Professional Documents

Culture Documents

Zdocs - Hu 773007136-A

Zdocs - Hu 773007136-A

Uploaded by

Mohamed RaafatCopyright:

Available Formats

You might also like

- A Step-by-Step Guide To Identification and Resolution of Error in Clinical Test SystemsDocument1 pageA Step-by-Step Guide To Identification and Resolution of Error in Clinical Test Systemsrose_almonte60% (5)

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Inspection Certificate Leser CGA (EN)Document3 pagesInspection Certificate Leser CGA (EN)Mohamed RaafatNo ratings yet

- 0342 Mill TestDocument19 pages0342 Mill Test11tkt1133% (3)

- NamaazENabvi ShaikhAlbaaniRahimahullahDocument208 pagesNamaazENabvi ShaikhAlbaaniRahimahullahIslamic Reserch Center (IRC)0% (1)

- 10515-0120-4200 (RF-1912E - T Antennas Installation - Deployment Manual - March 2002 Rev. B) PDFDocument105 pages10515-0120-4200 (RF-1912E - T Antennas Installation - Deployment Manual - March 2002 Rev. B) PDFRaimundo Cesar Matos da Costa100% (2)

- Check Valve 6in HT 6YF4Document1 pageCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNo ratings yet

- Certificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Document1 pageCertificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Raul Esteban Jaimes GalvisNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- MTC Item # 01Document18 pagesMTC Item # 01ClarkFedele27No ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Document8 pages2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan Ortega100% (1)

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

- LF' JLRDocument1 pageLF' JLRIslam SahafayatNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- Weflo Valve Co., LTD.: Material Test CertificateDocument1 pageWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNo ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Mgoha : ' "Xsjjl8Document1 pageMgoha : ' "Xsjjl8PetroPower OilandgasNo ratings yet

- Mill Test Certificate-En10204/3.1-2004Document2 pagesMill Test Certificate-En10204/3.1-2004Rescos KasarachiNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- Strainers FycDocument1 pageStrainers FycrodolfostiNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- Mill Test Certificate: Zibo Camel Material Co., LTDDocument1 pageMill Test Certificate: Zibo Camel Material Co., LTDJoseph Arturo SolisNo ratings yet

- TTU Fittings Ttu Industrial LTD.: Manufacturer'SDocument1 pageTTU Fittings Ttu Industrial LTD.: Manufacturer'SMohamed RaafatNo ratings yet

- MTC, Annexure & Tally Sheet PDFDocument23 pagesMTC, Annexure & Tally Sheet PDFashish.mathur1No ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- Po31510 Fres30x24 SF48410Document1 pagePo31510 Fres30x24 SF48410Keshia Murillo PinnockNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Quality Certificated 123Document1 pageQuality Certificated 123Zaid Raslan Ayoub100% (1)

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- Material Test Report: ISO EN 10204 2004-3.1Document4 pagesMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- 30 MM Round Bar - EN8 - MTCDocument1 page30 MM Round Bar - EN8 - MTCMohammad Adil0% (1)

- Fme Mesaieed MTC 1103Document1 pageFme Mesaieed MTC 1103KyNo ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- M 001 22Document1 pageM 001 22LUISNo ratings yet

- 08.05.2019 Npu 400Document2 pages08.05.2019 Npu 400Yasin BaturNo ratings yet

- 1613 00443 PDFDocument69 pages1613 00443 PDFzaheerNo ratings yet

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- TRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSDocument111 pagesTRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSMohamed RaafatNo ratings yet

- Mill Test Certificate: Arcelormittal Olaberria-BergaraDocument3 pagesMill Test Certificate: Arcelormittal Olaberria-BergarabladimyrNo ratings yet

- Atul 30,36-LoescheDocument16 pagesAtul 30,36-LoescheSales ITANo ratings yet

- Certificado de Calidad Tubo Galvanizado Instratec 2Document1 pageCertificado de Calidad Tubo Galvanizado Instratec 2Yerson Cuba100% (3)

