Professional Documents

Culture Documents

Pipe Thickness Calculation: Inputs From

Pipe Thickness Calculation: Inputs From

Uploaded by

BankaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Thickness Calculation: Inputs From

Pipe Thickness Calculation: Inputs From

Uploaded by

BankaiCopyright:

Available Formats

PIPE

THICKNESS CALCULATION

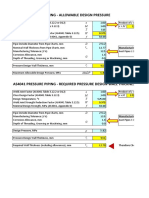

THICKNESS PARAMETERS UNITS/ SIZES 2" 4" Inputs From

Max. Design Pressure P, KSI 1.4 1.4 Process Engineer

Outside Dia of Pipe D, mm 60.33 114.3 ASME B 36.10 / 36.19

Stress Value S, KSI 20 20 ASME B 31.3 TABLE A‐1

Quality Factor E 1 1 ASME B 31.3 TABLE A‐ 1B

Weld Jointstrength reduction Factor W 1 1 From Clause 302.3.5

Coefficient for t<D/6 Y 0.4 0.4 Table 304.1.1

Corrosion Allowance c, mm 3 3 Material Engineer

Required Thickness

as per ASME B31.3 t , mm 2.05 3.89

Required Thickness

as per ASME B31.3 (tm=t+c) tm, mm 5.05 6.89

Selected Pipe Schedule sch 160 80 ASME B 36.10 / 36.19

Thickness as per Pipe Schedule Tsch, mm 8.74 8.56 ASME B 36.10 / 36.19

T = Thickness Exlcuding Mill tolerance (12.5%) T, mm 7.6475 7.49

Qualify Thickness T>tm T > tm 2.59 0.60

Approval Acceptable Acceptable

b) t > D/6 or P/SE 0.07 Not applicable

You might also like

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument11 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknessamini_mohiNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipe ThicknessDocument2 pagesPipe Thicknessgherd barkNo ratings yet

- Pipe Thickness CalculationsDocument3 pagesPipe Thickness Calculationswaheedulhassan56No ratings yet

- Cong Thuc Tinh Toan Piping ThicknessDocument108 pagesCong Thuc Tinh Toan Piping ThicknessTruong Ngoc SonNo ratings yet

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- AstmDocument1 pageAstmGalih Prianggodo100% (1)

- BỀ DÀY ÔNG NƯỚCDocument5 pagesBỀ DÀY ÔNG NƯỚCLazy PhanNo ratings yet

- 1707 DD Pi 3 Cal 3001 - Tinh Toan Be Day Thanh OngDocument3 pages1707 DD Pi 3 Cal 3001 - Tinh Toan Be Day Thanh OngNguyễn DuyNo ratings yet

- Design Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal PressureDocument10 pagesDesign Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal Pressurefaisman100% (1)

- Asme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureDocument1 pageAsme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureRicardo LanderNo ratings yet

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- Thickness Calc.-30 Inch-PV-21019Document25 pagesThickness Calc.-30 Inch-PV-21019RajeshvbNo ratings yet

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Pipe Thickness Calculation AS Per ASME 31.3Document11 pagesPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNo ratings yet

- Idoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318Document9 pagesIdoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318GEMSL MONo ratings yet

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Document30 pagesDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012No ratings yet

- Piping Wall Thickness Cal - Ver HT10.2-HTTEK FullDocument47 pagesPiping Wall Thickness Cal - Ver HT10.2-HTTEK Fullthinhvipro100% (1)

- Pipe Wall Thickness CalculationDocument1 pagePipe Wall Thickness Calculationmahesh070No ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument1 pageAS4041 ASME B31 - 3 Pipe Wall ThicknesselleNo ratings yet

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- ASME B31.3 Process PipingDocument1 pageASME B31.3 Process PipingalvinchuanNo ratings yet

- ASME B31.4-Wall Thickness Calc For 6 InchDocument2 pagesASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoNo ratings yet

- 3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of ComponentsDocument1 page3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of Components7761430No ratings yet

- Pipe Thickness CalculationDocument4 pagesPipe Thickness CalculationHarryNo ratings yet

- ASME B31.3 CalculationDocument11 pagesASME B31.3 CalculationAnonymous wIPMQ5rhNo ratings yet

- Piping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Document40 pagesPiping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Ahmet OVENNo ratings yet

- As4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmDocument8 pagesAs4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmAkhil CNo ratings yet

- Pipe Wall Thickness (ASME B31.3)Document12 pagesPipe Wall Thickness (ASME B31.3)Rachmad HidayatNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument8 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNo ratings yet

- Piping Sizing Final Rev01 12Document1 pagePiping Sizing Final Rev01 12aNo ratings yet

- Wall Thickness 2Document18 pagesWall Thickness 2Imam Zulfir RamandhaNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument12 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessAnggaNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument12 pages8 AS4041 ASME B31 3 Pipe Wall Thicknesswhah11No ratings yet

- Branch RF CalcDocument6 pagesBranch RF CalcHarish Harish0% (1)

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Brance Pipe CALDocument6 pagesBrance Pipe CALKlaikangwol AnuwarnNo ratings yet

- Calculation of Pipe Reinforcement Asme b31 3Document3 pagesCalculation of Pipe Reinforcement Asme b31 3KomedianTunggalNo ratings yet

- SS Stub End Thickness CalculationDocument1 pageSS Stub End Thickness CalculationSrinivas KadivetiNo ratings yet

- Pipe Thickness Design Calculation 1500 MMDocument1 pagePipe Thickness Design Calculation 1500 MMSanda PribicNo ratings yet

- Asme B31.8Document14 pagesAsme B31.8omar equihua100% (1)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinNo ratings yet

- Case Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLDocument13 pagesCase Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedNo ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- PIPECALC ASME B31.4 - Rev 2Document24 pagesPIPECALC ASME B31.4 - Rev 2Mohsin RazaNo ratings yet

- Pipe Thickness Calculations - : ClassDocument1 pagePipe Thickness Calculations - : ClassOluwachidiNo ratings yet

- E-402 CalcDocument5 pagesE-402 Calcbiren shahNo ratings yet

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet