Ed - Milo KoretskyDocument20 pagesSolution Manual For Engineering and Chemical Thermodynamics 2nd Ed - Milo KoretskyAbolfazl29% (7)

- Principles of Hydrostatics: Unit Pressure or Pressure, PDocument58 pagesPrinciples of Hydrostatics: Unit Pressure or Pressure, PMay Ann ParallagNo ratings yet

- Instrumentation Interview Questions Answers GuideDocument12 pagesInstrumentation Interview Questions Answers GuideSANJAY100% (1)

- Calculation of Air Pipe SizeDocument6 pagesCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- Asce 7-22 CH 30 - For PCDocument60 pagesAsce 7-22 CH 30 - For PCsharethefiles100% (1)

- Pipe Tubing Inspection ChecklistDocument6 pagesPipe Tubing Inspection ChecklistParewa ScorpNo ratings yet

- Lesson 2 - Unit 1 - MTF1 - Basic Concepts Ot Thermodynamcis - 2021Document10 pagesLesson 2 - Unit 1 - MTF1 - Basic Concepts Ot Thermodynamcis - 2021Thabo MokgosiNo ratings yet

- Tutorial - Lecture 2 Solutions-1Document8 pagesTutorial - Lecture 2 Solutions-1Bastián Olfos MárquezNo ratings yet

- Chapter 3-Pressure and Fluid Statics.2015-1Document54 pagesChapter 3-Pressure and Fluid Statics.2015-1Elizabeth Navarro De CabanaNo ratings yet

- 2b FLUID STATIC - Pressure MeasurementDocument27 pages2b FLUID STATIC - Pressure Measurement翁绍棠No ratings yet

- Chapter 2: Measurement of PressureDocument9 pagesChapter 2: Measurement of PressurenursyahzananiNo ratings yet

- 5 2018 03 05!01 13 43 PMDocument40 pages5 2018 03 05!01 13 43 PMquike6041-150% (2)

- Chapter 2Document76 pagesChapter 2Siew YongNo ratings yet

- Experiment 1,2 Me 234 PDFDocument55 pagesExperiment 1,2 Me 234 PDFchinnavenkateswarluNo ratings yet

- FM 3 Fluid StaticsDocument68 pagesFM 3 Fluid Staticsعبدالرحمن الحازميNo ratings yet

- Instructor: Dr. Najmur Rahman,: Taibah UniversityDocument32 pagesInstructor: Dr. Najmur Rahman,: Taibah Universityعبدالرحمن الحازميNo ratings yet

- Sessions XX Week 3Document13 pagesSessions XX Week 3Mohammad AlRiyamNo ratings yet

- Principles of HydraulicsDocument59 pagesPrinciples of Hydraulicsjason mr.perfect11No ratings yet

- Pressure 1Document10 pagesPressure 1devonlaratt359No ratings yet

- Pressure Lecture 2Document31 pagesPressure Lecture 2Juan Miguel ValledorNo ratings yet

- Chapter 3: Pressure and Fluid StaticsDocument28 pagesChapter 3: Pressure and Fluid StaticsJoyce AldeaNo ratings yet

- Assumptions 1 All The Liquids Are Incompressible. 2Document2 pagesAssumptions 1 All The Liquids Are Incompressible. 2Kaffi RockavankaNo ratings yet

- Chapter 6 - Fluid Mechanics - UpdatedDocument43 pagesChapter 6 - Fluid Mechanics - UpdatedMuhammad Aminnur Hasmin B. HasminNo ratings yet

- Defining Hydrostatics and Pressure: Figure 1. Pressure Distribution Around A Column of LiquidDocument10 pagesDefining Hydrostatics and Pressure: Figure 1. Pressure Distribution Around A Column of LiquidJohn GaviolaNo ratings yet

- Lecture 2Document47 pagesLecture 2Ivy AlNo ratings yet

- Sunu3 2020Document58 pagesSunu3 2020Mir BedirhanNo ratings yet

- DCC30122 - Fluids MechanicsDocument9 pagesDCC30122 - Fluids MechanicsHadif NuqmanNo ratings yet

- Expressed in Kpa, Pa, Psi, PSFDocument26 pagesExpressed in Kpa, Pa, Psi, PSFYandi TVNo ratings yet