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Globe Control Valve: TYPE 3241Document6 pagesGlobe Control Valve: TYPE 3241Mohamed RaafatNo ratings yet

- ANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument12 pagesANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 PsigDocument2 pagesFTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 PsigMohamed RaafatNo ratings yet

- Certificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IDocument1 pageCertificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IMohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument2 pagesCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed Raafat100% (1)

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

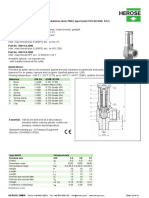

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed Raafat100% (1)

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- A64 ANSI150: Flanged Type Ball Valve, Full BoreDocument1 pageA64 ANSI150: Flanged Type Ball Valve, Full BoreMohamed RaafatNo ratings yet

- Typ 06011 1 enDocument2 pagesTyp 06011 1 enMohamed RaafatNo ratings yet

- We Know How: Stainless SteelDocument4 pagesWe Know How: Stainless SteelMohamed RaafatNo ratings yet

- Check Valve: Data Sheet 003001 Englisch (English)Document12 pagesCheck Valve: Data Sheet 003001 Englisch (English)Mohamed RaafatNo ratings yet

- Strainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionDocument3 pagesStrainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

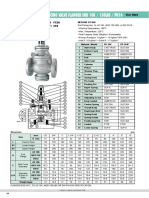

- Pressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Document1 pagePressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Mohamed RaafatNo ratings yet

- KK 821 enDocument9 pagesKK 821 enMohamed RaafatNo ratings yet

- 1 - Body Manufactured From Extruded Aluminium Uni 6060Document3 pages1 - Body Manufactured From Extruded Aluminium Uni 6060Mohamed RaafatNo ratings yet

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument8 pagesDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- Leser Transmittal (EN)Document1 pageLeser Transmittal (EN)Mohamed RaafatNo ratings yet

- A New Post Tensioned Continuity Detail For Super Tees BGE David MolloyDocument11 pagesA New Post Tensioned Continuity Detail For Super Tees BGE David MolloyTamaduianu IoanNo ratings yet

- 5 AQV09AWBN SM en Exploded View Part List (Ver2.0)Document7 pages5 AQV09AWBN SM en Exploded View Part List (Ver2.0)Leonel ValençaNo ratings yet

- WW2 Military Bldgs PDFDocument102 pagesWW2 Military Bldgs PDFone-eyed fat manNo ratings yet

- Chemistry Playbook: & Restricted Substances ListDocument118 pagesChemistry Playbook: & Restricted Substances ListRight LeftNo ratings yet

- Lesson Plan in English Using SRF: I. ObjectiveDocument10 pagesLesson Plan in English Using SRF: I. ObjectiveShee AntonioNo ratings yet

- Development of Anti-Corrosive Paint Incorporated W PDFDocument11 pagesDevelopment of Anti-Corrosive Paint Incorporated W PDFnanoNo ratings yet

- Catalogue SDocument8 pagesCatalogue SSHINOS 3SNo ratings yet

- 111年下A卷題庫Document10 pages111年下A卷題庫陳奕安No ratings yet

- Polymers - Chemistry ProjectDocument28 pagesPolymers - Chemistry ProjectKaku Bwj67% (3)

- Mis 024Document223 pagesMis 024ysanyasirajuNo ratings yet

- 2) Spray Nozzle Specification PDFDocument41 pages2) Spray Nozzle Specification PDFkasvikrajNo ratings yet

- Classic Puzzle SolvingDocument13 pagesClassic Puzzle SolvingYashraj BagariNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDFjignesh chauhan100% (1)

- ICDL Module 6 PresentationDocument40 pagesICDL Module 6 PresentationcaphilNo ratings yet

- E 211 - 82 (2010)Document3 pagesE 211 - 82 (2010)ruben carcamoNo ratings yet

- Lsa DWG 190703 98 Ejm SignedDocument1 pageLsa DWG 190703 98 Ejm SignedAgung PerbowoNo ratings yet