- Lecture No - 2 PressureDocument86 pagesLecture No - 2 PressureresearchditNo ratings yet

- OshDocument81 pagesOshMohamad AzmeerNo ratings yet

- 3.) Principles of Hydrostatics PDFDocument7 pages3.) Principles of Hydrostatics PDFShan Yi HaiNo ratings yet

- Fluids-Pressure (Incomplete Notes)Document3 pagesFluids-Pressure (Incomplete Notes)Trafalgar Jane LawNo ratings yet

- Flow MeasurementDocument12 pagesFlow MeasurementParth MehraNo ratings yet

- Chapter 3 - FluidDocument45 pagesChapter 3 - Fluidfieyza adnNo ratings yet

- Solution#1Document5 pagesSolution#1Exel Dua CincinNo ratings yet

- Ch2 Fluid StaticsDocument131 pagesCh2 Fluid StaticsAsif SunnyNo ratings yet

- Pressure Measurement Apparatus: Operating Instruction Manual ofDocument10 pagesPressure Measurement Apparatus: Operating Instruction Manual ofRavi ParikhNo ratings yet

- Chapter 3 Process and Process Variables 2 Fall22Document24 pagesChapter 3 Process and Process Variables 2 Fall22iB13eNo ratings yet

- Lab O2. Variation of Atmospheric Pressure With Altitude: 5 N M Lbs inDocument10 pagesLab O2. Variation of Atmospheric Pressure With Altitude: 5 N M Lbs inAnil PrabhuNo ratings yet

- ThermoDocument2 pagesThermoColeen AbrenicaNo ratings yet

- CHAPTER 2 FluidsDocument14 pagesCHAPTER 2 FluidsIvan JadeNo ratings yet

- Chapter-2 - Fluid Statics - 230928 - 154632Document55 pagesChapter-2 - Fluid Statics - 230928 - 154632iqra abbasiNo ratings yet

- Nama: Moh Rais K Mentemas Nim: 20183020072 Kelas: TMDocument11 pagesNama: Moh Rais K Mentemas Nim: 20183020072 Kelas: TMMuhamad ZuhriNo ratings yet

- Nama: Galih Achmad Prawiradiawan NIM: 20183020094 Kelas: D3 Teknologi Mesin B Tugas 3Document15 pagesNama: Galih Achmad Prawiradiawan NIM: 20183020094 Kelas: D3 Teknologi Mesin B Tugas 3Muhamad ZuhriNo ratings yet

- Barometer and Atmospheric PressureDocument2 pagesBarometer and Atmospheric PressureEhtisham RiazNo ratings yet

- Pumps and PipingDocument51 pagesPumps and PipingAbhijeet KeerNo ratings yet

- Lab Session 2Document12 pagesLab Session 2Shahid FarooqNo ratings yet

- 2-67 The Gage Pressure of Air in A Pressurized Water Tank Is Measured Simultaneously by Both A PressureDocument1 page2-67 The Gage Pressure of Air in A Pressurized Water Tank Is Measured Simultaneously by Both A PressureIllion IllionNo ratings yet

- Chapter 3Document14 pagesChapter 3آڃمْڊ آلُنْمْرNo ratings yet

- Fluid MechanicsDocument162 pagesFluid MechanicshellothereNo ratings yet

- Chapter 3Document21 pagesChapter 3hailemebrahtuNo ratings yet

- Pressure MeasurementDocument16 pagesPressure Measurementgtdombo100% (1)

- Unidad II Termo I PDFDocument60 pagesUnidad II Termo I PDFRoutine Of Nepal BandaNo ratings yet

- AE 233 (Chapter 2) Fluid Mechanics For Chemical EngineeringDocument36 pagesAE 233 (Chapter 2) Fluid Mechanics For Chemical EngineeringKemalMalovcic100% (1)

- Fluid Static1Document36 pagesFluid Static1ChitOoMaungNo ratings yet

- ChE 220 Mod 6 Flow of Compressible FluidDocument53 pagesChE 220 Mod 6 Flow of Compressible FluidMay May MagluyanNo ratings yet

- Chapter 3 - Flow of Compressible FluidsDocument38 pagesChapter 3 - Flow of Compressible FluidsFatin FatehaNo ratings yet

- 3 Process Variables Part 2Document22 pages3 Process Variables Part 2Snow DropNo ratings yet

- Chapter - 02 Pressure and Fluid StaticsDocument41 pagesChapter - 02 Pressure and Fluid StaticsShehab Abou GamrahNo ratings yet

- Lec 5Document34 pagesLec 5Moazzam Ali ToorNo ratings yet

- Chapter 3Document84 pagesChapter 3Pınar SoyoğuzNo ratings yet

- L5 - Fluid Mechanics IDocument11 pagesL5 - Fluid Mechanics Ishamiul himelNo ratings yet

- Hydrostatic ForcesDocument9 pagesHydrostatic ForcesEhtisham RiazNo ratings yet

- Barometer and Atmospheric PressureDocument2 pagesBarometer and Atmospheric PressureEhtisham RiazNo ratings yet

- Fluid in Rigid Body MotionDocument3 pagesFluid in Rigid Body MotionEhtisham RiazNo ratings yet

- CEPDocument2 pagesCEPEhtisham RiazNo ratings yet

- Bernoulli's Equation (Am)Document8 pagesBernoulli's Equation (Am)Ehtisham RiazNo ratings yet

- Guidelines in Preparation of The Lab ReportDocument2 pagesGuidelines in Preparation of The Lab ReportEhtisham RiazNo ratings yet

- WPH05 01 Que 20180117Document28 pagesWPH05 01 Que 20180117NyraStardollNo ratings yet

- Appendix C: Summary of FormulasDocument25 pagesAppendix C: Summary of FormulaschkzaNo ratings yet

- 1216.0 Required Gas Piping SizeDocument70 pages1216.0 Required Gas Piping SizeHu Hin AngNo ratings yet

- Frialoc 3RDocument0 pagesFrialoc 3RThuc TruongNo ratings yet

- Catalogo ValvulasDocument20 pagesCatalogo ValvulasCatalina Velásquez GodoyNo ratings yet

- Evapotranspiration: Noel Jr. A. Lanquibo Kyle Anjao Alex Kent Belicario Paolo Benedict SurDocument16 pagesEvapotranspiration: Noel Jr. A. Lanquibo Kyle Anjao Alex Kent Belicario Paolo Benedict SurPeter Adrian NgoNo ratings yet

- IFTPS Retort - Processing - Guidelines - 02 - 13 - 14 PDFDocument65 pagesIFTPS Retort - Processing - Guidelines - 02 - 13 - 14 PDFrocanrol2No ratings yet

- CIVIL ENGINEERING Curriculum PDFDocument178 pagesCIVIL ENGINEERING Curriculum PDFChirag N PatelNo ratings yet

- McGarry (1983)Document10 pagesMcGarry (1983)Anonymous PO7VwbBnNo ratings yet

- Válvulas de Alívio NaucoDocument12 pagesVálvulas de Alívio NaucoBruno CoutoNo ratings yet

- Lec 5Document23 pagesLec 5erdo mandanaNo ratings yet

- Chapter 9: Fluid Dynamics: A. The Equation of Continuity - Conservation of MassDocument12 pagesChapter 9: Fluid Dynamics: A. The Equation of Continuity - Conservation of MassLorenzo Miguel GonzalesNo ratings yet

- Vol 10 No 1 - 2014 PlatformDocument60 pagesVol 10 No 1 - 2014 PlatformJulendra AriatedjaNo ratings yet

- 2.applied Aero-L2-5 (Atmosphere)Document27 pages2.applied Aero-L2-5 (Atmosphere)Ali RazaNo ratings yet

- Construction Hand BookDocument237 pagesConstruction Hand BookNson Lee100% (1)

- Air CoolersDocument50 pagesAir CoolersMohamed Sayed Abdo100% (1)

- Best PneumaticsDocument16 pagesBest PneumaticsAshok DevarajNo ratings yet

- D70REVDocument88 pagesD70REVsteva037No ratings yet

- VMG LettersDocument23 pagesVMG LettersMOHAMMA MUSANo ratings yet

- Packed ColumnDocument4 pagesPacked ColumnSantosh ReddyNo ratings yet

- NR-220301 - Mechanics of FluidsDocument8 pagesNR-220301 - Mechanics of FluidsSrinivasa Rao GNo ratings yet