- (4) Involuteσ Worm And Helical Gear Design SystemDocument3 pages(4) Involuteσ Worm And Helical Gear Design SystemIrena SavuNo ratings yet

- UNIT-2-NOTES - Self Management Skills-IXDocument8 pagesUNIT-2-NOTES - Self Management Skills-IXVaishnavi JoshiNo ratings yet

- AC2 Specification SheetDocument4 pagesAC2 Specification SheetWiwa Hernandez DonosoNo ratings yet

- 2389 Amdocs Placement Paper SQLDocument3 pages2389 Amdocs Placement Paper SQLSahil Shashikant BhosleNo ratings yet

- Management La Distanta-Tipuri de ManagememtDocument9 pagesManagement La Distanta-Tipuri de ManagememtAndreeaDeEaNo ratings yet

- Manajemen OperasiDocument37 pagesManajemen OperasiHELWAH AMINAH ACHMADNo ratings yet

- Horiba ABX Micros 60 - User Manual PDFDocument136 pagesHoriba ABX Micros 60 - User Manual PDFkang opik100% (1)

- H. Tristram Engelhardt The Philosophy of Medicine Framing The Field 2000Document263 pagesH. Tristram Engelhardt The Philosophy of Medicine Framing The Field 2000Chaia Ashkenazy100% (2)

- LX 300 BrochureDocument3 pagesLX 300 BrochureROBERTO CESPEDESNo ratings yet

- Self Healing RobotsDocument5 pagesSelf Healing RobotsshaluNo ratings yet

- Agexcomm 1 Q&aDocument25 pagesAgexcomm 1 Q&aWaren LlorenNo ratings yet

Zdocs - Hu 773007136-A

Zdocs - Hu 773007136-A

Uploaded by

Mohamed RaafatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zdocs - Hu 773007136-A

Zdocs - Hu 773007136-A

Uploaded by

Mohamed RaafatCopyright:

Available Formats

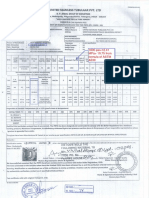

SINCE 1982

INSPECTION/ TEST CERTIFICATE

(EN10204 TYPE 3.1)

Client GS Engineering & Construction Corp. P.O. No. 0-6798-PG216B-135-A220

ReportNo. 0160'1001-01-112 \ Date of lssue 2019. May. 11

Item Description : Forged Steel GLOBE Valves Class 300# LF2 / 316 HF INT FLG'D

Tag No. 8A05-16 Size 1/2" Q'ty 50 Pcs

PRES SURE AND LEAK TEST(API 598 2009 Edition,MESC SPE 77/101ASME Result Pass

Hydrostatic

81 6.34) : Shell 1125 Psi 78.5 Bar Pneumatic Seat/Back Seat: Psi

I !

N/A

Test [Seat/Back Seat: 825 Psi 57.9 Bar Test NIA Bar

Test durations / Permissible leakage Shell : 60 sec / No leakage j Seat/Back Seat: 60 sec/ No leakage"

Dimension Inspection : GOOD Visual Inspection : GOOD Function Test(torque): 1 '\O -140.N

MATERIAL SPECIFICATION(ASTM-Latest Edition, MESC SPE 77/101,302)

Product Name Body Bonnet I Disc

Material A105 (CL.1) A105 (CL.1) A182-F316

QTY

\ I

BN81 AP90 BK80 AW50 BK8M 20

Heat/Lot

BN82 AP90 BK81 9RH BK8M 30

Remarks Normalized(880'C±14 C) & Tempered(620 C±14 't) Stellite #6 HF

° °

CHEMICAL COMPOSITION

Element C I Mn P I S Si i Ni Cr Mo Cu V Nb B(•) Cr+Mo

t

Hea NO

.I· · :�:·. . .