- Characterization of U.S. Coking Coals byake it easier for other people to find your content by providing more information about it. AGREGAR MÁS ARCHIVOS Arrastre los archivos de su equipo hasta esta área. Archivo 1 de 4 |Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf|Cargando... 13% Cargando... Puntaje de detección 1/5 Nombre de archivo: Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf *Título: (Campo requerido) *Descripción:(Campo requerido) Etiquetas: Categoría: Scribd Store: the Sapozhnikov and G Caking IndexDocument19 pagesCharacterization of U.S. Coking Coals byake it easier for other people to find your content by providing more information about it. AGREGAR MÁS ARCHIVOS Arrastre los archivos de su equipo hasta esta área. Archivo 1 de 4 |Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf|Cargando... 13% Cargando... Puntaje de detección 1/5 Nombre de archivo: Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf *Título: (Campo requerido) *Descripción:(Campo requerido) Etiquetas: Categoría: Scribd Store: the Sapozhnikov and G Caking IndexMarcos CarreroNo ratings yet

- Air-Water Two Phase Flow Simulation UsingDocument6 pagesAir-Water Two Phase Flow Simulation Using박송환No ratings yet

- Description Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsDocument30 pagesDescription Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsMROstop.comNo ratings yet

- Plant Hazard ChecklistDocument4 pagesPlant Hazard Checklistnaveen chandNo ratings yet

- DO Analyser ManualDocument24 pagesDO Analyser ManualambeshNo ratings yet

P P F F A A F A F A: Lifting of A Large Weight by A Small Force by The Application of Pascal's Principle

P P F F A A F A F A: Lifting of A Large Weight by A Small Force by The Application of Pascal's Principle

Uploaded by

Ehtisham RiazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P P F F A A F A F A: Lifting of A Large Weight by A Small Force by The Application of Pascal's Principle

P P F F A A F A F A: Lifting of A Large Weight by A Small Force by The Application of Pascal's Principle

Uploaded by

Ehtisham RiazCopyright:

Available Formats

since both pistons are at the same level (the effect of small height differences F2 = P 2 A 2

is negligible, especially at high pressures), the ratio of output force to input F 1 = P1A 1

force is determined to be

F1 F2 F2 A2

P1 P2

A1 A2 F1 A1

The area ratio A2/A1 is called the ideal mechanical advantage of the hydraulic

lift. Using a hydraulic car jack with a piston area ratio of A2/A1 10, for

1 A1 A2 2

example, a person can lift a 1000-kg car by applying a force of just 100 kgf P1 P2

( 908 N).

Lifting of a large weight by a small

We notice from Eq. 2–24 that an elevation change of z of a fluid corresponds

force by the application of Pascal’s

to P/ g, which suggests that a fluid column can be used to measure pressure principle.

differences. A device based on this principle is called a manometer, and

it is commonly used to measure small and moderate pressure differences.

A manometer mainly consists of a glass or plastic U-tube containing one or

more fluids such as mercury, water, alcohol, or oil. To keep the size of the

manometer to a manageable level, heavy fluids such as mercury are used if

large pressure differences are anticipated.

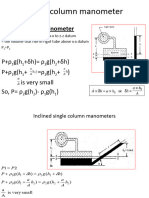

Consider the manometer shown in Fig. 2–46 that is used to measure the

pressure in the tank. Since the gravitational effects of gases are negligible, the

pressure anywhere in the tank and at position 1 has the same value. Further-

more, since pressure in a fluid does not vary in the horizontal direction within Gas

a fluid, the pressure at point 2 is the same as the pressure at 1, P2 P1. h

The differential fluid column of height h is in static equilibrium, and it is

open to the atmosphere. Then the pressure at point 2 is determined directly 1 2

from Eq. 2–25 to be

P2 Patm gh

where is the density of the fluid in the tube. Note that the cross-sectional

area of the tube has no effect on the differential height h, and thus the pressure The basic manometer.

exerted by the fluid. However, the diameter of the tube should be large enough

(more than a few millimeters) to ensure that the surface tension effect and thus

the capillary rise is negligible.

Patm = 96 kPa

P=?

h = 55 cm

SG = 0.85

Sketch for Example 2–5.