S22511

·····o·.-23· f . · �:·�� . . ···o�cfa"s".I ··6:646...... �: }�·· ·I···· o:46····1··-··(5�:fo - 0.12 0 .40 0.080 0.02 1. 00 o.�2

0.18 j 0.85 0.012 0.010 0.30 0.07 0.22 0.03 0.04 0.001 0.002 0.36 0.25

S23205 0. 1 8 0.81 0.012 0.011 0.28 0.07 0.18 0.02 0.06 0.001 0.001 0.33 0.20

I

S19015 0.18 0.84 0.011 0.011 0.28 0.06 0.19 0.03 0.05 0.001 0.002 0.33 0.22

+·�·�:��· . ��:�� �:�� · · . ..-... .. · · · · - · · · · · · · · ·

--------- Element C \ Mn P S Si i Ni Cr Mo Cu I V Nb N Tf

... ·

Heat No.I ;��·. 0.08 j z'."06········6:ci'45.. ...o:o3ci" ···foo 0.10 ··---· ···-··

572609 \ 0.017 \ 1.BO 0.029 \ 0.027 0.37 10.12 16.B9 2.09 - - - 0.074 -

MECHANICAL P ROPERTIES(0.2% Offset)

Tensile Yield Reduction

Elongation Hardness

S\renglh Strength of Area lmpactTest (J/-50t)

I

�Item

(MPa) (MPa) (HB)

Lot No. S.T.D 485.0 to 655.0 min. 250.0 min. 22.0 min. 30.0 max. 237

(%) (%)

1st 2nd 3rd

AP90 532. 2 410.3 36.6 65.7 150,152 36 32 39

AW50 512.2 363.3 32.7 67.8 142,148 96 54 41

9RH 652.2 541.3 34.4 42.9 156,158 106 50

Yield

96

Tensile Reduction

Elongation Hardness

� Strength Strength of Area Remarks

(MPa) (MPa)

Item

� (%) (% ) (HB)

Lot No. I S.T.D min. 515.0 min. 205.0 min. 30.0 min. 50.0 - I

572609 606.7 255.1 72.3 61.2 -

�Jotes 1. Mandatory Additional Requirements MESC SPE 77/101, 300A, 302, 312. 85/103, 2 0_3,_2_0_4 _____-,

� _

2. Flange shall be in accordance with ASME B 16.5 ,.,:.;�, \{'.

1

! .--·� J--�--. ·.

,'3. CE= C+Mn/6 + (Cr+Mo+V)/S+{Cu+Ni)/15:,; 0.43 / B(') = Cu+Ni+Cr+V+Mo (, ) 1 (.,/"'.

'4. NACE MR0103 / SOUR S ERIVCE .,L-f•7' <7">;JJl2!fd.:_ :"nE&(!

5. Fugitive Emission Class: B 1-:i � µ'-(_>-0, /4;-/_j I

We hereby certify that the result Witnessed/Reviewed by Q.C Manager

mentioned above are true and

correct in every details. H. Han

FORM: QAP-8090-04(Rev.1) ILSHIN V.�LVE CO., LTD. Item No 112 of 146

You might also like

- A Step-by-Step Guide To Identification and Resolution of Error in Clinical Test SystemsDocument1 pageA Step-by-Step Guide To Identification and Resolution of Error in Clinical Test Systemsrose_almonte60% (5)

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Inspection Certificate Leser CGA (EN)Document3 pagesInspection Certificate Leser CGA (EN)Mohamed RaafatNo ratings yet

- 0342 Mill TestDocument19 pages0342 Mill Test11tkt1133% (3)

- NamaazENabvi ShaikhAlbaaniRahimahullahDocument208 pagesNamaazENabvi ShaikhAlbaaniRahimahullahIslamic Reserch Center (IRC)0% (1)

- 10515-0120-4200 (RF-1912E - T Antennas Installation - Deployment Manual - March 2002 Rev. B) PDFDocument105 pages10515-0120-4200 (RF-1912E - T Antennas Installation - Deployment Manual - March 2002 Rev. B) PDFRaimundo Cesar Matos da Costa100% (2)

- Check Valve 6in HT 6YF4Document1 pageCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNo ratings yet

- Certificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Document1 pageCertificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Raul Esteban Jaimes GalvisNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- MTC Item # 01Document18 pagesMTC Item # 01ClarkFedele27No ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Document8 pages2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan Ortega100% (1)

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

- LF' JLRDocument1 pageLF' JLRIslam SahafayatNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- Weflo Valve Co., LTD.: Material Test CertificateDocument1 pageWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNo ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Mgoha : ' "Xsjjl8Document1 pageMgoha : ' "Xsjjl8PetroPower OilandgasNo ratings yet

- Mill Test Certificate-En10204/3.1-2004Document2 pagesMill Test Certificate-En10204/3.1-2004Rescos KasarachiNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- Strainers FycDocument1 pageStrainers FycrodolfostiNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- Mill Test Certificate: Zibo Camel Material Co., LTDDocument1 pageMill Test Certificate: Zibo Camel Material Co., LTDJoseph Arturo SolisNo ratings yet

- TTU Fittings Ttu Industrial LTD.: Manufacturer'SDocument1 pageTTU Fittings Ttu Industrial LTD.: Manufacturer'SMohamed RaafatNo ratings yet

- MTC, Annexure & Tally Sheet PDFDocument23 pagesMTC, Annexure & Tally Sheet PDFashish.mathur1No ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- Po31510 Fres30x24 SF48410Document1 pagePo31510 Fres30x24 SF48410Keshia Murillo PinnockNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Quality Certificated 123Document1 pageQuality Certificated 123Zaid Raslan Ayoub100% (1)

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- Material Test Report: ISO EN 10204 2004-3.1Document4 pagesMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- 30 MM Round Bar - EN8 - MTCDocument1 page30 MM Round Bar - EN8 - MTCMohammad Adil0% (1)

- Fme Mesaieed MTC 1103Document1 pageFme Mesaieed MTC 1103KyNo ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- M 001 22Document1 pageM 001 22LUISNo ratings yet

- 08.05.2019 Npu 400Document2 pages08.05.2019 Npu 400Yasin BaturNo ratings yet

- 1613 00443 PDFDocument69 pages1613 00443 PDFzaheerNo ratings yet

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- TRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSDocument111 pagesTRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSMohamed RaafatNo ratings yet

- Mill Test Certificate: Arcelormittal Olaberria-BergaraDocument3 pagesMill Test Certificate: Arcelormittal Olaberria-BergarabladimyrNo ratings yet

- Atul 30,36-LoescheDocument16 pagesAtul 30,36-LoescheSales ITANo ratings yet

- Certificado de Calidad Tubo Galvanizado Instratec 2Document1 pageCertificado de Calidad Tubo Galvanizado Instratec 2Yerson Cuba100% (3)

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Globe Control Valve: TYPE 3241Document6 pagesGlobe Control Valve: TYPE 3241Mohamed RaafatNo ratings yet

- ANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument12 pagesANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 PsigDocument2 pagesFTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 PsigMohamed RaafatNo ratings yet

- Certificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IDocument1 pageCertificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IMohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument2 pagesCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed Raafat100% (1)

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed Raafat100% (1)

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- A64 ANSI150: Flanged Type Ball Valve, Full BoreDocument1 pageA64 ANSI150: Flanged Type Ball Valve, Full BoreMohamed RaafatNo ratings yet

- Typ 06011 1 enDocument2 pagesTyp 06011 1 enMohamed RaafatNo ratings yet

- We Know How: Stainless SteelDocument4 pagesWe Know How: Stainless SteelMohamed RaafatNo ratings yet

- Check Valve: Data Sheet 003001 Englisch (English)Document12 pagesCheck Valve: Data Sheet 003001 Englisch (English)Mohamed RaafatNo ratings yet

- Strainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionDocument3 pagesStrainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- Pressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Document1 pagePressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Mohamed RaafatNo ratings yet

- KK 821 enDocument9 pagesKK 821 enMohamed RaafatNo ratings yet

- 1 - Body Manufactured From Extruded Aluminium Uni 6060Document3 pages1 - Body Manufactured From Extruded Aluminium Uni 6060Mohamed RaafatNo ratings yet