SG ( H2O) (0.85) (1000 kg/m3) 850 kg/m3

P Patm gh

1N 1 kPa

96 kPa (850 kg/m3) (9.81 m/s2) (0.55 m)

1 kg · m/s2 1000 N/m2

100.6 kPa

Many engineering problems and some manometers involve multiple im-

misciple fluids of different densities stacked on top of each other. Such

systems can be analyzed easily by remembering that (1) the pressure change

across a fluid column of height h is P gh, (2) pressure increases down-

ward in a given fluid and decreases upward (i.e., Pbottom Ptop), and (3) two

points at the same elevation in a continuous fluid at rest are at the same

Patm

pressure.

Fluid 1

The last principle, also known as Pascal’s law, allows us to “jump” from

h1 one fluid column to the next in manometers without worrying about pressure

change as long as we don’t jump over a different fluid, and the fluid is at rest.

Fluid 2 Then the pressure at any point can be determined by starting with a point of

h2

known pressure, and adding or subtracting gh terms as we advance toward

Fluid 3

the point of interest. For example, the pressure at the bottom of the tank in Fig.

h3 2–48 can be determined by starting at the free surface where the pressure is

1

Patm, and moving downward until we reach point 1 at the bottom, and setting

the result equal to P1. It gives

In stacked-up fluid layers, the pressure

Patm 1gh1 2gh2 3gh3 P1

change across a fluid layer of density

and height h is gh.

In the special case of all fluids having the same density, this relation reduces

to Eq. 2–29, as expected.

A flow section

Manometers are particularly well-suited to measure pressure drops across a

or flow device

horizontal flow section between two specified points due to the presence of

Fluid a device such as a valve or heat exchanger or any resistance to flow. This is

done by connecting the two legs of the manometer to these two points, as

shown in Fig. 2–49. The working fluid can be either a gas or a liquid whose

1 2

density is 1. The density of the manometer fluid is 2, and the differential

a fluid height is h.

A relation for the pressure difference P1 P2 can be obtained by starting at

h

point 1 with P1 and moving along the tube by adding or subtracting the gh

1

terms until we reach point 2, and setting the result equal to P2:

A B

P1 1g (a h) 2gh 1ga P2

2

Note that we jumped from point A horizontally to point B and ignored the part

Measuring the pressure drop across a underneath since the pressure at both points is the same. Simplifying,

flow section or a flow device by a

differential manometer. P1 P2 ( 2 1) gh

You might also like

- Solution Manual For Engineering and Chemical Thermodynamics 2nd Ed - Milo KoretskyDocument20 pagesSolution Manual For Engineering and Chemical Thermodynamics 2nd Ed - Milo KoretskyAbolfazl29% (7)

- Principles of Hydrostatics: Unit Pressure or Pressure, PDocument58 pagesPrinciples of Hydrostatics: Unit Pressure or Pressure, PMay Ann ParallagNo ratings yet

- Instrumentation Interview Questions Answers GuideDocument12 pagesInstrumentation Interview Questions Answers GuideSANJAY100% (1)

- Calculation of Air Pipe SizeDocument6 pagesCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- Asce 7-22 CH 30 - For PCDocument60 pagesAsce 7-22 CH 30 - For PCsharethefiles100% (1)

- Pipe Tubing Inspection ChecklistDocument6 pagesPipe Tubing Inspection ChecklistParewa ScorpNo ratings yet

- Lesson 2 - Unit 1 - MTF1 - Basic Concepts Ot Thermodynamcis - 2021Document10 pagesLesson 2 - Unit 1 - MTF1 - Basic Concepts Ot Thermodynamcis - 2021Thabo MokgosiNo ratings yet

- Tutorial - Lecture 2 Solutions-1Document8 pagesTutorial - Lecture 2 Solutions-1Bastián Olfos MárquezNo ratings yet

- Chapter 3-Pressure and Fluid Statics.2015-1Document54 pagesChapter 3-Pressure and Fluid Statics.2015-1Elizabeth Navarro De CabanaNo ratings yet

- 2b FLUID STATIC - Pressure MeasurementDocument27 pages2b FLUID STATIC - Pressure Measurement翁绍棠No ratings yet

- Chapter 2: Measurement of PressureDocument9 pagesChapter 2: Measurement of PressurenursyahzananiNo ratings yet

- 5 2018 03 05!01 13 43 PMDocument40 pages5 2018 03 05!01 13 43 PMquike6041-150% (2)

- Chapter 2Document76 pagesChapter 2Siew YongNo ratings yet

- Experiment 1,2 Me 234 PDFDocument55 pagesExperiment 1,2 Me 234 PDFchinnavenkateswarluNo ratings yet

- FM 3 Fluid StaticsDocument68 pagesFM 3 Fluid Staticsعبدالرحمن الحازميNo ratings yet

- Instructor: Dr. Najmur Rahman,: Taibah UniversityDocument32 pagesInstructor: Dr. Najmur Rahman,: Taibah Universityعبدالرحمن الحازميNo ratings yet

- Sessions XX Week 3Document13 pagesSessions XX Week 3Mohammad AlRiyamNo ratings yet

- Principles of HydraulicsDocument59 pagesPrinciples of Hydraulicsjason mr.perfect11No ratings yet

- Pressure 1Document10 pagesPressure 1devonlaratt359No ratings yet

- Pressure Lecture 2Document31 pagesPressure Lecture 2Juan Miguel ValledorNo ratings yet

- Chapter 3: Pressure and Fluid StaticsDocument28 pagesChapter 3: Pressure and Fluid StaticsJoyce AldeaNo ratings yet

- Assumptions 1 All The Liquids Are Incompressible. 2Document2 pagesAssumptions 1 All The Liquids Are Incompressible. 2Kaffi RockavankaNo ratings yet

- Chapter 6 - Fluid Mechanics - UpdatedDocument43 pagesChapter 6 - Fluid Mechanics - UpdatedMuhammad Aminnur Hasmin B. HasminNo ratings yet

- Defining Hydrostatics and Pressure: Figure 1. Pressure Distribution Around A Column of LiquidDocument10 pagesDefining Hydrostatics and Pressure: Figure 1. Pressure Distribution Around A Column of LiquidJohn GaviolaNo ratings yet

- Lecture 2Document47 pagesLecture 2Ivy AlNo ratings yet

- Sunu3 2020Document58 pagesSunu3 2020Mir BedirhanNo ratings yet

- DCC30122 - Fluids MechanicsDocument9 pagesDCC30122 - Fluids MechanicsHadif NuqmanNo ratings yet

- Expressed in Kpa, Pa, Psi, PSFDocument26 pagesExpressed in Kpa, Pa, Psi, PSFYandi TVNo ratings yet

- Lecture No - 2 PressureDocument86 pagesLecture No - 2 PressureresearchditNo ratings yet

- OshDocument81 pagesOshMohamad AzmeerNo ratings yet

- 3.) Principles of Hydrostatics PDFDocument7 pages3.) Principles of Hydrostatics PDFShan Yi HaiNo ratings yet

- Fluids-Pressure (Incomplete Notes)Document3 pagesFluids-Pressure (Incomplete Notes)Trafalgar Jane LawNo ratings yet

- Flow MeasurementDocument12 pagesFlow MeasurementParth MehraNo ratings yet

- Chapter 3 - FluidDocument45 pagesChapter 3 - Fluidfieyza adnNo ratings yet

- Solution#1Document5 pagesSolution#1Exel Dua CincinNo ratings yet

- Ch2 Fluid StaticsDocument131 pagesCh2 Fluid StaticsAsif SunnyNo ratings yet

- Pressure Measurement Apparatus: Operating Instruction Manual ofDocument10 pagesPressure Measurement Apparatus: Operating Instruction Manual ofRavi ParikhNo ratings yet

- Chapter 3 Process and Process Variables 2 Fall22Document24 pagesChapter 3 Process and Process Variables 2 Fall22iB13eNo ratings yet

- Lab O2. Variation of Atmospheric Pressure With Altitude: 5 N M Lbs inDocument10 pagesLab O2. Variation of Atmospheric Pressure With Altitude: 5 N M Lbs inAnil PrabhuNo ratings yet

- ThermoDocument2 pagesThermoColeen AbrenicaNo ratings yet

- CHAPTER 2 FluidsDocument14 pagesCHAPTER 2 FluidsIvan JadeNo ratings yet

- Chapter-2 - Fluid Statics - 230928 - 154632Document55 pagesChapter-2 - Fluid Statics - 230928 - 154632iqra abbasiNo ratings yet