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument8 pagesDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- Leser Transmittal (EN)Document1 pageLeser Transmittal (EN)Mohamed RaafatNo ratings yet

- A New Post Tensioned Continuity Detail For Super Tees BGE David MolloyDocument11 pagesA New Post Tensioned Continuity Detail For Super Tees BGE David MolloyTamaduianu IoanNo ratings yet

- 5 AQV09AWBN SM en Exploded View Part List (Ver2.0)Document7 pages5 AQV09AWBN SM en Exploded View Part List (Ver2.0)Leonel ValençaNo ratings yet

- WW2 Military Bldgs PDFDocument102 pagesWW2 Military Bldgs PDFone-eyed fat manNo ratings yet

- Chemistry Playbook: & Restricted Substances ListDocument118 pagesChemistry Playbook: & Restricted Substances ListRight LeftNo ratings yet

- Lesson Plan in English Using SRF: I. ObjectiveDocument10 pagesLesson Plan in English Using SRF: I. ObjectiveShee AntonioNo ratings yet

- Development of Anti-Corrosive Paint Incorporated W PDFDocument11 pagesDevelopment of Anti-Corrosive Paint Incorporated W PDFnanoNo ratings yet

- Catalogue SDocument8 pagesCatalogue SSHINOS 3SNo ratings yet

- 111年下A卷題庫Document10 pages111年下A卷題庫陳奕安No ratings yet

- Polymers - Chemistry ProjectDocument28 pagesPolymers - Chemistry ProjectKaku Bwj67% (3)

- Mis 024Document223 pagesMis 024ysanyasirajuNo ratings yet

- 2) Spray Nozzle Specification PDFDocument41 pages2) Spray Nozzle Specification PDFkasvikrajNo ratings yet

- Classic Puzzle SolvingDocument13 pagesClassic Puzzle SolvingYashraj BagariNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDFjignesh chauhan100% (1)

- ICDL Module 6 PresentationDocument40 pagesICDL Module 6 PresentationcaphilNo ratings yet

- E 211 - 82 (2010)Document3 pagesE 211 - 82 (2010)ruben carcamoNo ratings yet

- Lsa DWG 190703 98 Ejm SignedDocument1 pageLsa DWG 190703 98 Ejm SignedAgung PerbowoNo ratings yet

- (4) Involuteσ Worm And Helical Gear Design SystemDocument3 pages(4) Involuteσ Worm And Helical Gear Design SystemIrena SavuNo ratings yet

- UNIT-2-NOTES - Self Management Skills-IXDocument8 pagesUNIT-2-NOTES - Self Management Skills-IXVaishnavi JoshiNo ratings yet

- AC2 Specification SheetDocument4 pagesAC2 Specification SheetWiwa Hernandez DonosoNo ratings yet

- 2389 Amdocs Placement Paper SQLDocument3 pages2389 Amdocs Placement Paper SQLSahil Shashikant BhosleNo ratings yet

- Management La Distanta-Tipuri de ManagememtDocument9 pagesManagement La Distanta-Tipuri de ManagememtAndreeaDeEaNo ratings yet

- Manajemen OperasiDocument37 pagesManajemen OperasiHELWAH AMINAH ACHMADNo ratings yet

- Horiba ABX Micros 60 - User Manual PDFDocument136 pagesHoriba ABX Micros 60 - User Manual PDFkang opik100% (1)

- H. Tristram Engelhardt The Philosophy of Medicine Framing The Field 2000Document263 pagesH. Tristram Engelhardt The Philosophy of Medicine Framing The Field 2000Chaia Ashkenazy100% (2)

- LX 300 BrochureDocument3 pagesLX 300 BrochureROBERTO CESPEDESNo ratings yet

- Self Healing RobotsDocument5 pagesSelf Healing RobotsshaluNo ratings yet

- Agexcomm 1 Q&aDocument25 pagesAgexcomm 1 Q&aWaren LlorenNo ratings yet