- Nama: Moh Rais K Mentemas Nim: 20183020072 Kelas: TMDocument11 pagesNama: Moh Rais K Mentemas Nim: 20183020072 Kelas: TMMuhamad ZuhriNo ratings yet

- Nama: Galih Achmad Prawiradiawan NIM: 20183020094 Kelas: D3 Teknologi Mesin B Tugas 3Document15 pagesNama: Galih Achmad Prawiradiawan NIM: 20183020094 Kelas: D3 Teknologi Mesin B Tugas 3Muhamad ZuhriNo ratings yet

- Barometer and Atmospheric PressureDocument2 pagesBarometer and Atmospheric PressureEhtisham RiazNo ratings yet

- Pumps and PipingDocument51 pagesPumps and PipingAbhijeet KeerNo ratings yet

- Lab Session 2Document12 pagesLab Session 2Shahid FarooqNo ratings yet

- 2-67 The Gage Pressure of Air in A Pressurized Water Tank Is Measured Simultaneously by Both A PressureDocument1 page2-67 The Gage Pressure of Air in A Pressurized Water Tank Is Measured Simultaneously by Both A PressureIllion IllionNo ratings yet

- Chapter 3Document14 pagesChapter 3آڃمْڊ آلُنْمْرNo ratings yet

- Fluid MechanicsDocument162 pagesFluid MechanicshellothereNo ratings yet

- Chapter 3Document21 pagesChapter 3hailemebrahtuNo ratings yet

- Pressure MeasurementDocument16 pagesPressure Measurementgtdombo100% (1)

- Unidad II Termo I PDFDocument60 pagesUnidad II Termo I PDFRoutine Of Nepal BandaNo ratings yet

- AE 233 (Chapter 2) Fluid Mechanics For Chemical EngineeringDocument36 pagesAE 233 (Chapter 2) Fluid Mechanics For Chemical EngineeringKemalMalovcic100% (1)

- Fluid Static1Document36 pagesFluid Static1ChitOoMaungNo ratings yet

- ChE 220 Mod 6 Flow of Compressible FluidDocument53 pagesChE 220 Mod 6 Flow of Compressible FluidMay May MagluyanNo ratings yet

- Chapter 3 - Flow of Compressible FluidsDocument38 pagesChapter 3 - Flow of Compressible FluidsFatin FatehaNo ratings yet

- 3 Process Variables Part 2Document22 pages3 Process Variables Part 2Snow DropNo ratings yet

- Chapter - 02 Pressure and Fluid StaticsDocument41 pagesChapter - 02 Pressure and Fluid StaticsShehab Abou GamrahNo ratings yet

- Lec 5Document34 pagesLec 5Moazzam Ali ToorNo ratings yet

- Chapter 3Document84 pagesChapter 3Pınar SoyoğuzNo ratings yet

- L5 - Fluid Mechanics IDocument11 pagesL5 - Fluid Mechanics Ishamiul himelNo ratings yet

- Hydrostatic ForcesDocument9 pagesHydrostatic ForcesEhtisham RiazNo ratings yet

- Barometer and Atmospheric PressureDocument2 pagesBarometer and Atmospheric PressureEhtisham RiazNo ratings yet

- Fluid in Rigid Body MotionDocument3 pagesFluid in Rigid Body MotionEhtisham RiazNo ratings yet

- CEPDocument2 pagesCEPEhtisham RiazNo ratings yet

- Bernoulli's Equation (Am)Document8 pagesBernoulli's Equation (Am)Ehtisham RiazNo ratings yet

- Guidelines in Preparation of The Lab ReportDocument2 pagesGuidelines in Preparation of The Lab ReportEhtisham RiazNo ratings yet

- WPH05 01 Que 20180117Document28 pagesWPH05 01 Que 20180117NyraStardollNo ratings yet

- Appendix C: Summary of FormulasDocument25 pagesAppendix C: Summary of FormulaschkzaNo ratings yet

- 1216.0 Required Gas Piping SizeDocument70 pages1216.0 Required Gas Piping SizeHu Hin AngNo ratings yet

- Frialoc 3RDocument0 pagesFrialoc 3RThuc TruongNo ratings yet

- Catalogo ValvulasDocument20 pagesCatalogo ValvulasCatalina Velásquez GodoyNo ratings yet

- Evapotranspiration: Noel Jr. A. Lanquibo Kyle Anjao Alex Kent Belicario Paolo Benedict SurDocument16 pagesEvapotranspiration: Noel Jr. A. Lanquibo Kyle Anjao Alex Kent Belicario Paolo Benedict SurPeter Adrian NgoNo ratings yet

- IFTPS Retort - Processing - Guidelines - 02 - 13 - 14 PDFDocument65 pagesIFTPS Retort - Processing - Guidelines - 02 - 13 - 14 PDFrocanrol2No ratings yet

- CIVIL ENGINEERING Curriculum PDFDocument178 pagesCIVIL ENGINEERING Curriculum PDFChirag N PatelNo ratings yet

- McGarry (1983)Document10 pagesMcGarry (1983)Anonymous PO7VwbBnNo ratings yet

- Válvulas de Alívio NaucoDocument12 pagesVálvulas de Alívio NaucoBruno CoutoNo ratings yet

- Lec 5Document23 pagesLec 5erdo mandanaNo ratings yet

- Chapter 9: Fluid Dynamics: A. The Equation of Continuity - Conservation of MassDocument12 pagesChapter 9: Fluid Dynamics: A. The Equation of Continuity - Conservation of MassLorenzo Miguel GonzalesNo ratings yet

- Vol 10 No 1 - 2014 PlatformDocument60 pagesVol 10 No 1 - 2014 PlatformJulendra AriatedjaNo ratings yet

- 2.applied Aero-L2-5 (Atmosphere)Document27 pages2.applied Aero-L2-5 (Atmosphere)Ali RazaNo ratings yet

- Construction Hand BookDocument237 pagesConstruction Hand BookNson Lee100% (1)

- Air CoolersDocument50 pagesAir CoolersMohamed Sayed Abdo100% (1)

- Best PneumaticsDocument16 pagesBest PneumaticsAshok DevarajNo ratings yet

- D70REVDocument88 pagesD70REVsteva037No ratings yet

- VMG LettersDocument23 pagesVMG LettersMOHAMMA MUSANo ratings yet

- Packed ColumnDocument4 pagesPacked ColumnSantosh ReddyNo ratings yet

- NR-220301 - Mechanics of FluidsDocument8 pagesNR-220301 - Mechanics of FluidsSrinivasa Rao GNo ratings yet

- Characterization of U.S. Coking Coals byake it easier for other people to find your content by providing more information about it. AGREGAR MÁS ARCHIVOS Arrastre los archivos de su equipo hasta esta área. Archivo 1 de 4 |Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf|Cargando... 13% Cargando... Puntaje de detección 1/5 Nombre de archivo: Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf *Título: (Campo requerido) *Descripción:(Campo requerido) Etiquetas: Categoría: Scribd Store: the Sapozhnikov and G Caking IndexDocument19 pagesCharacterization of U.S. Coking Coals byake it easier for other people to find your content by providing more information about it. AGREGAR MÁS ARCHIVOS Arrastre los archivos de su equipo hasta esta área. Archivo 1 de 4 |Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf|Cargando... 13% Cargando... Puntaje de detección 1/5 Nombre de archivo: Characterization of U.S. Coking Coals by the Sapozhnikov and G Caking Index.pdf *Título: (Campo requerido) *Descripción:(Campo requerido) Etiquetas: Categoría: Scribd Store: the Sapozhnikov and G Caking IndexMarcos CarreroNo ratings yet

- Air-Water Two Phase Flow Simulation UsingDocument6 pagesAir-Water Two Phase Flow Simulation Using박송환No ratings yet

- Description Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsDocument30 pagesDescription Assembly Order No.: Style Blind Nuts, 1/4 NPT W01-358-5405 1T14C-3 Two Ply BellowsMROstop.comNo ratings yet

- Plant Hazard ChecklistDocument4 pagesPlant Hazard Checklistnaveen chandNo ratings yet

- DO Analyser ManualDocument24 pagesDO Analyser ManualambeshNo ratings yet